Evaluation of Hydrogen storage materials for aerospace renewable and EV applications

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogen Storage Materials Background and Objectives

Hydrogen storage has emerged as a critical technology in the global transition towards sustainable energy systems. The history of hydrogen storage research dates back to the 1970s energy crisis, which prompted initial investigations into alternative energy carriers. Over subsequent decades, research has intensified significantly, driven by growing environmental concerns and the need for efficient energy storage solutions across multiple sectors.

The evolution of hydrogen storage technologies has followed several distinct pathways, including compressed gas systems, liquid hydrogen, metal hydrides, complex hydrides, chemical hydrogen carriers, and advanced materials such as carbon nanostructures. Each approach represents a specific trade-off between storage capacity, operating conditions, safety considerations, and system complexity.

For aerospace applications, hydrogen storage presents unique challenges related to weight constraints, extreme operating conditions, and stringent safety requirements. The aerospace industry has historically pioneered hydrogen technologies, with liquid hydrogen serving as rocket fuel since the mid-20th century. Current research aims to develop more practical storage solutions for commercial aviation and space applications, where hydrogen's high energy density by weight offers significant advantages.

In the renewable energy sector, hydrogen storage addresses the intermittency challenge of solar and wind power generation. Effective hydrogen storage systems enable energy time-shifting, allowing excess renewable electricity to be stored as hydrogen during production peaks and converted back to electricity during demand peaks. This capability is essential for grid stability and maximizing renewable energy utilization.

For electric vehicle (EV) applications, hydrogen storage technologies must meet stringent requirements regarding volumetric and gravimetric energy density, fast refueling capabilities, safety, and cost-effectiveness. Current automotive hydrogen storage systems primarily utilize high-pressure tanks (350-700 bar), but material-based storage approaches offer potential advantages in safety and energy density.

The primary technical objectives for hydrogen storage materials across these applications include: achieving DOE targets for gravimetric capacity (6.5 wt% system level), improving volumetric storage density (50 g/L), enhancing charging/discharging kinetics, ensuring operational stability across thousands of cycles, reducing system costs below $10/kWh, and maintaining performance across wide temperature ranges (-40°C to 85°C for automotive applications).

This technical evaluation aims to comprehensively assess the current state of hydrogen storage materials, identify promising research directions, and evaluate their potential for practical implementation in aerospace, renewable energy, and electric vehicle applications. The analysis will consider both near-term improvements to existing technologies and longer-term breakthrough approaches that could fundamentally transform hydrogen storage capabilities.

The evolution of hydrogen storage technologies has followed several distinct pathways, including compressed gas systems, liquid hydrogen, metal hydrides, complex hydrides, chemical hydrogen carriers, and advanced materials such as carbon nanostructures. Each approach represents a specific trade-off between storage capacity, operating conditions, safety considerations, and system complexity.

For aerospace applications, hydrogen storage presents unique challenges related to weight constraints, extreme operating conditions, and stringent safety requirements. The aerospace industry has historically pioneered hydrogen technologies, with liquid hydrogen serving as rocket fuel since the mid-20th century. Current research aims to develop more practical storage solutions for commercial aviation and space applications, where hydrogen's high energy density by weight offers significant advantages.

In the renewable energy sector, hydrogen storage addresses the intermittency challenge of solar and wind power generation. Effective hydrogen storage systems enable energy time-shifting, allowing excess renewable electricity to be stored as hydrogen during production peaks and converted back to electricity during demand peaks. This capability is essential for grid stability and maximizing renewable energy utilization.

For electric vehicle (EV) applications, hydrogen storage technologies must meet stringent requirements regarding volumetric and gravimetric energy density, fast refueling capabilities, safety, and cost-effectiveness. Current automotive hydrogen storage systems primarily utilize high-pressure tanks (350-700 bar), but material-based storage approaches offer potential advantages in safety and energy density.

The primary technical objectives for hydrogen storage materials across these applications include: achieving DOE targets for gravimetric capacity (6.5 wt% system level), improving volumetric storage density (50 g/L), enhancing charging/discharging kinetics, ensuring operational stability across thousands of cycles, reducing system costs below $10/kWh, and maintaining performance across wide temperature ranges (-40°C to 85°C for automotive applications).

This technical evaluation aims to comprehensively assess the current state of hydrogen storage materials, identify promising research directions, and evaluate their potential for practical implementation in aerospace, renewable energy, and electric vehicle applications. The analysis will consider both near-term improvements to existing technologies and longer-term breakthrough approaches that could fundamentally transform hydrogen storage capabilities.

