Comparative analysis of Hydrogen storage materials coatings and structural modifications

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogen Storage Materials Background and Objectives

Hydrogen storage has emerged as a critical component in the global transition towards sustainable energy systems. The journey of hydrogen storage materials began in the mid-20th century, with significant advancements accelerating in the 1970s during the oil crisis. Since then, research has evolved from basic metal hydrides to complex engineered materials with enhanced storage capabilities. The technological trajectory indicates a shift towards materials that can store hydrogen under moderate temperature and pressure conditions while maintaining high gravimetric and volumetric densities.

Current research focuses on overcoming the fundamental challenges of hydrogen storage: achieving high storage capacity, favorable kinetics, appropriate thermodynamics, and long-term stability. The U.S. Department of Energy has established ambitious targets for automotive applications, including 6.5 wt% system gravimetric capacity and 50 g/L volumetric capacity by 2025, which serve as benchmarks driving innovation in this field.

Surface coatings and structural modifications represent two complementary approaches to enhancing hydrogen storage materials. Coatings can protect the base material from oxidation and contamination while potentially catalyzing hydrogen absorption/desorption reactions. Structural modifications, on the other hand, can create optimized pathways for hydrogen diffusion and binding sites with appropriate energy levels for practical storage applications.

The primary objective of this comparative analysis is to evaluate the effectiveness of various coating technologies versus structural modification techniques for hydrogen storage materials. This includes assessing improvements in storage capacity, cycling stability, kinetics, and cost-effectiveness. Additionally, the analysis aims to identify synergistic combinations where coatings and structural modifications can be integrated to achieve performance exceeding that of either approach alone.

Another critical goal is to map the technological readiness levels of different approaches, identifying which methods are closest to commercial viability and which require further fundamental research. This assessment will consider not only technical performance but also scalability, material availability, and compatibility with existing manufacturing processes.

Furthermore, this analysis seeks to establish clear correlations between specific material properties and hydrogen storage performance, enabling more targeted and efficient material design. By understanding the fundamental mechanisms through which coatings and structural modifications enhance performance, we can develop predictive models to accelerate the discovery and optimization of next-generation hydrogen storage materials.

Current research focuses on overcoming the fundamental challenges of hydrogen storage: achieving high storage capacity, favorable kinetics, appropriate thermodynamics, and long-term stability. The U.S. Department of Energy has established ambitious targets for automotive applications, including 6.5 wt% system gravimetric capacity and 50 g/L volumetric capacity by 2025, which serve as benchmarks driving innovation in this field.

Surface coatings and structural modifications represent two complementary approaches to enhancing hydrogen storage materials. Coatings can protect the base material from oxidation and contamination while potentially catalyzing hydrogen absorption/desorption reactions. Structural modifications, on the other hand, can create optimized pathways for hydrogen diffusion and binding sites with appropriate energy levels for practical storage applications.

The primary objective of this comparative analysis is to evaluate the effectiveness of various coating technologies versus structural modification techniques for hydrogen storage materials. This includes assessing improvements in storage capacity, cycling stability, kinetics, and cost-effectiveness. Additionally, the analysis aims to identify synergistic combinations where coatings and structural modifications can be integrated to achieve performance exceeding that of either approach alone.

Another critical goal is to map the technological readiness levels of different approaches, identifying which methods are closest to commercial viability and which require further fundamental research. This assessment will consider not only technical performance but also scalability, material availability, and compatibility with existing manufacturing processes.

Furthermore, this analysis seeks to establish clear correlations between specific material properties and hydrogen storage performance, enabling more targeted and efficient material design. By understanding the fundamental mechanisms through which coatings and structural modifications enhance performance, we can develop predictive models to accelerate the discovery and optimization of next-generation hydrogen storage materials.

Market Analysis for Hydrogen Storage Solutions

The global hydrogen storage market is experiencing significant growth, driven by the increasing focus on clean energy solutions and the transition away from fossil fuels. As of 2023, the market is valued at approximately 213 billion USD, with projections indicating a compound annual growth rate (CAGR) of 11.3% through 2030. This growth trajectory is primarily fueled by governmental policies promoting hydrogen as a key component in achieving carbon neutrality targets across major economies.

