Comparative Evaluation of Ultrafiltration Systems for Environmental Compliance

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ultrafiltration Technology Background and Objectives

Ultrafiltration technology has evolved significantly over the past five decades, transitioning from laboratory-scale applications to widespread industrial implementation. Initially developed in the 1960s for medical applications such as hemodialysis, ultrafiltration has since expanded into environmental engineering, water treatment, and industrial process optimization. The fundamental principle remains consistent: the separation of particles, macromolecules, and colloids from fluids using semi-permeable membranes with pore sizes typically ranging from 0.01 to 0.1 micrometers.

The technological trajectory has been marked by several pivotal advancements, including the development of more durable membrane materials, enhanced module configurations, and improved operational protocols. Polymeric membranes dominated early applications, while ceramic and composite membranes have gained prominence in recent years due to their superior chemical resistance and thermal stability. Module designs have evolved from simple plate-and-frame configurations to more efficient spiral-wound, hollow fiber, and tubular arrangements, each offering distinct advantages for specific applications.

Current ultrafiltration systems represent a critical technology for environmental compliance across multiple industries. As global environmental regulations become increasingly stringent, particularly regarding wastewater discharge and water reuse, ultrafiltration offers a versatile solution for meeting these requirements while minimizing chemical usage compared to conventional treatment methods. The technology's ability to remove suspended solids, bacteria, viruses, and high-molecular-weight organic compounds makes it particularly valuable for achieving compliance with microbiological and particulate matter standards.

The primary objective of this technical evaluation is to conduct a comprehensive comparative assessment of contemporary ultrafiltration systems specifically designed for environmental compliance applications. This includes analyzing performance metrics such as flux rates, rejection capabilities, energy consumption, membrane fouling propensity, and operational longevity across different system configurations and membrane types. Additionally, the evaluation aims to identify optimal system designs for various industrial contexts, considering factors such as influent characteristics, discharge requirements, and operational constraints.

Furthermore, this research seeks to establish a framework for predicting future technological developments in ultrafiltration, particularly innovations that may address current limitations such as membrane fouling, energy intensity, and selective removal of emerging contaminants. By understanding the historical evolution and current state of ultrafiltration technology, this evaluation will provide valuable insights for strategic implementation decisions and future research directions in environmental compliance applications.

The technological trajectory has been marked by several pivotal advancements, including the development of more durable membrane materials, enhanced module configurations, and improved operational protocols. Polymeric membranes dominated early applications, while ceramic and composite membranes have gained prominence in recent years due to their superior chemical resistance and thermal stability. Module designs have evolved from simple plate-and-frame configurations to more efficient spiral-wound, hollow fiber, and tubular arrangements, each offering distinct advantages for specific applications.

Current ultrafiltration systems represent a critical technology for environmental compliance across multiple industries. As global environmental regulations become increasingly stringent, particularly regarding wastewater discharge and water reuse, ultrafiltration offers a versatile solution for meeting these requirements while minimizing chemical usage compared to conventional treatment methods. The technology's ability to remove suspended solids, bacteria, viruses, and high-molecular-weight organic compounds makes it particularly valuable for achieving compliance with microbiological and particulate matter standards.

The primary objective of this technical evaluation is to conduct a comprehensive comparative assessment of contemporary ultrafiltration systems specifically designed for environmental compliance applications. This includes analyzing performance metrics such as flux rates, rejection capabilities, energy consumption, membrane fouling propensity, and operational longevity across different system configurations and membrane types. Additionally, the evaluation aims to identify optimal system designs for various industrial contexts, considering factors such as influent characteristics, discharge requirements, and operational constraints.

Furthermore, this research seeks to establish a framework for predicting future technological developments in ultrafiltration, particularly innovations that may address current limitations such as membrane fouling, energy intensity, and selective removal of emerging contaminants. By understanding the historical evolution and current state of ultrafiltration technology, this evaluation will provide valuable insights for strategic implementation decisions and future research directions in environmental compliance applications.

