Comparative storage density of compressed and liquid green hydrogen

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogen Storage Evolution and Objectives

Hydrogen storage technology has evolved significantly over the past century, with major advancements occurring in response to energy security concerns and environmental challenges. Initially, hydrogen storage was primarily developed for industrial applications, but since the 1970s energy crisis, research has expanded to explore hydrogen as an energy carrier. The evolution of hydrogen storage methods has progressed from basic compressed gas cylinders to sophisticated cryogenic liquid systems and advanced material-based solutions.

The comparative storage density between compressed and liquid hydrogen represents a critical technological consideration. Compressed hydrogen typically achieves volumetric densities of 0.08 kg/L at 700 bar, while liquid hydrogen reaches approximately 0.07 kg/L at -253°C. This seemingly counterintuitive relationship—where high-pressure compression yields slightly higher density than liquefaction—highlights the complex thermodynamic properties of hydrogen and the technical challenges in maximizing storage efficiency.

The green hydrogen revolution has accelerated storage technology development, as renewable energy-derived hydrogen requires efficient storage solutions to address intermittency issues. The U.S. Department of Energy has established progressive targets for hydrogen storage systems, aiming for volumetric densities of 0.050 kg H₂/L by 2025, with ultimate targets of 0.070 kg H₂/L for light-duty vehicles, demonstrating the ambitious trajectory for this technology.

Current objectives in hydrogen storage research focus on increasing volumetric and gravimetric densities while reducing energy losses and costs. For compressed hydrogen, research aims to develop composite materials capable of withstanding higher pressures while reducing weight. For liquid hydrogen, efforts concentrate on minimizing boil-off rates and reducing the substantial energy requirements for liquefaction, which currently consumes approximately 30% of hydrogen's energy content.

The convergence of materials science, thermodynamics, and renewable energy integration represents the frontier of hydrogen storage innovation. Novel approaches combining physical and chemical storage methods are emerging, with hybrid systems potentially offering superior performance characteristics compared to single-method approaches. These developments are crucial for enabling hydrogen's role in decarbonizing sectors like transportation, industry, and grid-scale energy storage.

The ultimate objective remains developing storage solutions that balance technical performance with economic viability. Current cost estimates for compressed hydrogen storage systems range from $500-800/kg H₂, while liquid hydrogen systems cost approximately $700-1,000/kg H₂. Future targets aim to reduce these costs below $300/kg H₂ to achieve commercial competitiveness with conventional energy storage technologies.

The comparative storage density between compressed and liquid hydrogen represents a critical technological consideration. Compressed hydrogen typically achieves volumetric densities of 0.08 kg/L at 700 bar, while liquid hydrogen reaches approximately 0.07 kg/L at -253°C. This seemingly counterintuitive relationship—where high-pressure compression yields slightly higher density than liquefaction—highlights the complex thermodynamic properties of hydrogen and the technical challenges in maximizing storage efficiency.

The green hydrogen revolution has accelerated storage technology development, as renewable energy-derived hydrogen requires efficient storage solutions to address intermittency issues. The U.S. Department of Energy has established progressive targets for hydrogen storage systems, aiming for volumetric densities of 0.050 kg H₂/L by 2025, with ultimate targets of 0.070 kg H₂/L for light-duty vehicles, demonstrating the ambitious trajectory for this technology.

Current objectives in hydrogen storage research focus on increasing volumetric and gravimetric densities while reducing energy losses and costs. For compressed hydrogen, research aims to develop composite materials capable of withstanding higher pressures while reducing weight. For liquid hydrogen, efforts concentrate on minimizing boil-off rates and reducing the substantial energy requirements for liquefaction, which currently consumes approximately 30% of hydrogen's energy content.

The convergence of materials science, thermodynamics, and renewable energy integration represents the frontier of hydrogen storage innovation. Novel approaches combining physical and chemical storage methods are emerging, with hybrid systems potentially offering superior performance characteristics compared to single-method approaches. These developments are crucial for enabling hydrogen's role in decarbonizing sectors like transportation, industry, and grid-scale energy storage.

The ultimate objective remains developing storage solutions that balance technical performance with economic viability. Current cost estimates for compressed hydrogen storage systems range from $500-800/kg H₂, while liquid hydrogen systems cost approximately $700-1,000/kg H₂. Future targets aim to reduce these costs below $300/kg H₂ to achieve commercial competitiveness with conventional energy storage technologies.

