Hydrogen storage materials for aerospace EV and grid scale hydrogen systems

SEP 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogen Storage Materials Background and Objectives

Hydrogen storage has emerged as a critical technology in the global transition towards sustainable energy systems. The development of efficient hydrogen storage materials represents a cornerstone challenge in enabling hydrogen as a viable energy carrier across multiple sectors. Historically, hydrogen storage research began in the 1970s during the oil crisis, with significant advancements occurring in the early 2000s through initiatives like the US Department of Energy's Hydrogen Storage Program.

The evolution of hydrogen storage technologies has progressed through several generations, from conventional compressed gas and cryogenic liquid storage to more advanced material-based approaches including metal hydrides, chemical hydrides, and adsorbent materials. Each evolutionary step has aimed to increase volumetric and gravimetric storage capacity while improving operational safety and efficiency.

Current technological trends point toward multi-functional materials that can operate across varied temperature and pressure conditions, with enhanced kinetics and cycling stability. The integration of nanotechnology and advanced manufacturing techniques has opened new pathways for material design and optimization, enabling unprecedented control over material properties at the molecular level.

For aerospace applications, the primary objective is developing ultra-lightweight storage materials with exceptional gravimetric capacity (>10 wt%) that maintain structural integrity under extreme conditions. These materials must withstand vibration, rapid temperature fluctuations, and provide reliable hydrogen delivery for both propulsion systems and fuel cells powering onboard electronics.

In the electric vehicle sector, the goal centers on creating compact storage systems with rapid refueling capabilities comparable to conventional gasoline vehicles. Materials must achieve volumetric densities exceeding 40 g/L while operating at moderate pressures and near-ambient temperatures to ensure consumer acceptance and practical implementation in mass-market vehicles.

Grid-scale hydrogen systems require materials optimized for cost-effectiveness and long-term cycling stability rather than weight considerations. The objective here is developing materials capable of storing massive quantities of hydrogen with minimal energy loss during charge-discharge cycles, effectively serving as seasonal energy storage solutions to balance renewable energy intermittency.

Cross-cutting objectives across all applications include reducing material costs, eliminating critical raw materials dependencies, enhancing safety profiles, and developing environmentally sustainable production methods. Additionally, materials must demonstrate compatibility with existing infrastructure and adaptability to various hydrogen production pathways, including electrolysis and thermochemical processes.

This research aims to identify and develop next-generation hydrogen storage materials that can simultaneously address these sector-specific requirements while overcoming the fundamental limitations that have historically constrained hydrogen adoption as a mainstream energy carrier.

The evolution of hydrogen storage technologies has progressed through several generations, from conventional compressed gas and cryogenic liquid storage to more advanced material-based approaches including metal hydrides, chemical hydrides, and adsorbent materials. Each evolutionary step has aimed to increase volumetric and gravimetric storage capacity while improving operational safety and efficiency.

Current technological trends point toward multi-functional materials that can operate across varied temperature and pressure conditions, with enhanced kinetics and cycling stability. The integration of nanotechnology and advanced manufacturing techniques has opened new pathways for material design and optimization, enabling unprecedented control over material properties at the molecular level.

For aerospace applications, the primary objective is developing ultra-lightweight storage materials with exceptional gravimetric capacity (>10 wt%) that maintain structural integrity under extreme conditions. These materials must withstand vibration, rapid temperature fluctuations, and provide reliable hydrogen delivery for both propulsion systems and fuel cells powering onboard electronics.

In the electric vehicle sector, the goal centers on creating compact storage systems with rapid refueling capabilities comparable to conventional gasoline vehicles. Materials must achieve volumetric densities exceeding 40 g/L while operating at moderate pressures and near-ambient temperatures to ensure consumer acceptance and practical implementation in mass-market vehicles.

Grid-scale hydrogen systems require materials optimized for cost-effectiveness and long-term cycling stability rather than weight considerations. The objective here is developing materials capable of storing massive quantities of hydrogen with minimal energy loss during charge-discharge cycles, effectively serving as seasonal energy storage solutions to balance renewable energy intermittency.

