Research on Hydrogen storage materials for electronics and energy device integration

SEP 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogen Storage Materials Background and Objectives

Hydrogen storage materials have emerged as a critical component in the transition towards a sustainable energy ecosystem, with their development history spanning over five decades. Initially focused on bulk storage for transportation, the research paradigm has evolved significantly to address the integration needs of electronics and energy devices. This technological evolution reflects the broader shift from fossil fuels to clean energy sources, with hydrogen positioned as a versatile energy carrier capable of addressing intermittency issues in renewable energy systems.

The fundamental objective of hydrogen storage materials research for electronics and energy device integration is to develop materials that can safely store hydrogen at high densities under moderate temperature and pressure conditions, while maintaining rapid absorption/desorption kinetics. These materials must also demonstrate long-term stability, cost-effectiveness, and compatibility with miniaturized electronic components and energy conversion systems.

Current technological trends indicate a convergence of nanotechnology, materials science, and electronic engineering to create advanced hydrogen storage solutions. Metal hydrides, complex hydrides, chemical hydrides, and nanoporous materials represent the primary material classes under investigation, each offering distinct advantages for specific applications in electronics and energy devices.

The integration of hydrogen storage materials with electronics presents unique challenges and opportunities. For electronics applications, the focus lies on developing ultra-compact hydrogen storage systems that can power portable devices with higher energy densities than conventional batteries. In energy device integration, hydrogen storage materials serve as critical components in fuel cells, hydrogen sensors, and energy harvesting systems, enabling more efficient energy conversion and utilization.

Global research efforts are increasingly directed toward addressing key performance metrics: gravimetric and volumetric hydrogen capacity, operating temperature and pressure conditions, cycling stability, and system integration capabilities. The U.S. Department of Energy has established ambitious targets for hydrogen storage systems, including 6.5 wt% system gravimetric capacity and 50 g/L system volumetric capacity by 2025, driving innovation in this field.

The strategic importance of hydrogen storage materials extends beyond technical considerations to encompass geopolitical and economic factors. As countries worldwide invest in hydrogen infrastructure and technologies, advanced storage materials will play a pivotal role in determining the commercial viability and widespread adoption of hydrogen-based energy systems. This research area thus represents not only a technological frontier but also a critical enabler for the broader hydrogen economy and sustainable energy transition.

The fundamental objective of hydrogen storage materials research for electronics and energy device integration is to develop materials that can safely store hydrogen at high densities under moderate temperature and pressure conditions, while maintaining rapid absorption/desorption kinetics. These materials must also demonstrate long-term stability, cost-effectiveness, and compatibility with miniaturized electronic components and energy conversion systems.

Current technological trends indicate a convergence of nanotechnology, materials science, and electronic engineering to create advanced hydrogen storage solutions. Metal hydrides, complex hydrides, chemical hydrides, and nanoporous materials represent the primary material classes under investigation, each offering distinct advantages for specific applications in electronics and energy devices.

The integration of hydrogen storage materials with electronics presents unique challenges and opportunities. For electronics applications, the focus lies on developing ultra-compact hydrogen storage systems that can power portable devices with higher energy densities than conventional batteries. In energy device integration, hydrogen storage materials serve as critical components in fuel cells, hydrogen sensors, and energy harvesting systems, enabling more efficient energy conversion and utilization.

Global research efforts are increasingly directed toward addressing key performance metrics: gravimetric and volumetric hydrogen capacity, operating temperature and pressure conditions, cycling stability, and system integration capabilities. The U.S. Department of Energy has established ambitious targets for hydrogen storage systems, including 6.5 wt% system gravimetric capacity and 50 g/L system volumetric capacity by 2025, driving innovation in this field.

The strategic importance of hydrogen storage materials extends beyond technical considerations to encompass geopolitical and economic factors. As countries worldwide invest in hydrogen infrastructure and technologies, advanced storage materials will play a pivotal role in determining the commercial viability and widespread adoption of hydrogen-based energy systems. This research area thus represents not only a technological frontier but also a critical enabler for the broader hydrogen economy and sustainable energy transition.