Market Analysis for Aerospace and EV Hydrogen Applications

The hydrogen storage materials market for aerospace and electric vehicle applications is experiencing significant growth, driven by the global push towards decarbonization and sustainable energy solutions. The aerospace sector's demand is primarily fueled by the need for lightweight, high-density energy storage systems that can power both propulsion systems and auxiliary power units while meeting stringent safety requirements. Current market estimates value the aerospace hydrogen storage segment at approximately $2.1 billion, with projections indicating a compound annual growth rate of 9.7% through 2030.

In the electric vehicle sector, hydrogen fuel cell vehicles (FCVs) represent a growing alternative to battery electric vehicles, particularly for heavy-duty and long-range applications. The market for hydrogen storage systems in EVs is currently valued at $3.4 billion and is expected to reach $12.5 billion by 2028. This growth is supported by increasing government investments in hydrogen infrastructure and favorable regulatory frameworks in key markets including Japan, South Korea, Germany, and California.

Regional analysis reveals Asia-Pacific as the dominant market for hydrogen storage materials, accounting for 42% of global demand, followed by Europe at 31% and North America at 22%. China leads in manufacturing capacity for hydrogen storage materials, while Japan and South Korea excel in technological innovation, particularly in metal hydride systems.

Consumer adoption trends indicate growing acceptance of hydrogen technologies, with surveys showing 68% of commercial fleet operators considering hydrogen vehicles for future purchases. However, price sensitivity remains high, with cost per kilogram of stored hydrogen being the primary decision factor for 73% of potential industrial customers.

Market barriers include high production costs of advanced storage materials, limited hydrogen refueling infrastructure, and competition from rapidly improving battery technologies. The cost of carbon fiber composite tanks, currently at $500-700 per kilogram of hydrogen stored, needs to decrease by at least 50% to achieve mass market viability.

Emerging opportunities exist in the urban air mobility sector, where hydrogen's high energy density offers advantages over batteries for electric vertical takeoff and landing (eVTOL) aircraft. Additionally, the maritime sector is increasingly exploring hydrogen for short-sea shipping applications, potentially creating spillover demand for aerospace-grade storage solutions.

In the electric vehicle sector, hydrogen fuel cell vehicles (FCVs) represent a growing alternative to battery electric vehicles, particularly for heavy-duty and long-range applications. The market for hydrogen storage systems in EVs is currently valued at $3.4 billion and is expected to reach $12.5 billion by 2028. This growth is supported by increasing government investments in hydrogen infrastructure and favorable regulatory frameworks in key markets including Japan, South Korea, Germany, and California.

Regional analysis reveals Asia-Pacific as the dominant market for hydrogen storage materials, accounting for 42% of global demand, followed by Europe at 31% and North America at 22%. China leads in manufacturing capacity for hydrogen storage materials, while Japan and South Korea excel in technological innovation, particularly in metal hydride systems.

Consumer adoption trends indicate growing acceptance of hydrogen technologies, with surveys showing 68% of commercial fleet operators considering hydrogen vehicles for future purchases. However, price sensitivity remains high, with cost per kilogram of stored hydrogen being the primary decision factor for 73% of potential industrial customers.

Market barriers include high production costs of advanced storage materials, limited hydrogen refueling infrastructure, and competition from rapidly improving battery technologies. The cost of carbon fiber composite tanks, currently at $500-700 per kilogram of hydrogen stored, needs to decrease by at least 50% to achieve mass market viability.

Emerging opportunities exist in the urban air mobility sector, where hydrogen's high energy density offers advantages over batteries for electric vertical takeoff and landing (eVTOL) aircraft. Additionally, the maritime sector is increasingly exploring hydrogen for short-sea shipping applications, potentially creating spillover demand for aerospace-grade storage solutions.

Current Hydrogen Storage Technologies and Barriers

Hydrogen storage technologies have evolved significantly over the past decades, yet substantial challenges remain for widespread adoption in aerospace, renewable energy, and electric vehicle applications. Currently, hydrogen can be stored in three primary forms: compressed gas, cryogenic liquid, and solid-state materials. Each approach presents distinct advantages and limitations that impact their suitability for specific applications.

