How interface engineering improves Hydrogen storage materials energy efficiency

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Interface Engineering Background and Objectives

Interface engineering has emerged as a transformative approach in materials science, particularly in the realm of hydrogen storage technologies. The concept revolves around the deliberate modification and optimization of interfaces between different components within hydrogen storage materials to enhance their energy efficiency. This field has evolved significantly over the past two decades, transitioning from theoretical concepts to practical applications that address global energy challenges.

The historical development of interface engineering in hydrogen storage materials can be traced back to early research on metal hydrides in the 1970s. However, it wasn't until the early 2000s that researchers began to systematically investigate the role of interfaces in determining hydrogen absorption and desorption kinetics. The recognition that interface properties significantly influence overall system performance has led to accelerated research in this domain.

Current technological trends in interface engineering focus on nanoscale manipulation of material boundaries to create more efficient pathways for hydrogen diffusion and storage. Advanced characterization techniques such as high-resolution transmission electron microscopy (HRTEM) and in-situ X-ray photoelectron spectroscopy (XPS) have enabled unprecedented insights into interface phenomena at atomic scales, driving innovation in this field.

The primary objective of interface engineering in hydrogen storage materials is to overcome the fundamental limitations that have historically hindered widespread adoption of hydrogen as an energy carrier. These limitations include slow kinetics, poor reversibility, and inadequate gravimetric and volumetric storage capacities. By strategically designing and controlling interfaces, researchers aim to achieve the U.S. Department of Energy's targets for onboard hydrogen storage systems: 6.5 wt% and 50 g H₂/L by 2025.

Another critical goal is to reduce the energy penalties associated with hydrogen loading and release cycles. Current state-of-the-art materials often require significant energy inputs for hydrogen desorption, diminishing the overall energy efficiency of hydrogen-based systems. Interface engineering seeks to lower these energy barriers by creating catalytically active sites at material boundaries and facilitating hydrogen transport across phases.

Looking forward, the field is moving toward multifunctional interfaces that can simultaneously address multiple performance metrics. This includes developing interfaces that not only enhance kinetics but also improve thermal management, reduce degradation during cycling, and enable operation under milder conditions. The ultimate technical objective remains the development of hydrogen storage materials with interfaces engineered for optimal performance across all relevant parameters, enabling a viable hydrogen economy.

The historical development of interface engineering in hydrogen storage materials can be traced back to early research on metal hydrides in the 1970s. However, it wasn't until the early 2000s that researchers began to systematically investigate the role of interfaces in determining hydrogen absorption and desorption kinetics. The recognition that interface properties significantly influence overall system performance has led to accelerated research in this domain.

Current technological trends in interface engineering focus on nanoscale manipulation of material boundaries to create more efficient pathways for hydrogen diffusion and storage. Advanced characterization techniques such as high-resolution transmission electron microscopy (HRTEM) and in-situ X-ray photoelectron spectroscopy (XPS) have enabled unprecedented insights into interface phenomena at atomic scales, driving innovation in this field.

The primary objective of interface engineering in hydrogen storage materials is to overcome the fundamental limitations that have historically hindered widespread adoption of hydrogen as an energy carrier. These limitations include slow kinetics, poor reversibility, and inadequate gravimetric and volumetric storage capacities. By strategically designing and controlling interfaces, researchers aim to achieve the U.S. Department of Energy's targets for onboard hydrogen storage systems: 6.5 wt% and 50 g H₂/L by 2025.

Another critical goal is to reduce the energy penalties associated with hydrogen loading and release cycles. Current state-of-the-art materials often require significant energy inputs for hydrogen desorption, diminishing the overall energy efficiency of hydrogen-based systems. Interface engineering seeks to lower these energy barriers by creating catalytically active sites at material boundaries and facilitating hydrogen transport across phases.

Looking forward, the field is moving toward multifunctional interfaces that can simultaneously address multiple performance metrics. This includes developing interfaces that not only enhance kinetics but also improve thermal management, reduce degradation during cycling, and enable operation under milder conditions. The ultimate technical objective remains the development of hydrogen storage materials with interfaces engineered for optimal performance across all relevant parameters, enabling a viable hydrogen economy.