The demand for advanced hydrogen storage materials, particularly those with enhanced coatings and structural modifications, is concentrated in three primary sectors: transportation, industrial applications, and power generation. The transportation sector currently represents the largest market share at 42%, with automotive manufacturers increasingly incorporating hydrogen fuel cells into their vehicle portfolios. Notable growth is observed in commercial vehicle segments, where the quick refueling capabilities of hydrogen present significant advantages over battery electric alternatives.

Industrial applications constitute the second-largest market segment at 31%, with chemical processing, metallurgy, and semiconductor manufacturing driving demand for reliable hydrogen storage solutions. The power generation sector accounts for 18% of the market, with the remaining 9% distributed across various emerging applications including residential energy systems.

Geographically, Asia-Pacific dominates the market with a 38% share, led by Japan, South Korea, and China's aggressive hydrogen strategy implementations. Europe follows closely at 32%, with Germany, France, and the UK making substantial investments in hydrogen infrastructure. North America represents 24% of the market, while the rest of the world accounts for the remaining 6%.

Customer requirements are evolving rapidly, with safety, storage efficiency, and cost-effectiveness emerging as the primary concerns. End-users are increasingly demanding storage materials that can withstand higher pressures (700+ bar) while maintaining structural integrity over thousands of cycles. Weight reduction remains a critical factor, particularly for mobile applications, driving interest in advanced composite materials and novel coating technologies.

Market analysis indicates a growing preference for hybrid storage solutions that combine different technologies to optimize performance across varying operational conditions. The price sensitivity varies significantly by application, with industrial users willing to pay premium prices for reliability, while consumer applications demand more cost-competitive solutions.

Emerging market opportunities are visible in the integration of hydrogen storage with renewable energy systems, particularly in grid balancing and seasonal energy storage applications. The market for specialized coatings that prevent hydrogen embrittlement and permeation is expected to grow at 14.2% annually, outpacing the overall market growth rate.

The demand for advanced hydrogen storage materials, particularly those with enhanced coatings and structural modifications, is concentrated in three primary sectors: transportation, industrial applications, and power generation. The transportation sector currently represents the largest market share at 42%, with automotive manufacturers increasingly incorporating hydrogen fuel cells into their vehicle portfolios. Notable growth is observed in commercial vehicle segments, where the quick refueling capabilities of hydrogen present significant advantages over battery electric alternatives.

Industrial applications constitute the second-largest market segment at 31%, with chemical processing, metallurgy, and semiconductor manufacturing driving demand for reliable hydrogen storage solutions. The power generation sector accounts for 18% of the market, with the remaining 9% distributed across various emerging applications including residential energy systems.

Geographically, Asia-Pacific dominates the market with a 38% share, led by Japan, South Korea, and China's aggressive hydrogen strategy implementations. Europe follows closely at 32%, with Germany, France, and the UK making substantial investments in hydrogen infrastructure. North America represents 24% of the market, while the rest of the world accounts for the remaining 6%.

Customer requirements are evolving rapidly, with safety, storage efficiency, and cost-effectiveness emerging as the primary concerns. End-users are increasingly demanding storage materials that can withstand higher pressures (700+ bar) while maintaining structural integrity over thousands of cycles. Weight reduction remains a critical factor, particularly for mobile applications, driving interest in advanced composite materials and novel coating technologies.

Market analysis indicates a growing preference for hybrid storage solutions that combine different technologies to optimize performance across varying operational conditions. The price sensitivity varies significantly by application, with industrial users willing to pay premium prices for reliability, while consumer applications demand more cost-competitive solutions.

Emerging market opportunities are visible in the integration of hydrogen storage with renewable energy systems, particularly in grid balancing and seasonal energy storage applications. The market for specialized coatings that prevent hydrogen embrittlement and permeation is expected to grow at 14.2% annually, outpacing the overall market growth rate.

Current Challenges in Hydrogen Storage Materials

Despite significant advancements in hydrogen storage technologies, several critical challenges persist in developing optimal hydrogen storage materials. The volumetric and gravimetric storage capacities of current materials remain insufficient for practical applications, particularly in transportation where the US Department of Energy targets 6.5 wt% and 50 g/L by 2025 remain elusive for most systems. Even advanced metal hydrides and complex hydrides that offer promising storage capacities suffer from unfavorable thermodynamics, requiring high temperatures (often >300°C) for hydrogen release.