Market Analysis for Green Hydrogen Storage Solutions

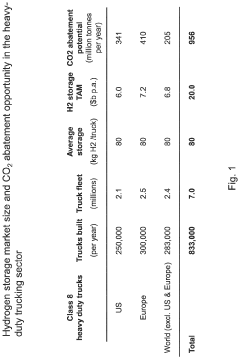

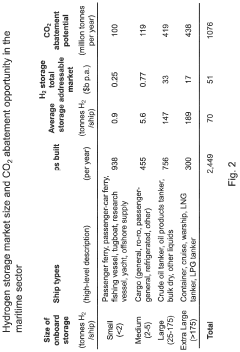

The global green hydrogen storage market is experiencing significant growth, driven by the increasing focus on decarbonization and renewable energy integration. Current market valuations place the green hydrogen storage sector at approximately $300 million in 2023, with projections indicating a compound annual growth rate of 15-20% through 2030, potentially reaching $1.2 billion by the end of the decade.

Storage density comparison between compressed and liquid hydrogen represents a critical factor influencing market adoption. Compressed hydrogen storage systems currently dominate the commercial market with approximately 60% market share, primarily due to technological maturity and lower implementation costs. However, liquid hydrogen storage solutions are gaining traction, growing at a faster rate of 22% annually, owing to their superior volumetric efficiency.

Regional market analysis reveals distinct patterns of adoption. Europe leads the market with 38% share, driven by aggressive climate policies and substantial government investments in hydrogen infrastructure. The European Hydrogen Backbone initiative has allocated €43 billion specifically for developing hydrogen storage solutions. Asia-Pacific follows at 32% market share, with Japan and South Korea making significant investments in liquid hydrogen technologies for transportation applications.

End-user segmentation shows industrial applications commanding 45% of the market, followed by transportation at 30% and power generation at 15%. The transportation sector demonstrates the highest growth potential for liquid hydrogen storage solutions, particularly in heavy-duty vehicles and maritime applications where higher energy density provides competitive advantages.

Market challenges include high capital expenditure requirements, with liquid hydrogen storage systems costing 2.5-3 times more than compressed systems on initial investment. However, lifecycle cost analysis indicates potential long-term economic benefits for liquid storage in high-throughput applications due to reduced transportation costs and higher energy efficiency.

Consumer preference analysis indicates growing interest in liquid hydrogen solutions among large-scale industrial users and transportation fleet operators, while smaller distributed applications continue to favor compressed storage systems. This bifurcation is creating distinct market segments with different growth trajectories and competitive dynamics.

Market forecasts suggest that by 2028, liquid hydrogen storage solutions will achieve cost parity with compressed systems for certain applications, potentially triggering accelerated market adoption. This inflection point represents a significant opportunity for technology providers positioned to capitalize on the transition toward higher-density storage solutions.

Storage density comparison between compressed and liquid hydrogen represents a critical factor influencing market adoption. Compressed hydrogen storage systems currently dominate the commercial market with approximately 60% market share, primarily due to technological maturity and lower implementation costs. However, liquid hydrogen storage solutions are gaining traction, growing at a faster rate of 22% annually, owing to their superior volumetric efficiency.

Regional market analysis reveals distinct patterns of adoption. Europe leads the market with 38% share, driven by aggressive climate policies and substantial government investments in hydrogen infrastructure. The European Hydrogen Backbone initiative has allocated €43 billion specifically for developing hydrogen storage solutions. Asia-Pacific follows at 32% market share, with Japan and South Korea making significant investments in liquid hydrogen technologies for transportation applications.

End-user segmentation shows industrial applications commanding 45% of the market, followed by transportation at 30% and power generation at 15%. The transportation sector demonstrates the highest growth potential for liquid hydrogen storage solutions, particularly in heavy-duty vehicles and maritime applications where higher energy density provides competitive advantages.

Market challenges include high capital expenditure requirements, with liquid hydrogen storage systems costing 2.5-3 times more than compressed systems on initial investment. However, lifecycle cost analysis indicates potential long-term economic benefits for liquid storage in high-throughput applications due to reduced transportation costs and higher energy efficiency.

Consumer preference analysis indicates growing interest in liquid hydrogen solutions among large-scale industrial users and transportation fleet operators, while smaller distributed applications continue to favor compressed storage systems. This bifurcation is creating distinct market segments with different growth trajectories and competitive dynamics.