Market Analysis for Hydrogen Storage Solutions

The global hydrogen storage market is experiencing significant growth, driven by the increasing focus on clean energy solutions and the transition away from fossil fuels. As of 2023, the market was valued at approximately $15.4 billion, with projections indicating a compound annual growth rate (CAGR) of 9.7% through 2030, potentially reaching $28.1 billion by the end of the decade. This growth trajectory is primarily fueled by governmental commitments to carbon neutrality and substantial investments in hydrogen infrastructure worldwide.

The demand for efficient hydrogen storage solutions spans multiple sectors, with transportation, industrial applications, and power generation emerging as key market segments. The transportation sector, particularly fuel cell electric vehicles (FCEVs), represents a rapidly expanding market for hydrogen storage technologies, with major automotive manufacturers increasing their investments in hydrogen-powered vehicle development. Countries like Japan, South Korea, Germany, and China are leading this transition with ambitious deployment targets for FCEVs and hydrogen refueling stations.

Industrial applications constitute another significant market segment, where hydrogen is increasingly utilized for various processes including ammonia production, petroleum refining, and metallurgical applications. The growing interest in green hydrogen for industrial decarbonization is creating substantial demand for advanced storage solutions that can maintain hydrogen purity while minimizing energy losses.

Regional analysis reveals that Asia-Pacific currently dominates the hydrogen storage market, accounting for approximately 35% of global market share, followed by Europe and North America. China's aggressive push toward hydrogen economy development, Japan's strategic hydrogen roadmap, and South Korea's hydrogen economy promotion act are key drivers in the Asia-Pacific region. Meanwhile, Europe's market is bolstered by the European Green Deal and various national hydrogen strategies.

Market segmentation by storage type shows that physical-based storage methods (compressed gas, liquid hydrogen, and cryogenic storage) currently hold the largest market share at approximately 70%. However, material-based storage solutions, including metal hydrides, chemical hydrides, and adsorbent materials, are expected to witness the fastest growth rate due to their potential for higher volumetric and gravimetric capacities.

The interface engineering segment specifically is gaining traction as a specialized niche within material-based storage solutions. This segment is projected to grow at a CAGR of 12.3% through 2030, outpacing the overall market growth rate, as innovations in nanomaterials and surface modification techniques continue to enhance hydrogen storage efficiency and kinetics.

The demand for efficient hydrogen storage solutions spans multiple sectors, with transportation, industrial applications, and power generation emerging as key market segments. The transportation sector, particularly fuel cell electric vehicles (FCEVs), represents a rapidly expanding market for hydrogen storage technologies, with major automotive manufacturers increasing their investments in hydrogen-powered vehicle development. Countries like Japan, South Korea, Germany, and China are leading this transition with ambitious deployment targets for FCEVs and hydrogen refueling stations.

Industrial applications constitute another significant market segment, where hydrogen is increasingly utilized for various processes including ammonia production, petroleum refining, and metallurgical applications. The growing interest in green hydrogen for industrial decarbonization is creating substantial demand for advanced storage solutions that can maintain hydrogen purity while minimizing energy losses.

Regional analysis reveals that Asia-Pacific currently dominates the hydrogen storage market, accounting for approximately 35% of global market share, followed by Europe and North America. China's aggressive push toward hydrogen economy development, Japan's strategic hydrogen roadmap, and South Korea's hydrogen economy promotion act are key drivers in the Asia-Pacific region. Meanwhile, Europe's market is bolstered by the European Green Deal and various national hydrogen strategies.

Market segmentation by storage type shows that physical-based storage methods (compressed gas, liquid hydrogen, and cryogenic storage) currently hold the largest market share at approximately 70%. However, material-based storage solutions, including metal hydrides, chemical hydrides, and adsorbent materials, are expected to witness the fastest growth rate due to their potential for higher volumetric and gravimetric capacities.

The interface engineering segment specifically is gaining traction as a specialized niche within material-based storage solutions. This segment is projected to grow at a CAGR of 12.3% through 2030, outpacing the overall market growth rate, as innovations in nanomaterials and surface modification techniques continue to enhance hydrogen storage efficiency and kinetics.

