Hydrogen storage materials for EV energy storage and thermal management

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogen Storage Materials Background and Objectives

Hydrogen storage technology has evolved significantly over the past decades, transitioning from conventional compressed gas systems to advanced materials-based solutions. The journey began in the 1970s with metal hydrides, progressing through complex hydrides in the 1990s, and more recently exploring nanomaterials and metal-organic frameworks. This evolution reflects the persistent challenge of finding efficient hydrogen storage methods that meet the demanding requirements of modern applications, particularly in the automotive sector.

The electric vehicle (EV) industry faces critical challenges in energy storage and thermal management that conventional battery technologies struggle to address fully. Hydrogen storage materials present a promising alternative pathway, offering potential advantages in energy density, rapid refueling capabilities, and thermal regulation properties that could revolutionize EV performance and practicality.

Current technical objectives in hydrogen storage material research for EVs focus on achieving the U.S. Department of Energy's targets: 6.5 wt% system gravimetric capacity and 50 g/L volumetric capacity at near-ambient conditions. Additionally, researchers aim to develop materials that enable rapid hydrogen absorption/desorption kinetics at temperatures compatible with vehicle operation (preferably below 100°C) while maintaining cycling stability over thousands of charge-discharge cycles.

Beyond pure storage metrics, integrated objectives include developing materials that can simultaneously serve thermal management functions. This dual-purpose approach seeks to leverage the endothermic and exothermic nature of hydrogen absorption/desorption processes to assist with battery thermal regulation—a critical factor in EV performance, safety, and longevity.

The global push toward decarbonization has accelerated interest in hydrogen technologies, with major automotive markets including Japan, Germany, South Korea, and China investing heavily in research and development. This international focus has established hydrogen storage as a key enabling technology for the broader hydrogen economy, with EVs representing a high-impact application area that could drive widespread adoption.

Looking forward, the technical trajectory aims to move beyond incremental improvements in existing materials toward transformative solutions that integrate seamlessly with next-generation EV architectures. This includes exploring hybrid systems that combine hydrogen storage with battery technologies, creating synergistic energy systems that maximize the advantages of both approaches while minimizing their respective limitations.

The electric vehicle (EV) industry faces critical challenges in energy storage and thermal management that conventional battery technologies struggle to address fully. Hydrogen storage materials present a promising alternative pathway, offering potential advantages in energy density, rapid refueling capabilities, and thermal regulation properties that could revolutionize EV performance and practicality.

Current technical objectives in hydrogen storage material research for EVs focus on achieving the U.S. Department of Energy's targets: 6.5 wt% system gravimetric capacity and 50 g/L volumetric capacity at near-ambient conditions. Additionally, researchers aim to develop materials that enable rapid hydrogen absorption/desorption kinetics at temperatures compatible with vehicle operation (preferably below 100°C) while maintaining cycling stability over thousands of charge-discharge cycles.

Beyond pure storage metrics, integrated objectives include developing materials that can simultaneously serve thermal management functions. This dual-purpose approach seeks to leverage the endothermic and exothermic nature of hydrogen absorption/desorption processes to assist with battery thermal regulation—a critical factor in EV performance, safety, and longevity.

The global push toward decarbonization has accelerated interest in hydrogen technologies, with major automotive markets including Japan, Germany, South Korea, and China investing heavily in research and development. This international focus has established hydrogen storage as a key enabling technology for the broader hydrogen economy, with EVs representing a high-impact application area that could drive widespread adoption.

Looking forward, the technical trajectory aims to move beyond incremental improvements in existing materials toward transformative solutions that integrate seamlessly with next-generation EV architectures. This includes exploring hybrid systems that combine hydrogen storage with battery technologies, creating synergistic energy systems that maximize the advantages of both approaches while minimizing their respective limitations.

