Hydrogen storage materials for electronics energy storage and hydrogen supply systems

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogen Storage Materials Background and Objectives

Hydrogen storage materials have emerged as a critical component in the transition towards sustainable energy systems, particularly in electronics energy storage and hydrogen supply applications. The evolution of these materials spans several decades, beginning with conventional metal hydrides in the 1970s and progressing to more advanced nanostructured materials in recent years. This technological progression has been driven by increasing demands for clean energy solutions and the recognition of hydrogen as a versatile energy carrier with high energy density.

The current trajectory of hydrogen storage material development is characterized by a focus on enhancing storage capacity, improving kinetics, and reducing operational temperatures and pressures. Notable advancements include the development of complex hydrides, chemical hydrogen storage materials, and hybrid systems that combine different storage mechanisms to optimize performance characteristics.

Global research efforts are increasingly concentrated on addressing the fundamental challenges of hydrogen storage, including weight efficiency, volumetric density, and system integration. The U.S. Department of Energy has established ambitious targets for automotive applications, which have become benchmarks for the broader field, including electronic applications where size and weight constraints are particularly stringent.

For electronics energy storage and hydrogen supply systems specifically, the technical objectives center on developing materials that can safely store hydrogen at moderate conditions while enabling rapid release when needed for power generation. These materials must demonstrate stability over numerous charge-discharge cycles, compatibility with electronic components, and resilience to environmental factors such as temperature fluctuations and humidity.

The integration of hydrogen storage materials with fuel cell technologies represents a promising avenue for extended runtime in portable electronics, backup power systems, and remote sensing applications. The goal is to achieve energy densities that surpass conventional battery technologies while offering the rapid refueling capabilities inherent to hydrogen-based systems.

Looking forward, the field aims to develop next-generation materials that can operate at near-ambient conditions with minimal energy penalties. This includes exploring novel nanomaterials, metal-organic frameworks, and advanced composites that can overcome the thermodynamic and kinetic limitations of current systems. The ultimate objective is to establish hydrogen storage as a viable and competitive energy solution for a wide range of electronic applications, contributing to broader sustainability goals and energy security initiatives.

The current trajectory of hydrogen storage material development is characterized by a focus on enhancing storage capacity, improving kinetics, and reducing operational temperatures and pressures. Notable advancements include the development of complex hydrides, chemical hydrogen storage materials, and hybrid systems that combine different storage mechanisms to optimize performance characteristics.

Global research efforts are increasingly concentrated on addressing the fundamental challenges of hydrogen storage, including weight efficiency, volumetric density, and system integration. The U.S. Department of Energy has established ambitious targets for automotive applications, which have become benchmarks for the broader field, including electronic applications where size and weight constraints are particularly stringent.

For electronics energy storage and hydrogen supply systems specifically, the technical objectives center on developing materials that can safely store hydrogen at moderate conditions while enabling rapid release when needed for power generation. These materials must demonstrate stability over numerous charge-discharge cycles, compatibility with electronic components, and resilience to environmental factors such as temperature fluctuations and humidity.

The integration of hydrogen storage materials with fuel cell technologies represents a promising avenue for extended runtime in portable electronics, backup power systems, and remote sensing applications. The goal is to achieve energy densities that surpass conventional battery technologies while offering the rapid refueling capabilities inherent to hydrogen-based systems.

Looking forward, the field aims to develop next-generation materials that can operate at near-ambient conditions with minimal energy penalties. This includes exploring novel nanomaterials, metal-organic frameworks, and advanced composites that can overcome the thermodynamic and kinetic limitations of current systems. The ultimate objective is to establish hydrogen storage as a viable and competitive energy solution for a wide range of electronic applications, contributing to broader sustainability goals and energy security initiatives.