Market Analysis for Hydrogen-Based Electronics and Energy Systems

The global market for hydrogen-based electronics and energy systems is experiencing significant growth, driven by the increasing demand for clean energy solutions and the push towards decarbonization across various industries. The market size for hydrogen technologies was valued at approximately $130 billion in 2020 and is projected to reach $500 billion by 2030, representing a compound annual growth rate (CAGR) of 14.5% during the forecast period.

The demand for hydrogen storage materials in electronics and energy device integration is primarily fueled by three key sectors: portable electronics, stationary power systems, and transportation. In the portable electronics segment, hydrogen fuel cells offer potential advantages over conventional lithium-ion batteries, including higher energy density and faster recharging capabilities. This segment is expected to grow at a CAGR of 18% through 2028.

Stationary power systems represent another significant market opportunity, particularly for backup power applications in telecommunications, data centers, and remote locations. This segment currently accounts for 35% of the total market share and is projected to maintain steady growth as grid reliability concerns increase globally.

The transportation sector, especially fuel cell electric vehicles (FCEVs), presents perhaps the most substantial long-term market potential. Major automotive manufacturers including Toyota, Hyundai, and Honda have made significant investments in hydrogen fuel cell technology. The global FCEV market is expected to grow from 25,000 units in 2020 to over 1 million units by 2030.

Regional analysis indicates that Asia-Pacific currently dominates the market with 45% share, led by Japan, South Korea, and China's aggressive hydrogen strategies. Europe follows with 30% market share, driven by strong policy support and investments in hydrogen infrastructure. North America accounts for 20% of the market, with significant growth potential as new federal incentives take effect.

Consumer electronics applications for hydrogen storage materials represent an emerging niche with high growth potential. Miniaturized fuel cells for smartphones, laptops, and wearable devices could potentially extend device runtime by 2-3 times compared to current battery technologies. This segment is projected to grow at a CAGR of 22% through 2028, albeit from a relatively small base.

Key market challenges include cost competitiveness with established technologies, infrastructure development requirements, and technical limitations of current hydrogen storage materials. However, ongoing research in advanced materials such as metal-organic frameworks (MOFs), complex hydrides, and nanostructured materials is expected to address many of these limitations in the coming years.

The demand for hydrogen storage materials in electronics and energy device integration is primarily fueled by three key sectors: portable electronics, stationary power systems, and transportation. In the portable electronics segment, hydrogen fuel cells offer potential advantages over conventional lithium-ion batteries, including higher energy density and faster recharging capabilities. This segment is expected to grow at a CAGR of 18% through 2028.

Stationary power systems represent another significant market opportunity, particularly for backup power applications in telecommunications, data centers, and remote locations. This segment currently accounts for 35% of the total market share and is projected to maintain steady growth as grid reliability concerns increase globally.

The transportation sector, especially fuel cell electric vehicles (FCEVs), presents perhaps the most substantial long-term market potential. Major automotive manufacturers including Toyota, Hyundai, and Honda have made significant investments in hydrogen fuel cell technology. The global FCEV market is expected to grow from 25,000 units in 2020 to over 1 million units by 2030.

Regional analysis indicates that Asia-Pacific currently dominates the market with 45% share, led by Japan, South Korea, and China's aggressive hydrogen strategies. Europe follows with 30% market share, driven by strong policy support and investments in hydrogen infrastructure. North America accounts for 20% of the market, with significant growth potential as new federal incentives take effect.

Consumer electronics applications for hydrogen storage materials represent an emerging niche with high growth potential. Miniaturized fuel cells for smartphones, laptops, and wearable devices could potentially extend device runtime by 2-3 times compared to current battery technologies. This segment is projected to grow at a CAGR of 22% through 2028, albeit from a relatively small base.