Cross-cutting objectives across all applications include reducing material costs, eliminating critical raw materials dependencies, enhancing safety profiles, and developing environmentally sustainable production methods. Additionally, materials must demonstrate compatibility with existing infrastructure and adaptability to various hydrogen production pathways, including electrolysis and thermochemical processes.

This research aims to identify and develop next-generation hydrogen storage materials that can simultaneously address these sector-specific requirements while overcoming the fundamental limitations that have historically constrained hydrogen adoption as a mainstream energy carrier.

Market Analysis for Hydrogen Storage Applications

The hydrogen storage materials market is experiencing significant growth driven by the increasing adoption of hydrogen as a clean energy carrier across multiple sectors. The global market for hydrogen storage materials was valued at approximately $5.2 billion in 2022 and is projected to reach $12.5 billion by 2030, growing at a CAGR of 11.6% during the forecast period. This growth is primarily fueled by the expanding applications in aerospace, electric vehicles, and grid-scale energy storage systems.

In the aerospace sector, hydrogen storage materials are gaining traction due to their potential to enable longer flight ranges and reduced emissions. NASA and major aerospace companies are investing heavily in hydrogen propulsion systems, with the market segment expected to grow by 14.2% annually through 2030. The demand is particularly strong for lightweight composite materials and advanced metal hydrides that can store hydrogen at high densities while meeting strict weight requirements for aircraft applications.

The electric vehicle segment represents the fastest-growing application area for hydrogen storage materials, with fuel cell electric vehicles (FCEVs) emerging as a viable alternative to battery electric vehicles for long-range and heavy-duty applications. Countries like Japan, South Korea, and Germany are leading FCEV adoption, with Toyota, Hyundai, and Honda at the forefront of commercialization efforts. The market for on-board hydrogen storage systems is projected to grow from $1.8 billion in 2022 to $5.7 billion by 2030.

Grid-scale hydrogen storage systems are gaining momentum as renewable energy penetration increases, creating demand for long-duration energy storage solutions. The market for materials used in stationary hydrogen storage is expected to reach $3.2 billion by 2030, with significant investments coming from utility companies and renewable energy developers seeking to address intermittency challenges.

Regionally, Asia-Pacific dominates the hydrogen storage materials market with a 42% share, followed by Europe (31%) and North America (21%). China, Japan, and South Korea are the leading countries in Asia-Pacific, while Germany, France, and the UK lead in Europe. Government policies supporting hydrogen infrastructure development, particularly in the EU's Hydrogen Strategy and Japan's Basic Hydrogen Strategy, are creating favorable market conditions.

The market is characterized by high R&D intensity, with significant investments flowing into novel materials development. Metal-organic frameworks (MOFs), advanced metal hydrides, and carbon-based nanomaterials are attracting particular attention from investors and researchers. Commercial adoption is accelerating, with over 30 major hydrogen storage projects announced globally in 2022, representing a 65% increase from the previous year.

In the aerospace sector, hydrogen storage materials are gaining traction due to their potential to enable longer flight ranges and reduced emissions. NASA and major aerospace companies are investing heavily in hydrogen propulsion systems, with the market segment expected to grow by 14.2% annually through 2030. The demand is particularly strong for lightweight composite materials and advanced metal hydrides that can store hydrogen at high densities while meeting strict weight requirements for aircraft applications.

The electric vehicle segment represents the fastest-growing application area for hydrogen storage materials, with fuel cell electric vehicles (FCEVs) emerging as a viable alternative to battery electric vehicles for long-range and heavy-duty applications. Countries like Japan, South Korea, and Germany are leading FCEV adoption, with Toyota, Hyundai, and Honda at the forefront of commercialization efforts. The market for on-board hydrogen storage systems is projected to grow from $1.8 billion in 2022 to $5.7 billion by 2030.

