What are the key regulatory requirements for Hydrogen storage materials deployment

SEP 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogen Storage Materials Regulatory Landscape and Objectives

Hydrogen storage materials have evolved significantly over the past decades, transitioning from experimental concepts to commercially viable solutions. The regulatory landscape governing these materials has similarly developed, reflecting growing recognition of hydrogen's potential as a clean energy carrier. Initially focused primarily on safety concerns, regulations have expanded to encompass environmental impact, material sustainability, and integration with existing energy infrastructure frameworks.

The evolution of hydrogen storage technology has been marked by several distinct phases, beginning with conventional physical storage methods such as compressed gas and cryogenic liquid storage. These approaches, while technically straightforward, presented significant regulatory challenges related to high-pressure containment and extreme temperature management. As materials-based storage solutions emerged, including metal hydrides, chemical hydrides, and advanced sorbent materials, regulatory frameworks have had to adapt to address novel safety profiles and performance standards.

Current regulatory objectives for hydrogen storage materials deployment center on establishing harmonized international standards that balance safety requirements with the need for technological innovation. Key objectives include developing performance-based certification protocols rather than prescriptive requirements, which can potentially stifle emerging technologies. Regulatory bodies aim to create frameworks that address the entire lifecycle of storage materials, from raw material sourcing to end-of-life disposal or recycling.

Safety remains paramount in regulatory considerations, with particular emphasis on thermal management, pressure control, and material stability under various environmental conditions. Regulations increasingly focus on quantifiable risk assessment methodologies specific to different hydrogen storage material classes, moving beyond generic hazardous material classifications that may be inappropriately restrictive for newer technologies.

Environmental sustainability has emerged as a critical regulatory objective, with growing requirements for lifecycle assessment of storage materials. This includes evaluation of resource intensity in manufacturing, energy efficiency during operation, and environmental impact of decommissioning. Regulatory frameworks increasingly incorporate carbon footprint considerations, recognizing that the environmental benefits of hydrogen depend significantly on the sustainability of storage solutions.

Interoperability and standardization represent another key regulatory goal, with efforts focused on establishing common interfaces, testing protocols, and performance metrics across international markets. This standardization aims to prevent market fragmentation and accelerate commercial deployment by reducing compliance costs and technical barriers to entry.

The ultimate regulatory objective is to facilitate widespread adoption of hydrogen storage technologies while maintaining public safety and environmental protection. This requires balancing rigorous safety standards with sufficient flexibility to accommodate rapid technological advancement in this dynamic field.

The evolution of hydrogen storage technology has been marked by several distinct phases, beginning with conventional physical storage methods such as compressed gas and cryogenic liquid storage. These approaches, while technically straightforward, presented significant regulatory challenges related to high-pressure containment and extreme temperature management. As materials-based storage solutions emerged, including metal hydrides, chemical hydrides, and advanced sorbent materials, regulatory frameworks have had to adapt to address novel safety profiles and performance standards.

Current regulatory objectives for hydrogen storage materials deployment center on establishing harmonized international standards that balance safety requirements with the need for technological innovation. Key objectives include developing performance-based certification protocols rather than prescriptive requirements, which can potentially stifle emerging technologies. Regulatory bodies aim to create frameworks that address the entire lifecycle of storage materials, from raw material sourcing to end-of-life disposal or recycling.

Safety remains paramount in regulatory considerations, with particular emphasis on thermal management, pressure control, and material stability under various environmental conditions. Regulations increasingly focus on quantifiable risk assessment methodologies specific to different hydrogen storage material classes, moving beyond generic hazardous material classifications that may be inappropriately restrictive for newer technologies.

Environmental sustainability has emerged as a critical regulatory objective, with growing requirements for lifecycle assessment of storage materials. This includes evaluation of resource intensity in manufacturing, energy efficiency during operation, and environmental impact of decommissioning. Regulatory frameworks increasingly incorporate carbon footprint considerations, recognizing that the environmental benefits of hydrogen depend significantly on the sustainability of storage solutions.

Interoperability and standardization represent another key regulatory goal, with efforts focused on establishing common interfaces, testing protocols, and performance metrics across international markets. This standardization aims to prevent market fragmentation and accelerate commercial deployment by reducing compliance costs and technical barriers to entry.