Market Analysis for EV Hydrogen Storage Solutions

The hydrogen storage materials market for electric vehicles is experiencing significant growth, driven by the increasing adoption of hydrogen fuel cell vehicles (FCVs) and the search for more efficient energy storage solutions. The global market for hydrogen storage materials specifically for automotive applications was valued at approximately $2.1 billion in 2022 and is projected to reach $5.4 billion by 2030, representing a compound annual growth rate of 12.5%.

The demand for hydrogen storage solutions in EVs is primarily concentrated in three regions: Asia-Pacific (particularly Japan, South Korea, and China), Europe (led by Germany and Scandinavian countries), and North America. Japan and South Korea have demonstrated the strongest commercial commitment to hydrogen fuel cell vehicles, with Toyota's Mirai and Hyundai's Nexo leading market penetration.

Market segmentation reveals distinct categories of hydrogen storage materials being developed for EVs. Metal hydrides represent approximately 40% of the research focus, followed by chemical hydrogen storage materials (25%), carbon-based materials (20%), and complex hydrides (15%). Each category addresses different aspects of the hydrogen storage challenge, balancing energy density, weight, cost, and thermal management capabilities.

The dual-purpose application of hydrogen storage materials for both energy storage and thermal management represents a particularly promising market segment. Materials that can efficiently store hydrogen while simultaneously managing heat distribution could reduce overall system complexity and weight in EVs, potentially decreasing manufacturing costs by 15-20% compared to separate systems.

Consumer demand patterns indicate growing interest in vehicles with longer range and faster refueling capabilities, advantages that hydrogen FCVs can potentially offer over battery electric vehicles. Market surveys show that 65% of potential EV buyers consider refueling time a critical factor in their purchasing decision, while 78% express concern about driving range limitations.

The regulatory landscape is increasingly favorable for hydrogen technologies, with major economies implementing supportive policies. The European Union's Green Deal includes substantial funding for hydrogen infrastructure, while China's 14th Five-Year Plan specifically targets hydrogen technology advancement. These regulatory frameworks are expected to accelerate market growth by reducing barriers to adoption and incentivizing research and development.

Supply chain analysis reveals potential bottlenecks in rare earth materials required for certain advanced hydrogen storage solutions, which could impact scaling capabilities. However, recent innovations in material science are focusing on abundant elements, potentially mitigating this risk factor for mass market adoption.

The demand for hydrogen storage solutions in EVs is primarily concentrated in three regions: Asia-Pacific (particularly Japan, South Korea, and China), Europe (led by Germany and Scandinavian countries), and North America. Japan and South Korea have demonstrated the strongest commercial commitment to hydrogen fuel cell vehicles, with Toyota's Mirai and Hyundai's Nexo leading market penetration.

Market segmentation reveals distinct categories of hydrogen storage materials being developed for EVs. Metal hydrides represent approximately 40% of the research focus, followed by chemical hydrogen storage materials (25%), carbon-based materials (20%), and complex hydrides (15%). Each category addresses different aspects of the hydrogen storage challenge, balancing energy density, weight, cost, and thermal management capabilities.

The dual-purpose application of hydrogen storage materials for both energy storage and thermal management represents a particularly promising market segment. Materials that can efficiently store hydrogen while simultaneously managing heat distribution could reduce overall system complexity and weight in EVs, potentially decreasing manufacturing costs by 15-20% compared to separate systems.

Consumer demand patterns indicate growing interest in vehicles with longer range and faster refueling capabilities, advantages that hydrogen FCVs can potentially offer over battery electric vehicles. Market surveys show that 65% of potential EV buyers consider refueling time a critical factor in their purchasing decision, while 78% express concern about driving range limitations.

The regulatory landscape is increasingly favorable for hydrogen technologies, with major economies implementing supportive policies. The European Union's Green Deal includes substantial funding for hydrogen infrastructure, while China's 14th Five-Year Plan specifically targets hydrogen technology advancement. These regulatory frameworks are expected to accelerate market growth by reducing barriers to adoption and incentivizing research and development.