Grid-scale hydrogen storage systems are gaining momentum as renewable energy penetration increases, creating demand for long-duration energy storage solutions. The market for materials used in stationary hydrogen storage is expected to reach $3.2 billion by 2030, with significant investments coming from utility companies and renewable energy developers seeking to address intermittency challenges.

Regionally, Asia-Pacific dominates the hydrogen storage materials market with a 42% share, followed by Europe (31%) and North America (21%). China, Japan, and South Korea are the leading countries in Asia-Pacific, while Germany, France, and the UK lead in Europe. Government policies supporting hydrogen infrastructure development, particularly in the EU's Hydrogen Strategy and Japan's Basic Hydrogen Strategy, are creating favorable market conditions.

The market is characterized by high R&D intensity, with significant investments flowing into novel materials development. Metal-organic frameworks (MOFs), advanced metal hydrides, and carbon-based nanomaterials are attracting particular attention from investors and researchers. Commercial adoption is accelerating, with over 30 major hydrogen storage projects announced globally in 2022, representing a 65% increase from the previous year.

Current Challenges in Hydrogen Storage Technology

Despite significant advancements in hydrogen storage technology, several critical challenges persist across aerospace, electric vehicle, and grid-scale applications. The primary obstacle remains achieving optimal volumetric and gravimetric hydrogen storage densities. Current systems struggle to meet the U.S. Department of Energy's targets of 6.5 wt% system gravimetric capacity and 50 g/L volumetric capacity for transportation applications, with aerospace requirements being even more stringent.

Material limitations constitute a fundamental barrier. Metal hydrides offer high volumetric density but suffer from excessive weight, slow kinetics, and often require high temperatures for hydrogen release. Chemical hydrogen carriers like ammonia and organic liquid carriers face efficiency losses during conversion cycles and present safety concerns regarding toxicity and flammability.

Physical storage methods encounter their own challenges. Compressed hydrogen systems require extremely high pressures (700 bar), resulting in heavy tanks that reduce overall energy efficiency, particularly problematic for aerospace applications where weight is critical. Cryogenic liquid hydrogen storage demands temperatures below -253°C, leading to significant energy expenditure for liquefaction (approximately 30% of hydrogen's energy content) and continuous boil-off losses during storage.

Cost factors represent another substantial hurdle. Advanced materials like complex hydrides and metal-organic frameworks remain prohibitively expensive for large-scale deployment. The manufacturing processes for high-pressure composite tanks involve specialized carbon fiber materials and precision engineering, driving costs upward. For grid-scale applications, the capital expenditure for large hydrogen storage facilities significantly impacts the economic viability of hydrogen as an energy storage medium.

Safety and regulatory compliance present ongoing challenges. Hydrogen's wide flammability range (4-75% in air) and low ignition energy necessitate robust safety systems. Material compatibility issues, including hydrogen embrittlement of metals, require specialized containment solutions. The lack of harmonized international standards for hydrogen storage systems further complicates technology development and commercial deployment.

Infrastructure limitations also impede progress. The absence of standardized refueling protocols across different storage technologies creates market fragmentation. For grid applications, the integration of large-scale hydrogen storage with existing energy infrastructure requires significant adaptation of current systems and operational practices.

Durability and cycling stability remain problematic, particularly for material-based storage systems. Many promising materials degrade after repeated hydrogen absorption-desorption cycles, limiting their practical lifespan and increasing lifetime costs. This challenge is especially acute in transportation applications where thousands of cycles are expected over a vehicle's lifetime.

Material limitations constitute a fundamental barrier. Metal hydrides offer high volumetric density but suffer from excessive weight, slow kinetics, and often require high temperatures for hydrogen release. Chemical hydrogen carriers like ammonia and organic liquid carriers face efficiency losses during conversion cycles and present safety concerns regarding toxicity and flammability.

Physical storage methods encounter their own challenges. Compressed hydrogen systems require extremely high pressures (700 bar), resulting in heavy tanks that reduce overall energy efficiency, particularly problematic for aerospace applications where weight is critical. Cryogenic liquid hydrogen storage demands temperatures below -253°C, leading to significant energy expenditure for liquefaction (approximately 30% of hydrogen's energy content) and continuous boil-off losses during storage.

