Evaluation of Hydrogen storage materials patents for competitive intelligence

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogen Storage Materials Evolution and Research Objectives

Hydrogen storage has evolved significantly over the past century, with major advancements occurring in response to global energy challenges. The journey began in the early 20th century with basic metal hydride research, but gained momentum during the 1970s oil crisis when alternative energy sources became a priority. This period marked the first serious scientific exploration of hydrogen as an energy carrier, though storage limitations prevented widespread adoption.

The 1990s witnessed renewed interest in hydrogen technologies as environmental concerns grew. Research shifted toward developing materials capable of storing hydrogen safely and efficiently. Metal hydrides, complex hydrides, and carbon-based materials emerged as primary research focuses, each offering unique advantages and challenges for hydrogen containment.

Since 2000, hydrogen storage research has accelerated dramatically with significant investments from governments and industry. The U.S. Department of Energy established ambitious targets for storage systems, driving innovation across multiple material classes. Nanotechnology integration has revolutionized the field, enabling the engineering of materials at atomic scales to optimize hydrogen uptake and release kinetics.

Current research objectives center on developing materials that meet practical requirements for commercial applications. These include achieving high gravimetric and volumetric storage capacities (>6 wt% and >40 g/L respectively), operating under moderate temperature and pressure conditions, demonstrating fast kinetics for hydrogen absorption/desorption, and maintaining performance over thousands of cycles.

Material safety and cost-effectiveness represent equally critical objectives. Researchers aim to develop storage solutions that minimize risks associated with hydrogen's flammability while keeping manufacturing costs competitive with conventional energy technologies. Environmental sustainability has also become a key consideration, with emphasis on materials composed of abundant elements and environmentally benign production processes.

Patent activity in hydrogen storage materials has grown exponentially, reflecting the strategic importance of this technology. Analysis reveals concentrated patent portfolios among automotive manufacturers, energy companies, and specialized materials science firms. Geographic distribution shows leadership from Japan, the United States, Germany, South Korea, and increasingly China, with each region focusing on slightly different material approaches.

The ultimate research goal remains developing a hydrogen storage solution that enables practical hydrogen-powered transportation and stationary applications. This requires balancing fundamental scientific breakthroughs with engineering practicality to create systems that can be manufactured at scale while meeting performance requirements. Success in this domain would represent a critical enabler for the hydrogen economy, potentially transforming global energy systems toward greater sustainability.

The 1990s witnessed renewed interest in hydrogen technologies as environmental concerns grew. Research shifted toward developing materials capable of storing hydrogen safely and efficiently. Metal hydrides, complex hydrides, and carbon-based materials emerged as primary research focuses, each offering unique advantages and challenges for hydrogen containment.

Since 2000, hydrogen storage research has accelerated dramatically with significant investments from governments and industry. The U.S. Department of Energy established ambitious targets for storage systems, driving innovation across multiple material classes. Nanotechnology integration has revolutionized the field, enabling the engineering of materials at atomic scales to optimize hydrogen uptake and release kinetics.

Current research objectives center on developing materials that meet practical requirements for commercial applications. These include achieving high gravimetric and volumetric storage capacities (>6 wt% and >40 g/L respectively), operating under moderate temperature and pressure conditions, demonstrating fast kinetics for hydrogen absorption/desorption, and maintaining performance over thousands of cycles.

Material safety and cost-effectiveness represent equally critical objectives. Researchers aim to develop storage solutions that minimize risks associated with hydrogen's flammability while keeping manufacturing costs competitive with conventional energy technologies. Environmental sustainability has also become a key consideration, with emphasis on materials composed of abundant elements and environmentally benign production processes.

Patent activity in hydrogen storage materials has grown exponentially, reflecting the strategic importance of this technology. Analysis reveals concentrated patent portfolios among automotive manufacturers, energy companies, and specialized materials science firms. Geographic distribution shows leadership from Japan, the United States, Germany, South Korea, and increasingly China, with each region focusing on slightly different material approaches.