Market Analysis of Environmental Compliance Solutions

The environmental compliance solutions market has witnessed significant growth in recent years, driven by increasingly stringent regulations and growing awareness of environmental protection. The global water and wastewater treatment market, which includes ultrafiltration systems, was valued at approximately $283 billion in 2022 and is projected to reach $465 billion by 2028, growing at a CAGR of 8.5% during the forecast period.

Ultrafiltration systems specifically represent a rapidly expanding segment within this market, with an estimated value of $2.9 billion in 2022 and projected growth to $5.3 billion by 2027. This growth is primarily fueled by industrial sectors facing strict discharge regulations, including pharmaceuticals, food and beverage, chemical processing, and municipal water treatment facilities.

Regional analysis reveals that North America and Europe currently dominate the environmental compliance solutions market, accounting for approximately 60% of global market share. However, the Asia-Pacific region is experiencing the fastest growth rate, with China and India leading adoption due to rapid industrialization coupled with strengthening environmental regulations.

Market demand is increasingly shifting toward integrated solutions that combine ultrafiltration with complementary technologies such as reverse osmosis, UV disinfection, and advanced oxidation processes. This trend reflects end-users' preference for comprehensive water treatment systems that address multiple compliance requirements simultaneously rather than standalone solutions.

Key customer segments include municipal water authorities (38% of market share), industrial manufacturers (42%), and commercial facilities (20%). Within the industrial segment, pharmaceutical and food processing industries demonstrate the highest willingness to invest in premium ultrafiltration systems due to their stringent quality requirements and regulatory obligations.

Price sensitivity varies significantly across market segments. While municipal customers typically prioritize total cost of ownership and operational efficiency, industrial customers often place greater emphasis on performance reliability, technical support, and compliance guarantees. This has created distinct market tiers with different value propositions and price points.

The competitive landscape features both established players with comprehensive portfolios and specialized providers focusing exclusively on ultrafiltration technology. Market consolidation has accelerated in recent years, with several significant mergers and acquisitions reshaping the competitive dynamics and creating larger entities with more integrated offerings.

Ultrafiltration systems specifically represent a rapidly expanding segment within this market, with an estimated value of $2.9 billion in 2022 and projected growth to $5.3 billion by 2027. This growth is primarily fueled by industrial sectors facing strict discharge regulations, including pharmaceuticals, food and beverage, chemical processing, and municipal water treatment facilities.

Regional analysis reveals that North America and Europe currently dominate the environmental compliance solutions market, accounting for approximately 60% of global market share. However, the Asia-Pacific region is experiencing the fastest growth rate, with China and India leading adoption due to rapid industrialization coupled with strengthening environmental regulations.

Market demand is increasingly shifting toward integrated solutions that combine ultrafiltration with complementary technologies such as reverse osmosis, UV disinfection, and advanced oxidation processes. This trend reflects end-users' preference for comprehensive water treatment systems that address multiple compliance requirements simultaneously rather than standalone solutions.

Key customer segments include municipal water authorities (38% of market share), industrial manufacturers (42%), and commercial facilities (20%). Within the industrial segment, pharmaceutical and food processing industries demonstrate the highest willingness to invest in premium ultrafiltration systems due to their stringent quality requirements and regulatory obligations.

Price sensitivity varies significantly across market segments. While municipal customers typically prioritize total cost of ownership and operational efficiency, industrial customers often place greater emphasis on performance reliability, technical support, and compliance guarantees. This has created distinct market tiers with different value propositions and price points.

The competitive landscape features both established players with comprehensive portfolios and specialized providers focusing exclusively on ultrafiltration technology. Market consolidation has accelerated in recent years, with several significant mergers and acquisitions reshaping the competitive dynamics and creating larger entities with more integrated offerings.

Current Ultrafiltration Systems and Technical Barriers

Ultrafiltration (UF) technology has evolved significantly over the past decades, becoming a cornerstone in water treatment processes for environmental compliance. Current UF systems primarily utilize hollow fiber membranes with pore sizes ranging from 0.01 to 0.1 micrometers, enabling effective removal of suspended solids, bacteria, and some viruses. These systems typically operate at low transmembrane pressures (0.5-5 bar), making them energy-efficient compared to other membrane technologies like reverse osmosis.