Key market challenges include cost competitiveness with established technologies, infrastructure development requirements, and technical limitations of current hydrogen storage materials. However, ongoing research in advanced materials such as metal-organic frameworks (MOFs), complex hydrides, and nanostructured materials is expected to address many of these limitations in the coming years.

Current Status and Challenges in Hydrogen Storage Technology

Hydrogen storage technology has evolved significantly over the past decades, yet remains at varying stages of maturity across different applications. Currently, physical storage methods dominate commercial applications, with compressed gas (350-700 bar) and cryogenic liquid hydrogen being the most widely implemented solutions. However, these conventional approaches face substantial limitations in energy density, safety concerns, and integration challenges, particularly for electronic and energy device applications where space constraints and thermal management are critical factors.

Material-based hydrogen storage has seen remarkable research progress but faces significant commercialization barriers. Metal hydrides offer promising volumetric densities (up to 150 kg H₂/m³) but struggle with slow kinetics and high operating temperatures. Complex hydrides demonstrate higher theoretical capacities but face even more severe kinetic limitations. Meanwhile, chemical hydrogen carriers like ammonia and formic acid present alternative pathways but introduce additional conversion complexity and energy penalties.

For electronics integration specifically, the current landscape reveals a substantial gap between available technologies and application requirements. Conventional storage methods are simply too bulky and unsafe for direct integration, while advanced materials often require operating conditions incompatible with sensitive electronic components. The miniaturization challenge remains largely unresolved, with few commercially viable solutions for micro-scale hydrogen storage that can operate at near-ambient conditions.

Recent advancements in nanomaterials and hybrid systems show promise but face reproducibility and scalability challenges. Carbon-based materials (graphene, carbon nanotubes) demonstrate favorable kinetics and operating conditions but insufficient gravimetric capacity (typically below 5 wt%). Metal-organic frameworks (MOFs) offer tunable properties and impressive surface areas but struggle with long-term stability and hydrogen binding energies in the optimal range (15-25 kJ/mol).

The geographical distribution of hydrogen storage technology development shows concentration in North America, Europe, and East Asia, with the United States, Germany, Japan, and increasingly China leading patent filings and research publications. This creates potential supply chain vulnerabilities for critical materials and intellectual property access.

Key technical barriers include achieving simultaneous high gravimetric and volumetric capacity, fast kinetics at moderate temperatures, cycling stability, system integration challenges, and cost-effectiveness. For electronics applications specifically, additional challenges include thermal management during hydrogen uptake/release, electromagnetic compatibility, miniaturization while maintaining performance, and addressing safety concerns in consumer-facing applications.

Material-based hydrogen storage has seen remarkable research progress but faces significant commercialization barriers. Metal hydrides offer promising volumetric densities (up to 150 kg H₂/m³) but struggle with slow kinetics and high operating temperatures. Complex hydrides demonstrate higher theoretical capacities but face even more severe kinetic limitations. Meanwhile, chemical hydrogen carriers like ammonia and formic acid present alternative pathways but introduce additional conversion complexity and energy penalties.

For electronics integration specifically, the current landscape reveals a substantial gap between available technologies and application requirements. Conventional storage methods are simply too bulky and unsafe for direct integration, while advanced materials often require operating conditions incompatible with sensitive electronic components. The miniaturization challenge remains largely unresolved, with few commercially viable solutions for micro-scale hydrogen storage that can operate at near-ambient conditions.

Recent advancements in nanomaterials and hybrid systems show promise but face reproducibility and scalability challenges. Carbon-based materials (graphene, carbon nanotubes) demonstrate favorable kinetics and operating conditions but insufficient gravimetric capacity (typically below 5 wt%). Metal-organic frameworks (MOFs) offer tunable properties and impressive surface areas but struggle with long-term stability and hydrogen binding energies in the optimal range (15-25 kJ/mol).