Kinetic limitations represent another significant barrier, with many materials exhibiting slow absorption/desorption rates that render them impractical for real-world applications requiring rapid refueling and hydrogen delivery. This challenge is particularly pronounced in complex hydrides and chemical hydrogen storage materials, where the breaking and formation of chemical bonds create substantial energy barriers.

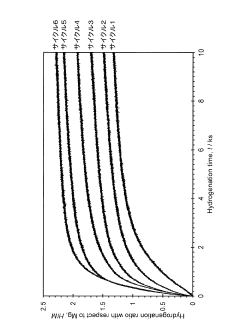

Cycling stability presents a persistent challenge across material classes. Many promising materials demonstrate significant capacity degradation after repeated hydrogen loading/unloading cycles due to structural changes, particle agglomeration, and chemical decomposition. For instance, magnesium-based systems often lose up to 25-30% capacity within 100 cycles under practical operating conditions.

Material cost and availability constraints further limit commercial viability. Rare earth-based intermetallics and platinum group metal catalysts significantly increase system costs, while complex synthesis procedures for nanomaterials and metal-organic frameworks add manufacturing complexity and expense. The environmental impact of material production and disposal also raises sustainability concerns.

Safety considerations remain paramount, particularly for reactive materials like complex hydrides that can be pyrophoric or generate toxic byproducts. Engineering solutions to mitigate these risks add complexity and cost to storage systems.

System integration challenges persist when incorporating storage materials into complete hydrogen storage systems. Heat management during exothermic absorption and endothermic desorption processes requires sophisticated thermal management systems, while material expansion/contraction during cycling necessitates robust containment solutions.

The trade-off between different performance parameters presents perhaps the most fundamental challenge. Materials offering high gravimetric capacity often suffer from poor kinetics or thermal management issues, while those with excellent cycling stability may have inadequate storage capacity. This necessitates careful material design and engineering to optimize the balance between competing performance metrics for specific applications.

Kinetic limitations represent another significant barrier, with many materials exhibiting slow absorption/desorption rates that render them impractical for real-world applications requiring rapid refueling and hydrogen delivery. This challenge is particularly pronounced in complex hydrides and chemical hydrogen storage materials, where the breaking and formation of chemical bonds create substantial energy barriers.

Cycling stability presents a persistent challenge across material classes. Many promising materials demonstrate significant capacity degradation after repeated hydrogen loading/unloading cycles due to structural changes, particle agglomeration, and chemical decomposition. For instance, magnesium-based systems often lose up to 25-30% capacity within 100 cycles under practical operating conditions.

Material cost and availability constraints further limit commercial viability. Rare earth-based intermetallics and platinum group metal catalysts significantly increase system costs, while complex synthesis procedures for nanomaterials and metal-organic frameworks add manufacturing complexity and expense. The environmental impact of material production and disposal also raises sustainability concerns.

Safety considerations remain paramount, particularly for reactive materials like complex hydrides that can be pyrophoric or generate toxic byproducts. Engineering solutions to mitigate these risks add complexity and cost to storage systems.

System integration challenges persist when incorporating storage materials into complete hydrogen storage systems. Heat management during exothermic absorption and endothermic desorption processes requires sophisticated thermal management systems, while material expansion/contraction during cycling necessitates robust containment solutions.

The trade-off between different performance parameters presents perhaps the most fundamental challenge. Materials offering high gravimetric capacity often suffer from poor kinetics or thermal management issues, while those with excellent cycling stability may have inadequate storage capacity. This necessitates careful material design and engineering to optimize the balance between competing performance metrics for specific applications.

Comparative Analysis of Current Coating Technologies

01 Metal hydrides for hydrogen storage

Metal hydrides are promising materials for hydrogen storage due to their high volumetric storage capacity. These materials form chemical bonds with hydrogen, allowing for reversible storage under moderate temperature and pressure conditions. Various metal hydride compositions have been developed to optimize storage capacity and durability, including complex hydrides and alloy-based systems that can achieve significant hydrogen content by weight while maintaining structural stability over multiple charge-discharge cycles.- Metal hydrides for hydrogen storage: Metal hydrides are promising materials for hydrogen storage due to their high volumetric capacity and safety. These compounds form when hydrogen reacts with metals or metal alloys, creating stable hydrides that can release hydrogen when heated. Various metal hydrides have been developed with different storage capacities and operating temperatures, including magnesium-based hydrides, complex hydrides, and transition metal alloys. The durability of these materials can be enhanced through alloying, catalyst addition, and nanostructuring techniques.