Compressed hydrogen gas storage represents the most mature technology, typically utilizing high-pressure tanks (350-700 bar) made from carbon fiber composites. While this method offers simplicity and immediate availability, it suffers from low volumetric energy density (approximately 40 g/L at 700 bar), creating significant space constraints for mobile applications. The high-pressure requirements also introduce safety concerns and energy penalties during compression, reducing overall system efficiency.

Liquid hydrogen storage achieves higher volumetric density (70 g/L) but requires cryogenic temperatures (-253°C). This approach necessitates sophisticated insulation systems to minimize boil-off losses, which can reach 1-3% daily in conventional systems. The liquefaction process itself consumes approximately 30% of hydrogen's energy content, presenting a substantial efficiency barrier. Additionally, the complexity of cryogenic systems increases maintenance requirements and operational costs.

Solid-state hydrogen storage materials offer promising alternatives through various mechanisms including absorption (metal hydrides), adsorption (carbon-based materials, MOFs), and chemical storage (ammonia, organic liquid carriers). Metal hydrides can achieve volumetric densities exceeding 100 g/L but face challenges with slow kinetics, heat management during charging/discharging, and material degradation over multiple cycles. Their weight penalties are particularly problematic for aerospace and automotive applications.

Nanoporous materials like MOFs and carbon nanostructures demonstrate fast kinetics and reversibility but currently achieve insufficient gravimetric capacities (typically 5-7 wt%) at ambient conditions. Chemical carriers offer high densities but require energy-intensive conversion processes that reduce round-trip efficiency.

The U.S. Department of Energy has established ambitious targets for hydrogen storage systems: 6.5 wt% gravimetric capacity and 50 g/L volumetric capacity by 2025, with ultimate targets of 7.5 wt% and 70 g/L. Current technologies fall short of meeting these combined metrics under practical operating conditions.

Cross-cutting barriers include thermal management during hydrogen uptake and release, material degradation over cycling, system complexity, cost factors, and safety considerations. For aerospace applications specifically, weight constraints are paramount, while EV applications face volumetric limitations and refueling time challenges. Both sectors require storage solutions that maintain performance across wide temperature ranges and operational conditions.

Compressed hydrogen gas storage represents the most mature technology, typically utilizing high-pressure tanks (350-700 bar) made from carbon fiber composites. While this method offers simplicity and immediate availability, it suffers from low volumetric energy density (approximately 40 g/L at 700 bar), creating significant space constraints for mobile applications. The high-pressure requirements also introduce safety concerns and energy penalties during compression, reducing overall system efficiency.

Liquid hydrogen storage achieves higher volumetric density (70 g/L) but requires cryogenic temperatures (-253°C). This approach necessitates sophisticated insulation systems to minimize boil-off losses, which can reach 1-3% daily in conventional systems. The liquefaction process itself consumes approximately 30% of hydrogen's energy content, presenting a substantial efficiency barrier. Additionally, the complexity of cryogenic systems increases maintenance requirements and operational costs.

Solid-state hydrogen storage materials offer promising alternatives through various mechanisms including absorption (metal hydrides), adsorption (carbon-based materials, MOFs), and chemical storage (ammonia, organic liquid carriers). Metal hydrides can achieve volumetric densities exceeding 100 g/L but face challenges with slow kinetics, heat management during charging/discharging, and material degradation over multiple cycles. Their weight penalties are particularly problematic for aerospace and automotive applications.

Nanoporous materials like MOFs and carbon nanostructures demonstrate fast kinetics and reversibility but currently achieve insufficient gravimetric capacities (typically 5-7 wt%) at ambient conditions. Chemical carriers offer high densities but require energy-intensive conversion processes that reduce round-trip efficiency.

The U.S. Department of Energy has established ambitious targets for hydrogen storage systems: 6.5 wt% gravimetric capacity and 50 g/L volumetric capacity by 2025, with ultimate targets of 7.5 wt% and 70 g/L. Current technologies fall short of meeting these combined metrics under practical operating conditions.

Cross-cutting barriers include thermal management during hydrogen uptake and release, material degradation over cycling, system complexity, cost factors, and safety considerations. For aerospace applications specifically, weight constraints are paramount, while EV applications face volumetric limitations and refueling time challenges. Both sectors require storage solutions that maintain performance across wide temperature ranges and operational conditions.