The ultimate regulatory objective is to facilitate widespread adoption of hydrogen storage technologies while maintaining public safety and environmental protection. This requires balancing rigorous safety standards with sufficient flexibility to accommodate rapid technological advancement in this dynamic field.

Market Analysis for Hydrogen Storage Solutions

The global hydrogen storage market is experiencing significant growth, driven by increasing focus on clean energy solutions and decarbonization efforts across industries. Current market valuations place the hydrogen storage sector at approximately 15 billion USD in 2023, with projections indicating a compound annual growth rate of 11-13% through 2030. This growth trajectory is primarily fueled by governmental commitments to carbon neutrality and substantial investments in hydrogen infrastructure development.

Demand patterns reveal distinct regional variations, with Europe leading adoption rates due to aggressive climate policies and substantial funding mechanisms like the European Green Deal. Asia-Pacific follows closely, with Japan, South Korea, and increasingly China making strategic investments in hydrogen technologies as part of their energy transition roadmaps. North America shows growing interest, particularly in industrial applications and transportation sectors.

Market segmentation analysis indicates that material-based storage solutions, including metal hydrides, chemical hydrides, and adsorbent materials, currently represent about 25% of the total hydrogen storage market. Compressed and liquid hydrogen storage technologies maintain dominance with approximately 70% market share, though this balance is expected to shift as material-based solutions overcome technical challenges.

Key demand drivers include the transportation sector, particularly heavy-duty vehicles and maritime applications where battery-electric solutions face limitations. Industrial decarbonization represents another significant market segment, with steel production, chemical manufacturing, and refining processes increasingly exploring hydrogen as an alternative to fossil fuels. The stationary power sector also shows growing interest in hydrogen storage for grid balancing and energy security applications.

Consumer adoption barriers remain significant, primarily centered around cost considerations, with hydrogen storage systems currently commanding premium prices compared to conventional energy storage solutions. Safety perceptions and limited infrastructure availability further constrain market expansion in consumer-facing applications.

Market forecasts suggest material-based hydrogen storage solutions will gain substantial market share by 2030, potentially reaching 40% of the total hydrogen storage market as technological advancements address current limitations in energy density, operating conditions, and system integration. This growth will be particularly pronounced in applications requiring high volumetric efficiency and safety parameters, such as passenger vehicles and portable power systems.

The competitive landscape features established industrial gas companies expanding their hydrogen portfolios alongside specialized materials technology firms and emerging startups focused exclusively on advanced storage materials development.

Demand patterns reveal distinct regional variations, with Europe leading adoption rates due to aggressive climate policies and substantial funding mechanisms like the European Green Deal. Asia-Pacific follows closely, with Japan, South Korea, and increasingly China making strategic investments in hydrogen technologies as part of their energy transition roadmaps. North America shows growing interest, particularly in industrial applications and transportation sectors.

Market segmentation analysis indicates that material-based storage solutions, including metal hydrides, chemical hydrides, and adsorbent materials, currently represent about 25% of the total hydrogen storage market. Compressed and liquid hydrogen storage technologies maintain dominance with approximately 70% market share, though this balance is expected to shift as material-based solutions overcome technical challenges.

Key demand drivers include the transportation sector, particularly heavy-duty vehicles and maritime applications where battery-electric solutions face limitations. Industrial decarbonization represents another significant market segment, with steel production, chemical manufacturing, and refining processes increasingly exploring hydrogen as an alternative to fossil fuels. The stationary power sector also shows growing interest in hydrogen storage for grid balancing and energy security applications.

Consumer adoption barriers remain significant, primarily centered around cost considerations, with hydrogen storage systems currently commanding premium prices compared to conventional energy storage solutions. Safety perceptions and limited infrastructure availability further constrain market expansion in consumer-facing applications.

Market forecasts suggest material-based hydrogen storage solutions will gain substantial market share by 2030, potentially reaching 40% of the total hydrogen storage market as technological advancements address current limitations in energy density, operating conditions, and system integration. This growth will be particularly pronounced in applications requiring high volumetric efficiency and safety parameters, such as passenger vehicles and portable power systems.

The competitive landscape features established industrial gas companies expanding their hydrogen portfolios alongside specialized materials technology firms and emerging startups focused exclusively on advanced storage materials development.