The ultimate research goal remains developing a hydrogen storage solution that enables practical hydrogen-powered transportation and stationary applications. This requires balancing fundamental scientific breakthroughs with engineering practicality to create systems that can be manufactured at scale while meeting performance requirements. Success in this domain would represent a critical enabler for the hydrogen economy, potentially transforming global energy systems toward greater sustainability.

Market Analysis for Hydrogen Storage Technologies

The global hydrogen storage market is experiencing significant growth, driven by increasing focus on clean energy solutions and decarbonization efforts across industries. Current market valuations place the hydrogen storage technologies sector at approximately $15 billion as of 2023, with projections indicating a compound annual growth rate (CAGR) of 8-10% through 2030. This growth trajectory is primarily fueled by substantial investments in hydrogen infrastructure development across North America, Europe, and parts of Asia-Pacific.

Demand patterns reveal distinct regional variations, with Europe leading adoption rates due to aggressive carbon neutrality targets and supportive regulatory frameworks. The European Hydrogen Strategy aims to install at least 40 gigawatts of renewable hydrogen electrolyzers by 2030, creating substantial downstream demand for storage solutions. Meanwhile, Japan and South Korea have positioned themselves as early market leaders in Asia, particularly in transportation applications.

Market segmentation analysis indicates that industrial applications currently dominate the hydrogen storage market, accounting for approximately 45% of total demand. However, the transportation sector is emerging as the fastest-growing segment, with projected annual growth rates exceeding 12% as hydrogen fuel cell vehicles gain commercial traction. Energy storage applications represent another high-potential growth segment, particularly for grid-scale seasonal storage requirements.

From a materials perspective, the market shows increasing diversification beyond conventional compressed gas and cryogenic liquid storage methods. Metal hydrides, complex hydrides, and chemical hydrogen carriers collectively represent approximately 25% of current market share, with this proportion expected to increase significantly as these technologies mature. Patent analysis reveals that material-based storage solutions have seen a 35% increase in patent filings over the past five years, indicating accelerating R&D investment.

Key market drivers include stringent emission regulations, renewable energy integration challenges, and increasing industrial demand for green hydrogen. Conversely, market restraints primarily revolve around high infrastructure costs, technical challenges in achieving DOE storage targets, and competition from battery technologies in certain applications. The cost trajectory remains a critical factor, with current levelized costs of hydrogen storage ranging from $0.5-4 per kilogram depending on technology and scale.

Customer adoption patterns indicate that early market penetration is concentrated in industrial clusters with existing hydrogen infrastructure, while broader commercial adoption hinges on achieving cost reductions of 40-60% across the hydrogen value chain. This market analysis suggests that material-based hydrogen storage technologies represent a high-growth opportunity space with significant potential for competitive differentiation through patent-protected innovations.

Demand patterns reveal distinct regional variations, with Europe leading adoption rates due to aggressive carbon neutrality targets and supportive regulatory frameworks. The European Hydrogen Strategy aims to install at least 40 gigawatts of renewable hydrogen electrolyzers by 2030, creating substantial downstream demand for storage solutions. Meanwhile, Japan and South Korea have positioned themselves as early market leaders in Asia, particularly in transportation applications.

Market segmentation analysis indicates that industrial applications currently dominate the hydrogen storage market, accounting for approximately 45% of total demand. However, the transportation sector is emerging as the fastest-growing segment, with projected annual growth rates exceeding 12% as hydrogen fuel cell vehicles gain commercial traction. Energy storage applications represent another high-potential growth segment, particularly for grid-scale seasonal storage requirements.

From a materials perspective, the market shows increasing diversification beyond conventional compressed gas and cryogenic liquid storage methods. Metal hydrides, complex hydrides, and chemical hydrogen carriers collectively represent approximately 25% of current market share, with this proportion expected to increase significantly as these technologies mature. Patent analysis reveals that material-based storage solutions have seen a 35% increase in patent filings over the past five years, indicating accelerating R&D investment.

Key market drivers include stringent emission regulations, renewable energy integration challenges, and increasing industrial demand for green hydrogen. Conversely, market restraints primarily revolve around high infrastructure costs, technical challenges in achieving DOE storage targets, and competition from battery technologies in certain applications. The cost trajectory remains a critical factor, with current levelized costs of hydrogen storage ranging from $0.5-4 per kilogram depending on technology and scale.