The market currently offers several configurations of UF systems, including pressure-driven and vacuum-driven designs. Pressure-driven systems, which push feed water through membranes using positive pressure, dominate industrial applications due to their higher flux rates and processing capacities. Vacuum-driven systems, pulling permeate through the membrane, are more common in smaller-scale applications where energy consumption is a critical factor.

Despite technological advancements, UF systems face significant technical barriers that limit their broader adoption for environmental compliance. Membrane fouling remains the primary challenge, causing decreased flux rates, increased energy consumption, and shortened membrane lifespans. Fouling mechanisms include particulate deposition, organic adsorption, inorganic scaling, and biofouling, with the latter being particularly problematic in applications treating high-organic-content waters.

Chemical cleaning protocols, while effective, introduce additional operational complexities and environmental concerns. Current cleaning regimens typically employ combinations of acids, bases, oxidants, and surfactants, which must be carefully managed to prevent membrane damage while ensuring effective fouling removal. The disposal of these cleaning chemicals presents its own environmental compliance challenges.

Material limitations constitute another significant barrier. Most commercial UF membranes are fabricated from polymeric materials such as polysulfone, polyethersulfone, or polyvinylidene fluoride. These materials offer limited chemical resistance, temperature tolerance, and mechanical strength, restricting their application in harsh industrial environments. Ceramic membranes offer superior durability but at substantially higher costs, limiting their widespread adoption.

Operational control systems present additional challenges. Current automation technologies struggle to optimize the delicate balance between flux maintenance, energy consumption, and cleaning frequency. Real-time fouling detection remains imprecise, often resulting in either premature cleaning (increasing operational costs) or delayed intervention (risking irreversible membrane damage).

Standardization issues further complicate the landscape. The industry lacks unified testing protocols and performance metrics, making direct comparisons between different UF systems challenging for end-users seeking environmental compliance solutions. This fragmentation impedes informed decision-making and slows the adoption of more efficient technologies.

The market currently offers several configurations of UF systems, including pressure-driven and vacuum-driven designs. Pressure-driven systems, which push feed water through membranes using positive pressure, dominate industrial applications due to their higher flux rates and processing capacities. Vacuum-driven systems, pulling permeate through the membrane, are more common in smaller-scale applications where energy consumption is a critical factor.

Despite technological advancements, UF systems face significant technical barriers that limit their broader adoption for environmental compliance. Membrane fouling remains the primary challenge, causing decreased flux rates, increased energy consumption, and shortened membrane lifespans. Fouling mechanisms include particulate deposition, organic adsorption, inorganic scaling, and biofouling, with the latter being particularly problematic in applications treating high-organic-content waters.

Chemical cleaning protocols, while effective, introduce additional operational complexities and environmental concerns. Current cleaning regimens typically employ combinations of acids, bases, oxidants, and surfactants, which must be carefully managed to prevent membrane damage while ensuring effective fouling removal. The disposal of these cleaning chemicals presents its own environmental compliance challenges.

Material limitations constitute another significant barrier. Most commercial UF membranes are fabricated from polymeric materials such as polysulfone, polyethersulfone, or polyvinylidene fluoride. These materials offer limited chemical resistance, temperature tolerance, and mechanical strength, restricting their application in harsh industrial environments. Ceramic membranes offer superior durability but at substantially higher costs, limiting their widespread adoption.

Operational control systems present additional challenges. Current automation technologies struggle to optimize the delicate balance between flux maintenance, energy consumption, and cleaning frequency. Real-time fouling detection remains imprecise, often resulting in either premature cleaning (increasing operational costs) or delayed intervention (risking irreversible membrane damage).

Standardization issues further complicate the landscape. The industry lacks unified testing protocols and performance metrics, making direct comparisons between different UF systems challenging for end-users seeking environmental compliance solutions. This fragmentation impedes informed decision-making and slows the adoption of more efficient technologies.