Cost factors represent another substantial hurdle. Advanced materials like complex hydrides and metal-organic frameworks remain prohibitively expensive for large-scale deployment. The manufacturing processes for high-pressure composite tanks involve specialized carbon fiber materials and precision engineering, driving costs upward. For grid-scale applications, the capital expenditure for large hydrogen storage facilities significantly impacts the economic viability of hydrogen as an energy storage medium.

Safety and regulatory compliance present ongoing challenges. Hydrogen's wide flammability range (4-75% in air) and low ignition energy necessitate robust safety systems. Material compatibility issues, including hydrogen embrittlement of metals, require specialized containment solutions. The lack of harmonized international standards for hydrogen storage systems further complicates technology development and commercial deployment.

Infrastructure limitations also impede progress. The absence of standardized refueling protocols across different storage technologies creates market fragmentation. For grid applications, the integration of large-scale hydrogen storage with existing energy infrastructure requires significant adaptation of current systems and operational practices.

Durability and cycling stability remain problematic, particularly for material-based storage systems. Many promising materials degrade after repeated hydrogen absorption-desorption cycles, limiting their practical lifespan and increasing lifetime costs. This challenge is especially acute in transportation applications where thousands of cycles are expected over a vehicle's lifetime.

Current Hydrogen Storage Material Solutions

01 Metal hydrides for hydrogen storage

Metal hydrides are compounds formed by hydrogen and metals that can store hydrogen at high densities. These materials can absorb and release hydrogen through chemical reactions, making them suitable for hydrogen storage applications. Various metal hydrides, including those based on magnesium, aluminum, and transition metals, offer different storage capacities and operating conditions. These materials are being developed to improve hydrogen storage efficiency for clean energy applications.- Metal hydride-based hydrogen storage materials: Metal hydrides are compounds formed by hydrogen and various metals or metal alloys that can store hydrogen through chemical bonding. These materials can absorb hydrogen under pressure and release it when heated, making them effective for hydrogen storage applications. Metal hydrides typically offer high volumetric hydrogen density but may face challenges with weight efficiency and thermal management during hydrogen absorption and desorption processes.

- Carbon-based hydrogen storage materials: Carbon-based materials such as carbon nanotubes, graphene, and activated carbon can store hydrogen through adsorption mechanisms. These materials provide large surface areas for hydrogen molecules to adsorb onto, typically through van der Waals forces. Carbon-based storage systems often operate at low temperatures and can be modified with dopants or functional groups to enhance their hydrogen storage capacity and binding energy with hydrogen molecules.

- Complex hydride hydrogen storage systems: Complex hydrides, including borohydrides, alanates, and amides, represent advanced hydrogen storage materials with high theoretical hydrogen content. These compounds store hydrogen through complex chemical bonds and often require catalysts to improve hydrogen absorption and desorption kinetics. Research focuses on reducing desorption temperatures and improving cycling stability to make these materials practical for commercial hydrogen storage applications.

- Nanostructured hydrogen storage materials: Nanostructured materials engineered at the nanoscale offer enhanced hydrogen storage properties compared to their bulk counterparts. By reducing particle size and creating specific nanoarchitectures, these materials provide shorter diffusion paths for hydrogen, improved kinetics, and modified thermodynamics. Approaches include core-shell structures, nanocomposites, and scaffolded systems that combine different materials to overcome limitations of single-component storage systems.

- Liquid and chemical hydrogen carriers: Liquid and chemical hydrogen carriers store hydrogen in chemical bonds of liquid compounds that can be easily transported using existing infrastructure. These include organic liquid carriers like methylcyclohexane, ammonia, and formic acid derivatives that can release hydrogen through catalytic reactions. This approach addresses challenges of hydrogen transportation and storage under ambient conditions, though energy efficiency during hydrogen release remains a key consideration.