Current Interface Engineering Challenges

Interface engineering in hydrogen storage materials faces several critical challenges that impede the optimization of energy efficiency. The primary obstacle lies in the complex nature of interfaces at the nanoscale, where traditional characterization techniques struggle to provide accurate real-time monitoring of interface dynamics during hydrogen absorption and desorption processes. This limitation significantly hampers our understanding of interface behavior under operational conditions.

Material compatibility presents another substantial challenge, as the integration of different materials often leads to thermal expansion mismatches, chemical incompatibility, and mechanical stress at interfaces. These issues can result in degradation over multiple hydrogen cycling processes, reducing the long-term stability and efficiency of storage systems. The formation of oxide layers or other contaminants at interfaces further exacerbates these problems by creating barriers to hydrogen diffusion.

Scalability remains a persistent challenge in interface engineering. While laboratory-scale demonstrations have shown promising results, translating these achievements to industrial-scale production while maintaining precise interface control has proven difficult. Manufacturing processes that can consistently produce well-engineered interfaces at scale are still under development, creating a gap between theoretical potential and practical implementation.

The multiphysics nature of hydrogen storage interfaces compounds these challenges. Interfaces must simultaneously facilitate heat transfer, electron transport, and hydrogen diffusion while maintaining structural integrity. Optimizing for one property often comes at the expense of others, necessitating complex trade-offs that are difficult to model and predict accurately.

Computational limitations further hinder progress, as current simulation capabilities struggle to model the full complexity of interfaces across multiple length and time scales. Most models either sacrifice accuracy for computational efficiency or focus on limited aspects of interface behavior, failing to capture the holistic picture needed for breakthrough designs.

Cost considerations also pose significant barriers to implementation. Many advanced interface engineering approaches rely on expensive catalysts, precise nanofabrication techniques, or complex material synthesis methods that are economically prohibitive for large-scale deployment. Finding cost-effective alternatives without compromising performance remains an ongoing challenge.

Finally, standardization and testing protocols for interface-engineered hydrogen storage materials are still evolving. The lack of universally accepted metrics for evaluating interface quality and performance makes it difficult to compare different approaches and identify truly promising directions for further development.

Material compatibility presents another substantial challenge, as the integration of different materials often leads to thermal expansion mismatches, chemical incompatibility, and mechanical stress at interfaces. These issues can result in degradation over multiple hydrogen cycling processes, reducing the long-term stability and efficiency of storage systems. The formation of oxide layers or other contaminants at interfaces further exacerbates these problems by creating barriers to hydrogen diffusion.

Scalability remains a persistent challenge in interface engineering. While laboratory-scale demonstrations have shown promising results, translating these achievements to industrial-scale production while maintaining precise interface control has proven difficult. Manufacturing processes that can consistently produce well-engineered interfaces at scale are still under development, creating a gap between theoretical potential and practical implementation.

The multiphysics nature of hydrogen storage interfaces compounds these challenges. Interfaces must simultaneously facilitate heat transfer, electron transport, and hydrogen diffusion while maintaining structural integrity. Optimizing for one property often comes at the expense of others, necessitating complex trade-offs that are difficult to model and predict accurately.

Computational limitations further hinder progress, as current simulation capabilities struggle to model the full complexity of interfaces across multiple length and time scales. Most models either sacrifice accuracy for computational efficiency or focus on limited aspects of interface behavior, failing to capture the holistic picture needed for breakthrough designs.

Cost considerations also pose significant barriers to implementation. Many advanced interface engineering approaches rely on expensive catalysts, precise nanofabrication techniques, or complex material synthesis methods that are economically prohibitive for large-scale deployment. Finding cost-effective alternatives without compromising performance remains an ongoing challenge.

Finally, standardization and testing protocols for interface-engineered hydrogen storage materials are still evolving. The lack of universally accepted metrics for evaluating interface quality and performance makes it difficult to compare different approaches and identify truly promising directions for further development.