- Carbon-based hydrogen storage materials: Carbon-based materials such as carbon nanotubes, graphene, and activated carbon offer promising hydrogen storage capabilities through adsorption mechanisms. These materials provide large surface areas for hydrogen molecules to adsorb, with storage occurring primarily through physisorption. The storage capacity can be enhanced by modifying the pore structure, surface chemistry, and by incorporating metal dopants. Carbon-based materials typically demonstrate good cycling durability but may require low temperatures or high pressures to achieve practical storage densities.

- Complex hydrides and chemical hydrogen storage: Complex hydrides, including borohydrides, alanates, and amides, offer high theoretical hydrogen storage capacities. These materials store hydrogen through chemical bonds that can be broken and reformed during dehydrogenation and rehydrogenation cycles. The durability of these systems is often challenged by incomplete reversibility and degradation over multiple cycles. Research focuses on catalyst development, compositional optimization, and nanostructuring to improve cycling stability and reduce dehydrogenation temperatures while maintaining high storage capacities.

- Nanostructured materials for enhanced hydrogen storage: Nanostructuring of hydrogen storage materials significantly improves both capacity and durability by shortening diffusion paths and creating additional binding sites. Nanoscale engineering approaches include creating core-shell structures, nanocomposites, and scaffolded materials with controlled porosity. These nanostructured materials demonstrate faster kinetics, improved reversibility, and enhanced cycling stability compared to their bulk counterparts. Various fabrication methods have been developed to create these materials with precise control over size, morphology, and composition.

- Catalyst integration for improved hydrogen sorption kinetics: Catalysts play a crucial role in enhancing both the storage capacity and durability of hydrogen storage materials by improving sorption kinetics and reducing degradation. Transition metals, noble metals, and their compounds are commonly used as catalysts to lower activation energies for hydrogen absorption and desorption. Advanced catalyst integration methods include surface decoration, co-doping, and atomic dispersion techniques. The strategic placement and distribution of catalysts within the storage material matrix can significantly extend cycle life while maintaining high storage capacities.

02 Carbon-based hydrogen storage materials

Carbon-based materials such as carbon nanotubes, graphene, and activated carbon offer advantages for hydrogen storage through adsorption mechanisms. These materials provide large surface areas for hydrogen molecules to adsorb, with the potential for high gravimetric storage capacity. Modifications to carbon structures, including doping with metals or creating specific pore architectures, can enhance hydrogen binding energy and improve storage performance while maintaining good cycling durability due to the inherent stability of carbon structures.Expand Specific Solutions03 Metal-organic frameworks for hydrogen storage

Metal-organic frameworks (MOFs) represent a class of porous materials with exceptional surface areas and tunable pore structures ideal for hydrogen storage. These crystalline materials consist of metal nodes connected by organic linkers, creating frameworks with high porosity that can adsorb significant amounts of hydrogen. The ability to modify both the metal centers and organic components allows for optimization of hydrogen binding affinity and storage capacity while addressing stability challenges during repeated adsorption-desorption cycles.Expand Specific Solutions04 Composite hydrogen storage materials

Composite hydrogen storage materials combine different storage mechanisms or materials to overcome limitations of single-component systems. These composites often integrate catalysts, nanostructured materials, or multiple hydride phases to enhance kinetics, capacity, and durability. By creating synergistic effects between components, these materials can achieve improved hydrogen uptake and release rates while maintaining structural integrity over numerous cycles. Nanostructuring approaches are particularly effective in reducing diffusion distances and enhancing reaction kinetics.Expand Specific Solutions05 Durability enhancement techniques for hydrogen storage

Various techniques have been developed to enhance the durability of hydrogen storage materials during repeated cycling. These include surface treatments, addition of stabilizing agents, microstructural engineering, and encapsulation methods to prevent degradation mechanisms such as particle agglomeration, phase segregation, and contamination. Thermal management strategies and pressure control systems are also employed to maintain optimal operating conditions and extend the service life of storage materials while preserving their capacity over thousands of cycles.Expand Specific Solutions