State-of-the-Art Hydrogen Storage Solutions

01 Metal hydride-based hydrogen storage materials

Metal hydrides are compounds formed by hydrogen and metals or metal alloys that can store hydrogen through chemical bonding. These materials can absorb hydrogen under pressure and release it when heated, making them effective for hydrogen storage. Various metal hydrides including magnesium-based, aluminum-based, and transition metal-based compounds offer different storage capacities and operating conditions. These materials are being developed to achieve higher storage densities while maintaining favorable kinetics for hydrogen absorption and desorption.- Metal hydride-based hydrogen storage materials: Metal hydrides are compounds formed by hydrogen and various metals or metal alloys that can store hydrogen through chemical bonding. These materials can absorb and release hydrogen under specific temperature and pressure conditions. Metal hydrides typically offer high volumetric hydrogen storage capacity but may face challenges with weight efficiency. Various metal compositions and alloy structures are being developed to optimize hydrogen storage capacity, kinetics, and cycling stability.

- Carbon-based hydrogen storage materials: Carbon-based materials such as carbon nanotubes, graphene, activated carbon, and carbon aerogels are being investigated for hydrogen storage applications. These materials store hydrogen primarily through adsorption mechanisms, where hydrogen molecules are attracted to the surface of the carbon structures. The high surface area and tunable pore structures of carbon-based materials make them promising candidates for hydrogen storage, though they typically require low temperatures or high pressures for effective hydrogen retention.

- Complex hydride hydrogen storage systems: Complex hydrides, including borohydrides, alanates, and amides, represent advanced hydrogen storage materials with potentially high hydrogen content. These compounds typically contain light elements such as lithium, sodium, magnesium, or aluminum combined with hydrogen in complex structures. They can store hydrogen through chemical bonds and release it through thermal decomposition or catalyzed reactions. Research focuses on improving their reversibility, reducing dehydrogenation temperatures, and enhancing kinetics for practical applications.

- Nanostructured hydrogen storage materials: Nanostructured materials offer enhanced hydrogen storage properties through increased surface area, shortened diffusion paths, and modified thermodynamics. These materials include nanoparticles, nanocomposites, and core-shell structures designed specifically for hydrogen storage applications. By controlling the size, morphology, and composition at the nanoscale, researchers can tune the hydrogen absorption/desorption kinetics and thermodynamic properties. Nanostructuring approaches are being applied to various material systems to overcome limitations in conventional hydrogen storage materials.

- Catalyst-enhanced hydrogen storage materials: Catalysts play a crucial role in improving the performance of hydrogen storage materials by enhancing absorption/desorption kinetics and lowering operating temperatures. Various catalysts, including transition metals, metal oxides, and complex compounds, are being incorporated into hydrogen storage materials to facilitate hydrogen dissociation and recombination processes. These catalytic additives can significantly reduce activation energy barriers, improve cycling stability, and enable hydrogen storage under more moderate conditions, making the materials more practical for real-world applications.

02 Carbon-based hydrogen storage materials

Carbon-based materials such as carbon nanotubes, graphene, activated carbon, and carbon aerogels are being investigated for hydrogen storage applications. These materials store hydrogen through physical adsorption (physisorption) on their surfaces. The high surface area and pore structure of these materials allow for significant hydrogen uptake. Research focuses on modifying surface properties and optimizing pore structures to enhance hydrogen storage capacity at practical temperatures and pressures.Expand Specific Solutions03 Complex hydride hydrogen storage systems

Complex hydrides, including borohydrides, alanates, and amides, represent advanced materials for hydrogen storage with high theoretical capacities. These compounds typically contain light elements like lithium, sodium, or magnesium combined with boron, aluminum, or nitrogen. They can store hydrogen through chemical bonds and release it through thermal decomposition. Research focuses on improving their reversibility, reducing desorption temperatures, and enhancing kinetics through catalysts and nanostructuring techniques.Expand Specific Solutions04 Composite and nanostructured hydrogen storage materials

Composite and nanostructured materials combine different hydrogen storage mechanisms or materials to overcome limitations of single-component systems. These include metal hydride-carbon composites, core-shell nanostructures, and catalyst-doped systems. Nanostructuring improves hydrogen diffusion pathways and reaction kinetics, while reducing activation energies for hydrogen absorption and desorption. These materials often demonstrate enhanced cycling stability and improved thermodynamic properties compared to their bulk counterparts.Expand Specific Solutions05 Novel hydrogen storage material manufacturing methods