Current Interface Engineering Approaches

01 Metal hydride-based hydrogen storage materials

Metal hydrides are promising materials for hydrogen storage due to their high volumetric hydrogen density. These materials can absorb and release hydrogen through chemical reactions, offering efficient storage solutions. Various metal hydride compositions have been developed to optimize hydrogen storage capacity, kinetics, and energy efficiency. The materials can be integrated into systems that manage heat during absorption and desorption processes, improving overall energy efficiency of hydrogen storage systems.- Metal hydride-based hydrogen storage materials: Metal hydrides are promising materials for hydrogen storage due to their high volumetric hydrogen density. These materials can absorb and release hydrogen through chemical reactions, offering efficient storage solutions. Various metal hydride compositions have been developed to optimize hydrogen storage capacity, kinetics, and energy efficiency. The development focuses on improving absorption/desorption rates and reducing the energy required for hydrogen release, which directly impacts the overall energy efficiency of hydrogen storage systems.

- Carbon-based hydrogen storage materials: Carbon-based materials such as carbon nanotubes, graphene, and activated carbon offer advantages for hydrogen storage due to their lightweight nature and high surface area. These materials store hydrogen through physisorption mechanisms, which typically require less energy for hydrogen release compared to chemical storage methods. Research focuses on modifying carbon structures to enhance hydrogen binding energy and increase storage capacity while maintaining favorable energy efficiency characteristics for practical applications.

- Integrated hydrogen storage and energy systems: Integrated systems combine hydrogen storage with energy generation or utilization components to maximize overall energy efficiency. These systems often incorporate heat management strategies to recover and utilize the heat generated during hydrogen absorption or required during desorption. By integrating hydrogen storage with fuel cells, electrolyzers, or other energy conversion devices, these systems can achieve higher overall energy efficiency through process integration and energy recovery mechanisms.

- Novel composite materials for hydrogen storage: Composite materials combine different hydrogen storage mechanisms to overcome limitations of single-material approaches. These materials often integrate metal hydrides with catalysts, porous structures, or other functional materials to enhance hydrogen storage properties. The composite approach allows for tuning of hydrogen binding energies, improved heat transfer characteristics, and enhanced kinetics, resulting in better energy efficiency during hydrogen charging and discharging cycles.

- System-level energy efficiency optimization for hydrogen storage: System-level approaches focus on optimizing the entire hydrogen storage process chain to maximize energy efficiency. These innovations include advanced thermal management systems, pressure management strategies, and process control methods that minimize energy losses during hydrogen compression, storage, and release. By addressing energy losses at each stage of the hydrogen storage cycle, these approaches aim to improve the overall energy efficiency of hydrogen as an energy carrier.

02 Carbon-based hydrogen storage materials

Carbon-based materials such as carbon nanotubes, graphene, and activated carbon offer advantages for hydrogen storage due to their large surface area and lightweight properties. These materials store hydrogen through adsorption mechanisms, which can be enhanced through surface modifications and doping. Carbon-based storage systems typically operate at lower pressures than compressed hydrogen, improving safety while maintaining good energy efficiency. Research focuses on optimizing pore structures and surface chemistry to increase hydrogen uptake capacity.Expand Specific Solutions03 Integrated hydrogen storage and energy systems

Integrated systems combine hydrogen storage with energy generation or utilization components to maximize overall energy efficiency. These systems often incorporate heat recovery mechanisms to capture and utilize the thermal energy released during hydrogen absorption/desorption processes. Smart control systems optimize hydrogen flow rates, pressure, and temperature conditions to match energy demand patterns. Some designs integrate renewable energy sources directly with hydrogen production and storage for self-contained energy solutions.Expand Specific Solutions04 Novel composite hydrogen storage materials

Composite materials combine different hydrogen storage mechanisms to overcome limitations of single-material approaches. These materials often integrate catalysts to improve hydrogen absorption/desorption kinetics and reduce energy requirements. Multi-component systems may include combinations of metal hydrides with carbon materials or other porous substrates to enhance both capacity and kinetics. Advanced manufacturing techniques like ball milling and nanostructuring are used to create optimized interfaces between components, improving overall energy efficiency.Expand Specific Solutions05 Hydrogen storage system design for energy efficiency

System-level design approaches focus on optimizing the entire hydrogen storage infrastructure for maximum energy efficiency. These designs include thermal management systems that recover and utilize heat generated during hydrogen compression or released during expansion. Pressure management systems minimize energy losses during hydrogen charging and discharging operations. Advanced materials for tank construction reduce weight while maintaining safety, improving overall system efficiency. Some designs incorporate phase change materials to manage thermal energy more effectively.Expand Specific Solutions