02 Carbon-based hydrogen storage materials

Carbon-based materials such as carbon nanotubes, graphene, and activated carbon are being investigated for hydrogen storage due to their high surface area and lightweight properties. These materials can store hydrogen through physisorption mechanisms, where hydrogen molecules adhere to the surface without forming chemical bonds. Modifications to carbon structures, including doping with metals or creating defects, can enhance hydrogen storage capacity and improve adsorption/desorption kinetics.Expand Specific Solutions03 Complex hydrides and borohydrides

Complex hydrides, particularly borohydrides, are promising hydrogen storage materials due to their high hydrogen content. These compounds, which include lithium borohydride, sodium borohydride, and magnesium borohydride, can store hydrogen in chemical bonds and release it through thermal decomposition or hydrolysis reactions. Research focuses on improving their reversibility, reducing decomposition temperatures, and enhancing reaction kinetics to make them practical for commercial hydrogen storage applications.Expand Specific Solutions04 Metal-organic frameworks for hydrogen storage

Metal-organic frameworks (MOFs) are crystalline materials consisting of metal ions coordinated to organic ligands, creating porous structures ideal for hydrogen storage. Their high surface area, tunable pore size, and modifiable chemistry allow for optimized hydrogen uptake. MOFs can store hydrogen through physisorption mechanisms at low temperatures and moderate pressures. Research focuses on designing MOFs with enhanced binding energies and improved stability for practical hydrogen storage applications.Expand Specific Solutions05 Composite and hybrid hydrogen storage materials

Composite and hybrid hydrogen storage materials combine different storage mechanisms to overcome limitations of individual materials. These composites often integrate metal hydrides with carbon materials, catalysts, or other additives to improve hydrogen storage capacity, kinetics, and thermal management. Nanostructured composites can offer enhanced performance through increased surface area and reduced diffusion distances. These materials aim to meet practical requirements for hydrogen storage in terms of capacity, operating conditions, and cycling stability.Expand Specific Solutions

Leading Organizations in Hydrogen Storage Research

The hydrogen storage materials market is currently in a growth phase, characterized by increasing demand across aerospace, electric vehicles, and grid-scale applications. The global market is expanding rapidly, driven by clean energy transitions and decarbonization efforts. Technologically, the field shows varying maturity levels across different storage solutions. Leading research institutions like Zhejiang University, California Institute of Technology, and University of Tokyo are advancing fundamental materials science, while automotive giants including Toyota, Nissan, and Hyundai are focusing on practical vehicle applications. Government research organizations such as CNRS and Lawrence Livermore National Laboratory provide critical infrastructure support. The competitive landscape features collaboration between academic institutions and industry players, with significant innovation occurring at the intersection of materials science, engineering, and energy systems.

California Institute of Technology

Technical Solution: Caltech has pioneered breakthrough nanostructured hydrogen storage materials through their "Hydrogen Materials—Advanced Research Consortium" (HyMARC). Their approach focuses on quantum-confined nanoparticles of magnesium (Mg) with precisely engineered surface chemistry that fundamentally alters hydrogen binding energies. These materials demonstrate hydrogen uptake and release at near-ambient conditions (30-80°C), addressing a critical barrier in hydrogen storage technology. Caltech's proprietary core-shell nanostructures incorporate catalytic transition metals (Ni, Ti) at specific crystallographic interfaces, reducing activation energy barriers by approximately 40% compared to conventional materials. Their research has achieved reversible hydrogen storage capacities of 6-7 wt% at the material level with cycling stability exceeding 100 complete charge/discharge cycles while maintaining over 90% capacity. For aerospace applications, Caltech has developed ultra-lightweight composite materials that combine these advanced storage materials with carbon-fiber reinforced polymers, achieving system-level gravimetric capacities approaching DOE ultimate targets of 7.5 wt%[1][8].