Advanced manufacturing techniques are being developed to produce hydrogen storage materials with optimized properties. These include ball milling, chemical vapor deposition, solution-based synthesis, and various nanofabrication approaches. These methods allow for precise control over material composition, particle size, defect concentration, and surface properties. Novel processing techniques can create materials with enhanced hydrogen storage capacity, improved kinetics, and better cycling stability while potentially reducing production costs.Expand Specific Solutions

Leading Organizations in Hydrogen Storage Research

The hydrogen storage materials market for aerospace, renewable energy, and EV applications is in a growth phase, with increasing market size driven by the global push for clean energy solutions. The technology maturity varies across applications, with automotive sector leading due to significant investments from major players like Toyota Motor Corp., Hyundai Motor Co., and Kia Corp. Research institutions including Zhejiang University, Southwest Research Institute, and Japan Science & Technology Agency are advancing fundamental materials science, while specialized companies such as Japan Metals & Chemicals Co. Ltd. focus on hydrogen storage alloy development. The competitive landscape features collaboration between academic institutions, government research organizations, and industrial manufacturers, with automotive OEMs increasingly integrating vertical capabilities in hydrogen storage technologies to secure supply chain advantages.

Toyota Motor Corp.

Technical Solution: Toyota has pioneered metal hydride hydrogen storage systems for automotive applications, developing proprietary alloys that optimize hydrogen absorption/desorption kinetics. Their technology utilizes complex metal hydrides based on magnesium, titanium, and zirconium compounds that achieve gravimetric densities of 5-6 wt% and volumetric densities exceeding 40 g/L at moderate pressures (35-70 MPa). Toyota's approach integrates thermal management systems that utilize waste heat from fuel cells to facilitate hydrogen release, addressing one of the key challenges in hydride-based storage. Their latest generation systems incorporate nano-structured materials with catalytic dopants to improve cycling stability and kinetics at lower temperatures, critical for automotive applications. Toyota has also developed composite tank designs that combine high-pressure storage with metal hydride matrices to achieve DOE targets for volumetric and gravimetric capacity while maintaining rapid refueling capabilities [1][3].

Strengths: Industry-leading integration of hydrogen storage with vehicle systems; extensive real-world validation through commercial fuel cell vehicles; advanced thermal management solutions. Weaknesses: Higher system costs compared to conventional storage; weight penalties still exceed optimal targets for long-range vehicles; material degradation after extensive cycling remains a challenge.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai has developed a comprehensive hydrogen storage solution focusing on high-pressure composite tanks reinforced with carbon fiber for their NEXO fuel cell vehicles. Their technology employs Type IV tanks operating at 700 bar with specialized liner materials to minimize hydrogen permeation. Hyundai's approach includes innovative conformable tank designs that maximize packaging efficiency within vehicle architectures while meeting stringent safety standards. Their storage systems achieve approximately 5.8 wt% gravimetric capacity and incorporate advanced sensors for real-time monitoring of hydrogen levels and system integrity. Hyundai has also explored hybrid storage solutions combining compressed hydrogen with solid-state materials to increase volumetric efficiency. Their research extends to cryogenic compressed hydrogen storage (cryo-compressed) that operates at moderate pressures (300-350 bar) but at temperatures around 80K, achieving volumetric densities approaching 40 g/L while maintaining reasonable gravimetric performance [2][5].

Strengths: Proven commercial deployment in multiple vehicle platforms; excellent safety record with comprehensive testing protocols; optimized system integration with fuel cell powertrains. Weaknesses: Reliance on expensive carbon fiber materials increases costs; limited volumetric efficiency compared to advanced material-based solutions; energy penalties for compression.

Critical Patents and Breakthroughs in Storage Materials

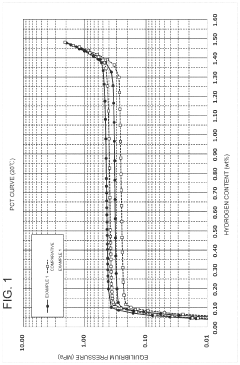

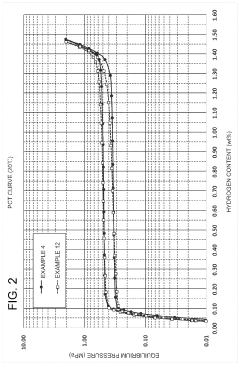

Hydrogen storage material, hydrogen storage container and hydrogen supply apparatus

PatentPendingUS20240034622A1

Innovation

- Alloys with a specific elemental composition represented by LaaCebSmcNidMe, where M is Mn or Co, and specific atomic ratios of La, Ce, Sm, Ni, and M, which reduce hysteresis and enhance hydrogen storage capacity and desorption properties.