Customer adoption patterns indicate that early market penetration is concentrated in industrial clusters with existing hydrogen infrastructure, while broader commercial adoption hinges on achieving cost reductions of 40-60% across the hydrogen value chain. This market analysis suggests that material-based hydrogen storage technologies represent a high-growth opportunity space with significant potential for competitive differentiation through patent-protected innovations.

Current Challenges in Hydrogen Storage Materials Development

Despite significant advancements in hydrogen storage technologies, several critical challenges continue to impede widespread adoption and commercialization. Material-based storage systems face persistent limitations in achieving optimal hydrogen capacity while maintaining practical operating conditions. Current metal hydride materials exhibit either high storage capacities with unfavorable thermodynamics or suitable thermodynamics with insufficient capacity, creating a fundamental performance trade-off that remains unresolved.

Temperature management represents another significant hurdle, as many promising materials require either extremely high temperatures for hydrogen release or cryogenic conditions for adequate storage density. This creates substantial energy penalties and system complexity that reduce overall efficiency. The heat management during rapid charging and discharging cycles further complicates system design and operation.

Kinetics of hydrogen absorption and desorption continues to limit practical applications, with many materials demonstrating slow loading and unloading rates that fail to meet the demands of real-world applications, particularly in transportation where rapid refueling is essential. Catalyst development has shown promise but remains insufficient for achieving target performance metrics.

Cycling stability presents another major challenge, as repeated hydrogen loading and unloading cycles often lead to material degradation, structural changes, and capacity loss over time. This durability issue significantly impacts the economic viability of hydrogen storage systems, requiring more robust materials or regeneration strategies.

Manufacturing scalability and cost-effectiveness represent critical barriers to commercialization. Many advanced materials with promising laboratory performance utilize expensive rare earth elements or require complex synthesis procedures that are difficult to scale. The absence of economically viable mass production methods hampers industrial adoption.

Safety concerns persist across various storage technologies, with issues ranging from pyrophoricity in some metal hydrides to high-pressure risks in compressed systems. Addressing these safety challenges requires sophisticated engineering solutions that often add complexity and cost to storage systems.

Environmental considerations and lifecycle assessment have emerged as increasingly important challenges. The production of certain storage materials involves energy-intensive processes or environmentally harmful chemicals, raising questions about the overall sustainability of these technologies despite hydrogen's clean energy potential.

Standardization and regulatory frameworks remain underdeveloped, creating uncertainty for manufacturers and slowing technology deployment. The lack of unified testing protocols and safety standards complicates comparative analysis and technology validation across different research groups and commercial entities.

Temperature management represents another significant hurdle, as many promising materials require either extremely high temperatures for hydrogen release or cryogenic conditions for adequate storage density. This creates substantial energy penalties and system complexity that reduce overall efficiency. The heat management during rapid charging and discharging cycles further complicates system design and operation.

Kinetics of hydrogen absorption and desorption continues to limit practical applications, with many materials demonstrating slow loading and unloading rates that fail to meet the demands of real-world applications, particularly in transportation where rapid refueling is essential. Catalyst development has shown promise but remains insufficient for achieving target performance metrics.

Cycling stability presents another major challenge, as repeated hydrogen loading and unloading cycles often lead to material degradation, structural changes, and capacity loss over time. This durability issue significantly impacts the economic viability of hydrogen storage systems, requiring more robust materials or regeneration strategies.

Manufacturing scalability and cost-effectiveness represent critical barriers to commercialization. Many advanced materials with promising laboratory performance utilize expensive rare earth elements or require complex synthesis procedures that are difficult to scale. The absence of economically viable mass production methods hampers industrial adoption.

Safety concerns persist across various storage technologies, with issues ranging from pyrophoricity in some metal hydrides to high-pressure risks in compressed systems. Addressing these safety challenges requires sophisticated engineering solutions that often add complexity and cost to storage systems.

Environmental considerations and lifecycle assessment have emerged as increasingly important challenges. The production of certain storage materials involves energy-intensive processes or environmentally harmful chemicals, raising questions about the overall sustainability of these technologies despite hydrogen's clean energy potential.