Current Regulatory Challenges for Hydrogen Storage Materials

The regulatory landscape for hydrogen storage materials presents significant challenges for industry stakeholders seeking to deploy these technologies at scale. Current regulations vary considerably across jurisdictions, creating a complex compliance environment that impedes standardization and market growth. In the United States, the Department of Energy (DOE) and Department of Transportation (DOT) have established guidelines for hydrogen storage systems, but these often lack specificity for emerging material-based storage solutions such as metal hydrides, chemical hydrides, and adsorbent materials.

Safety standards represent the most pressing regulatory challenge, with requirements focusing on mechanical integrity, thermal management, and leak prevention. The ISO/TC 197 committee has developed several international standards for hydrogen technologies, yet many countries have adopted modified versions, creating regulatory inconsistencies. For instance, pressure vessel codes like ASME BPVC in the US and PED in Europe impose different testing protocols for similar hydrogen storage systems.

Material certification processes present another significant hurdle. Current frameworks were largely designed for conventional gas storage and fail to adequately address the unique properties of advanced hydrogen storage materials. The certification process typically requires extensive cycling tests, environmental exposure assessments, and accelerated aging studies that can take 2-3 years to complete, substantially delaying market entry for innovative solutions.

Environmental regulations add another layer of complexity. Materials containing rare earth elements or potentially toxic compounds face stringent disposal and recycling requirements under frameworks like the EU's REACH regulation and RoHS directive. These regulations, while necessary for environmental protection, often fail to provide clear pathways for novel hydrogen storage materials.

Permitting procedures for hydrogen storage installations remain fragmented and inconsistent. Local building codes, fire safety regulations, and zoning requirements vary significantly between municipalities, creating uncertainty for project developers. The lack of harmonized standards increases compliance costs and extends project timelines, with some installations facing delays of 12-18 months solely due to regulatory approval processes.

Transportation regulations present particular challenges for material-based hydrogen storage. The UN Model Regulations and modal regulations like ADR (road), RID (rail), and IMDG (maritime) classify hydrogen storage materials differently depending on their physical state and chemical composition, creating logistical complications for supply chain management and international deployment.

Insurance requirements further complicate deployment, as many insurers lack actuarial data to properly assess risks associated with novel hydrogen storage materials, resulting in higher premiums or coverage limitations that impact project economics.

Safety standards represent the most pressing regulatory challenge, with requirements focusing on mechanical integrity, thermal management, and leak prevention. The ISO/TC 197 committee has developed several international standards for hydrogen technologies, yet many countries have adopted modified versions, creating regulatory inconsistencies. For instance, pressure vessel codes like ASME BPVC in the US and PED in Europe impose different testing protocols for similar hydrogen storage systems.

Material certification processes present another significant hurdle. Current frameworks were largely designed for conventional gas storage and fail to adequately address the unique properties of advanced hydrogen storage materials. The certification process typically requires extensive cycling tests, environmental exposure assessments, and accelerated aging studies that can take 2-3 years to complete, substantially delaying market entry for innovative solutions.

Environmental regulations add another layer of complexity. Materials containing rare earth elements or potentially toxic compounds face stringent disposal and recycling requirements under frameworks like the EU's REACH regulation and RoHS directive. These regulations, while necessary for environmental protection, often fail to provide clear pathways for novel hydrogen storage materials.

Permitting procedures for hydrogen storage installations remain fragmented and inconsistent. Local building codes, fire safety regulations, and zoning requirements vary significantly between municipalities, creating uncertainty for project developers. The lack of harmonized standards increases compliance costs and extends project timelines, with some installations facing delays of 12-18 months solely due to regulatory approval processes.

Transportation regulations present particular challenges for material-based hydrogen storage. The UN Model Regulations and modal regulations like ADR (road), RID (rail), and IMDG (maritime) classify hydrogen storage materials differently depending on their physical state and chemical composition, creating logistical complications for supply chain management and international deployment.

Insurance requirements further complicate deployment, as many insurers lack actuarial data to properly assess risks associated with novel hydrogen storage materials, resulting in higher premiums or coverage limitations that impact project economics.