Market forecasts suggest that by 2028, liquid hydrogen storage solutions will achieve cost parity with compressed systems for certain applications, potentially triggering accelerated market adoption. This inflection point represents a significant opportunity for technology providers positioned to capitalize on the transition toward higher-density storage solutions.

Current Challenges in Hydrogen Storage Technologies

Despite hydrogen's potential as a clean energy carrier, significant challenges persist in its storage technologies, particularly when comparing compressed and liquid forms. The volumetric energy density of hydrogen remains substantially lower than conventional fuels, with liquid hydrogen at 8.5 MJ/L and compressed hydrogen (700 bar) at 4.5 MJ/L, compared to gasoline's 32 MJ/L. This fundamental limitation necessitates larger storage systems, creating design constraints for mobile applications.

Compressed hydrogen storage requires substantial energy input, consuming approximately 10-15% of the hydrogen's energy content for compression to 700 bar. The high-pressure vessels also face weight challenges, typically utilizing expensive carbon fiber composites to achieve acceptable gravimetric densities while maintaining safety standards.

Liquid hydrogen storage presents different obstacles, requiring cryogenic temperatures of -253°C. The liquefaction process consumes approximately 30% of hydrogen's energy content, significantly reducing overall system efficiency. Additionally, even with advanced insulation, boil-off losses remain problematic, with rates of 1-3% per day in current systems, making long-term storage challenging.

Material compatibility issues affect both storage methods. Hydrogen embrittlement compromises structural integrity in metallic components, while permeation through polymer liners in composite tanks leads to gradual hydrogen loss. These phenomena necessitate specialized materials and regular integrity monitoring, increasing system complexity and cost.

Infrastructure limitations further complicate widespread adoption. Compressed hydrogen requires specialized high-pressure refueling stations with complex cooling systems to manage compression-induced heating. Liquid hydrogen demands sophisticated cryogenic handling infrastructure with specialized insulated transfer systems to minimize boil-off during refueling operations.

Safety concerns persist across both technologies. Compressed hydrogen's high pressure creates risks of mechanical failure, while liquid hydrogen's extreme cold temperature presents cryogenic hazards. Both forms require robust leak detection systems and safety protocols due to hydrogen's wide flammability range (4-75% in air) and low ignition energy.

Economic barriers remain significant, with compressed storage systems costing approximately $500-700/kWh and liquid systems even higher at $700-900/kWh of storage capacity. These costs substantially exceed the DOE's target of $8/kWh for competitive hydrogen storage, highlighting the need for breakthrough technologies or manufacturing innovations to achieve cost parity with conventional energy storage systems.

Compressed hydrogen storage requires substantial energy input, consuming approximately 10-15% of the hydrogen's energy content for compression to 700 bar. The high-pressure vessels also face weight challenges, typically utilizing expensive carbon fiber composites to achieve acceptable gravimetric densities while maintaining safety standards.

Liquid hydrogen storage presents different obstacles, requiring cryogenic temperatures of -253°C. The liquefaction process consumes approximately 30% of hydrogen's energy content, significantly reducing overall system efficiency. Additionally, even with advanced insulation, boil-off losses remain problematic, with rates of 1-3% per day in current systems, making long-term storage challenging.

Material compatibility issues affect both storage methods. Hydrogen embrittlement compromises structural integrity in metallic components, while permeation through polymer liners in composite tanks leads to gradual hydrogen loss. These phenomena necessitate specialized materials and regular integrity monitoring, increasing system complexity and cost.

Infrastructure limitations further complicate widespread adoption. Compressed hydrogen requires specialized high-pressure refueling stations with complex cooling systems to manage compression-induced heating. Liquid hydrogen demands sophisticated cryogenic handling infrastructure with specialized insulated transfer systems to minimize boil-off during refueling operations.

Safety concerns persist across both technologies. Compressed hydrogen's high pressure creates risks of mechanical failure, while liquid hydrogen's extreme cold temperature presents cryogenic hazards. Both forms require robust leak detection systems and safety protocols due to hydrogen's wide flammability range (4-75% in air) and low ignition energy.

Economic barriers remain significant, with compressed storage systems costing approximately $500-700/kWh and liquid systems even higher at $700-900/kWh of storage capacity. These costs substantially exceed the DOE's target of $8/kWh for competitive hydrogen storage, highlighting the need for breakthrough technologies or manufacturing innovations to achieve cost parity with conventional energy storage systems.