Standardization and regulatory frameworks remain underdeveloped, creating uncertainty for manufacturers and slowing technology deployment. The lack of unified testing protocols and safety standards complicates comparative analysis and technology validation across different research groups and commercial entities.

Current Patent Landscape for Hydrogen Storage Materials

01 Metal hydride-based hydrogen storage materials

Metal hydrides are compounds formed by metals or metal alloys that can absorb and release hydrogen under specific temperature and pressure conditions. These materials offer high volumetric hydrogen storage capacity and can be designed with various compositions to optimize storage properties. Common metal hydride systems include magnesium-based hydrides, aluminum-based hydrides, and transition metal-based hydrides that provide efficient and reversible hydrogen storage solutions.- Metal hydrides for hydrogen storage: Metal hydrides are compounds formed by hydrogen and metals, offering high volumetric hydrogen storage capacity. These materials can absorb and release hydrogen through chemical reactions under specific temperature and pressure conditions. Metal hydrides provide advantages such as safety, stability, and reversible hydrogen storage capabilities, making them suitable for various hydrogen storage applications including fuel cells and energy systems.

- Carbon-based hydrogen storage materials: Carbon-based materials such as carbon nanotubes, graphene, and activated carbon can store hydrogen through adsorption mechanisms. These materials offer advantages including lightweight properties, large surface areas, and tunable pore structures that enhance hydrogen uptake. The hydrogen molecules are typically adsorbed onto the surface of these materials through weak van der Waals forces, allowing for relatively fast kinetics but requiring optimization of surface area and pore size distribution.

- Complex hydrides for hydrogen storage: Complex hydrides, including alanates, borohydrides, and amides, represent advanced materials for hydrogen storage with high gravimetric capacity. These compounds typically contain light elements bonded with hydrogen in complex structures. They can store hydrogen through chemical bonds and release it through thermal decomposition or catalyzed reactions. Research focuses on improving their reversibility, kinetics, and operating temperature conditions to make them practical for commercial applications.

- Hydrogen storage system design and engineering: Engineering aspects of hydrogen storage systems involve the design of containers, heat management systems, pressure regulation, and safety features. These systems must address challenges such as thermal management during hydrogen absorption/desorption, pressure containment, weight optimization, and integration with fuel cells or other hydrogen utilization technologies. Advanced designs incorporate composite materials, efficient heat exchangers, and smart control systems to enhance performance and safety.

- Novel composite and hybrid hydrogen storage materials: Composite and hybrid materials combine different hydrogen storage mechanisms to overcome limitations of single-material approaches. These materials may integrate metal hydrides with carbon structures, incorporate catalysts to enhance kinetics, or use nanoscale engineering to improve performance. By creating multi-functional materials, researchers aim to achieve higher storage capacities, improved kinetics, and better thermal management while operating under moderate temperature and pressure conditions.

02 Carbon-based hydrogen storage materials

Carbon-based materials such as carbon nanotubes, graphene, activated carbon, and carbon nanofibers can store hydrogen through physisorption or chemisorption mechanisms. These materials offer advantages including lightweight structure, high surface area, and tunable pore sizes that enhance hydrogen adsorption capacity. Various surface modifications and doping strategies can be employed to improve the hydrogen storage capacity of carbon-based materials at ambient conditions.Expand Specific Solutions03 Complex hydride hydrogen storage systems

Complex hydrides, including borohydrides, alanates, and amides, offer high gravimetric hydrogen storage capacity. These materials store hydrogen through chemical bonds within complex structures and can release hydrogen through thermal decomposition or catalytic reactions. Research focuses on improving their reversibility, reducing dehydrogenation temperatures, and enhancing kinetics through catalysts and compositional modifications to make them suitable for practical applications.Expand Specific Solutions04 Nanostructured hydrogen storage materials

Nanostructuring of hydrogen storage materials significantly improves hydrogen sorption kinetics and capacity by increasing surface area and reducing diffusion distances. These materials include nanoparticles, nanowires, core-shell structures, and nanocomposites that combine different storage mechanisms. The nanoscale architecture allows for faster hydrogen uptake and release, lower operating temperatures, and improved cycling stability compared to their bulk counterparts.Expand Specific Solutions05 Catalyst-enhanced hydrogen storage materials