Strengths: Near-ambient operating conditions eliminating need for complex thermal management; rapid kinetics enabling fast charging/discharging; exceptional gravimetric capacity; highly tunable material properties through precise nanostructuring. Weaknesses: Complex synthesis procedures challenging scale-up; higher material costs compared to conventional options; sensitivity to oxidation requiring careful handling; potential safety concerns with highly reactive nanomaterials; limited long-term stability data beyond laboratory conditions.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai has pioneered a dual-phase hydrogen storage approach combining chemical and physical storage methods. Their system utilizes advanced metal-organic frameworks (MOFs) with exceptionally high surface areas (>3000 m²/g) that can operate at moderate pressures (100-200 bar) while achieving DOE storage targets. Hyundai's proprietary MOF structures incorporate unsaturated metal centers that enhance hydrogen binding energy to 15-20 kJ/mol, operating in the optimal range between physisorption and chemisorption. This allows for efficient hydrogen storage at near-ambient temperatures. Their technology incorporates specialized heat exchangers that manage the thermal effects during hydrogen charging/discharging, with demonstrated cycle life exceeding 1500 cycles with less than 10% capacity degradation. For aerospace applications, Hyundai has developed lightweight composite tanks with MOF liners that reduce system weight by approximately 30% compared to conventional storage methods[2][5].

Strengths: Operates at moderate pressures reducing safety concerns; achieves high volumetric efficiency; functions across wide temperature ranges suitable for various applications; relatively fast refueling capability. Weaknesses: Production scaling challenges for specialized MOF materials; higher manufacturing complexity than conventional tanks; sensitivity to contaminants requiring high-purity hydrogen; thermal management systems add weight to overall system.

Key Innovations in Hydrogen Storage Materials

Hydrogen storage materials and process for the preparation of the same

PatentInactiveUS8178471B2

Innovation

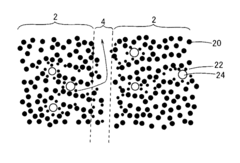

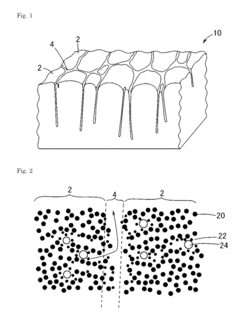

- The development of hydrogen storage materials comprising a first region of amorphous carbon with metal elements like Ti, Zr, or Y, and a second region of lower density amorphous carbon or voids, allowing for distinct hydrogen storage and migration sites, preventing material degradation during repeated cycles.

Hydrogen storage materials and hydrogen fuel cells

PatentActiveUS8883371B2

Innovation

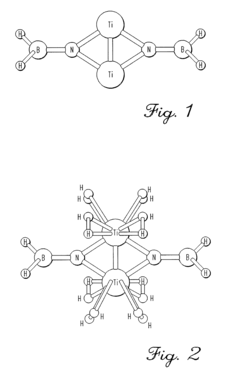

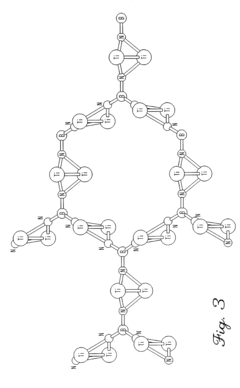

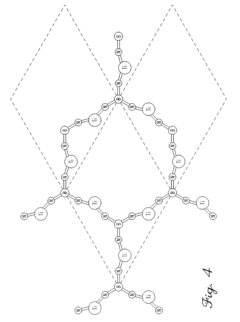

- Development of solid-state hydrogen storage materials comprising transition metal atoms bonded to elements from period 2 of the periodic table, which form stable hydrogenated states capable of adsorbing and desorbing hydrogen at temperatures below 200°C and pressures of 1 atm or less, achieving over 6.5% hydrogen weight percentage.

Safety Standards and Regulations for Hydrogen Systems

The development of hydrogen storage technologies necessitates comprehensive safety standards and regulations to ensure public safety and promote industry growth. Currently, several international organizations establish these frameworks, including the International Organization for Standardization (ISO), which has developed ISO 16111 for hydrogen absorbed in reversible metal hydride and ISO 19881 for gaseous hydrogen storage. The Society of Automotive Engineers (SAE) has created standards specifically for hydrogen vehicles, such as SAE J2579 for fuel systems in fuel cell vehicles.