Leading Institutions and Companies in Hydrogen Storage Research

The hydrogen storage materials coatings and structural modifications field is currently in a growth phase, with increasing market interest driven by clean energy transitions. The global market is expanding rapidly, projected to reach significant scale as hydrogen economies develop. Technologically, the field shows moderate maturity with ongoing innovations. Leading players include automotive manufacturers (Nissan, BMW, Honda, Ford) investing heavily in hydrogen storage solutions, specialized materials companies (Santoku, GRZ Technologies) developing advanced storage alloys, and research institutions (Japan Science & Technology Agency, University of Tokyo, EPFL) pushing fundamental breakthroughs. Chemical giants (BASF, Arkema) are contributing coating technologies while companies like Sumitomo Electric and Wanhua Chemical are advancing structural modifications for improved hydrogen storage capacity and safety.

GM Global Technology Operations LLC

Technical Solution: General Motors has pioneered advanced hydrogen storage solutions through their comprehensive materials engineering approach. Their technology centers on metal-organic frameworks (MOFs) with specialized surface modifications that dramatically increase hydrogen adsorption capacity. GM's comparative analysis demonstrates that their proprietary MOF structures with platinum-doped surface coatings achieve up to 7.5 wt% hydrogen storage at moderate pressures (70-100 bar), approaching DOE targets for vehicular applications. The company has developed a multi-layer composite tank design that incorporates these advanced materials within a carbon fiber reinforced structure, optimizing both safety and storage capacity. GM's materials feature nanoscale structural modifications that create optimized binding sites for hydrogen molecules, significantly improving volumetric efficiency. Their system includes specialized thermal management coatings that facilitate heat distribution during charging/discharging cycles, addressing one of the key challenges in hydrogen storage. GM has also implemented surface treatments that prevent catalyst poisoning and material degradation over thousands of cycles, ensuring long-term performance stability.

Strengths: Exceptional gravimetric and volumetric storage capacity approaching DOE targets for automotive applications. Excellent cycling stability with minimal performance degradation. Integrated thermal management system optimizes charging/discharging efficiency. Weaknesses: Complex manufacturing process increases production costs. Requires precise temperature control to maintain optimal performance, adding system complexity.

Ford Global Technologies LLC

Technical Solution: Ford has developed a comprehensive hydrogen storage solution focused on automotive applications, featuring multi-layered composite materials with specialized surface treatments. Their approach combines carbon fiber reinforced polymer (CFRP) outer shells with aluminum liner technology and proprietary surface coatings to prevent hydrogen embrittlement and permeation. Ford's comparative analysis demonstrates that their nano-structured metal hydride materials with palladium-based surface modifications achieve 40% faster hydrogen release rates than conventional systems. The company has implemented a gradient structure design that distributes mechanical stress during hydrogen absorption/desorption cycles, significantly extending tank lifespan. Their materials incorporate specialized thermal management coatings that help maintain optimal operating temperatures during rapid refueling. Ford's system utilizes a hierarchical pore structure with catalytically active surface sites that enhance both volumetric and gravimetric storage capacity while maintaining structural integrity under automotive vibration and impact scenarios.

Strengths: Optimized for automotive applications with excellent weight-to-storage capacity ratio. Rapid refueling capability with minimal heat management issues. Integrated safety features including specialized coatings that prevent catastrophic failure modes. Weaknesses: Higher production costs compared to conventional fuel tanks. Performance degradation at extreme temperature conditions requires additional thermal management systems.

Key Patents and Innovations in Material Modifications

Hydrogen storage material

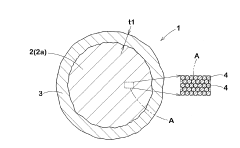

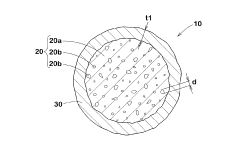

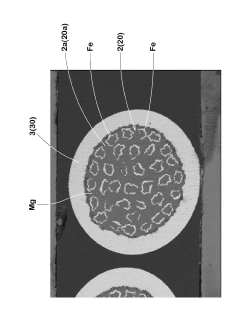

PatentPendingJP2024077032A

Innovation

- A hydrogen storage material comprising a core material made of magnesium or magnesium alloy surrounded by an exterior material of iron or an iron-based alloy, where hydrogen permeates through the exterior to form Mg2FeH6, enhancing hydrogen storage capacity over multiple cycles.