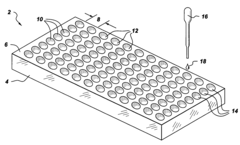

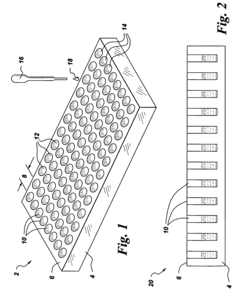

Methods for synthesis and evaluation of hydrogen storage compositions

PatentInactiveUS7445937B2

Innovation

- A method for rapid evaluation and selection of hydrogen storage materials involves synthesizing arrays of hydrides or borohydrides, mixing them with specific precursor materials like SiO2, Al2O3, and metal oxides, and analyzing hydrogen content using techniques like ToF-SIMS and IR spectroscopy to determine storage capacity, enabling parallel preparation and analysis of multiple samples for enhanced hydrogen storage capability.

Safety Standards and Certification Requirements

The implementation of hydrogen storage technologies in aerospace, renewable energy, and electric vehicle applications necessitates adherence to rigorous safety standards and certification requirements. These frameworks are essential due to hydrogen's flammability and potential hazards when improperly handled. International organizations such as ISO (International Organization for Standardization) and national bodies like NFPA (National Fire Protection Association) have established comprehensive guidelines specifically addressing hydrogen storage materials and systems.

For aerospace applications, standards such as SAE AIR6464 and ASTM F3005 provide detailed requirements for hydrogen storage systems in aircraft. These standards emphasize material compatibility, structural integrity under extreme conditions, and leak detection mechanisms. The European Aviation Safety Agency (EASA) and Federal Aviation Administration (FAA) have also developed certification processes that evaluate hydrogen storage materials against stringent safety criteria including resistance to thermal cycling, vibration, and impact.

In the renewable energy sector, standards like ISO/TS 19883 and IEC 62282 govern hydrogen storage for stationary applications. These frameworks focus on material degradation over extended periods, environmental exposure effects, and integration with other renewable energy systems. Certification in this domain typically requires extensive cycling tests to verify long-term stability and performance consistency of storage materials.

For electric vehicle applications, regulations such as UN GTR No. 13 and SAE J2579 establish safety requirements for hydrogen storage systems. These standards mandate rigorous testing protocols including pressure cycling, extreme temperature exposure, and crash safety evaluations. Materials must demonstrate compliance through third-party testing and certification processes overseen by organizations like TÜV and UL.

Material-specific certification requirements vary based on storage type. Metal hydrides must meet standards regarding thermal management and hydrogen embrittlement resistance, while carbon-based materials face scrutiny regarding adsorption stability and thermal conductivity. Certification for complex hydrides focuses on reaction reversibility and catalyst stability over thousands of cycles.

Recent regulatory developments have introduced performance-based certification approaches, allowing innovative materials to demonstrate safety through alternative testing methodologies. This shift has facilitated faster integration of novel storage solutions while maintaining rigorous safety standards. However, harmonization challenges persist between different regional certification frameworks, creating potential barriers for global deployment of hydrogen storage technologies.

For aerospace applications, standards such as SAE AIR6464 and ASTM F3005 provide detailed requirements for hydrogen storage systems in aircraft. These standards emphasize material compatibility, structural integrity under extreme conditions, and leak detection mechanisms. The European Aviation Safety Agency (EASA) and Federal Aviation Administration (FAA) have also developed certification processes that evaluate hydrogen storage materials against stringent safety criteria including resistance to thermal cycling, vibration, and impact.

In the renewable energy sector, standards like ISO/TS 19883 and IEC 62282 govern hydrogen storage for stationary applications. These frameworks focus on material degradation over extended periods, environmental exposure effects, and integration with other renewable energy systems. Certification in this domain typically requires extensive cycling tests to verify long-term stability and performance consistency of storage materials.

For electric vehicle applications, regulations such as UN GTR No. 13 and SAE J2579 establish safety requirements for hydrogen storage systems. These standards mandate rigorous testing protocols including pressure cycling, extreme temperature exposure, and crash safety evaluations. Materials must demonstrate compliance through third-party testing and certification processes overseen by organizations like TÜV and UL.