Comparative Analysis of Compressed vs. Liquid Hydrogen

01 Metal hydride storage systems for green hydrogen

Metal hydrides offer high volumetric storage density for hydrogen by forming chemical bonds with hydrogen molecules. These materials can store hydrogen in a compact form at moderate pressures and temperatures, making them suitable for stationary and mobile applications. The hydrogen is released through controlled heating, providing a safe and efficient storage solution with energy densities several times higher than compressed gas systems.- Metal hydride storage systems: Metal hydrides offer a promising solution for hydrogen storage due to their high volumetric storage density. These materials chemically bind hydrogen atoms within their crystal structure, allowing for compact storage under moderate pressure and temperature conditions. Various metal alloys and compounds can be engineered to optimize hydrogen absorption and desorption kinetics, making them suitable for both stationary and mobile green hydrogen storage applications.

- Liquid organic hydrogen carriers: Liquid organic hydrogen carriers (LOHCs) represent an innovative approach to hydrogen storage by chemically binding hydrogen to organic compounds. This method allows hydrogen to be stored in liquid form at ambient conditions, significantly increasing storage density compared to compressed gas. The hydrogen can be released through a catalytic dehydrogenation process when needed, and the carrier can be reused in a closed-loop system, offering advantages for long-term storage and transportation.

- Compressed hydrogen storage technologies: Advanced compressed hydrogen storage systems utilize high-pressure tanks and composite materials to achieve greater storage densities. These systems typically operate at pressures of 350-700 bar and incorporate specialized materials to minimize hydrogen permeation and ensure safety. Recent innovations focus on optimizing tank design, reducing weight, and improving volumetric efficiency to make compressed hydrogen storage more practical for various applications including transportation and grid-scale energy storage.

- Cryogenic and hybrid storage systems: Cryogenic storage involves maintaining hydrogen in liquid form at extremely low temperatures (around -253°C), significantly increasing storage density. Hybrid systems combine cryogenic cooling with moderate pressure to achieve optimal storage conditions. These approaches can achieve higher volumetric density than compressed gas storage alone, making them suitable for applications where space constraints are critical. Advanced insulation materials and efficient liquefaction processes are key to improving the energy efficiency of these storage methods.

- Novel materials and nanostructured adsorbents: Emerging materials such as metal-organic frameworks (MOFs), carbon nanostructures, and porous polymers offer promising hydrogen storage capabilities through adsorption mechanisms. These materials provide high surface areas and optimized binding sites for hydrogen molecules, potentially achieving higher storage densities at more moderate pressures and temperatures than conventional methods. Research focuses on tailoring pore sizes, surface chemistry, and material stability to maximize hydrogen uptake while maintaining practical operating conditions for green hydrogen applications.

02 Liquid organic hydrogen carriers (LOHC) technology

Liquid organic hydrogen carriers provide a method for storing hydrogen in chemical form at ambient conditions. These organic compounds can absorb and release hydrogen through reversible hydrogenation and dehydrogenation reactions. LOHCs offer advantages including high storage density, ease of transport using existing infrastructure, and safety benefits compared to compressed or liquefied hydrogen storage methods.Expand Specific Solutions03 Compressed and liquefied hydrogen storage solutions

Traditional physical storage methods involve compressing hydrogen gas at high pressures (350-700 bar) or liquefying it at cryogenic temperatures (-253°C). These approaches require specialized tanks and equipment to maintain the required conditions. While these methods are technologically mature, they face challenges including energy losses during compression/liquefaction and limitations in volumetric storage density compared to chemical storage methods.Expand Specific Solutions04 Novel materials and nanostructures for hydrogen adsorption

Advanced materials including metal-organic frameworks (MOFs), carbon nanostructures, and porous polymers can physically adsorb hydrogen molecules on their surfaces. These materials feature extremely high surface areas and optimized pore structures that enhance hydrogen uptake. Research focuses on increasing binding energies and improving volumetric storage densities through material design and surface modifications to achieve practical storage densities at moderate pressures and temperatures.Expand Specific Solutions05 Integrated systems and infrastructure for hydrogen storage

Comprehensive hydrogen storage solutions involve integrated systems that combine multiple storage technologies with production and utilization infrastructure. These systems may incorporate hybrid storage approaches, energy recovery mechanisms, and smart management systems to optimize efficiency. Developments include underground storage in salt caverns, integration with renewable energy sources, and multi-modal transport solutions that address the entire hydrogen value chain to maximize overall system storage density and efficiency.Expand Specific Solutions