Regulatory frameworks vary significantly across regions. The European Union implements regulations through directives like 2014/94/EU for alternative fuels infrastructure and the Pressure Equipment Directive (2014/68/EU). In the United States, the Department of Energy (DOE) and Department of Transportation (DOT) oversee hydrogen safety, with specific codes like NFPA 2 (Hydrogen Technologies Code) providing detailed safety requirements. Asian markets, particularly Japan and South Korea, have established progressive regulatory frameworks supporting hydrogen infrastructure development.

Material-specific safety regulations are particularly relevant for hydrogen storage materials research. These regulations address unique challenges such as pyrophoricity of certain metal hydrides, thermal management during hydrogen absorption/desorption, and potential material degradation over multiple cycles. For aerospace applications, additional stringent requirements exist due to extreme operating conditions and critical safety concerns, governed by authorities like the Federal Aviation Administration (FAA) and European Union Aviation Safety Agency (EASA).

Testing protocols for hydrogen storage materials have evolved to include accelerated aging tests, extreme temperature cycling, and impact resistance evaluations. These protocols ensure materials maintain integrity under various operational scenarios. Certification processes typically involve third-party verification and extensive documentation of material properties, manufacturing processes, and quality control measures.

Recent regulatory trends show movement toward performance-based standards rather than prescriptive requirements, allowing greater innovation while maintaining safety. Harmonization efforts are underway to align international standards, reducing barriers to global deployment of hydrogen technologies. Risk assessment methodologies have become more sophisticated, incorporating probabilistic approaches and considering the entire lifecycle of hydrogen storage systems.

For researchers and manufacturers developing novel hydrogen storage materials, early engagement with regulatory bodies is increasingly important. This collaborative approach helps identify potential compliance challenges during the research phase rather than later in commercialization, potentially accelerating the path to market for promising new materials while ensuring they meet all necessary safety requirements.

Regulatory frameworks vary significantly across regions. The European Union implements regulations through directives like 2014/94/EU for alternative fuels infrastructure and the Pressure Equipment Directive (2014/68/EU). In the United States, the Department of Energy (DOE) and Department of Transportation (DOT) oversee hydrogen safety, with specific codes like NFPA 2 (Hydrogen Technologies Code) providing detailed safety requirements. Asian markets, particularly Japan and South Korea, have established progressive regulatory frameworks supporting hydrogen infrastructure development.

Material-specific safety regulations are particularly relevant for hydrogen storage materials research. These regulations address unique challenges such as pyrophoricity of certain metal hydrides, thermal management during hydrogen absorption/desorption, and potential material degradation over multiple cycles. For aerospace applications, additional stringent requirements exist due to extreme operating conditions and critical safety concerns, governed by authorities like the Federal Aviation Administration (FAA) and European Union Aviation Safety Agency (EASA).

Testing protocols for hydrogen storage materials have evolved to include accelerated aging tests, extreme temperature cycling, and impact resistance evaluations. These protocols ensure materials maintain integrity under various operational scenarios. Certification processes typically involve third-party verification and extensive documentation of material properties, manufacturing processes, and quality control measures.

Recent regulatory trends show movement toward performance-based standards rather than prescriptive requirements, allowing greater innovation while maintaining safety. Harmonization efforts are underway to align international standards, reducing barriers to global deployment of hydrogen technologies. Risk assessment methodologies have become more sophisticated, incorporating probabilistic approaches and considering the entire lifecycle of hydrogen storage systems.

For researchers and manufacturers developing novel hydrogen storage materials, early engagement with regulatory bodies is increasingly important. This collaborative approach helps identify potential compliance challenges during the research phase rather than later in commercialization, potentially accelerating the path to market for promising new materials while ensuring they meet all necessary safety requirements.