The geographical distribution of hydrogen storage technology development shows concentration in North America, Europe, and East Asia, with the United States, Germany, Japan, and increasingly China leading patent filings and research publications. This creates potential supply chain vulnerabilities for critical materials and intellectual property access.

Key technical barriers include achieving simultaneous high gravimetric and volumetric capacity, fast kinetics at moderate temperatures, cycling stability, system integration challenges, and cost-effectiveness. For electronics applications specifically, additional challenges include thermal management during hydrogen uptake/release, electromagnetic compatibility, miniaturization while maintaining performance, and addressing safety concerns in consumer-facing applications.

Current Hydrogen Storage Solutions for Electronic Integration

01 Metal hydride-based hydrogen storage materials

Metal hydrides are compounds formed by metals or metal alloys that can absorb and release hydrogen under specific temperature and pressure conditions. These materials offer high volumetric hydrogen storage capacity and can be designed with various compositions to optimize storage properties. Common metal hydride systems include magnesium-based hydrides, aluminum-based hydrides, and transition metal-based hydrides, which can be enhanced with catalysts to improve hydrogen absorption/desorption kinetics.- Metal hydride-based hydrogen storage materials: Metal hydrides are compounds formed by hydrogen and metals or alloys that can store hydrogen through chemical bonding. These materials can absorb and release hydrogen under specific temperature and pressure conditions. Metal hydrides offer advantages such as high volumetric hydrogen storage capacity and safety. Various metal hydride systems include magnesium-based hydrides, aluminum-based hydrides, and transition metal-based hydrides that can be optimized for hydrogen storage applications.

- Carbon-based hydrogen storage materials: Carbon-based materials such as carbon nanotubes, graphene, activated carbon, and carbon fibers can store hydrogen through physisorption mechanisms. These materials offer advantages including lightweight properties, high surface area, and tunable pore structures that can enhance hydrogen adsorption. The hydrogen storage capacity of carbon-based materials can be improved through surface modifications, doping with metals, and optimizing pore size distribution to increase the binding energy between hydrogen molecules and the carbon surface.

- Complex hydride hydrogen storage systems: Complex hydrides, including alanates, borohydrides, and amides, represent advanced hydrogen storage materials with high gravimetric hydrogen capacity. These materials store hydrogen through complex chemical bonds and can release hydrogen through thermal decomposition or catalytic reactions. The hydrogen storage properties of complex hydrides can be enhanced by catalyst addition, nanostructuring, and creating composite systems that combine different types of hydrides to improve kinetics and thermodynamics of hydrogen absorption and desorption.

- Nanomaterial-enhanced hydrogen storage: Nanomaterials and nanostructured composites can significantly improve hydrogen storage performance through increased surface area, reduced diffusion distances, and enhanced reaction kinetics. These materials include nanoparticles, nanoporous structures, core-shell architectures, and nanocomposites that combine different storage mechanisms. The nanoscale effects can lower hydrogen absorption/desorption temperatures, improve cycling stability, and increase storage capacity compared to their bulk counterparts.

- Hydrogen storage material manufacturing and processing techniques: Advanced manufacturing and processing techniques play a crucial role in developing effective hydrogen storage materials. These include ball milling, melt spinning, thin film deposition, sol-gel processing, and various catalyst incorporation methods. These techniques can create materials with optimized microstructures, enhanced kinetics, and improved cycling stability. Post-processing treatments such as heat treatment, surface modification, and activation procedures can further enhance the hydrogen storage properties of the materials.