Compliance Frameworks for Hydrogen Storage Deployment

01 Safety regulations for hydrogen storage materials

Hydrogen storage materials must comply with specific safety regulations due to the flammable and potentially explosive nature of hydrogen. These regulations cover aspects such as material integrity, leak prevention, pressure resistance, and safety testing protocols. Manufacturers must ensure that storage materials can withstand various environmental conditions and prevent hydrogen leakage, which could lead to safety hazards. Compliance with these safety standards is mandatory before commercial deployment of hydrogen storage technologies.- Safety standards for hydrogen storage materials: Regulatory requirements for hydrogen storage materials include safety standards to prevent hazards such as leakage, explosion, and fire. These standards specify testing protocols for material integrity, pressure resistance, and thermal stability. Manufacturers must demonstrate compliance with these safety standards through rigorous testing and certification processes before commercial deployment of hydrogen storage systems.

- Environmental compliance for hydrogen storage technologies: Hydrogen storage materials must meet environmental regulations regarding production, use, and disposal. These requirements focus on minimizing environmental impact, reducing carbon footprint, and ensuring sustainable material sourcing. Manufacturers need to conduct life cycle assessments and provide documentation on the environmental performance of their hydrogen storage solutions to comply with regional and international environmental standards.

- Transportation and handling regulations: Specific regulations govern the transportation and handling of hydrogen storage materials across different jurisdictions. These include requirements for proper labeling, packaging, and documentation during transport. Special permits may be required for moving certain types of hydrogen storage materials, with restrictions on quantity, pressure levels, and transportation methods to ensure public safety and prevent accidents during transit.

- Material certification and quality control requirements: Hydrogen storage materials must undergo certification processes to verify their composition, purity, and performance characteristics. Quality control requirements include batch testing, material traceability, and documentation of manufacturing processes. Regulatory bodies may require periodic re-certification and quality audits to ensure continued compliance with material specifications and performance standards throughout the product lifecycle.

- Installation and operational compliance: Regulations specify requirements for the installation and operation of hydrogen storage systems, including facility design, ventilation, monitoring systems, and emergency protocols. Operators must obtain permits and licenses, conduct regular inspections, and maintain detailed records of system performance and maintenance. Personnel handling hydrogen storage systems must receive specialized training and certification to ensure safe operation and proper response to potential incidents.

02 Environmental compliance requirements

Hydrogen storage materials must meet environmental regulations regarding their production, use, and disposal. These requirements focus on minimizing environmental impact throughout the lifecycle of the materials, including sustainable sourcing of raw materials, energy-efficient manufacturing processes, and proper end-of-life management. Environmental compliance also covers emissions standards during hydrogen production and storage, as well as requirements for recyclability and waste reduction to ensure that hydrogen storage solutions contribute to overall environmental sustainability goals.Expand Specific Solutions03 Material certification and standardization

Hydrogen storage materials require specific certification and must conform to established industry standards. These standards define the physical and chemical properties that materials must possess, including purity levels, structural integrity, and performance characteristics. Certification processes involve rigorous testing to verify compliance with these standards, ensuring consistency and reliability across different manufacturers. Standardization efforts are ongoing globally to harmonize requirements for hydrogen storage materials, facilitating international trade and technology adoption while maintaining quality and safety benchmarks.Expand Specific Solutions04 Transportation and handling regulations

Specific regulations govern the transportation and handling of hydrogen storage materials to ensure safety during transit and use. These regulations include requirements for proper labeling, packaging, and documentation when shipping hydrogen storage materials. They also specify training requirements for personnel involved in handling these materials and outline emergency response procedures in case of accidents. Transportation regulations may vary by region and mode of transport, with additional restrictions for air transport or crossing international borders, requiring manufacturers and distributors to maintain compliance with multiple regulatory frameworks.Expand Specific Solutions05 Performance and efficiency requirements

Regulatory frameworks establish minimum performance and efficiency standards for hydrogen storage materials. These requirements specify metrics such as hydrogen storage capacity, charging/discharging rates, cycle durability, and energy efficiency. Materials must demonstrate reliable performance under various operating conditions, including temperature and pressure variations. Performance standards are designed to ensure that hydrogen storage solutions meet the needs of end applications, whether for stationary power generation, transportation, or portable devices. Compliance with these standards is essential for market approval and commercial viability of hydrogen storage technologies.Expand Specific Solutions