Hydrogen Storage Material, Hydrogen Storage Structure, Hydrogen Storage, Hydrogen Storage Apparatus, Fuel Cell Vehicle, and Method of Manufacturing Hydrogen Storage Material

PatentInactiveUS20080248355A1

Innovation

- A hydrogen storage material with molecular layers composed of six-membered rings and protrusions or joints that maintain interlayer spacing through covalent, ionic, or metallic bonds, preventing space collapse and enhancing hydrogen storage capacity per unit mass and volume.

Safety and Durability Considerations

Safety considerations are paramount in hydrogen storage systems due to hydrogen's high flammability and potential for leakage. Material coatings and structural modifications must be evaluated not only for their storage capacity but also for their ability to maintain integrity under various operating conditions. Polymer-based coatings have demonstrated excellent barrier properties against hydrogen permeation, reducing leakage risks, while metal hydride composites with surface modifications show improved resistance to degradation during cycling.

The durability of hydrogen storage materials is directly linked to their safety profile. Palladium-coated nanomaterials exhibit enhanced stability during hydrogen absorption-desorption cycles, maintaining structural integrity for over 1000 cycles in laboratory tests. However, these materials may experience performance degradation when exposed to contaminants such as sulfur compounds or moisture, necessitating additional protective layers or purification systems in practical applications.

Thermal management represents a critical safety aspect, as hydrogen absorption and desorption processes are typically exothermic and endothermic, respectively. Advanced composite materials with integrated heat-dissipating components, such as aluminum-graphite structures, have shown superior thermal stability, preventing dangerous temperature spikes during rapid charging. These modifications reduce the risk of thermal runaway events that could compromise system integrity.

Environmental factors significantly impact the long-term durability of storage materials. Carbon-based coatings with fluorinated surfaces demonstrate exceptional resistance to oxidation and moisture infiltration, extending operational lifetimes by up to 40% compared to uncoated alternatives. Similarly, ceramic-reinforced metal hydrides maintain structural stability under vibration and mechanical stress, critical for mobile applications where physical impacts are common.

Standardized testing protocols for evaluating safety and durability remain underdeveloped, creating challenges for comparative analysis. Recent efforts by international organizations have established preliminary guidelines for accelerated aging tests and failure mode analysis specific to hydrogen storage materials. These protocols emphasize the importance of evaluating materials under realistic operating conditions, including temperature cycling, pressure fluctuations, and exposure to potential contaminants.

The trade-off between storage capacity and safety continues to drive research in this field. Novel core-shell nanostructures with gradient compositions offer promising solutions, providing both high hydrogen uptake and enhanced mechanical stability. These materials incorporate sacrificial outer layers designed to degrade predictably, maintaining system integrity even as performance gradually diminishes over time.

The durability of hydrogen storage materials is directly linked to their safety profile. Palladium-coated nanomaterials exhibit enhanced stability during hydrogen absorption-desorption cycles, maintaining structural integrity for over 1000 cycles in laboratory tests. However, these materials may experience performance degradation when exposed to contaminants such as sulfur compounds or moisture, necessitating additional protective layers or purification systems in practical applications.

Thermal management represents a critical safety aspect, as hydrogen absorption and desorption processes are typically exothermic and endothermic, respectively. Advanced composite materials with integrated heat-dissipating components, such as aluminum-graphite structures, have shown superior thermal stability, preventing dangerous temperature spikes during rapid charging. These modifications reduce the risk of thermal runaway events that could compromise system integrity.

Environmental factors significantly impact the long-term durability of storage materials. Carbon-based coatings with fluorinated surfaces demonstrate exceptional resistance to oxidation and moisture infiltration, extending operational lifetimes by up to 40% compared to uncoated alternatives. Similarly, ceramic-reinforced metal hydrides maintain structural stability under vibration and mechanical stress, critical for mobile applications where physical impacts are common.

Standardized testing protocols for evaluating safety and durability remain underdeveloped, creating challenges for comparative analysis. Recent efforts by international organizations have established preliminary guidelines for accelerated aging tests and failure mode analysis specific to hydrogen storage materials. These protocols emphasize the importance of evaluating materials under realistic operating conditions, including temperature cycling, pressure fluctuations, and exposure to potential contaminants.