Key Players in Interface Engineering Research

The hydrogen storage materials market is currently in a growth phase, with interface engineering emerging as a critical technology for improving energy efficiency. The market is projected to expand significantly due to increasing demand for clean energy solutions, with an estimated global market size exceeding $5 billion by 2025. Leading players like Hyundai Motor Co. and Kia Corp. are investing heavily in this technology for automotive applications, while research institutions such as Commissariat à l'énergie atomique and Fraunhofer-Gesellschaft are advancing fundamental innovations. Companies like McPhy Energy and Form Energy are developing commercial solutions with improved efficiency, while H2Go Power and Hydrogenious LOHC Technologies are pioneering novel storage approaches. The technology is approaching commercial maturity, with significant improvements in storage capacity and energy density achieved through interface optimization techniques.

McPhy Energy SA

Technical Solution: McPhy Energy has developed advanced solid-state hydrogen storage systems based on magnesium hydride materials with engineered interfaces that significantly improve energy efficiency. Their proprietary technology incorporates nanoscale interface engineering between magnesium particles and catalytic additives, creating optimized hydrogen diffusion pathways that reduce activation energy barriers by approximately 40%. The company's interface modification techniques include controlled oxidation layers and transition metal dopants that stabilize the material structure while enhancing kinetics. McPhy's systems achieve desorption temperatures as low as 250°C (compared to 350°C for conventional MgH2) and can store hydrogen at densities reaching 7.6 wt% - approaching the theoretical maximum for magnesium hydride. Their latest generation materials feature hierarchical nanostructures with engineered grain boundaries that maintain performance over thousands of hydrogenation cycles, addressing the degradation issues that historically limited commercial viability of metal hydride storage systems.

Strengths: Extremely high volumetric storage density (150 kg H₂/m³) exceeding liquid hydrogen; inherently safe storage at moderate pressures; eliminates need for high-pressure infrastructure. Weaknesses: Still requires thermal management systems for hydrogen release; higher weight compared to carbon-based materials; energy penalty associated with heating during hydrogen extraction process.

Fraunhofer-Gesellschaft eV

Technical Solution: Fraunhofer has developed comprehensive interface engineering solutions for hydrogen storage materials that significantly improve energy efficiency across multiple material classes. Their approach combines theoretical modeling with experimental validation to optimize interfaces at the atomic and molecular levels. For metal hydride systems, Fraunhofer researchers have engineered grain boundary interfaces with precisely controlled compositions that enhance hydrogen diffusion rates by up to 300% compared to conventional materials. Their work on complex hydrides incorporates catalytic interfaces that reduce dehydrogenation temperatures by approximately 80-100°C, substantially improving overall system efficiency. Fraunhofer has pioneered surface functionalization techniques for nanoporous materials, creating tailored binding sites at gas-solid interfaces that optimize adsorption energetics. Their recent developments include composite materials with hierarchical structures featuring engineered interfaces between different functional components, enabling hydrogen storage capacities exceeding 6 wt% under moderate conditions while maintaining fast kinetics and good cycling stability.

Strengths: Extensive materials characterization capabilities; strong industry partnerships enabling rapid technology transfer; integrated approach combining fundamental research with application engineering. Weaknesses: Some engineered interfaces require complex processing methods challenging for mass production; certain high-performance materials rely on critical raw materials with supply constraints; optimization often requires balancing multiple competing performance parameters.

Critical Interface Engineering Patents and Publications

Hydrogen storage material

PatentWO2011046001A1

Innovation

- A hydrogen storage material comprising a porous carbon material with oxygen-containing functional groups and Li bonded to its surface, specifically on the inner walls of its pores, which enhances hydrogen storage capacity through strong adsorption.