Key Regulatory Bodies and Industry Stakeholders

The hydrogen storage materials regulatory landscape is evolving as the market transitions from early development to commercial deployment phase. The competitive field features diverse players across multiple regions, with significant activity from both established energy corporations and research institutions. China's Huaneng Group demonstrates strong vertical integration through multiple subsidiaries focused on hydrogen energy technology, while Western companies like GM, Air Products & Chemicals, and Robert Bosch bring automotive and industrial expertise. Research leadership is distributed among institutions like California Institute of Technology, University of Houston, and Beijing Institute of Technology, which are advancing material science innovations. The technology remains in mid-maturity phase, with regulatory frameworks still developing to address safety standards, material certification, and cross-border transport requirements.

Advanced Industrial Science & Technology

Technical Solution: Advanced Industrial Science & Technology (AIST) has developed hydrogen storage materials that address regulatory requirements through innovative nanomaterial engineering. Their technology focuses on carbon-based nanostructured materials and metal-organic frameworks (MOFs) that comply with Japanese High Pressure Gas Safety Act regulations and international standards. AIST's hydrogen storage systems incorporate specialized pressure vessel designs that meet KHK (High Pressure Gas Safety Institute of Japan) standards and ASME Section VIII requirements. Their materials undergo rigorous testing protocols for hydrogen compatibility according to ISO 16111 and JIS (Japanese Industrial Standards) specifications. AIST has pioneered safety evaluation methodologies for novel storage materials that address concerns about material degradation, thermal management, and gas purity requirements in accordance with ISO/TR 15916 guidelines for hydrogen system safety. Their storage solutions feature integrated monitoring systems that comply with IEC 61508 functional safety standards and incorporate fail-safe mechanisms for pressure relief that meet JIS B 8270 requirements. AIST has also developed specialized protocols for material characterization that align with ISO 16111 requirements for transportable gas storage devices using reversible metal hydrides.

Strengths: Strong scientific foundation with extensive material characterization data supporting regulatory submissions; close collaboration with Japanese regulatory authorities provides streamlined approval pathways; comprehensive safety testing protocols exceed minimum requirements. Weaknesses: Some advanced materials still in research phase face uncertain regulatory pathways; higher material production costs may impact commercial viability; international harmonization of standards for novel materials remains challenging.

Council of Scientific & Industrial Research

Technical Solution: The Council of Scientific & Industrial Research (CSIR) has developed hydrogen storage materials technologies that address regulatory requirements through a comprehensive approach to material science and safety engineering. Their work focuses on metal hydrides and carbon nanostructures that comply with Indian standards set by the Petroleum and Explosives Safety Organisation (PESO) and international guidelines. CSIR has pioneered specialized testing protocols for hydrogen storage materials that align with ISO 16111 requirements and incorporate additional safety parameters specific to high-temperature and high-humidity environments common in India. Their storage systems feature multi-layered safety mechanisms including pressure relief devices, thermal management systems, and gas detection technologies that meet IEC 60079 standards for explosive atmospheres. CSIR has developed material qualification procedures that address hydrogen embrittlement concerns according to ASME Article KD-10 requirements and incorporate accelerated aging tests to predict long-term material performance. Their regulatory compliance framework includes specialized risk assessment methodologies aligned with ISO 31000 principles and guidelines for hydrogen storage facilities. CSIR also implements rigorous quality control procedures for material production that conform to ISO 9001 standards and environmental management systems according to ISO 14001.

Strengths: Specialized expertise in developing materials suitable for diverse climatic conditions; strong government backing facilitates regulatory pathway development; cost-effective solutions designed for emerging market deployment. Weaknesses: Limited international deployment history creates challenges for global regulatory acceptance; some technologies still transitioning from laboratory to commercial scale face uncertain regulatory pathways; harmonization with international standards remains an ongoing process.

Critical Standards and Certification Requirements

Hydrogen storage material

PatentInactiveUS20090035175A1

Innovation

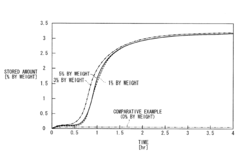

- A hydrogen storage material comprising a mixture of poorly activatable BCC hydrogen storage components and activated hydrogen storage components, where the activated component accelerates the activation of the poorly activatable component under low temperature and low pressure conditions, without adding additional elements or complicating the production process, by transferring active hydrogen atoms to reduce the oxide layer on the surface of the BCC component.