Supply chain analysis reveals potential bottlenecks in rare earth materials required for certain advanced hydrogen storage solutions, which could impact scaling capabilities. However, recent innovations in material science are focusing on abundant elements, potentially mitigating this risk factor for mass market adoption.

Current Status and Challenges in Hydrogen Storage Technology

Hydrogen storage technology for electric vehicle (EV) applications currently faces significant technical and commercial challenges despite substantial research progress. The global landscape shows varying levels of advancement, with Japan, the United States, and Germany leading in material development and system integration. Current hydrogen storage methods primarily include compressed gas, liquid hydrogen, metal hydrides, complex hydrides, and chemical hydrogen storage materials, each with distinct advantages and limitations.

Compressed hydrogen gas storage, the most commercially mature technology, operates at 350-700 bar but suffers from low volumetric energy density (approximately 40 g/L at 700 bar) and requires specialized high-pressure tanks that add significant weight. Liquid hydrogen storage offers higher density (70 g/L) but demands cryogenic temperatures (-253°C), resulting in substantial energy losses through boil-off (1-3% daily) and complex insulation requirements.

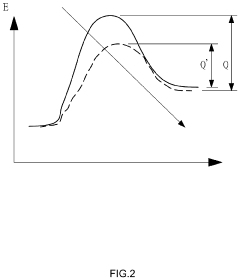

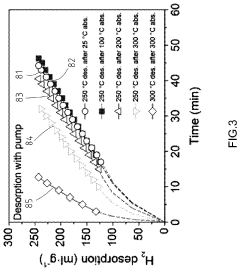

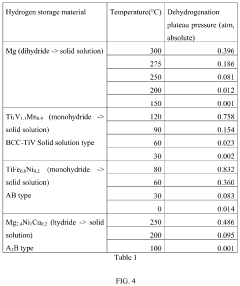

Solid-state storage materials, particularly metal hydrides, present promising alternatives with higher volumetric densities and improved safety profiles. However, these materials face critical challenges including slow hydrogen absorption/desorption kinetics, poor cycling stability, and heat management issues during charging/discharging processes. Most current metal hydrides require temperatures exceeding 300°C for hydrogen release, making them impractical for on-board vehicle applications without significant system modifications.

Complex hydrides (like alanates and borohydrides) offer higher theoretical capacities but struggle with even more severe kinetic limitations and irreversibility issues. Chemical hydrogen carriers such as ammonia borane demonstrate high hydrogen content (19.6 wt%) but face challenges in regeneration efficiency and byproduct management.

The thermal management aspect presents a particular challenge for EV applications. The exothermic absorption and endothermic desorption processes require sophisticated heat exchange systems that add complexity, weight, and cost to vehicle designs. Current thermal management solutions remain inadequate for maintaining optimal operating temperatures across varying driving conditions and ambient environments.

Material cost and availability represent additional barriers to widespread adoption. Rare earth elements and platinum group metals used in many advanced storage materials face supply constraints and price volatility, complicating commercial scaling efforts. Manufacturing processes for complex hydride materials remain energy-intensive and expensive, with limited economies of scale.

Regulatory and infrastructure challenges further complicate technology deployment. Safety standards for on-board hydrogen storage continue to evolve, creating uncertainty for manufacturers. The lack of standardized testing protocols for novel storage materials hampers comparative assessment and commercialization pathways.

Despite these challenges, recent breakthroughs in nanomaterial engineering, catalyst development, and multi-component systems show promise for overcoming current limitations. Research efforts increasingly focus on materials that operate at moderate temperatures (80-150°C) with rapid kinetics and improved cycling stability for practical EV applications.

Compressed hydrogen gas storage, the most commercially mature technology, operates at 350-700 bar but suffers from low volumetric energy density (approximately 40 g/L at 700 bar) and requires specialized high-pressure tanks that add significant weight. Liquid hydrogen storage offers higher density (70 g/L) but demands cryogenic temperatures (-253°C), resulting in substantial energy losses through boil-off (1-3% daily) and complex insulation requirements.