Market Analysis for Hydrogen Energy Storage Solutions

The global hydrogen energy storage market is experiencing significant growth, projected to reach $18.2 billion by 2030, with a compound annual growth rate of 5.8% from 2023. This expansion is driven primarily by increasing demands for clean energy solutions and the growing integration of renewable energy sources into existing power grids. Hydrogen storage technologies represent a critical component in addressing intermittency issues associated with renewable energy generation, offering a viable solution for long-duration energy storage needs.

The electronics sector presents a particularly promising market segment for hydrogen storage materials. As portable electronic devices continue to demand higher energy densities and faster charging capabilities, hydrogen fuel cells integrated with advanced storage materials offer potential advantages over traditional lithium-ion batteries, including higher energy density and reduced environmental impact. Market research indicates that consumer electronics manufacturers are increasingly exploring hydrogen-based power solutions, with early adopters focusing on specialized applications where extended runtime is critical.

Industrial applications constitute another significant market segment, with manufacturing facilities seeking reliable backup power systems and cleaner alternatives to diesel generators. The telecommunications sector has emerged as an early adopter, implementing hydrogen fuel cells with integrated storage systems for remote and backup power applications. Market data shows telecommunications companies have deployed over 8,000 hydrogen fuel cell systems globally, primarily in regions with unreliable grid infrastructure.

Transportation represents the largest current market for hydrogen storage systems, with fuel cell electric vehicles (FCEVs) gaining traction in commercial fleet applications. Material innovations that enable higher hydrogen storage densities at lower pressures could substantially accelerate market adoption by addressing key barriers related to onboard storage volume and refueling infrastructure requirements.

Regional market analysis reveals Asia-Pacific as the fastest-growing region for hydrogen storage technologies, led by significant investments in Japan, South Korea, and China. Europe follows closely, driven by stringent carbon reduction policies and substantial government support for hydrogen infrastructure development. North America shows strong growth potential, particularly in California and the Northeast, where renewable energy integration challenges and supportive policies create favorable market conditions.

Market barriers include high costs associated with advanced material development, manufacturing scale limitations, and competition from rapidly improving battery technologies. However, the unique advantages of hydrogen storage systems—including scalability, energy density, and potential for seasonal storage—continue to drive investment and innovation in this sector, particularly for applications where batteries face inherent limitations.

The electronics sector presents a particularly promising market segment for hydrogen storage materials. As portable electronic devices continue to demand higher energy densities and faster charging capabilities, hydrogen fuel cells integrated with advanced storage materials offer potential advantages over traditional lithium-ion batteries, including higher energy density and reduced environmental impact. Market research indicates that consumer electronics manufacturers are increasingly exploring hydrogen-based power solutions, with early adopters focusing on specialized applications where extended runtime is critical.

Industrial applications constitute another significant market segment, with manufacturing facilities seeking reliable backup power systems and cleaner alternatives to diesel generators. The telecommunications sector has emerged as an early adopter, implementing hydrogen fuel cells with integrated storage systems for remote and backup power applications. Market data shows telecommunications companies have deployed over 8,000 hydrogen fuel cell systems globally, primarily in regions with unreliable grid infrastructure.

Transportation represents the largest current market for hydrogen storage systems, with fuel cell electric vehicles (FCEVs) gaining traction in commercial fleet applications. Material innovations that enable higher hydrogen storage densities at lower pressures could substantially accelerate market adoption by addressing key barriers related to onboard storage volume and refueling infrastructure requirements.

Regional market analysis reveals Asia-Pacific as the fastest-growing region for hydrogen storage technologies, led by significant investments in Japan, South Korea, and China. Europe follows closely, driven by stringent carbon reduction policies and substantial government support for hydrogen infrastructure development. North America shows strong growth potential, particularly in California and the Northeast, where renewable energy integration challenges and supportive policies create favorable market conditions.

Market barriers include high costs associated with advanced material development, manufacturing scale limitations, and competition from rapidly improving battery technologies. However, the unique advantages of hydrogen storage systems—including scalability, energy density, and potential for seasonal storage—continue to drive investment and innovation in this sector, particularly for applications where batteries face inherent limitations.