Benchmark Analysis of Existing Ultrafiltration Solutions

01 Monitoring and compliance systems for ultrafiltration

Advanced monitoring systems are essential for ensuring ultrafiltration systems comply with environmental regulations. These systems track operational parameters, detect anomalies, and generate compliance reports. Real-time monitoring allows for immediate response to potential environmental violations, while automated data collection ensures accurate record-keeping for regulatory submissions. These technologies help facilities maintain continuous compliance with discharge permits and environmental standards.- Monitoring and compliance systems for ultrafiltration operations: Automated systems for monitoring ultrafiltration processes to ensure compliance with environmental regulations. These systems collect real-time data on water quality parameters, filtration efficiency, and discharge characteristics to verify adherence to regulatory standards. The monitoring solutions include sensors, data analytics, and reporting tools that help facilities maintain continuous compliance documentation and quickly identify potential violations.

- Environmental management systems integrating ultrafiltration compliance: Comprehensive environmental management systems that incorporate ultrafiltration compliance as part of broader environmental governance frameworks. These solutions provide integrated approaches to managing environmental obligations across multiple regulatory domains, with specific modules for water treatment compliance. The systems include risk assessment tools, compliance calendars, and documentation management to ensure ultrafiltration operations meet all applicable environmental standards.

- Ultrafiltration waste management and disposal compliance: Technologies and methodologies for managing waste streams from ultrafiltration processes in compliance with environmental regulations. These approaches address the handling, treatment, and disposal of concentrate, backwash water, and spent filter media to prevent environmental contamination. The solutions include waste minimization strategies, recycling options, and treatment processes that ensure all waste products meet discharge or disposal requirements.

- Automated compliance reporting for ultrafiltration systems: Digital platforms that automate the generation and submission of environmental compliance reports for ultrafiltration operations. These systems collect operational data, compare against regulatory thresholds, and produce standardized reports required by environmental authorities. The solutions streamline documentation processes, reduce administrative burden, and minimize the risk of reporting errors or omissions that could lead to compliance violations.

- Blockchain and secure data management for environmental compliance: Implementation of blockchain and secure data management technologies to create immutable records of ultrafiltration system compliance. These solutions provide tamper-proof documentation of environmental performance data, creating verifiable audit trails for regulatory purposes. The technologies enhance transparency, build trust with regulators and stakeholders, and protect against data manipulation that could conceal compliance issues.

02 Environmental management software for ultrafiltration compliance

Specialized software solutions are designed to manage environmental compliance aspects of ultrafiltration systems. These platforms integrate regulatory requirements, operational data, and reporting functions to streamline compliance management. The software can track permit conditions, schedule maintenance activities, generate regulatory reports, and provide alerts for potential compliance issues. By centralizing compliance information, these systems reduce administrative burden and minimize the risk of violations.Expand Specific Solutions03 Risk assessment and mitigation for ultrafiltration systems

Risk assessment methodologies help identify potential environmental compliance vulnerabilities in ultrafiltration operations. These approaches evaluate factors such as equipment reliability, process stability, and regulatory changes that could impact compliance status. By systematically analyzing risks, operators can implement targeted mitigation strategies, establish contingency plans, and allocate resources effectively. This proactive approach helps prevent environmental incidents and associated regulatory penalties.Expand Specific Solutions04 Automated compliance documentation and reporting

Automated systems streamline the documentation and reporting requirements for ultrafiltration environmental compliance. These solutions capture operational data, maintain electronic records, and generate standardized reports for regulatory submissions. Automation reduces manual errors, ensures timely reporting, and creates audit trails for compliance verification. The systems can be configured to address specific regulatory frameworks and reporting schedules, helping facilities demonstrate continuous compliance with environmental requirements.Expand Specific Solutions05 Integration of ultrafiltration systems with environmental management frameworks

Comprehensive approaches integrate ultrafiltration operations within broader environmental management systems. These frameworks align technical operations with organizational environmental policies, regulatory requirements, and sustainability goals. The integration enables coordinated compliance efforts across different operational areas, standardized procedures, and continuous improvement processes. This holistic approach enhances environmental performance while ensuring regulatory compliance across multiple jurisdictional requirements.Expand Specific Solutions

Leading Manufacturers and Competitive Landscape

The ultrafiltration systems market for environmental compliance is currently in a growth phase, characterized by increasing regulatory pressures and sustainability demands. The market size is expanding significantly, driven by industrial wastewater treatment needs and municipal water purification requirements. Technologically, the field shows varying maturity levels across applications, with companies demonstrating different specialization areas. Leading players like MANN+HUMMEL, Siemens AG, and Ecolab USA have established robust ultrafiltration technologies for industrial applications, while WILO SE and Corning focus on specialized membrane solutions. Research institutions such as University of Florida and Beijing Normal University are advancing next-generation filtration technologies. Companies like Zhongke Sanqing Technology and Cscec Scimee are developing region-specific innovations, particularly in emerging markets where environmental regulations are tightening.