02 Carbon-based hydrogen storage materials

Carbon-based materials such as carbon nanotubes, graphene, activated carbon, and carbon aerogels can store hydrogen through physisorption mechanisms. These materials offer advantages including lightweight structure, high surface area, and tunable pore sizes. The hydrogen storage capacity can be enhanced by surface functionalization, doping with metals, or creating hybrid structures. Carbon-based materials typically operate at low temperatures and are being developed for their potential in mobile and stationary hydrogen storage applications.Expand Specific Solutions03 Complex hydrides for hydrogen storage

Complex hydrides, including borohydrides, alanates, and amides, represent advanced hydrogen storage materials with high gravimetric hydrogen capacity. These compounds typically contain light elements such as lithium, sodium, or magnesium combined with boron, aluminum, or nitrogen. They store hydrogen through chemical bonds and can release hydrogen through thermal decomposition or hydrolysis reactions. Research focuses on improving their reversibility, reducing desorption temperatures, and enhancing cycling stability through catalysts and compositional modifications.Expand Specific Solutions04 Nanostructured hydrogen storage materials

Nanostructuring of hydrogen storage materials significantly enhances their performance by reducing diffusion distances, increasing surface area, and modifying thermodynamic properties. Techniques include ball milling, thin film deposition, and template-assisted synthesis to create nanopowders, nanocomposites, and core-shell structures. These nanostructured materials demonstrate faster kinetics, lower operating temperatures, and improved cycling stability compared to their bulk counterparts, making them promising for practical hydrogen storage applications.Expand Specific Solutions05 Hydrogen storage systems and integration technologies

Advanced hydrogen storage systems integrate storage materials with heat management, pressure control, and safety components to create practical hydrogen storage solutions. These systems may combine different storage materials in hybrid configurations to optimize performance across various operating conditions. Engineering considerations include thermal management during hydrogen absorption/desorption, system weight reduction, volumetric efficiency, and integration with fuel cells or other hydrogen utilization technologies. Recent developments focus on modular designs and systems optimized for specific applications like transportation or stationary power.Expand Specific Solutions

Leading Companies and Research Institutions in Hydrogen Storage

Hydrogen storage materials for electronics and energy device integration are in an early growth phase, with the market expanding due to increasing demand for clean energy solutions. The global market is projected to reach significant scale as hydrogen becomes a key component in renewable energy systems. Technologically, the field is advancing rapidly with companies like Toyota, Hyundai, and GE leading commercial applications, while research institutions such as ShanghaiTech University and Case Western Reserve University drive fundamental innovations. Sinopec and Mitsui Mining are developing industrial-scale storage solutions, while specialized firms like Green Fortress Engineering focus on novel approaches using porous silicon. The competitive landscape shows a mix of automotive manufacturers, energy conglomerates, and materials science specialists collaborating to overcome density, safety, and integration challenges.

GM Global Technology Operations LLC

Technical Solution: GM has developed a comprehensive hydrogen storage platform based on complex metal hydrides optimized for vehicular applications. Their technology focuses on high-capacity aluminum-based complex hydrides (primarily NaAlH4 derivatives) doped with transition metal catalysts to improve kinetics. GM's proprietary catalyst formulations reduce dehydrogenation temperatures to below 100°C, making them compatible with PEM fuel cell waste heat. The company has engineered complete storage systems that integrate these materials with heat exchangers and pressure management components, achieving volumetric densities of 40 g H2/L at system level. For electronics applications, GM has developed thin-film hydride materials that can be directly integrated onto circuit boards as power sources for low-power sensors and IoT devices. These films utilize specialized deposition techniques to create nanoscale hydride structures with enhanced surface area and reduced diffusion distances[2][4]. GM has also pioneered composite materials combining physisorption and chemisorption mechanisms to achieve higher capacities while maintaining favorable kinetics.