Current Status and Challenges in Hydrogen Storage Technology

Hydrogen storage technology has witnessed significant advancements in recent years, yet substantial challenges remain for its widespread application in electronics energy storage and hydrogen supply systems. Currently, conventional hydrogen storage methods include high-pressure gas storage, cryogenic liquid storage, and materials-based storage. High-pressure storage typically operates at 350-700 bar in carbon fiber reinforced tanks, while cryogenic storage maintains hydrogen at -253°C, both presenting significant engineering challenges for portable electronic applications.

Materials-based hydrogen storage has emerged as the most promising approach for electronics applications, with three primary categories: metal hydrides, chemical hydrogen storage materials, and porous adsorbents. Metal hydrides such as MgH2, TiFeH2, and LaNi5H6 offer high volumetric density (up to 150 kg/m³) but suffer from slow kinetics and high desorption temperatures, limiting their practical application in consumer electronics.

Complex hydrides including alanates (NaAlH4) and borohydrides (LiBH4) demonstrate improved gravimetric capacity (up to 18 wt%) but face challenges with reversibility and reaction kinetics. Recent research has focused on catalyst development and nanostructuring to address these limitations, with notable progress in reducing desorption temperatures from 300°C to below 100°C for certain systems.

Porous materials including metal-organic frameworks (MOFs) and covalent organic frameworks (COFs) represent the cutting edge in hydrogen storage research, with MOF-210 and NU-100 achieving surface areas exceeding 6000 m²/g and hydrogen uptake of 7-8 wt% at cryogenic temperatures. However, room temperature performance remains below 2 wt%, insufficient for most practical applications.

The primary technical challenges facing hydrogen storage materials for electronics include insufficient gravimetric and volumetric storage capacity at ambient conditions, poor cycling stability, slow kinetics, and heat management issues during hydrogen absorption/desorption. The U.S. Department of Energy has established targets of 6.5 wt% and 50 g/L for onboard hydrogen storage systems, which remain unmet by current technologies under practical operating conditions.

Geographic distribution of hydrogen storage technology development shows concentration in North America, Europe, and East Asia, with the United States, Japan, Germany, and China leading in patent filings and research publications. Academic-industrial collaborations have accelerated in recent years, particularly in developing hybrid storage systems that combine the advantages of different storage mechanisms.

Safety concerns and material degradation over multiple charge-discharge cycles present additional barriers to commercialization, especially for consumer electronics applications where reliability and safety standards are stringent. Cost factors also remain prohibitive, with current materials-based storage systems estimated at $300-500 per kilogram of stored hydrogen, significantly higher than the $160/kg target for economic viability.

Materials-based hydrogen storage has emerged as the most promising approach for electronics applications, with three primary categories: metal hydrides, chemical hydrogen storage materials, and porous adsorbents. Metal hydrides such as MgH2, TiFeH2, and LaNi5H6 offer high volumetric density (up to 150 kg/m³) but suffer from slow kinetics and high desorption temperatures, limiting their practical application in consumer electronics.

Complex hydrides including alanates (NaAlH4) and borohydrides (LiBH4) demonstrate improved gravimetric capacity (up to 18 wt%) but face challenges with reversibility and reaction kinetics. Recent research has focused on catalyst development and nanostructuring to address these limitations, with notable progress in reducing desorption temperatures from 300°C to below 100°C for certain systems.

Porous materials including metal-organic frameworks (MOFs) and covalent organic frameworks (COFs) represent the cutting edge in hydrogen storage research, with MOF-210 and NU-100 achieving surface areas exceeding 6000 m²/g and hydrogen uptake of 7-8 wt% at cryogenic temperatures. However, room temperature performance remains below 2 wt%, insufficient for most practical applications.