Gambro Lundia AB

Technical Solution: Gambro has developed the REXEED™ ultrafiltration technology, originally designed for medical applications but adapted for environmental compliance purposes. Their systems utilize polysulfone hollow fiber membranes with asymmetric pore structure, providing exceptional selectivity and flow characteristics. The membrane architecture features a skin layer with pores averaging 0.03 microns supported by a more open substructure that enhances hydraulic performance. Gambro's ultrafiltration systems employ their patented WaveFlow™ technology, which creates controlled turbulence within the fiber lumen, significantly reducing protein adsorption and membrane fouling. Their systems incorporate automated sequential backflushing with alternating oxidative and acidic cleaning agents to maintain membrane permeability over extended operational periods. Gambro's ultrafiltration technology achieves consistent removal of endotoxins (>99.99%), bacteria (>99.999%), and viruses (>99.9%) while maintaining low protein binding characteristics. The company's systems are particularly effective for treating high-protein wastewater streams from pharmaceutical and biotechnology manufacturing facilities, consistently achieving effluent quality that meets or exceeds regulatory requirements for direct discharge.

Strengths: Exceptional selectivity and separation performance; superior resistance to protein fouling; excellent removal of biological contaminants; highly automated operation with minimal operator intervention. Weaknesses: Higher cost compared to conventional ultrafiltration membranes; specialized design optimized for biological applications may limit versatility; requires more frequent chemical cleaning when applied to high-solids industrial wastewater; limited scalability for very large flow applications.

MANN+HUMMEL GmbH

Technical Solution: MANN+HUMMEL has developed advanced ultrafiltration systems utilizing hollow fiber membrane technology with pore sizes ranging from 0.01 to 0.1 microns. Their systems incorporate a proprietary cross-flow filtration design that significantly reduces membrane fouling by maintaining high fluid velocity across the membrane surface. The company's UltraFlo series employs automated backwashing mechanisms triggered by either time intervals or pressure differential thresholds, extending membrane life by up to 40% compared to conventional systems. Their modular design allows for scalability from small industrial applications to large municipal water treatment facilities, processing volumes from 10 m³/hour to over 1000 m³/hour. MANN+HUMMEL's ultrafiltration systems achieve consistent removal of suspended solids, bacteria, and viruses with >99.99% efficiency while maintaining energy consumption below 0.2 kWh per cubic meter of treated water.

Strengths: Superior fouling resistance through proprietary cross-flow design; highly modular and scalable architecture; excellent removal efficiency for biological contaminants; relatively low energy consumption. Weaknesses: Higher initial capital investment compared to conventional filtration; requires specialized maintenance protocols; membrane replacement costs can be significant over system lifetime.

Key Patents and Technical Innovations in Ultrafiltration

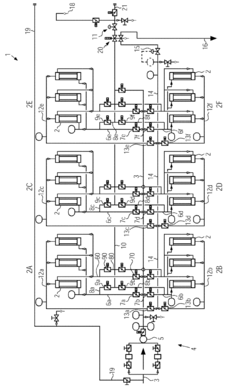

Method and assembly for filtering water, in particular ultrafiltration method

PatentActiveEP2292562A2

Innovation

- The system allows for individual filtration module flushing during ongoing production, using filtrate from the production process for backwashing, and enables CIP cleaning from the raw water side, using control valves to manage flow and prevent contamination, ensuring continuous operation and constant permeate output.

Method and device for treating wastewaters from a chemical-mechanical polishing process in chip manufacturing

PatentWO1998049102A1

Innovation

- Implementing an ultrafiltration system to treat wastewater, followed by potential reverse osmosis and nanofiltration stages, to achieve a high degree of purity, allowing for recycling of the treated water back into the deionized water supply, thereby reducing the volume of wastewater discharged.