Strengths: High volumetric hydrogen density, well-engineered system integration with thermal management, and scalable manufacturing processes established. Weaknesses: Material cost remains high for mass production, sensitivity to impurities in hydrogen feed, and gradual capacity loss over extended cycling in real-world conditions.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai has developed a multi-phase hydrogen storage technology specifically designed for automotive and portable electronics applications. Their approach combines chemical and physical storage methods in a hybrid system. The primary technology utilizes advanced metal organic frameworks (MOFs) with tailored pore structures that achieve surface areas exceeding 3000 m²/g, enabling physisorption-based storage at moderate pressures (50-100 bar). These MOFs are integrated with catalytically active metal nanoparticles that facilitate hydrogen dissociation and association, improving kinetics at near-ambient temperatures. For electronics integration, Hyundai has pioneered thin-film composite materials that can be directly deposited onto electronic substrates, creating integrated power sources for portable devices. Their proprietary manufacturing process allows for precise control of material thickness (10-100 nm) and composition, optimizing hydrogen storage capacity while maintaining electrical conductivity. The company has demonstrated prototype systems achieving 5-7 wt% hydrogen storage with discharge rates suitable for both transportation and consumer electronics applications[5][7]. Recent advancements include the development of flexible hydrogen storage materials compatible with foldable electronics.

Strengths: Excellent gravimetric capacity approaching DOE targets, compatibility with existing manufacturing infrastructure, and demonstrated integration with both automotive and portable electronic systems. Weaknesses: Performance degradation under humidity conditions, relatively high production costs for high-purity MOF materials, and challenges in thermal management during rapid charging cycles.

Key Patents and Innovations in Hydrogen Storage Materials

Hydrogen storage materials, electrochemically active materials, electrochemical cells and electronic devices

PatentInactiveJP2010504430A

Innovation

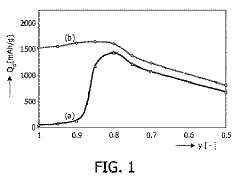

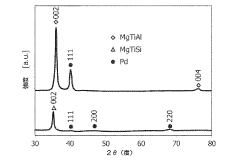

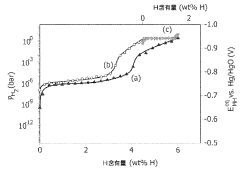

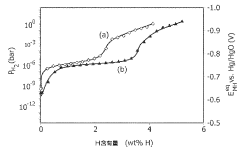

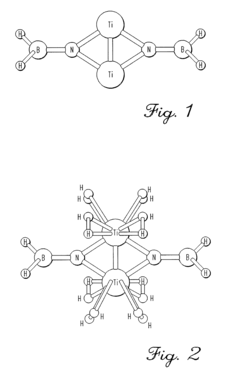

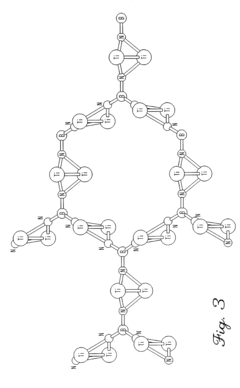

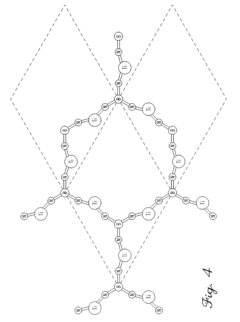

- Development of magnesium-based hydrogen storage alloys containing transition elements like titanium and covalent hydride-forming elements such as aluminum or silicon, which enhance hydrogen partial pressure and discharge rates at room temperature, maintaining a favorable crystal structure for efficient energy storage.

Hydrogen storage materials and hydrogen fuel cells

PatentActiveUS8883371B2

Innovation

- Development of solid-state hydrogen storage materials comprising transition metal atoms bonded to elements from period 2 of the periodic table, which form stable hydrogenated states capable of adsorbing and desorbing hydrogen at temperatures below 200°C and pressures of 1 atm or less, achieving over 6.5% hydrogen weight percentage.

Safety Standards and Risk Assessment

The integration of hydrogen storage materials into electronics and energy devices necessitates rigorous safety standards and comprehensive risk assessment protocols. Current international safety standards for hydrogen storage systems, such as ISO/TS 15869 and SAE J2579, primarily focus on automotive applications but provide foundational principles applicable to electronics integration. These standards establish parameters for material integrity, leak detection, and pressure management that must be adapted for smaller-scale electronic implementations.