Catalysts play a crucial role in improving the performance of hydrogen storage materials by lowering activation energy barriers for hydrogen absorption and desorption processes. Noble metals, transition metals, and their compounds are commonly used as catalysts to enhance reaction kinetics, reduce operating temperatures, and improve cycling stability. Catalyst distribution, particle size, and interaction with the base material are key factors that determine the overall efficiency of hydrogen storage systems.Expand Specific Solutions

Leading Companies and Research Institutions in Hydrogen Storage

The hydrogen storage materials patent landscape reflects an evolving market in the early commercialization phase, with significant growth potential as hydrogen economies develop globally. Major automotive players including Toyota, GM, Ford, and Nissan are actively building patent portfolios, indicating strategic positioning for future hydrogen-powered vehicles. Academic institutions like the University of Washington and University of Tokyo collaborate with industrial partners, bridging fundamental research and applications. Japanese corporations (Sony, Toshiba, GS Yuasa) demonstrate particular strength in materials innovation, while energy companies like Hydro-Québec and Form Energy focus on grid-scale storage solutions. The competitive landscape shows increasing technological maturity with diversification across metal hydrides, chemical carriers, and advanced composite materials.

GM Global Technology Operations LLC

Technical Solution: GM has pioneered a comprehensive hydrogen storage solution based on complex borohydride materials, particularly focusing on destabilized lithium borohydride systems. Their patented technology incorporates nano-catalysts that significantly reduce dehydrogenation temperatures from traditional 400°C to approximately 250°C, making them more practical for automotive applications [4]. GM's approach includes a multi-layer storage vessel design with integrated heat exchangers that manage the thermal requirements during hydrogen charging and discharging processes. Their patents cover specialized additives that prevent borohydride agglomeration during cycling, maintaining surface area and reaction kinetics over thousands of cycles. GM has developed a proprietary nanostructured scaffold material that hosts the borohydride compounds, providing structural stability while facilitating hydrogen diffusion pathways. The system includes pressure management subsystems that optimize hydrogen release rates based on vehicle power demands, with demonstrated volumetric capacities exceeding 40 g/L [5].

Strengths: Exceptionally high gravimetric hydrogen capacity (theoretical >10 wt%); solid-state storage eliminates high-pressure safety concerns; system integration with vehicle thermal management for improved efficiency. Weaknesses: Complex regeneration processes currently limiting on-board recharging capabilities; sensitivity to oxygen and moisture requiring robust containment systems; higher system costs compared to conventional compressed hydrogen storage.

Ford Global Technologies LLC

Technical Solution: Ford has developed a multi-phase hydrogen storage system utilizing advanced metal-organic frameworks (MOFs) with tailored pore structures. Their patented technology incorporates modified MOF-5 derivatives with enhanced binding sites that demonstrate up to 7.5 wt% hydrogen storage capacity at moderate pressures (50-100 bar) [2]. Ford's approach includes strategic metal doping of MOFs with transition metals like Ni and Pd to increase hydrogen binding energy without sacrificing kinetics. Their system integrates thermal management through phase-change materials that absorb heat during charging and release it during discharge, maintaining optimal operating temperatures. Ford has also patented composite storage materials that combine MOFs with carbon nanostructures to enhance thermal conductivity and mechanical stability during cycling. The system architecture includes pressure-responsive release mechanisms and multi-stage storage tanks that optimize hydrogen delivery based on vehicle power demands.

Strengths: Higher gravimetric storage capacity than conventional metal hydrides; faster refueling capabilities due to enhanced thermal management; modular design allowing scalability for different vehicle platforms. Weaknesses: MOF materials remain sensitive to moisture contamination requiring advanced sealing technologies; higher production costs compared to conventional storage systems; thermal management systems add complexity and weight to the overall system.