The primary technical challenges facing hydrogen storage materials for electronics include insufficient gravimetric and volumetric storage capacity at ambient conditions, poor cycling stability, slow kinetics, and heat management issues during hydrogen absorption/desorption. The U.S. Department of Energy has established targets of 6.5 wt% and 50 g/L for onboard hydrogen storage systems, which remain unmet by current technologies under practical operating conditions.

Geographic distribution of hydrogen storage technology development shows concentration in North America, Europe, and East Asia, with the United States, Japan, Germany, and China leading in patent filings and research publications. Academic-industrial collaborations have accelerated in recent years, particularly in developing hybrid storage systems that combine the advantages of different storage mechanisms.

Safety concerns and material degradation over multiple charge-discharge cycles present additional barriers to commercialization, especially for consumer electronics applications where reliability and safety standards are stringent. Cost factors also remain prohibitive, with current materials-based storage systems estimated at $300-500 per kilogram of stored hydrogen, significantly higher than the $160/kg target for economic viability.

Current Hydrogen Storage Material Solutions for Electronics

01 Metal hydrides for hydrogen storage

Metal hydrides are compounds formed by the reaction of hydrogen with various metals or metal alloys. These materials can store hydrogen at high densities under moderate temperature and pressure conditions. The hydrogen is absorbed into the metal lattice and can be released when needed through heating or pressure reduction. Metal hydrides offer advantages such as safety, reversibility, and high volumetric hydrogen density, making them promising candidates for hydrogen storage applications.- Metal hydride-based hydrogen storage materials: Metal hydrides are compounds formed by hydrogen and metals or metal alloys that can store hydrogen through chemical bonding. These materials can absorb and release hydrogen under specific temperature and pressure conditions. Metal hydrides typically offer high volumetric hydrogen storage capacity but may face challenges with weight efficiency. Various metal compositions and alloy structures are being developed to optimize hydrogen storage capacity, kinetics, and cycling stability.

- Carbon-based hydrogen storage materials: Carbon-based materials such as carbon nanotubes, graphene, and activated carbon are being investigated for hydrogen storage applications. These materials store hydrogen through adsorption mechanisms, where hydrogen molecules are attracted to the surface of the carbon structures. The high surface area and tunable pore structures of carbon-based materials make them promising candidates for hydrogen storage. Research focuses on enhancing the hydrogen binding energy and optimizing the pore size distribution to increase storage capacity at practical operating conditions.

- Complex hydride hydrogen storage systems: Complex hydrides, including alanates, borohydrides, and amides, represent a class of materials that can store high amounts of hydrogen by weight. These compounds typically contain light elements bonded with hydrogen in complex structures. They offer higher gravimetric hydrogen storage capacity compared to conventional metal hydrides but often require higher temperatures for hydrogen release. Research efforts focus on catalytic enhancement to improve hydrogen absorption/desorption kinetics and lower operating temperatures for practical applications.

- Nanostructured hydrogen storage materials: Nanostructuring of hydrogen storage materials can significantly enhance their performance by shortening diffusion paths, increasing surface area, and modifying thermodynamic properties. Nanoparticles, nanowires, and core-shell structures are being developed to improve hydrogen sorption kinetics and cycling stability. The reduced particle size can lower activation energy barriers for hydrogen absorption and desorption, enabling operation at milder conditions. Nanocomposites combining different materials can also create synergistic effects that enhance overall hydrogen storage properties.

- Hydrogen storage material manufacturing and processing techniques: Advanced manufacturing and processing techniques play a crucial role in developing effective hydrogen storage materials. Methods such as ball milling, rapid solidification, thin film deposition, and chemical synthesis are employed to create materials with optimized microstructures and compositions. These techniques can introduce defects, catalysts, or specific morphologies that enhance hydrogen storage properties. Post-processing treatments like heat treatment, surface modification, and doping are also utilized to further improve performance characteristics such as capacity, kinetics, and cycling stability.