Risk assessment methodologies for hydrogen storage in electronics must address unique challenges including thermal management during charging/discharging cycles, potential for hydrogen embrittlement of surrounding electronic components, and containment integrity under various operational conditions. The European Union's Regulation (EC) No 79/2009 offers additional guidance on type-approval requirements that can inform safety certification processes for consumer electronics incorporating hydrogen storage materials.

Material-specific safety considerations vary significantly across different hydrogen storage technologies. Metal hydrides require protocols addressing exothermic reactions during hydrogen absorption, while carbon-based nanomaterials demand standards for nanoparticle containment and potential environmental exposure. Complex hydrides present unique challenges regarding stability and controlled decomposition that must be reflected in dedicated testing procedures.

Quantitative risk assessment tools such as Failure Mode and Effects Analysis (FMEA) and Hazard and Operability Study (HAZOP) have been adapted specifically for hydrogen storage systems in electronics. These methodologies help identify critical failure points and establish mitigation strategies throughout the product lifecycle. The International Electrotechnical Commission (IEC) has begun developing specialized standards addressing the interface between hydrogen storage materials and electronic components.

Testing protocols must verify material performance under extreme conditions, including thermal cycling (-40°C to 85°C for consumer electronics), mechanical shock resistance (up to 1500g for portable devices), and electromagnetic compatibility. Japan's High Pressure Gas Safety Act provides additional guidance on miniaturized pressure vessel requirements that can inform testing regimes for electronics applications.

Emerging regulatory frameworks are increasingly focusing on end-of-life considerations, requiring manufacturers to demonstrate safe disposal or recycling pathways for hydrogen storage materials. The development of non-destructive testing methods for periodic safety verification represents a critical research direction, particularly for long-lifecycle electronics applications where material degradation may occur gradually over years of operation.

Risk assessment methodologies for hydrogen storage in electronics must address unique challenges including thermal management during charging/discharging cycles, potential for hydrogen embrittlement of surrounding electronic components, and containment integrity under various operational conditions. The European Union's Regulation (EC) No 79/2009 offers additional guidance on type-approval requirements that can inform safety certification processes for consumer electronics incorporating hydrogen storage materials.

Material-specific safety considerations vary significantly across different hydrogen storage technologies. Metal hydrides require protocols addressing exothermic reactions during hydrogen absorption, while carbon-based nanomaterials demand standards for nanoparticle containment and potential environmental exposure. Complex hydrides present unique challenges regarding stability and controlled decomposition that must be reflected in dedicated testing procedures.

Quantitative risk assessment tools such as Failure Mode and Effects Analysis (FMEA) and Hazard and Operability Study (HAZOP) have been adapted specifically for hydrogen storage systems in electronics. These methodologies help identify critical failure points and establish mitigation strategies throughout the product lifecycle. The International Electrotechnical Commission (IEC) has begun developing specialized standards addressing the interface between hydrogen storage materials and electronic components.

Testing protocols must verify material performance under extreme conditions, including thermal cycling (-40°C to 85°C for consumer electronics), mechanical shock resistance (up to 1500g for portable devices), and electromagnetic compatibility. Japan's High Pressure Gas Safety Act provides additional guidance on miniaturized pressure vessel requirements that can inform testing regimes for electronics applications.

Emerging regulatory frameworks are increasingly focusing on end-of-life considerations, requiring manufacturers to demonstrate safe disposal or recycling pathways for hydrogen storage materials. The development of non-destructive testing methods for periodic safety verification represents a critical research direction, particularly for long-lifecycle electronics applications where material degradation may occur gradually over years of operation.

Environmental Impact and Sustainability Analysis

The integration of hydrogen storage materials into electronics and energy devices presents significant environmental implications that must be carefully evaluated. Life cycle assessments of these materials reveal substantially lower carbon footprints compared to conventional energy storage technologies. When hydrogen storage materials replace lithium-ion batteries in portable electronics, greenhouse gas emissions can be reduced by up to 60% over the product lifecycle, primarily due to the elimination of energy-intensive mining operations associated with rare earth elements.