Key Industry Players in Hydrogen Storage Market

The green hydrogen storage market is in its early growth phase, with significant potential as the world transitions to cleaner energy sources. The market size is expanding rapidly, projected to reach billions by 2030, driven by decarbonization initiatives and renewable energy integration. Technologically, compressed and liquid hydrogen storage solutions are advancing at different rates. H2Go Power is pioneering compression-free storage technologies, potentially reducing costs by 50%. Major automotive players like Hyundai, Ford, and Kia are investing heavily in hydrogen fuel cell vehicles, requiring advanced storage solutions. Research institutions including Oxford University, Tongji University, and CNRS are developing next-generation materials for improved storage density. Industrial players such as Casale SA, UOP LLC, and Zhangjiagang Furui are scaling commercial applications, while companies like Intelligent Energy focus on lightweight, high-efficiency systems for various sectors.

H2Go Power Ltd.

Technical Solution: H2Go Power has developed advanced solid-state hydrogen storage technology that offers significantly higher volumetric density compared to both compressed and liquid hydrogen. Their proprietary metal-organic framework (MOF) materials can store hydrogen in a solid state at ambient temperatures and moderate pressures (30-50 bar), achieving volumetric densities of 40-60 g/L, which exceeds liquid hydrogen's typical 35-40 g/L density. This technology eliminates the energy-intensive liquefaction process that requires temperatures of -253°C and reduces approximately 30% of energy losses associated with conventional hydrogen storage methods. H2Go's system integrates smart AI-powered control systems that optimize hydrogen storage and release based on demand patterns, further enhancing efficiency across the hydrogen value chain.

Strengths: Higher volumetric density than both compressed and liquid hydrogen; operates at ambient temperatures eliminating costly cryogenic equipment; reduced energy losses compared to liquefaction processes. Weaknesses: Still in scaling phase with limited commercial deployment; higher upfront capital costs compared to conventional compressed storage systems; material degradation over multiple adsorption-desorption cycles remains a challenge.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai has pioneered a hybrid storage approach combining both compressed and liquid hydrogen technologies for their mobility applications. Their system utilizes a dual-storage architecture that maintains hydrogen in both states - compressed gas at 700 bar (achieving approximately 40 g/L) and liquid form at cryogenic temperatures (achieving approximately 70 g/L). This integrated system allows for optimized energy density while addressing the challenges of boil-off in liquid hydrogen storage. Hyundai's technology incorporates advanced thermal management systems that capture and reuse boil-off gas, reducing losses to under 1% per day compared to conventional 2-3% daily losses in standard liquid hydrogen systems. Their proprietary cryo-compression technology enables a 20-25% improvement in overall system volumetric efficiency compared to either storage method used independently.

Strengths: Maximizes volumetric efficiency by utilizing both storage methods; innovative boil-off gas management reduces waste; applicable across various vehicle platforms from passenger cars to heavy-duty trucks. Weaknesses: Complex system architecture increases manufacturing costs; requires sophisticated control systems to manage dual storage states; higher weight penalty compared to single-storage solutions.

Technical Innovations in Density Optimization

Cryo-compressed hydrogen storage multi-tank systems and their thermal management

PatentPendingUS20230392752A1

Innovation

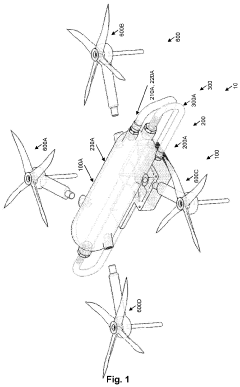

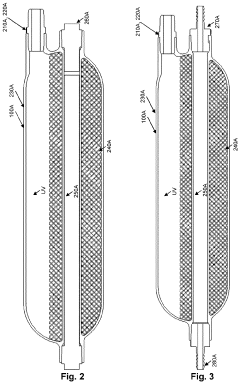

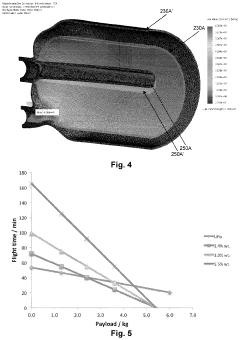

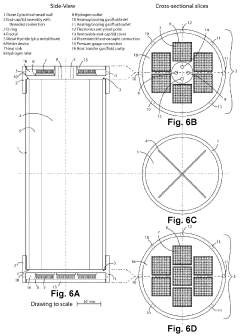

- A multi-tank cryo-compressed hydrogen storage system with a shared manifold for thermal management, where hydrogen is transferred between tanks to optimize energy density and reduce the need for in-tank heat exchangers and auxiliary tanks, minimizing void spaces and leak points, and utilizing a single insulation layer to enhance storage efficiency.