Key Patent Analysis and Technical Innovations

Hydrogen-occluding alloy and process for producing the same

PatentInactiveUS6773667B2

Innovation

- A hydrogen storage material with a specific nonstoichiometric composition and CaCu5 type crystal structure, characterized by a c-axis lattice length of 406.2 pm or more, is developed, allowing for reduced cobalt content while maintaining excellent grain size resistance, hydrogen storage, and output characteristics, achieved through a process involving specific casting and heat treatment conditions.

Method and system for identification of materials for hydrogen storage

PatentActiveUS20210293381A1

Innovation

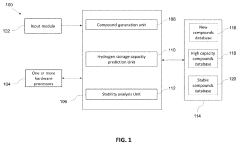

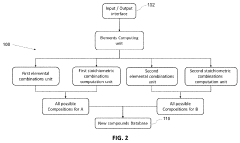

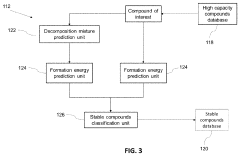

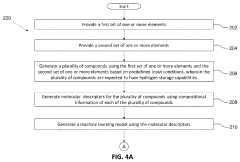

- A system comprising an input module, hardware processors, and memory with a compound generation unit, hydrogen storage capacity prediction unit, and stability analysis unit, which generates and evaluates intermetallic compounds for hydrogen storage capabilities using machine learning models and computational databases to predict thermodynamic stability.

Competitive Intelligence Framework for Hydrogen Technologies

The Competitive Intelligence Framework for Hydrogen Technologies provides a structured approach to analyzing the strategic landscape of hydrogen storage materials. This framework enables organizations to systematically gather, analyze, and interpret information about competitors, market trends, and technological developments in the hydrogen storage sector.

The framework begins with identifying key players in the hydrogen storage materials market, including established companies, emerging startups, research institutions, and government entities. These stakeholders are mapped according to their technological capabilities, patent portfolios, R&D investments, and market positioning. This mapping reveals competitive clusters and highlights potential collaboration or acquisition targets.

Patent analysis forms a critical component of this framework, involving the systematic examination of patent applications, grants, and citations related to hydrogen storage materials. Advanced patent analytics tools can identify filing trends, technology clusters, and emerging innovation hotspots. The framework incorporates both quantitative metrics (patent counts, citation rates) and qualitative assessments (technical significance, commercial applicability) to evaluate competitive positioning.

Market intelligence is integrated by analyzing commercial developments, including product launches, strategic partnerships, and investment activities. This provides context for understanding how patent portfolios translate into market offerings and competitive advantage. The framework correlates patent activity with market movements to identify companies effectively converting intellectual property into commercial success.

Technology trajectory mapping is another essential element, tracking the evolution of hydrogen storage materials from metal hydrides to complex hydrides, chemical hydrides, and advanced nanomaterials. This evolutionary perspective helps forecast future innovation directions and potential disruptions in the competitive landscape.

The framework also incorporates geopolitical analysis, recognizing that hydrogen technologies are increasingly influenced by national strategies and international collaborations. Regional innovation ecosystems, government funding priorities, and regulatory environments significantly impact competitive dynamics in this strategically important field.

Performance benchmarking completes the framework by establishing key performance indicators for hydrogen storage materials, such as gravimetric and volumetric capacity, operating conditions, cycling stability, and cost metrics. These standardized metrics enable objective comparison of competing technologies and identification of performance leaders across different application domains.

The framework begins with identifying key players in the hydrogen storage materials market, including established companies, emerging startups, research institutions, and government entities. These stakeholders are mapped according to their technological capabilities, patent portfolios, R&D investments, and market positioning. This mapping reveals competitive clusters and highlights potential collaboration or acquisition targets.

Patent analysis forms a critical component of this framework, involving the systematic examination of patent applications, grants, and citations related to hydrogen storage materials. Advanced patent analytics tools can identify filing trends, technology clusters, and emerging innovation hotspots. The framework incorporates both quantitative metrics (patent counts, citation rates) and qualitative assessments (technical significance, commercial applicability) to evaluate competitive positioning.

Market intelligence is integrated by analyzing commercial developments, including product launches, strategic partnerships, and investment activities. This provides context for understanding how patent portfolios translate into market offerings and competitive advantage. The framework correlates patent activity with market movements to identify companies effectively converting intellectual property into commercial success.