Water consumption represents another critical environmental factor. Traditional battery manufacturing processes require approximately 500,000 gallons of water per ton of lithium extracted, whereas advanced hydrogen storage materials utilizing metal-organic frameworks can reduce water requirements by 70-80%. This water conservation aspect becomes increasingly important as electronics production scales globally in water-stressed regions.

Waste management considerations also favor hydrogen storage technologies. Unlike conventional batteries that generate hazardous waste requiring specialized disposal procedures, many hydrogen storage materials can be recycled with recovery rates exceeding 90% for key components. Metal hydride systems particularly demonstrate excellent recyclability, with minimal degradation of storage capacity after multiple recycling cycles.

The sustainability advantages extend to resource utilization efficiency. Hydrogen storage materials frequently incorporate abundant elements like aluminum, magnesium, and carbon, reducing dependence on geographically concentrated resources. This diversification enhances supply chain resilience and mitigates geopolitical vulnerabilities associated with critical materials.

Energy payback periods—the time required for a storage system to generate energy equivalent to that consumed during its production—are markedly shorter for hydrogen storage systems. Advanced composite hydrogen storage materials achieve energy payback periods of 1-2 years compared to 3-5 years for comparable lithium-ion technologies.

Land use impacts also favor hydrogen storage technologies. The mining operations required for conventional battery materials disturb approximately 0.15-0.45 square kilometers per gigawatt-hour of storage capacity, while hydrogen storage material production requires 70-80% less land disturbance. This reduction in habitat disruption represents a significant ecological advantage, particularly in biodiversity-sensitive regions.

Transitioning to hydrogen storage materials in electronics and energy devices aligns with circular economy principles through design approaches that facilitate disassembly, component recovery, and material reuse. These sustainability advantages position hydrogen storage materials as environmentally preferable alternatives for next-generation energy storage applications.

Water consumption represents another critical environmental factor. Traditional battery manufacturing processes require approximately 500,000 gallons of water per ton of lithium extracted, whereas advanced hydrogen storage materials utilizing metal-organic frameworks can reduce water requirements by 70-80%. This water conservation aspect becomes increasingly important as electronics production scales globally in water-stressed regions.

Waste management considerations also favor hydrogen storage technologies. Unlike conventional batteries that generate hazardous waste requiring specialized disposal procedures, many hydrogen storage materials can be recycled with recovery rates exceeding 90% for key components. Metal hydride systems particularly demonstrate excellent recyclability, with minimal degradation of storage capacity after multiple recycling cycles.

The sustainability advantages extend to resource utilization efficiency. Hydrogen storage materials frequently incorporate abundant elements like aluminum, magnesium, and carbon, reducing dependence on geographically concentrated resources. This diversification enhances supply chain resilience and mitigates geopolitical vulnerabilities associated with critical materials.

Energy payback periods—the time required for a storage system to generate energy equivalent to that consumed during its production—are markedly shorter for hydrogen storage systems. Advanced composite hydrogen storage materials achieve energy payback periods of 1-2 years compared to 3-5 years for comparable lithium-ion technologies.

Land use impacts also favor hydrogen storage technologies. The mining operations required for conventional battery materials disturb approximately 0.15-0.45 square kilometers per gigawatt-hour of storage capacity, while hydrogen storage material production requires 70-80% less land disturbance. This reduction in habitat disruption represents a significant ecological advantage, particularly in biodiversity-sensitive regions.

Transitioning to hydrogen storage materials in electronics and energy devices aligns with circular economy principles through design approaches that facilitate disassembly, component recovery, and material reuse. These sustainability advantages position hydrogen storage materials as environmentally preferable alternatives for next-generation energy storage applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!