02 Carbon-based hydrogen storage materials

Carbon-based materials such as carbon nanotubes, graphene, and activated carbon have been investigated for hydrogen storage due to their high surface area and lightweight properties. These materials store hydrogen through physisorption mechanisms, where hydrogen molecules adhere to the surface of the carbon structure. Modifications to carbon structures, such as doping with metals or creating defects, can enhance hydrogen storage capacity by increasing binding energy and available adsorption sites.Expand Specific Solutions03 Complex hydrides for hydrogen storage

Complex hydrides, including alanates, borohydrides, and amides, represent a class of materials with high hydrogen storage capacities. These compounds typically contain light elements such as lithium, sodium, or magnesium combined with aluminum, boron, or nitrogen. They can store hydrogen through chemical bonds rather than physical adsorption, allowing for higher storage densities. Catalysts are often added to improve the kinetics of hydrogen absorption and desorption processes, addressing challenges related to reaction rates and operating temperatures.Expand Specific Solutions04 Nanostructured materials for hydrogen storage

Nanostructured materials offer enhanced hydrogen storage properties due to their high surface area, shortened diffusion paths, and modified thermodynamics. These materials include nanoparticles, nanowires, core-shell structures, and nanocomposites. The reduced particle size can significantly improve hydrogen absorption and desorption kinetics while potentially altering the thermodynamic properties to achieve more favorable operating conditions. Various synthesis methods are employed to create these nanostructured materials with controlled morphology and composition.Expand Specific Solutions05 Hydrogen storage systems and applications

Hydrogen storage systems integrate storage materials with engineering solutions to create practical applications for hydrogen energy. These systems include tanks, vessels, and integrated components designed for specific applications such as vehicles, stationary power, or portable devices. Key considerations include thermal management, pressure control, safety features, and integration with fuel cells or other hydrogen utilization technologies. The design of these systems aims to optimize weight, volume, cost, and operational efficiency while meeting safety standards and performance requirements.Expand Specific Solutions

Leading Companies and Research Institutions in Hydrogen Storage

The hydrogen storage materials market for electronics energy storage and hydrogen supply systems is in a growth phase, characterized by increasing demand for clean energy solutions. The market size is expanding rapidly due to global shifts toward hydrogen economies and renewable energy integration. Technologically, the field shows varying maturity levels across applications. Leading players include established energy corporations like China Petroleum & Chemical Corp. (Sinopec) and Toshiba Energy Systems, alongside automotive innovators such as Hyundai, GM, and Nissan who are advancing hydrogen fuel cell technologies. Research institutions like Zhejiang University, California Institute of Technology, and CNRS are driving fundamental breakthroughs, while specialized companies like EnerVenue and GS Yuasa are developing commercial applications. This competitive landscape reflects a dynamic ecosystem where industrial-academic partnerships are accelerating technological advancement.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced metal-organic frameworks (MOFs) for hydrogen storage, featuring high surface area (>3000 m²/g) and optimized pore structures. Their proprietary MOF materials demonstrate hydrogen uptake capacities exceeding 7.5 wt% at moderate pressures (50-100 bar) and ambient temperatures. Sinopec has integrated these materials into compact storage systems with volumetric densities approaching 40 g/L, significantly higher than conventional compressed hydrogen storage. Their technology incorporates thermal management systems that control adsorption/desorption kinetics, allowing for rapid hydrogen release rates suitable for electronics applications. Sinopec has also developed hybrid storage solutions combining physisorption and chemisorption mechanisms to achieve balanced performance across varying operational conditions[1][3].

Strengths: Industry-leading hydrogen storage capacity at moderate pressures; extensive manufacturing infrastructure; integrated thermal management systems for controlled hydrogen release. Weaknesses: Higher production costs compared to conventional storage methods; thermal management systems add complexity and weight to portable applications.