vehicle

PatentInactiveUS20220250762A1

Innovation

- A hydrogen storage device with a pressure vessel and thermally conducting network, featuring a lattice, gyroidal, or fractal geometry, that stores hydrogen at lower pressures, enhancing storage density and safety, and integrates as a structural component of the vehicle.

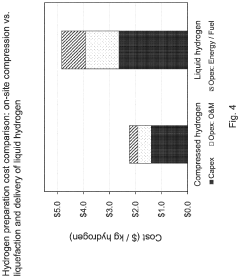

Economic Feasibility of Storage Methods

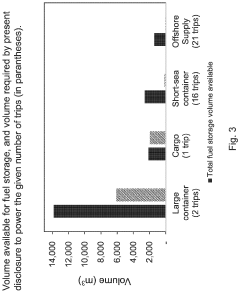

The economic feasibility of hydrogen storage methods is fundamentally tied to their capital expenditure, operational costs, and overall system efficiency. Compressed hydrogen storage typically requires initial investments of $500-1,500 per kg of storage capacity, while liquid hydrogen systems demand $1,200-1,800 per kg due to the sophisticated cryogenic equipment needed. These capital costs significantly impact the economic viability of different storage approaches.

Operational expenditures present another critical economic dimension. Compression systems consume approximately 2-3 kWh of electricity per kg of hydrogen stored, representing 5-8% of the hydrogen's energy content. Liquefaction processes are substantially more energy-intensive, requiring 8-12 kWh per kg, or 20-30% of the hydrogen's energy value. This energy penalty directly affects the total cost of hydrogen delivery to end-users.

Storage duration also influences economic calculations differently for each method. Compressed hydrogen systems exhibit minimal boil-off losses, making them suitable for long-term storage with steady operational costs. Conversely, liquid hydrogen systems face daily boil-off rates of 0.3-0.5%, necessitating either continuous consumption or reconversion infrastructure, adding complexity to economic modeling for extended storage scenarios.

Scale economics vary significantly between technologies. Compression systems demonstrate relatively linear scaling, with modest cost reductions at larger capacities. Liquid hydrogen storage exhibits more favorable economies of scale, with per-unit costs decreasing substantially as capacity increases, particularly beyond 50 tons of storage capacity.

Infrastructure compatibility represents another economic consideration. Compressed hydrogen integrates more readily with existing natural gas infrastructure with moderate modifications, whereas liquid hydrogen requires entirely new specialized infrastructure, significantly affecting total system costs when evaluating complete value chains.

The economic comparison must also account for transportation synergies. Liquid hydrogen's higher density translates to reduced transportation costs per unit of energy delivered, potentially offsetting higher storage costs in distributed energy systems where hydrogen must be transported significant distances from production facilities to end-users.

Operational expenditures present another critical economic dimension. Compression systems consume approximately 2-3 kWh of electricity per kg of hydrogen stored, representing 5-8% of the hydrogen's energy content. Liquefaction processes are substantially more energy-intensive, requiring 8-12 kWh per kg, or 20-30% of the hydrogen's energy value. This energy penalty directly affects the total cost of hydrogen delivery to end-users.

Storage duration also influences economic calculations differently for each method. Compressed hydrogen systems exhibit minimal boil-off losses, making them suitable for long-term storage with steady operational costs. Conversely, liquid hydrogen systems face daily boil-off rates of 0.3-0.5%, necessitating either continuous consumption or reconversion infrastructure, adding complexity to economic modeling for extended storage scenarios.

Scale economics vary significantly between technologies. Compression systems demonstrate relatively linear scaling, with modest cost reductions at larger capacities. Liquid hydrogen storage exhibits more favorable economies of scale, with per-unit costs decreasing substantially as capacity increases, particularly beyond 50 tons of storage capacity.

Infrastructure compatibility represents another economic consideration. Compressed hydrogen integrates more readily with existing natural gas infrastructure with moderate modifications, whereas liquid hydrogen requires entirely new specialized infrastructure, significantly affecting total system costs when evaluating complete value chains.