The trade-off between storage capacity and safety continues to drive research in this field. Novel core-shell nanostructures with gradient compositions offer promising solutions, providing both high hydrogen uptake and enhanced mechanical stability. These materials incorporate sacrificial outer layers designed to degrade predictably, maintaining system integrity even as performance gradually diminishes over time.

Environmental Impact Assessment

The environmental impact of hydrogen storage materials, their coatings, and structural modifications represents a critical consideration in the broader adoption of hydrogen as a clean energy carrier. Life cycle assessments of various hydrogen storage materials reveal significant differences in environmental footprints. Metal hydrides, while efficient for storage, often require energy-intensive manufacturing processes and utilize rare earth elements, leading to concerns about resource depletion and mining impacts.

Carbon-based materials such as activated carbon and carbon nanotubes present lower environmental impacts during production compared to metal hydrides, but their synthesis may involve hazardous chemicals. Metal-organic frameworks (MOFs) offer promising storage capabilities with potentially reduced environmental impacts, though large-scale production methods are still developing and their long-term environmental effects remain under investigation.

The coating processes employed for hydrogen storage materials introduce additional environmental considerations. Chemical vapor deposition techniques commonly used for applying protective coatings can release volatile organic compounds and greenhouse gases. Water-based coating alternatives have emerged as more environmentally friendly options, reducing emissions of harmful substances during application processes.

End-of-life management presents both challenges and opportunities. Many hydrogen storage materials contain valuable metals that can be recovered and recycled, potentially reducing the need for primary resource extraction. However, composite materials with multiple layers of different substances may complicate recycling efforts, necessitating the development of specialized recovery techniques.

The environmental benefits of advanced hydrogen storage systems must be weighed against their production impacts. While hydrogen as an energy carrier offers zero-emission operation, the full environmental value proposition depends on minimizing impacts across the entire life cycle of storage materials. Recent research indicates that structural modifications to storage materials can reduce the need for rare elements, potentially decreasing environmental burden.

Water consumption represents another significant environmental factor, particularly for manufacturing processes requiring extensive washing or purification steps. Innovations in dry synthesis methods and closed-loop water systems are helping to address these concerns, particularly important in water-stressed regions where hydrogen infrastructure may be deployed.

Carbon footprint analyses comparing different hydrogen storage approaches indicate that advanced materials with structural modifications can reduce lifetime greenhouse gas emissions by 15-30% compared to conventional storage methods, primarily through improved efficiency and extended service life.

Carbon-based materials such as activated carbon and carbon nanotubes present lower environmental impacts during production compared to metal hydrides, but their synthesis may involve hazardous chemicals. Metal-organic frameworks (MOFs) offer promising storage capabilities with potentially reduced environmental impacts, though large-scale production methods are still developing and their long-term environmental effects remain under investigation.

The coating processes employed for hydrogen storage materials introduce additional environmental considerations. Chemical vapor deposition techniques commonly used for applying protective coatings can release volatile organic compounds and greenhouse gases. Water-based coating alternatives have emerged as more environmentally friendly options, reducing emissions of harmful substances during application processes.

End-of-life management presents both challenges and opportunities. Many hydrogen storage materials contain valuable metals that can be recovered and recycled, potentially reducing the need for primary resource extraction. However, composite materials with multiple layers of different substances may complicate recycling efforts, necessitating the development of specialized recovery techniques.

The environmental benefits of advanced hydrogen storage systems must be weighed against their production impacts. While hydrogen as an energy carrier offers zero-emission operation, the full environmental value proposition depends on minimizing impacts across the entire life cycle of storage materials. Recent research indicates that structural modifications to storage materials can reduce the need for rare elements, potentially decreasing environmental burden.

Water consumption represents another significant environmental factor, particularly for manufacturing processes requiring extensive washing or purification steps. Innovations in dry synthesis methods and closed-loop water systems are helping to address these concerns, particularly important in water-stressed regions where hydrogen infrastructure may be deployed.

Carbon footprint analyses comparing different hydrogen storage approaches indicate that advanced materials with structural modifications can reduce lifetime greenhouse gas emissions by 15-30% compared to conventional storage methods, primarily through improved efficiency and extended service life.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!