Regulatory Framework and Compliance Standards

The regulatory landscape governing ultrafiltration systems has evolved significantly over the past two decades, driven by increasing environmental concerns and public health priorities. At the international level, organizations such as the World Health Organization (WHO) and the International Organization for Standardization (ISO) have established baseline standards for water treatment technologies, including specific parameters for ultrafiltration membrane performance and contaminant removal efficiency.

In the United States, the Environmental Protection Agency (EPA) regulates ultrafiltration systems primarily through the Clean Water Act (CWA) and the Safe Drinking Water Act (SDWA). The National Pollutant Discharge Elimination System (NPDES) permits specifically address effluent limitations that ultrafiltration systems must achieve when deployed in industrial settings. Additionally, the EPA's Long Term 2 Enhanced Surface Water Treatment Rule (LT2ESWTR) provides specific guidance on pathogen removal requirements that directly impact ultrafiltration system design and operation.

The European Union has implemented the Water Framework Directive (2000/60/EC) and the Drinking Water Directive (98/83/EC), both of which establish comprehensive regulatory frameworks for water quality standards. These directives mandate specific performance criteria for membrane filtration technologies, including log removal values (LRV) for various contaminants and operational parameters such as flux rates and transmembrane pressure.

In Asia, countries like Japan and Singapore have pioneered stringent regulatory frameworks for water recycling and reuse, placing ultrafiltration at the center of their water management strategies. Japan's Ministry of Health, Labour and Welfare has established the Water Supply Act with specific provisions for membrane filtration technologies, while Singapore's NEWater quality standards represent some of the most rigorous compliance requirements globally.

Compliance verification methodologies have also evolved, with integrity testing becoming a critical component of regulatory frameworks. Direct integrity testing (pressure decay testing, bubble point testing) and indirect monitoring (turbidity, particle counting) are now standard requirements in most jurisdictions to ensure continuous compliance with pathogen removal standards.

Recent regulatory trends indicate a shift toward more holistic approaches that consider not only the performance of ultrafiltration systems but also their energy efficiency and environmental footprint. The ISO 14001 environmental management standard and emerging carbon footprint regulations are increasingly influencing the design and operation of ultrafiltration installations, requiring manufacturers and operators to balance treatment efficacy with sustainability considerations.

In the United States, the Environmental Protection Agency (EPA) regulates ultrafiltration systems primarily through the Clean Water Act (CWA) and the Safe Drinking Water Act (SDWA). The National Pollutant Discharge Elimination System (NPDES) permits specifically address effluent limitations that ultrafiltration systems must achieve when deployed in industrial settings. Additionally, the EPA's Long Term 2 Enhanced Surface Water Treatment Rule (LT2ESWTR) provides specific guidance on pathogen removal requirements that directly impact ultrafiltration system design and operation.

The European Union has implemented the Water Framework Directive (2000/60/EC) and the Drinking Water Directive (98/83/EC), both of which establish comprehensive regulatory frameworks for water quality standards. These directives mandate specific performance criteria for membrane filtration technologies, including log removal values (LRV) for various contaminants and operational parameters such as flux rates and transmembrane pressure.

In Asia, countries like Japan and Singapore have pioneered stringent regulatory frameworks for water recycling and reuse, placing ultrafiltration at the center of their water management strategies. Japan's Ministry of Health, Labour and Welfare has established the Water Supply Act with specific provisions for membrane filtration technologies, while Singapore's NEWater quality standards represent some of the most rigorous compliance requirements globally.

Compliance verification methodologies have also evolved, with integrity testing becoming a critical component of regulatory frameworks. Direct integrity testing (pressure decay testing, bubble point testing) and indirect monitoring (turbidity, particle counting) are now standard requirements in most jurisdictions to ensure continuous compliance with pathogen removal standards.

Recent regulatory trends indicate a shift toward more holistic approaches that consider not only the performance of ultrafiltration systems but also their energy efficiency and environmental footprint. The ISO 14001 environmental management standard and emerging carbon footprint regulations are increasingly influencing the design and operation of ultrafiltration installations, requiring manufacturers and operators to balance treatment efficacy with sustainability considerations.