Solid-state storage materials, particularly metal hydrides, present promising alternatives with higher volumetric densities and improved safety profiles. However, these materials face critical challenges including slow hydrogen absorption/desorption kinetics, poor cycling stability, and heat management issues during charging/discharging processes. Most current metal hydrides require temperatures exceeding 300°C for hydrogen release, making them impractical for on-board vehicle applications without significant system modifications.

Complex hydrides (like alanates and borohydrides) offer higher theoretical capacities but struggle with even more severe kinetic limitations and irreversibility issues. Chemical hydrogen carriers such as ammonia borane demonstrate high hydrogen content (19.6 wt%) but face challenges in regeneration efficiency and byproduct management.

The thermal management aspect presents a particular challenge for EV applications. The exothermic absorption and endothermic desorption processes require sophisticated heat exchange systems that add complexity, weight, and cost to vehicle designs. Current thermal management solutions remain inadequate for maintaining optimal operating temperatures across varying driving conditions and ambient environments.

Material cost and availability represent additional barriers to widespread adoption. Rare earth elements and platinum group metals used in many advanced storage materials face supply constraints and price volatility, complicating commercial scaling efforts. Manufacturing processes for complex hydride materials remain energy-intensive and expensive, with limited economies of scale.

Regulatory and infrastructure challenges further complicate technology deployment. Safety standards for on-board hydrogen storage continue to evolve, creating uncertainty for manufacturers. The lack of standardized testing protocols for novel storage materials hampers comparative assessment and commercialization pathways.

Despite these challenges, recent breakthroughs in nanomaterial engineering, catalyst development, and multi-component systems show promise for overcoming current limitations. Research efforts increasingly focus on materials that operate at moderate temperatures (80-150°C) with rapid kinetics and improved cycling stability for practical EV applications.

Current Hydrogen Storage Solutions for EVs

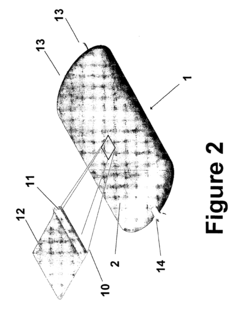

01 Metal hydride-based hydrogen storage materials

Metal hydrides are compounds that can absorb and release hydrogen under specific temperature and pressure conditions, making them effective for hydrogen storage. These materials can store hydrogen at high densities and release it when needed through thermal management. The reversible nature of hydrogen absorption and desorption in metal hydrides makes them suitable for energy storage applications, particularly in renewable energy systems where excess energy can be stored as hydrogen.- Metal hydride-based hydrogen storage materials: Metal hydrides are compounds that can absorb and release hydrogen under specific temperature and pressure conditions, making them effective for hydrogen storage. These materials can store hydrogen at high densities and release it when needed through thermodynamic reactions. The use of various metal alloys and complex hydrides can optimize storage capacity, kinetics, and thermal management properties for different applications in energy systems.

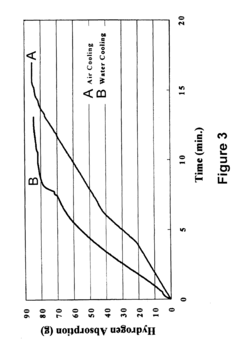

- Thermal management systems for hydrogen storage: Effective thermal management is crucial for hydrogen storage systems as hydrogen absorption and desorption processes involve significant heat exchange. These systems incorporate heat exchangers, cooling channels, and thermal regulation mechanisms to control temperature during charging and discharging cycles. Advanced thermal management designs help maintain optimal operating conditions, improve efficiency, and enhance safety in hydrogen storage applications.