The economic comparison must also account for transportation synergies. Liquid hydrogen's higher density translates to reduced transportation costs per unit of energy delivered, potentially offsetting higher storage costs in distributed energy systems where hydrogen must be transported significant distances from production facilities to end-users.

Environmental Impact Assessment

The environmental impact assessment of hydrogen storage methods is critical when comparing compressed and liquid green hydrogen technologies. Compressed hydrogen storage typically requires robust high-pressure tanks operating at 350-700 bar, which demand significant energy input during the compression process. This energy requirement can offset some of the environmental benefits of green hydrogen if the electricity used for compression comes from non-renewable sources.

Liquid hydrogen storage, operating at cryogenic temperatures of approximately -253°C, presents different environmental challenges. The liquefaction process consumes substantially more energy than compression—typically 30-40% of the hydrogen's energy content versus 10-15% for compression. This higher energy penalty can significantly impact the overall carbon footprint of liquid hydrogen systems unless powered by renewable energy sources.

Both storage methods face environmental concerns related to material usage. Compressed hydrogen tanks often utilize carbon fiber composites and specialized alloys to withstand high pressures, materials that have their own environmental footprints in terms of production and limited recyclability. Liquid hydrogen systems require sophisticated insulation materials and cryogenic-grade stainless steel, which also carry environmental manufacturing burdens.

Leakage risks present another environmental consideration. While hydrogen itself is not a direct pollutant, it can act as an indirect greenhouse gas by affecting atmospheric chemistry and potentially extending the lifetime of methane in the atmosphere. Liquid hydrogen systems typically experience "boil-off" losses of 0.3-3% daily, which must be managed to prevent environmental impact and safety hazards.

Land use requirements differ between the technologies. Compressed hydrogen generally requires more physical space per unit of energy stored compared to liquid hydrogen, potentially leading to greater land disturbance for large-scale applications. However, liquid hydrogen facilities need additional infrastructure for liquefaction and boil-off management, which can increase their overall environmental footprint.

Water consumption represents another environmental factor, particularly for green hydrogen production through electrolysis, which requires approximately 9 kg of water per kg of hydrogen. While this aspect is common to both storage methods, integrated systems must consider water availability and potential impacts on local water resources.

Life cycle assessments indicate that the environmental advantages of either storage method depend heavily on system design, operational efficiency, and most critically, the source of energy used throughout the hydrogen value chain. When powered by renewable energy, both systems can offer significant environmental benefits compared to fossil fuel alternatives, despite their different storage density characteristics.

Liquid hydrogen storage, operating at cryogenic temperatures of approximately -253°C, presents different environmental challenges. The liquefaction process consumes substantially more energy than compression—typically 30-40% of the hydrogen's energy content versus 10-15% for compression. This higher energy penalty can significantly impact the overall carbon footprint of liquid hydrogen systems unless powered by renewable energy sources.

Both storage methods face environmental concerns related to material usage. Compressed hydrogen tanks often utilize carbon fiber composites and specialized alloys to withstand high pressures, materials that have their own environmental footprints in terms of production and limited recyclability. Liquid hydrogen systems require sophisticated insulation materials and cryogenic-grade stainless steel, which also carry environmental manufacturing burdens.

Leakage risks present another environmental consideration. While hydrogen itself is not a direct pollutant, it can act as an indirect greenhouse gas by affecting atmospheric chemistry and potentially extending the lifetime of methane in the atmosphere. Liquid hydrogen systems typically experience "boil-off" losses of 0.3-3% daily, which must be managed to prevent environmental impact and safety hazards.

Land use requirements differ between the technologies. Compressed hydrogen generally requires more physical space per unit of energy stored compared to liquid hydrogen, potentially leading to greater land disturbance for large-scale applications. However, liquid hydrogen facilities need additional infrastructure for liquefaction and boil-off management, which can increase their overall environmental footprint.

Water consumption represents another environmental factor, particularly for green hydrogen production through electrolysis, which requires approximately 9 kg of water per kg of hydrogen. While this aspect is common to both storage methods, integrated systems must consider water availability and potential impacts on local water resources.

Life cycle assessments indicate that the environmental advantages of either storage method depend heavily on system design, operational efficiency, and most critically, the source of energy used throughout the hydrogen value chain. When powered by renewable energy, both systems can offer significant environmental benefits compared to fossil fuel alternatives, despite their different storage density characteristics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!