Material-specific certification requirements vary based on storage type. Metal hydrides must meet standards regarding thermal management and hydrogen embrittlement resistance, while carbon-based materials face scrutiny regarding adsorption stability and thermal conductivity. Certification for complex hydrides focuses on reaction reversibility and catalyst stability over thousands of cycles.

Recent regulatory developments have introduced performance-based certification approaches, allowing innovative materials to demonstrate safety through alternative testing methodologies. This shift has facilitated faster integration of novel storage solutions while maintaining rigorous safety standards. However, harmonization challenges persist between different regional certification frameworks, creating potential barriers for global deployment of hydrogen storage technologies.

Environmental Impact Assessment

The environmental impact of hydrogen storage materials represents a critical consideration in their application for aerospace, renewable energy, and electric vehicle sectors. Life cycle assessment studies indicate that different hydrogen storage technologies exhibit varying environmental footprints. Metal hydrides, while offering high storage densities, often require energy-intensive manufacturing processes and utilize rare earth elements, raising concerns about resource depletion and mining impacts.

Carbon-based materials such as activated carbon and carbon nanotubes present lower environmental burdens during production compared to metal-based alternatives. However, their synthesis often involves hazardous chemicals and high-temperature processes that contribute to greenhouse gas emissions. The environmental advantage lies in their potential recyclability and the abundance of carbon-based precursors.

Chemical hydrogen carriers like ammonia and organic liquid carriers demonstrate promising environmental profiles when integrated with renewable energy sources for hydrogen production. Nevertheless, potential ammonia leakage poses risks of eutrophication and acidification of aquatic ecosystems, necessitating robust containment systems, particularly in aerospace applications.

For aerospace and EV applications specifically, the weight-to-storage ratio of materials directly impacts fuel efficiency and consequently the operational environmental footprint. Lightweight composite materials incorporating nanomaterials show reduced environmental impact during the use phase but may present end-of-life management challenges due to limited recycling infrastructure.

Water consumption represents another significant environmental consideration, particularly for metal hydride production and processing. Regions experiencing water scarcity may face sustainability challenges when scaling up manufacturing of certain hydrogen storage materials, potentially creating geographical limitations for production facilities.

The end-of-life management of hydrogen storage materials presents varying challenges. While metal hydrides offer good recyclability potential, complex composite materials may require specialized processes for material recovery. Current recycling technologies for advanced nanomaterials remain underdeveloped, potentially leading to waste management issues as deployment scales.

Carbon footprint analyses reveal that the environmental benefits of hydrogen storage technologies are maximized when the hydrogen itself is produced through renewable pathways. The coupling of green hydrogen production with environmentally optimized storage materials creates a synergistic effect that substantially reduces lifecycle emissions compared to conventional energy storage and fossil fuel systems.

Carbon-based materials such as activated carbon and carbon nanotubes present lower environmental burdens during production compared to metal-based alternatives. However, their synthesis often involves hazardous chemicals and high-temperature processes that contribute to greenhouse gas emissions. The environmental advantage lies in their potential recyclability and the abundance of carbon-based precursors.

Chemical hydrogen carriers like ammonia and organic liquid carriers demonstrate promising environmental profiles when integrated with renewable energy sources for hydrogen production. Nevertheless, potential ammonia leakage poses risks of eutrophication and acidification of aquatic ecosystems, necessitating robust containment systems, particularly in aerospace applications.

For aerospace and EV applications specifically, the weight-to-storage ratio of materials directly impacts fuel efficiency and consequently the operational environmental footprint. Lightweight composite materials incorporating nanomaterials show reduced environmental impact during the use phase but may present end-of-life management challenges due to limited recycling infrastructure.

Water consumption represents another significant environmental consideration, particularly for metal hydride production and processing. Regions experiencing water scarcity may face sustainability challenges when scaling up manufacturing of certain hydrogen storage materials, potentially creating geographical limitations for production facilities.

The end-of-life management of hydrogen storage materials presents varying challenges. While metal hydrides offer good recyclability potential, complex composite materials may require specialized processes for material recovery. Current recycling technologies for advanced nanomaterials remain underdeveloped, potentially leading to waste management issues as deployment scales.

Carbon footprint analyses reveal that the environmental benefits of hydrogen storage technologies are maximized when the hydrogen itself is produced through renewable pathways. The coupling of green hydrogen production with environmentally optimized storage materials creates a synergistic effect that substantially reduces lifecycle emissions compared to conventional energy storage and fossil fuel systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!