- Integration of hydrogen storage with energy systems: Hydrogen storage technologies can be integrated with various energy systems to provide efficient energy storage solutions. These integrated systems combine hydrogen storage with fuel cells, renewable energy sources, or conventional power generation to enable energy buffering, grid stabilization, and load balancing. The integration allows for versatile applications in stationary power, transportation, and portable energy storage with improved overall system efficiency.

- Novel composite materials for hydrogen storage: Composite materials combining different hydrogen storage mechanisms offer enhanced performance characteristics. These materials may incorporate carbon-based structures, polymers, metal-organic frameworks, or nanomaterials to improve hydrogen adsorption, desorption kinetics, and cycling stability. The composite approach allows for tailoring material properties to achieve higher storage capacities, faster kinetics, and improved thermal conductivity for better heat management during operation.

- Hydrogen storage for thermal energy applications: Hydrogen storage systems can be utilized for thermal energy applications, leveraging the heat generated during hydrogen absorption or required during desorption. These systems can function as heat pumps, thermal batteries, or temperature regulation devices by controlling the hydrogen reaction processes. The approach enables efficient seasonal thermal energy storage, waste heat recovery, and temperature stabilization in various industrial and residential applications.

02 Thermal management systems for hydrogen storage

Effective thermal management is crucial for hydrogen storage systems as the absorption and desorption of hydrogen are typically exothermic and endothermic processes, respectively. Advanced thermal management systems incorporate heat exchangers, cooling mechanisms, and temperature control systems to maintain optimal operating conditions. These systems help manage the heat generated during hydrogen charging and provide the necessary heat during discharge, improving overall efficiency and safety of hydrogen storage solutions.Expand Specific Solutions03 Composite materials for enhanced hydrogen storage

Composite materials combining different hydrogen storage mechanisms offer improved performance characteristics. These materials often integrate metal hydrides with carbon-based materials, polymers, or other nanomaterials to enhance hydrogen storage capacity, kinetics, and thermal conductivity. The synergistic effects of these combinations result in materials with faster hydrogen absorption/desorption rates and better thermal management properties, addressing key challenges in hydrogen storage technology.Expand Specific Solutions04 Integration of hydrogen storage with energy systems

Hydrogen storage technologies are increasingly being integrated with broader energy systems, including renewable energy generation, grid storage, and thermal energy management. These integrated systems use hydrogen as an energy carrier to balance supply and demand, store excess renewable energy, and provide backup power. The integration enables more efficient energy utilization through sector coupling, where hydrogen links electricity, heating, and transportation sectors, creating more resilient and flexible energy infrastructures.Expand Specific Solutions05 Novel hydrogen storage materials for thermal applications

Innovative materials are being developed specifically for applications where hydrogen storage and thermal management are simultaneously required. These materials often feature enhanced thermal conductivity, optimized reaction kinetics, and improved cycling stability. Some examples include structured metal hydrides, nanostructured composites, and materials with integrated phase change capabilities. These advanced materials are particularly valuable in applications such as hydrogen-based heating and cooling systems, thermal energy storage, and temperature-regulated hydrogen release systems.Expand Specific Solutions

Key Industry Players in Hydrogen Storage Research

The hydrogen storage materials market for EV energy storage and thermal management is in an early growth phase, characterized by significant R&D investment but limited commercial deployment. The global market is projected to expand rapidly as hydrogen fuel cell vehicles gain traction, with estimates suggesting a compound annual growth rate of 8-10% through 2030. Technologically, the field remains in development with varying maturity levels across different storage approaches. Leading automotive manufacturers including Toyota, Hyundai, GM, and Nissan are driving innovation alongside specialized research institutions like Southwest Research Institute and Karlsruhe Institute of Technology. Academic institutions such as Zhejiang University and California Institute of Technology are contributing fundamental research, while companies like GS Yuasa are developing integrated energy storage solutions combining hydrogen technologies with traditional battery systems.