Catalyst enhanced MgAl-based hydrogen storage material

PatentInactiveUS20190390307A1

Innovation

- A catalyst-enhanced MgAl-based hydrogen storage material is developed through a process involving vacuum melting, ball milling, cold isostatic pressing, hot pressing, and heat treatment of Mg and Al with Ti, Zr, and V, eliminating the need for rare earth elements and achieving stable doping of catalysts, thereby improving hydrogen absorption and desorption properties.

Safety and Risk Assessment Protocols

The development of hydrogen storage materials necessitates comprehensive safety and risk assessment protocols to ensure their safe deployment across various applications. These protocols must address the unique properties of hydrogen, particularly its high flammability range (4-75% in air) and low ignition energy (0.02mJ), which present significant safety challenges.

Primary safety assessment frameworks for hydrogen storage materials include leak detection systems, pressure monitoring, and material integrity evaluations. These assessments must be conducted at multiple stages: during material development, system integration, and throughout operational lifecycles. International standards such as ISO/TC 197 and IEC 62282 provide foundational guidelines for these evaluations, though regulatory requirements vary significantly across jurisdictions.

Risk assessment methodologies for hydrogen storage typically employ Failure Mode and Effects Analysis (FMEA), Hazard and Operability Studies (HAZOP), and Quantitative Risk Assessment (QRA). These approaches help identify potential failure points, evaluate consequence severity, and determine mitigation strategies. For novel storage materials, additional testing protocols may be required to address unique degradation mechanisms or unexpected chemical interactions.

Material-specific safety considerations must account for different storage technologies. Metal hydrides require thermal management systems to control heat during absorption/desorption cycles. Chemical hydrogen carriers need assessments for potential toxic byproducts. Carbon-based materials must be evaluated for dust explosion risks and potential degradation products.

Environmental exposure testing represents another critical component of safety protocols. Materials must demonstrate stability under various conditions including temperature fluctuations, humidity variations, and vibration stresses. Accelerated aging tests are particularly important for predicting long-term performance and identifying potential failure modes before deployment.

Emergency response protocols must be integrated into the risk assessment framework. These include automated shutdown systems, pressure relief mechanisms, and containment strategies for potential leaks. Personnel training requirements should also be specified, ensuring operators understand material-specific hazards and appropriate response procedures.

Certification processes typically require documentation of all safety assessments, including test results, risk mitigation strategies, and compliance with relevant standards. Third-party verification is increasingly becoming mandatory in many jurisdictions, particularly for large-scale or public-facing applications. This verification process often includes site-specific risk assessments that consider local environmental conditions and proximity to population centers.

Primary safety assessment frameworks for hydrogen storage materials include leak detection systems, pressure monitoring, and material integrity evaluations. These assessments must be conducted at multiple stages: during material development, system integration, and throughout operational lifecycles. International standards such as ISO/TC 197 and IEC 62282 provide foundational guidelines for these evaluations, though regulatory requirements vary significantly across jurisdictions.

Risk assessment methodologies for hydrogen storage typically employ Failure Mode and Effects Analysis (FMEA), Hazard and Operability Studies (HAZOP), and Quantitative Risk Assessment (QRA). These approaches help identify potential failure points, evaluate consequence severity, and determine mitigation strategies. For novel storage materials, additional testing protocols may be required to address unique degradation mechanisms or unexpected chemical interactions.

Material-specific safety considerations must account for different storage technologies. Metal hydrides require thermal management systems to control heat during absorption/desorption cycles. Chemical hydrogen carriers need assessments for potential toxic byproducts. Carbon-based materials must be evaluated for dust explosion risks and potential degradation products.

Environmental exposure testing represents another critical component of safety protocols. Materials must demonstrate stability under various conditions including temperature fluctuations, humidity variations, and vibration stresses. Accelerated aging tests are particularly important for predicting long-term performance and identifying potential failure modes before deployment.

Emergency response protocols must be integrated into the risk assessment framework. These include automated shutdown systems, pressure relief mechanisms, and containment strategies for potential leaks. Personnel training requirements should also be specified, ensuring operators understand material-specific hazards and appropriate response procedures.