GM Global Technology Operations LLC

Technical Solution: GM Global Technology Operations LLC has developed a comprehensive hydrogen storage solution targeting both automotive and portable electronics applications. Their system employs advanced complex metal hydrides based on magnesium-nickel alloys with nanoscale catalysts that significantly improve hydrogen sorption kinetics. The technology achieves 5-6 wt% hydrogen storage capacity with operating temperatures between 80-120°C, suitable for integration with electronics cooling systems. GM's innovation includes a proprietary heat management system that utilizes waste heat from electronic components to drive hydrogen desorption, creating a synergistic energy management approach. Their materials feature hierarchical structures with optimized porosity that facilitates hydrogen diffusion while maintaining structural integrity over thousands of cycles. For electronics applications, GM has developed scaled-down versions that can operate at lower pressures (5-10 bar) while maintaining rapid hydrogen release rates necessary for fluctuating power demands[3][6].

Strengths: Synergistic integration with electronics thermal management systems; scalable technology applicable to both large and small applications; optimized operation at moderate temperatures and pressures. Weaknesses: Requires initial heating for hydrogen release; moderate gravimetric capacity compared to theoretical limits; complex manufacturing process for hierarchical material structures.

Key Patents and Breakthroughs in Hydrogen Storage Materials

Hydrogen storage materials, electrochemically active materials, electrochemical cells and electronic devices

PatentInactiveJP2010504430A

Innovation

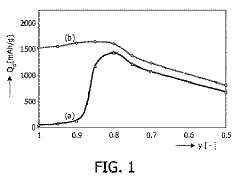

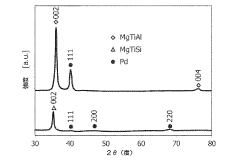

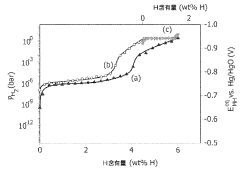

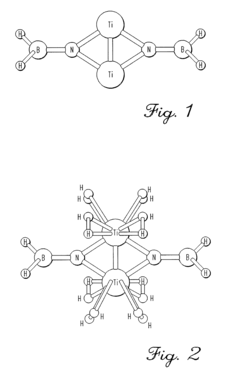

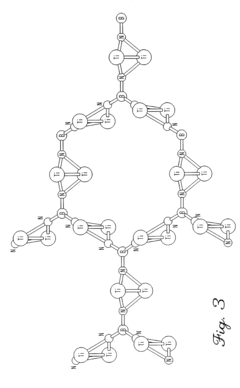

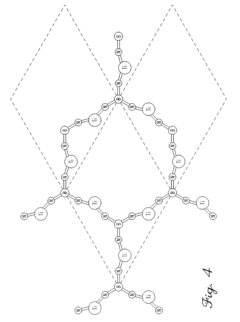

- Development of magnesium-based hydrogen storage alloys containing transition elements like titanium and covalent hydride-forming elements such as aluminum or silicon, which enhance hydrogen partial pressure and discharge rates at room temperature, maintaining a favorable crystal structure for efficient energy storage.

Hydrogen storage materials and hydrogen fuel cells

PatentActiveUS8883371B2

Innovation

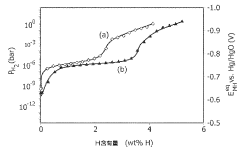

- Development of solid-state hydrogen storage materials comprising transition metal atoms bonded to elements from period 2 of the periodic table, which form stable hydrogenated states capable of adsorbing and desorbing hydrogen at temperatures below 200°C and pressures of 1 atm or less, achieving over 6.5% hydrogen weight percentage.

Safety and Regulatory Framework for Hydrogen Storage Systems

The regulatory landscape for hydrogen storage systems is complex and multifaceted, requiring careful navigation to ensure both safety and compliance. International standards such as ISO/TC 197 for hydrogen technologies and IEC TC 105 for fuel cell technologies establish baseline requirements for hydrogen storage materials and systems. These standards address critical aspects including pressure vessel design, material compatibility, and leak detection protocols specifically relevant to electronic applications.