Technology trajectory mapping is another essential element, tracking the evolution of hydrogen storage materials from metal hydrides to complex hydrides, chemical hydrides, and advanced nanomaterials. This evolutionary perspective helps forecast future innovation directions and potential disruptions in the competitive landscape.

The framework also incorporates geopolitical analysis, recognizing that hydrogen technologies are increasingly influenced by national strategies and international collaborations. Regional innovation ecosystems, government funding priorities, and regulatory environments significantly impact competitive dynamics in this strategically important field.

Performance benchmarking completes the framework by establishing key performance indicators for hydrogen storage materials, such as gravimetric and volumetric capacity, operating conditions, cycling stability, and cost metrics. These standardized metrics enable objective comparison of competing technologies and identification of performance leaders across different application domains.

Strategic Patent Portfolio Development Recommendations

Based on the comprehensive analysis of hydrogen storage materials patents, we recommend a strategic approach to patent portfolio development that balances defensive positioning with offensive innovation opportunities. Companies should prioritize filing patents in three key technological areas: metal hydrides with enhanced kinetics, advanced MOF structures with optimized pore geometries, and hybrid storage systems combining physical and chemical storage mechanisms.

Patent landscaping reveals significant white space in catalyst integration for low-temperature hydrogen release systems and in manufacturing processes for scaled production of complex hydride materials. Organizations should consider establishing dedicated innovation teams focused on these underexplored areas to secure foundational intellectual property before competition intensifies.

Cross-licensing opportunities exist particularly with automotive and energy storage companies that hold complementary patents in system integration. Strategic partnerships with these entities could provide access to critical application-specific intellectual property while reducing development costs and accelerating time-to-market for commercial solutions.

For maximum territorial coverage, we recommend prioritizing patent filings in the United States, Japan, Germany, South Korea, and China, which represent both the most active innovation hubs and the most promising markets for hydrogen technologies. The European Patent Office's unified patent protection should also be leveraged for cost-effective coverage across the European Union.

Patent quality should take precedence over quantity, with claims carefully structured to provide both broad conceptual protection and specific implementation details. This dual-layer approach ensures fundamental concepts are protected while maintaining enforceability through specific technical embodiments.

A defensive publication strategy should complement direct patent filings, particularly for incremental innovations that may not warrant full patent protection but should be prevented from being patented by competitors. This approach optimizes R&D investment by focusing patent resources on high-value innovations while still preventing competitive encroachment in adjacent technical spaces.

Regular portfolio reviews should be conducted quarterly to align intellectual property development with evolving market conditions and technological breakthroughs in the rapidly advancing hydrogen storage field.

Patent landscaping reveals significant white space in catalyst integration for low-temperature hydrogen release systems and in manufacturing processes for scaled production of complex hydride materials. Organizations should consider establishing dedicated innovation teams focused on these underexplored areas to secure foundational intellectual property before competition intensifies.

Cross-licensing opportunities exist particularly with automotive and energy storage companies that hold complementary patents in system integration. Strategic partnerships with these entities could provide access to critical application-specific intellectual property while reducing development costs and accelerating time-to-market for commercial solutions.

For maximum territorial coverage, we recommend prioritizing patent filings in the United States, Japan, Germany, South Korea, and China, which represent both the most active innovation hubs and the most promising markets for hydrogen technologies. The European Patent Office's unified patent protection should also be leveraged for cost-effective coverage across the European Union.

Patent quality should take precedence over quantity, with claims carefully structured to provide both broad conceptual protection and specific implementation details. This dual-layer approach ensures fundamental concepts are protected while maintaining enforceability through specific technical embodiments.

A defensive publication strategy should complement direct patent filings, particularly for incremental innovations that may not warrant full patent protection but should be prevented from being patented by competitors. This approach optimizes R&D investment by focusing patent resources on high-value innovations while still preventing competitive encroachment in adjacent technical spaces.

Regular portfolio reviews should be conducted quarterly to align intellectual property development with evolving market conditions and technological breakthroughs in the rapidly advancing hydrogen storage field.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!