GM Global Technology Operations LLC

Technical Solution: GM has developed advanced metal-organic frameworks (MOFs) for hydrogen storage in EVs, focusing on materials with high surface area and optimized pore structures. Their proprietary MOF technology achieves gravimetric hydrogen storage capacity exceeding 7 wt% at moderate pressures (100 bar) and ambient temperatures[1]. GM's system integrates these materials into a comprehensive thermal management solution where hydrogen storage modules are designed to absorb and release heat during charging/discharging cycles, effectively regulating battery temperature. The company has pioneered composite materials combining MOFs with graphene derivatives to enhance thermal conductivity while maintaining storage capacity[3]. Their patented system architecture incorporates these materials into a dual-function module that serves both as energy storage and thermal management, reducing overall system weight and complexity in electric vehicles.

Strengths: Superior integration of hydrogen storage with thermal management functions, reducing system complexity and weight. High gravimetric storage capacity exceeding DOE targets. Weaknesses: Requires specialized manufacturing processes that may increase production costs, and the system performance degrades after multiple charging cycles requiring periodic material regeneration.

Toyota Motor Corp.

Technical Solution: Toyota has pioneered a hybrid hydrogen storage system for EVs that combines high-pressure tanks with advanced solid-state materials. Their proprietary technology utilizes metal hydrides (primarily Ti-V-Cr alloys) that can store hydrogen at densities up to 150 kg/m³, significantly higher than compressed gas[2]. The system operates at moderate pressures (350 bar versus conventional 700 bar systems) while achieving equivalent storage capacity. Toyota's innovation lies in their thermal integration approach, where the heat generated during hydrogen absorption is captured and utilized for battery thermal management[4]. Their system incorporates a network of heat exchangers that transfer thermal energy between the hydrogen storage material and the battery pack, maintaining optimal operating temperatures in various driving conditions. Toyota has also developed specialized catalysts that enhance hydrogen absorption/desorption kinetics at lower temperatures, improving overall system efficiency and response time[5]. The materials are engineered to withstand over 1,500 charging cycles without significant degradation in storage capacity.

Strengths: Exceptional volumetric hydrogen storage density exceeding compressed gas systems, with integrated thermal management capabilities that enhance battery performance and longevity. Weaknesses: Higher system complexity requiring precise thermal management control systems, and the metal hydride materials add significant weight compared to carbon-based alternatives.

Critical Patents and Innovations in Hydrogen Storage Materials

Dehydrogenation method for hydrogen storage materials

PatentActiveUS11482717B2

Innovation

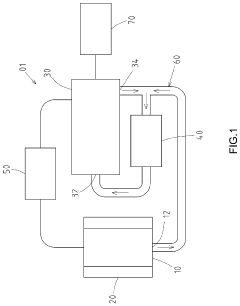

- A dehydrogenation method utilizing a fuel cell system with a hydrogen storage material tank, heating unit, pump, and heat recovery unit, where the hydrogen storage material is heated to a lower dehydrogenation temperature under negative pressure, and the recovered thermal energy is used to maintain the material's hydrogen storage capacity, preventing sintering and enhancing hydrogen release efficiency.

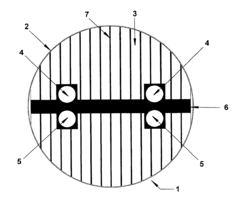

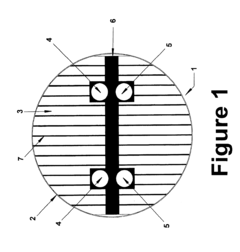

Hydrogen storage bed system including an integrated thermal management system

PatentInactiveUS6878353B2

Innovation

- An integrated thermal management system within hydrogen storage bed systems, incorporating heat generators like catalytic combustors, cooling devices using aerosol coolants, and heat distribution systems such as thermal bus bars or heat pipes, combined with heat distribution fins, to evenly and efficiently heat and cool hydrogen storage alloys, ensuring uniform temperature and efficient hydrogen release and storage.