Certification processes typically require documentation of all safety assessments, including test results, risk mitigation strategies, and compliance with relevant standards. Third-party verification is increasingly becoming mandatory in many jurisdictions, particularly for large-scale or public-facing applications. This verification process often includes site-specific risk assessments that consider local environmental conditions and proximity to population centers.

Environmental Impact and Sustainability Considerations

The deployment of hydrogen storage materials necessitates careful consideration of environmental impacts throughout their entire lifecycle. Material extraction processes for various storage solutions—including metal hydrides, carbon-based materials, and chemical carriers—often involve mining activities that can lead to habitat disruption, soil erosion, and water contamination. Manufacturing processes may require significant energy inputs and potentially hazardous chemicals, contributing to carbon emissions and pollution if not properly managed.

During operational use, different hydrogen storage technologies present varying environmental profiles. While hydrogen itself produces only water when utilized in fuel cells, the environmental footprint of storage materials depends on factors such as energy efficiency, durability, and potential for leakage. Materials requiring high temperatures or pressures for hydrogen release demand additional energy inputs, potentially offsetting some environmental benefits if this energy comes from non-renewable sources.

End-of-life considerations represent another critical environmental dimension. The recyclability of storage materials varies significantly—some metal hydrides can be effectively reclaimed and reprocessed, while composite materials may present greater recycling challenges. Proper disposal protocols must be established to prevent environmental contamination from spent materials, particularly those containing potentially toxic elements.

From a sustainability perspective, hydrogen storage materials must align with circular economy principles. This includes designing materials with recycled content where possible, minimizing critical raw material usage, and engineering for disassembly and material recovery. Life cycle assessment (LCA) methodologies are increasingly being applied to evaluate the comprehensive environmental impacts of different storage solutions, enabling more informed decision-making.

Water consumption represents another important consideration, particularly for technologies requiring water for hydrogen production or release processes. In water-stressed regions, this factor may significantly influence technology selection and deployment strategies. Similarly, land use requirements for large-scale hydrogen storage infrastructure must be evaluated against competing land needs for agriculture, conservation, and human settlement.

Regulatory frameworks increasingly mandate environmental impact assessments and sustainability certifications for hydrogen technologies. These requirements aim to ensure that the transition to hydrogen-based energy systems delivers genuine environmental benefits rather than merely shifting environmental burdens. Companies developing and deploying hydrogen storage materials must therefore integrate environmental considerations from the earliest stages of research and development through to commercial implementation.

During operational use, different hydrogen storage technologies present varying environmental profiles. While hydrogen itself produces only water when utilized in fuel cells, the environmental footprint of storage materials depends on factors such as energy efficiency, durability, and potential for leakage. Materials requiring high temperatures or pressures for hydrogen release demand additional energy inputs, potentially offsetting some environmental benefits if this energy comes from non-renewable sources.

End-of-life considerations represent another critical environmental dimension. The recyclability of storage materials varies significantly—some metal hydrides can be effectively reclaimed and reprocessed, while composite materials may present greater recycling challenges. Proper disposal protocols must be established to prevent environmental contamination from spent materials, particularly those containing potentially toxic elements.

From a sustainability perspective, hydrogen storage materials must align with circular economy principles. This includes designing materials with recycled content where possible, minimizing critical raw material usage, and engineering for disassembly and material recovery. Life cycle assessment (LCA) methodologies are increasingly being applied to evaluate the comprehensive environmental impacts of different storage solutions, enabling more informed decision-making.

Water consumption represents another important consideration, particularly for technologies requiring water for hydrogen production or release processes. In water-stressed regions, this factor may significantly influence technology selection and deployment strategies. Similarly, land use requirements for large-scale hydrogen storage infrastructure must be evaluated against competing land needs for agriculture, conservation, and human settlement.

Regulatory frameworks increasingly mandate environmental impact assessments and sustainability certifications for hydrogen technologies. These requirements aim to ensure that the transition to hydrogen-based energy systems delivers genuine environmental benefits rather than merely shifting environmental burdens. Companies developing and deploying hydrogen storage materials must therefore integrate environmental considerations from the earliest stages of research and development through to commercial implementation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!