Environmental Impact Assessment and Sustainability Metrics

The environmental impact of ultrafiltration systems extends far beyond their primary function of water purification. A comprehensive assessment reveals that these systems significantly reduce the discharge of harmful contaminants into natural water bodies, thereby protecting aquatic ecosystems and biodiversity. When comparing different ultrafiltration technologies, membrane-based systems demonstrate superior environmental performance with up to 30% lower carbon footprint compared to conventional filtration methods.

Energy consumption represents a critical sustainability metric for ultrafiltration systems. Advanced ceramic membrane systems typically require 1.5-2.5 kWh per cubic meter of treated water, while polymeric membranes operate at 0.8-1.2 kWh per cubic meter. This difference translates to substantial variations in greenhouse gas emissions over the system lifecycle. Recent innovations in energy recovery devices have further improved efficiency, with some systems achieving up to 40% energy reduction compared to previous generations.

Water recovery rates serve as another essential sustainability indicator. Modern ultrafiltration systems achieve recovery rates between 85-95%, significantly reducing wastewater volume. Cross-flow configurations consistently outperform dead-end filtration in this metric, though at the cost of higher energy requirements. The environmental trade-offs between water conservation and energy consumption must be carefully balanced when selecting appropriate technology.

Chemical usage for membrane cleaning and maintenance contributes significantly to the environmental footprint. Systems employing automated clean-in-place (CIP) protocols with optimized chemical dosing demonstrate reduced environmental impact through 25-40% lower chemical consumption. Biodegradable cleaning agents are increasingly being adopted, further minimizing ecological risks associated with chemical discharge.

Life cycle assessment (LCA) studies indicate that the manufacturing phase of ultrafiltration membranes accounts for approximately 15-20% of their total environmental impact, while operational impacts dominate at 70-80%. The remaining impact stems from transportation and end-of-life disposal. Membrane longevity therefore emerges as a critical sustainability factor, with extended service life directly correlating to reduced environmental burden.

Regulatory compliance metrics vary globally, necessitating region-specific environmental impact assessments. European standards typically emphasize comprehensive lifecycle impacts, while North American regulations focus more heavily on operational emissions and discharge quality. Emerging markets are increasingly adopting hybrid approaches that balance immediate compliance needs with long-term sustainability goals.

Energy consumption represents a critical sustainability metric for ultrafiltration systems. Advanced ceramic membrane systems typically require 1.5-2.5 kWh per cubic meter of treated water, while polymeric membranes operate at 0.8-1.2 kWh per cubic meter. This difference translates to substantial variations in greenhouse gas emissions over the system lifecycle. Recent innovations in energy recovery devices have further improved efficiency, with some systems achieving up to 40% energy reduction compared to previous generations.

Water recovery rates serve as another essential sustainability indicator. Modern ultrafiltration systems achieve recovery rates between 85-95%, significantly reducing wastewater volume. Cross-flow configurations consistently outperform dead-end filtration in this metric, though at the cost of higher energy requirements. The environmental trade-offs between water conservation and energy consumption must be carefully balanced when selecting appropriate technology.

Chemical usage for membrane cleaning and maintenance contributes significantly to the environmental footprint. Systems employing automated clean-in-place (CIP) protocols with optimized chemical dosing demonstrate reduced environmental impact through 25-40% lower chemical consumption. Biodegradable cleaning agents are increasingly being adopted, further minimizing ecological risks associated with chemical discharge.

Life cycle assessment (LCA) studies indicate that the manufacturing phase of ultrafiltration membranes accounts for approximately 15-20% of their total environmental impact, while operational impacts dominate at 70-80%. The remaining impact stems from transportation and end-of-life disposal. Membrane longevity therefore emerges as a critical sustainability factor, with extended service life directly correlating to reduced environmental burden.

Regulatory compliance metrics vary globally, necessitating region-specific environmental impact assessments. European standards typically emphasize comprehensive lifecycle impacts, while North American regulations focus more heavily on operational emissions and discharge quality. Emerging markets are increasingly adopting hybrid approaches that balance immediate compliance needs with long-term sustainability goals.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!