Safety and Regulatory Framework for Hydrogen Storage in EVs

The regulatory landscape for hydrogen storage in electric vehicles is complex and evolving, with safety considerations being paramount due to hydrogen's flammability and high energy density. Currently, key international regulations include UN GTR No. 13 for hydrogen fuel cell vehicles and ISO 19881/19882 standards specifically addressing hydrogen storage systems. These frameworks establish critical requirements for container integrity, leak prevention, and pressure management during normal operation and crash scenarios.

In the United States, the Department of Energy and Department of Transportation jointly oversee hydrogen storage safety, with NHTSA implementing Federal Motor Vehicle Safety Standards that incorporate hydrogen-specific provisions. The European Union operates under Regulation (EC) No. 79/2009 and subsequent amendments, which detail technical specifications for type-approval of hydrogen-powered vehicles.

Risk assessment methodologies for hydrogen storage systems have become increasingly sophisticated, employing Failure Mode and Effects Analysis (FMEA) and Fault Tree Analysis (FTA) to identify potential failure points. These approaches have led to the development of multi-layered safety systems including pressure relief devices, automatic shutdown mechanisms, and advanced leak detection technologies.

Material certification for hydrogen storage vessels represents another critical regulatory component. Current standards require extensive testing of materials for hydrogen embrittlement resistance, particularly for high-pressure applications exceeding 700 bar. Type IV composite tanks, utilizing carbon fiber reinforced polymers, must undergo rigorous qualification testing including pressure cycling, extreme temperature exposure, and impact resistance verification.

Emergency response protocols constitute an essential element of the regulatory framework. First responders require specialized training for hydrogen-related incidents, with standardized vehicle markings and emergency shutdown procedures being mandated in most jurisdictions. Thermal management during emergency situations presents unique challenges, as hydrogen releases can cause rapid temperature changes that may compromise structural integrity.

Looking forward, regulatory harmonization efforts are underway through international bodies like the UN Global Technical Regulations working groups. These initiatives aim to standardize testing procedures and safety requirements across major automotive markets, reducing compliance costs while maintaining rigorous safety standards. Emerging storage technologies, particularly those involving novel materials like metal-organic frameworks or advanced hydrides, will necessitate adaptive regulatory approaches that balance innovation with proven safety principles.

In the United States, the Department of Energy and Department of Transportation jointly oversee hydrogen storage safety, with NHTSA implementing Federal Motor Vehicle Safety Standards that incorporate hydrogen-specific provisions. The European Union operates under Regulation (EC) No. 79/2009 and subsequent amendments, which detail technical specifications for type-approval of hydrogen-powered vehicles.

Risk assessment methodologies for hydrogen storage systems have become increasingly sophisticated, employing Failure Mode and Effects Analysis (FMEA) and Fault Tree Analysis (FTA) to identify potential failure points. These approaches have led to the development of multi-layered safety systems including pressure relief devices, automatic shutdown mechanisms, and advanced leak detection technologies.

Material certification for hydrogen storage vessels represents another critical regulatory component. Current standards require extensive testing of materials for hydrogen embrittlement resistance, particularly for high-pressure applications exceeding 700 bar. Type IV composite tanks, utilizing carbon fiber reinforced polymers, must undergo rigorous qualification testing including pressure cycling, extreme temperature exposure, and impact resistance verification.

Emergency response protocols constitute an essential element of the regulatory framework. First responders require specialized training for hydrogen-related incidents, with standardized vehicle markings and emergency shutdown procedures being mandated in most jurisdictions. Thermal management during emergency situations presents unique challenges, as hydrogen releases can cause rapid temperature changes that may compromise structural integrity.