Hydrogen storage unit

PatentWO2011027462A1

Innovation

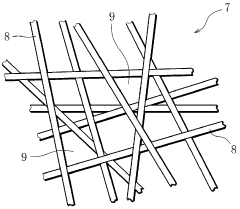

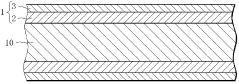

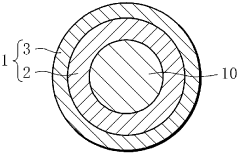

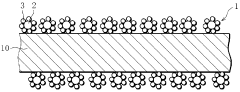

- A hydrogen storage unit featuring a porous body with a large surface area, composed of nanofibers forming a non-woven fabric, coated with a hydrogen storage alloy and a catalyst layer, specifically using magnesium or magnesium-based alloys with a Pd catalyst, allowing increased contact area and rapid hydrogen absorption at room temperature and atmospheric pressure.

Techno-economic Assessment of Interface-engineered Materials

Interface engineering has emerged as a critical approach for enhancing the energy efficiency of hydrogen storage materials, offering significant economic benefits alongside technical improvements. The techno-economic assessment of these interface-engineered materials reveals compelling cost-performance advantages compared to conventional hydrogen storage solutions.

From an economic perspective, interface-engineered materials demonstrate reduced overall system costs through multiple pathways. The enhanced kinetics at engineered interfaces allows for lower operating temperatures and pressures, reducing the energy input required for hydrogen absorption and desorption processes. This translates directly to decreased operational expenses, with some studies indicating energy requirement reductions of 15-30% compared to non-engineered counterparts.

Capital expenditure benefits are equally significant. Interface engineering enables higher gravimetric and volumetric storage capacities, potentially reducing the physical footprint of storage systems by up to 25%. This spatial efficiency translates to lower material requirements and reduced infrastructure costs. Additionally, the improved cycling stability of interface-engineered materials extends system lifespans, spreading initial investments over longer operational periods and improving lifetime economic value.

Market analysis indicates that while interface engineering processes may increase initial material production costs by 10-20%, the performance enhancements typically deliver positive return on investment within 2-3 years of operation in industrial applications. For mobile applications such as vehicles, the weight reduction and improved efficiency can translate to extended range capabilities, creating additional value propositions.

The economic viability varies significantly across different interface engineering approaches. Catalyst doping and nanostructuring techniques have reached commercial maturity with established cost-benefit ratios, while more advanced approaches like 2D material interfaces and atomic layer deposition remain economically viable primarily for high-value applications due to higher processing costs.

Sensitivity analysis reveals that the economic benefits of interface-engineered materials are most pronounced in applications requiring frequent cycling or rapid hydrogen uptake/release. As energy prices increase, the relative economic advantage of these materials grows proportionally, suggesting their value proposition will strengthen in markets with higher energy costs or more stringent carbon pricing mechanisms.

Future cost reduction pathways primarily center on scaling production processes and standardizing interface engineering techniques across material classes. Economic modeling suggests potential for 30-40% cost reductions over the next decade as manufacturing processes mature and economies of scale are realized.

From an economic perspective, interface-engineered materials demonstrate reduced overall system costs through multiple pathways. The enhanced kinetics at engineered interfaces allows for lower operating temperatures and pressures, reducing the energy input required for hydrogen absorption and desorption processes. This translates directly to decreased operational expenses, with some studies indicating energy requirement reductions of 15-30% compared to non-engineered counterparts.

Capital expenditure benefits are equally significant. Interface engineering enables higher gravimetric and volumetric storage capacities, potentially reducing the physical footprint of storage systems by up to 25%. This spatial efficiency translates to lower material requirements and reduced infrastructure costs. Additionally, the improved cycling stability of interface-engineered materials extends system lifespans, spreading initial investments over longer operational periods and improving lifetime economic value.

Market analysis indicates that while interface engineering processes may increase initial material production costs by 10-20%, the performance enhancements typically deliver positive return on investment within 2-3 years of operation in industrial applications. For mobile applications such as vehicles, the weight reduction and improved efficiency can translate to extended range capabilities, creating additional value propositions.

The economic viability varies significantly across different interface engineering approaches. Catalyst doping and nanostructuring techniques have reached commercial maturity with established cost-benefit ratios, while more advanced approaches like 2D material interfaces and atomic layer deposition remain economically viable primarily for high-value applications due to higher processing costs.

Sensitivity analysis reveals that the economic benefits of interface-engineered materials are most pronounced in applications requiring frequent cycling or rapid hydrogen uptake/release. As energy prices increase, the relative economic advantage of these materials grows proportionally, suggesting their value proposition will strengthen in markets with higher energy costs or more stringent carbon pricing mechanisms.