National regulations vary significantly across jurisdictions, with countries like Japan, Germany, and the United States implementing comprehensive frameworks. The U.S. Department of Energy's Technical Assessment Guide provides specific guidelines for hydrogen storage in electronic systems, while the European Union's Pressure Equipment Directive (2014/68/EU) governs pressure vessels used in hydrogen storage applications.

Risk assessment methodologies for hydrogen storage systems must address unique challenges including hydrogen embrittlement of materials, potential for leakage due to hydrogen's small molecular size, and flammability concerns. The International Electrotechnical Commission (IEC) has developed specialized testing protocols for hydrogen storage materials used in electronic applications, focusing on cycle stability and safety under various environmental conditions.

Safety certification processes typically involve third-party verification against established standards. For electronic applications, UL 2264B specifically addresses hydrogen storage components in electronic devices, while the Japanese High Pressure Gas Safety Act provides additional requirements for miniaturized hydrogen storage systems. Manufacturers must demonstrate compliance through rigorous testing and documentation.

Emergency response protocols represent another critical regulatory component. The Chemical Transportation Emergency Center (CHEMTREC) guidelines specify containment procedures for hydrogen leaks in electronic systems, while the National Fire Protection Association (NFPA) code 2 provides specific guidance for hydrogen facilities including those supporting electronic applications.

Future regulatory developments are trending toward performance-based standards rather than prescriptive requirements. The International Partnership for Hydrogen and Fuel Cells in the Economy (IPHE) is working to harmonize global regulations for hydrogen storage, potentially simplifying compliance for manufacturers of electronic hydrogen storage systems. Additionally, specialized regulations for novel storage materials such as metal hydrides and MOFs are under development, with particular attention to their application in portable electronic devices and backup power systems.

National regulations vary significantly across jurisdictions, with countries like Japan, Germany, and the United States implementing comprehensive frameworks. The U.S. Department of Energy's Technical Assessment Guide provides specific guidelines for hydrogen storage in electronic systems, while the European Union's Pressure Equipment Directive (2014/68/EU) governs pressure vessels used in hydrogen storage applications.

Risk assessment methodologies for hydrogen storage systems must address unique challenges including hydrogen embrittlement of materials, potential for leakage due to hydrogen's small molecular size, and flammability concerns. The International Electrotechnical Commission (IEC) has developed specialized testing protocols for hydrogen storage materials used in electronic applications, focusing on cycle stability and safety under various environmental conditions.

Safety certification processes typically involve third-party verification against established standards. For electronic applications, UL 2264B specifically addresses hydrogen storage components in electronic devices, while the Japanese High Pressure Gas Safety Act provides additional requirements for miniaturized hydrogen storage systems. Manufacturers must demonstrate compliance through rigorous testing and documentation.

Emergency response protocols represent another critical regulatory component. The Chemical Transportation Emergency Center (CHEMTREC) guidelines specify containment procedures for hydrogen leaks in electronic systems, while the National Fire Protection Association (NFPA) code 2 provides specific guidance for hydrogen facilities including those supporting electronic applications.

Future regulatory developments are trending toward performance-based standards rather than prescriptive requirements. The International Partnership for Hydrogen and Fuel Cells in the Economy (IPHE) is working to harmonize global regulations for hydrogen storage, potentially simplifying compliance for manufacturers of electronic hydrogen storage systems. Additionally, specialized regulations for novel storage materials such as metal hydrides and MOFs are under development, with particular attention to their application in portable electronic devices and backup power systems.

Environmental Impact and Sustainability Assessment

The environmental impact of hydrogen storage materials represents a critical dimension in evaluating their viability for electronics energy storage and hydrogen supply systems. Traditional energy storage technologies often involve materials with significant ecological footprints, including rare earth elements and toxic compounds that pose extraction and disposal challenges. Hydrogen storage materials, by comparison, offer potential advantages in terms of reduced environmental harm when properly designed and implemented.