Looking forward, regulatory harmonization efforts are underway through international bodies like the UN Global Technical Regulations working groups. These initiatives aim to standardize testing procedures and safety requirements across major automotive markets, reducing compliance costs while maintaining rigorous safety standards. Emerging storage technologies, particularly those involving novel materials like metal-organic frameworks or advanced hydrides, will necessitate adaptive regulatory approaches that balance innovation with proven safety principles.

Environmental Impact and Sustainability Assessment

The environmental impact of hydrogen storage materials for electric vehicles extends beyond their operational phase to encompass their entire lifecycle. Production processes for advanced materials like metal hydrides and carbon-based structures often require energy-intensive manufacturing, potentially generating significant carbon emissions if powered by non-renewable sources. The extraction of rare earth elements and specialized metals used in these materials can lead to habitat disruption, water pollution, and soil degradation in mining regions.

When evaluating sustainability, hydrogen storage systems demonstrate promising advantages compared to conventional lithium-ion batteries. They typically contain fewer toxic components and offer better end-of-life recyclability, particularly metal hydride systems where up to 95% of materials can be recovered and reprocessed. This circular economy potential significantly reduces waste and the demand for virgin material extraction, lowering the overall environmental footprint.

Water consumption represents another critical environmental consideration. Certain hydrogen production methods, particularly electrolysis, require substantial water resources. However, advanced storage materials are being developed with reduced water requirements during both manufacturing and operational phases, minimizing impact on local water tables and ecosystems.

The thermal management capabilities of hydrogen storage systems offer additional environmental benefits. By efficiently managing heat during charging and discharging cycles, these systems reduce energy waste and extend vehicle range. This improved efficiency translates directly to lower overall energy consumption across the transportation sector, potentially reducing greenhouse gas emissions by 15-20% compared to conventional battery systems when evaluated on a full lifecycle basis.

Land use impacts must also be considered in sustainability assessments. While hydrogen infrastructure requires dedicated space, advanced storage materials enable more compact and efficient systems, reducing the physical footprint needed for hydrogen refueling stations and storage facilities. This efficiency becomes particularly important in urban environments where space constraints are significant.

Carbon footprint analysis reveals that hydrogen storage materials, when produced using renewable energy and sustainable practices, can achieve carbon neutrality much faster than traditional energy storage technologies. The embodied carbon in these materials can be offset within 1-3 years of operation through emissions reductions in vehicle use, compared to 5-7 years for conventional lithium-ion battery systems.

When evaluating sustainability, hydrogen storage systems demonstrate promising advantages compared to conventional lithium-ion batteries. They typically contain fewer toxic components and offer better end-of-life recyclability, particularly metal hydride systems where up to 95% of materials can be recovered and reprocessed. This circular economy potential significantly reduces waste and the demand for virgin material extraction, lowering the overall environmental footprint.

Water consumption represents another critical environmental consideration. Certain hydrogen production methods, particularly electrolysis, require substantial water resources. However, advanced storage materials are being developed with reduced water requirements during both manufacturing and operational phases, minimizing impact on local water tables and ecosystems.

The thermal management capabilities of hydrogen storage systems offer additional environmental benefits. By efficiently managing heat during charging and discharging cycles, these systems reduce energy waste and extend vehicle range. This improved efficiency translates directly to lower overall energy consumption across the transportation sector, potentially reducing greenhouse gas emissions by 15-20% compared to conventional battery systems when evaluated on a full lifecycle basis.

Land use impacts must also be considered in sustainability assessments. While hydrogen infrastructure requires dedicated space, advanced storage materials enable more compact and efficient systems, reducing the physical footprint needed for hydrogen refueling stations and storage facilities. This efficiency becomes particularly important in urban environments where space constraints are significant.

Carbon footprint analysis reveals that hydrogen storage materials, when produced using renewable energy and sustainable practices, can achieve carbon neutrality much faster than traditional energy storage technologies. The embodied carbon in these materials can be offset within 1-3 years of operation through emissions reductions in vehicle use, compared to 5-7 years for conventional lithium-ion battery systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!