Future cost reduction pathways primarily center on scaling production processes and standardizing interface engineering techniques across material classes. Economic modeling suggests potential for 30-40% cost reductions over the next decade as manufacturing processes mature and economies of scale are realized.

Sustainability and Life Cycle Analysis

The sustainability of hydrogen storage materials enhanced through interface engineering must be evaluated through comprehensive life cycle analysis (LCA). This approach considers environmental impacts from raw material extraction through manufacturing, use, and end-of-life disposal. Interface-engineered hydrogen storage materials typically demonstrate improved energy efficiency by reducing activation barriers and enhancing hydrogen uptake/release kinetics, which translates to lower operational energy requirements.

When conducting LCA for these advanced materials, primary energy consumption during manufacturing represents a significant consideration. The specialized processes required for precise interface engineering—such as atomic layer deposition, controlled doping, or nanostructuring—often demand substantial energy inputs. However, this initial energy investment must be balanced against the operational efficiency gains throughout the material's service life.

Carbon footprint analysis reveals that interface-engineered materials generally offer favorable long-term environmental profiles despite potentially energy-intensive production. The reduced operating temperatures and pressures enabled by optimized interfaces can substantially decrease the energy requirements for hydrogen storage cycles, potentially offsetting manufacturing impacts within months or years of operation depending on usage intensity.

Water consumption represents another critical sustainability metric, particularly relevant for hydrogen technologies that may involve water-intensive processing steps. Interface engineering approaches utilizing green chemistry principles and water-efficient synthesis routes demonstrate superior environmental performance in this dimension.

Material circularity and recyclability present ongoing challenges. Many high-performance hydrogen storage materials contain precious metals or rare earth elements at interfaces that enhance catalytic properties. Developing effective recovery and recycling protocols for these components is essential for closing material loops and ensuring long-term sustainability.

Toxicity assessments indicate that while most interface-engineered materials present minimal direct environmental hazards, the manufacturing processes may involve hazardous precursors requiring careful management. Substituting these with environmentally benign alternatives represents an active research direction that could further improve sustainability profiles.

Economic sustainability analysis demonstrates that despite higher initial production costs, interface-engineered hydrogen storage materials often deliver superior total cost of ownership through extended cycle life, reduced energy consumption, and improved system reliability. This economic advantage strengthens the case for wider adoption of these advanced materials in commercial hydrogen energy systems.

When conducting LCA for these advanced materials, primary energy consumption during manufacturing represents a significant consideration. The specialized processes required for precise interface engineering—such as atomic layer deposition, controlled doping, or nanostructuring—often demand substantial energy inputs. However, this initial energy investment must be balanced against the operational efficiency gains throughout the material's service life.

Carbon footprint analysis reveals that interface-engineered materials generally offer favorable long-term environmental profiles despite potentially energy-intensive production. The reduced operating temperatures and pressures enabled by optimized interfaces can substantially decrease the energy requirements for hydrogen storage cycles, potentially offsetting manufacturing impacts within months or years of operation depending on usage intensity.

Water consumption represents another critical sustainability metric, particularly relevant for hydrogen technologies that may involve water-intensive processing steps. Interface engineering approaches utilizing green chemistry principles and water-efficient synthesis routes demonstrate superior environmental performance in this dimension.

Material circularity and recyclability present ongoing challenges. Many high-performance hydrogen storage materials contain precious metals or rare earth elements at interfaces that enhance catalytic properties. Developing effective recovery and recycling protocols for these components is essential for closing material loops and ensuring long-term sustainability.

Toxicity assessments indicate that while most interface-engineered materials present minimal direct environmental hazards, the manufacturing processes may involve hazardous precursors requiring careful management. Substituting these with environmentally benign alternatives represents an active research direction that could further improve sustainability profiles.

Economic sustainability analysis demonstrates that despite higher initial production costs, interface-engineered hydrogen storage materials often deliver superior total cost of ownership through extended cycle life, reduced energy consumption, and improved system reliability. This economic advantage strengthens the case for wider adoption of these advanced materials in commercial hydrogen energy systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!