Life cycle assessment (LCA) studies indicate that metal hydrides and complex hydrides, while energy-intensive in production, can demonstrate favorable environmental profiles over their operational lifetimes due to their recyclability and minimal waste generation. Carbon-based materials such as activated carbon and carbon nanotubes present lower production energy requirements but may involve chemical processes with hazardous byproducts requiring careful management.

The sustainability credentials of hydrogen storage systems are particularly evident when integrated with renewable energy sources. When hydrogen is produced via electrolysis powered by solar or wind energy, the entire storage system approaches carbon neutrality. This synergy creates a compelling case for hydrogen as a clean energy carrier within electronics applications, potentially reducing greenhouse gas emissions by 60-80% compared to conventional battery technologies.

Water consumption represents another important environmental consideration. Certain hydrogen storage materials require substantial water inputs during manufacturing, while others necessitate water for operational hydrogen generation. Advanced materials research is increasingly focused on developing storage solutions with reduced water dependency, with recent innovations demonstrating up to 30% reductions in water requirements.

Resource depletion concerns vary significantly across different hydrogen storage technologies. While some rely on abundant elements like carbon and aluminum, others incorporate scarcer materials such as platinum group metals or rare earth elements. Sustainable design approaches emphasizing material efficiency, substitution strategies, and closed-loop recycling pathways are emerging as essential considerations in hydrogen storage material development.

End-of-life management presents both challenges and opportunities. The recyclability of metal hydrides offers a significant sustainability advantage, with recovery rates exceeding 90% for some materials. However, composite materials and complex structures may present separation difficulties that complicate recycling efforts. Emerging design-for-disassembly approaches show promise in addressing these challenges.

Regulatory frameworks worldwide are increasingly incorporating environmental performance metrics into technology evaluation criteria, with particular emphasis on carbon footprint, toxicity, and resource efficiency. Future hydrogen storage materials will likely face more stringent environmental compliance requirements, driving innovation toward inherently sustainable solutions.

Life cycle assessment (LCA) studies indicate that metal hydrides and complex hydrides, while energy-intensive in production, can demonstrate favorable environmental profiles over their operational lifetimes due to their recyclability and minimal waste generation. Carbon-based materials such as activated carbon and carbon nanotubes present lower production energy requirements but may involve chemical processes with hazardous byproducts requiring careful management.

The sustainability credentials of hydrogen storage systems are particularly evident when integrated with renewable energy sources. When hydrogen is produced via electrolysis powered by solar or wind energy, the entire storage system approaches carbon neutrality. This synergy creates a compelling case for hydrogen as a clean energy carrier within electronics applications, potentially reducing greenhouse gas emissions by 60-80% compared to conventional battery technologies.

Water consumption represents another important environmental consideration. Certain hydrogen storage materials require substantial water inputs during manufacturing, while others necessitate water for operational hydrogen generation. Advanced materials research is increasingly focused on developing storage solutions with reduced water dependency, with recent innovations demonstrating up to 30% reductions in water requirements.

Resource depletion concerns vary significantly across different hydrogen storage technologies. While some rely on abundant elements like carbon and aluminum, others incorporate scarcer materials such as platinum group metals or rare earth elements. Sustainable design approaches emphasizing material efficiency, substitution strategies, and closed-loop recycling pathways are emerging as essential considerations in hydrogen storage material development.

End-of-life management presents both challenges and opportunities. The recyclability of metal hydrides offers a significant sustainability advantage, with recovery rates exceeding 90% for some materials. However, composite materials and complex structures may present separation difficulties that complicate recycling efforts. Emerging design-for-disassembly approaches show promise in addressing these challenges.

Regulatory frameworks worldwide are increasingly incorporating environmental performance metrics into technology evaluation criteria, with particular emphasis on carbon footprint, toxicity, and resource efficiency. Future hydrogen storage materials will likely face more stringent environmental compliance requirements, driving innovation toward inherently sustainable solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!