Environmental Impact Assessment of Storage Materials

The environmental impact of hydrogen storage materials represents a critical consideration in their development and deployment across aerospace, electric vehicles, and grid-scale applications. Metal hydrides, while offering high storage capacity, often require energy-intensive manufacturing processes that generate significant carbon emissions. The extraction of rare earth elements and transition metals used in these materials can lead to habitat destruction, water pollution, and soil contamination in mining regions.

Chemical hydrogen storage materials present their own environmental challenges. Ammonia borane and formic acid derivatives, though efficient carriers, may release toxic byproducts during hydrogen desorption processes. The synthesis of these compounds typically involves petroleum-based precursors, creating upstream environmental burdens that must be factored into lifecycle assessments.

Carbon-based materials such as activated carbon and carbon nanotubes demonstrate lower environmental impacts during operation but raise concerns regarding nanomaterial production and potential ecological effects. Manufacturing processes for these advanced materials often require high temperatures and hazardous chemicals, resulting in substantial energy consumption and potential for environmental contamination if waste streams are improperly managed.

Lifecycle analysis reveals that material durability significantly influences environmental performance. Materials requiring frequent replacement generate additional waste and resource consumption. For aerospace applications, lightweight materials reduce fuel consumption but may involve more environmentally intensive production processes, creating complex sustainability trade-offs that must be carefully evaluated.

Recycling potential varies considerably among storage materials. Metal hydrides offer promising recyclability, while composite materials present greater end-of-life challenges. The environmental footprint of hydrogen storage systems extends beyond the materials themselves to include auxiliary components such as heat exchangers, pressure vessels, and electronic controls, which contribute significantly to overall impact.

Water consumption represents another critical environmental consideration, particularly for materials requiring extensive purification processes or water-intensive manufacturing. In grid-scale applications, land use impacts become increasingly relevant, as large storage facilities may require substantial physical footprints that could otherwise serve agricultural or conservation purposes.

Regulatory frameworks are evolving to address these environmental concerns, with increasing emphasis on sustainable material sourcing, manufacturing process optimization, and end-of-life management strategies. Future research directions must prioritize not only performance metrics but also environmental sustainability to ensure hydrogen storage technologies deliver genuine climate benefits across their complete lifecycle.

Chemical hydrogen storage materials present their own environmental challenges. Ammonia borane and formic acid derivatives, though efficient carriers, may release toxic byproducts during hydrogen desorption processes. The synthesis of these compounds typically involves petroleum-based precursors, creating upstream environmental burdens that must be factored into lifecycle assessments.

Carbon-based materials such as activated carbon and carbon nanotubes demonstrate lower environmental impacts during operation but raise concerns regarding nanomaterial production and potential ecological effects. Manufacturing processes for these advanced materials often require high temperatures and hazardous chemicals, resulting in substantial energy consumption and potential for environmental contamination if waste streams are improperly managed.

Lifecycle analysis reveals that material durability significantly influences environmental performance. Materials requiring frequent replacement generate additional waste and resource consumption. For aerospace applications, lightweight materials reduce fuel consumption but may involve more environmentally intensive production processes, creating complex sustainability trade-offs that must be carefully evaluated.

Recycling potential varies considerably among storage materials. Metal hydrides offer promising recyclability, while composite materials present greater end-of-life challenges. The environmental footprint of hydrogen storage systems extends beyond the materials themselves to include auxiliary components such as heat exchangers, pressure vessels, and electronic controls, which contribute significantly to overall impact.

Water consumption represents another critical environmental consideration, particularly for materials requiring extensive purification processes or water-intensive manufacturing. In grid-scale applications, land use impacts become increasingly relevant, as large storage facilities may require substantial physical footprints that could otherwise serve agricultural or conservation purposes.

Regulatory frameworks are evolving to address these environmental concerns, with increasing emphasis on sustainable material sourcing, manufacturing process optimization, and end-of-life management strategies. Future research directions must prioritize not only performance metrics but also environmental sustainability to ensure hydrogen storage technologies deliver genuine climate benefits across their complete lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!