Comparative Studies of Polymer Use in Plasmonic Biosensor Construction

SEP 29, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polymer-Based Plasmonic Biosensor Development Background and Objectives

Plasmonic biosensors represent a significant advancement in sensing technology, combining the principles of surface plasmon resonance (SPR) with biological recognition elements to create highly sensitive detection systems. The evolution of these biosensors has been marked by continuous improvements in sensitivity, selectivity, and applicability across various fields including healthcare, environmental monitoring, and food safety. Polymers have emerged as crucial components in this technological progression, offering unique advantages in terms of biocompatibility, functionalization capabilities, and cost-effectiveness.

The historical development of polymer-based plasmonic biosensors can be traced back to the early 1990s when researchers began exploring alternatives to traditional metal-based SPR platforms. Initial efforts focused primarily on incorporating polymers as simple support structures, but rapidly evolved toward utilizing polymers as active components that could enhance sensor performance. By the early 2000s, significant breakthroughs in polymer science enabled the creation of more sophisticated plasmonic biosensor architectures with improved sensitivity and stability.

Recent technological advancements have further expanded the potential of polymer-based plasmonic biosensors. The integration of stimuli-responsive polymers has enabled the development of "smart" biosensors capable of adapting to environmental changes. Additionally, the emergence of conductive polymers has opened new avenues for sensor design, allowing for direct electronic coupling between the plasmonic elements and detection systems.

The global research landscape shows varying approaches to polymer utilization in plasmonic biosensor construction. European research institutions have predominantly focused on biodegradable polymer systems, while North American researchers have emphasized high-performance synthetic polymers. Asian research groups, particularly in Japan and South Korea, have made significant contributions in hybrid polymer-nanoparticle systems that demonstrate enhanced sensitivity.

The primary objectives of current research in this field include enhancing detection limits to reach single-molecule sensitivity, improving the stability and shelf-life of polymer-based sensors, and developing cost-effective manufacturing processes for large-scale production. There is also a growing emphasis on creating multiplexed sensing platforms capable of detecting multiple analytes simultaneously, which represents a significant technological challenge requiring innovative polymer engineering approaches.

Another critical research goal involves addressing the limitations of current polymer-based systems, particularly regarding non-specific binding issues and performance degradation in complex biological matrices. Researchers aim to develop new polymer formulations and surface modification strategies that maintain sensitivity while improving selectivity in real-world applications.

The convergence of polymer science, plasmonics, and biosensing technologies presents unprecedented opportunities for creating next-generation diagnostic and monitoring tools. As this field continues to evolve, the comparative analysis of different polymer systems in plasmonic biosensor construction will be instrumental in identifying optimal materials and designs for specific applications.

The historical development of polymer-based plasmonic biosensors can be traced back to the early 1990s when researchers began exploring alternatives to traditional metal-based SPR platforms. Initial efforts focused primarily on incorporating polymers as simple support structures, but rapidly evolved toward utilizing polymers as active components that could enhance sensor performance. By the early 2000s, significant breakthroughs in polymer science enabled the creation of more sophisticated plasmonic biosensor architectures with improved sensitivity and stability.

Recent technological advancements have further expanded the potential of polymer-based plasmonic biosensors. The integration of stimuli-responsive polymers has enabled the development of "smart" biosensors capable of adapting to environmental changes. Additionally, the emergence of conductive polymers has opened new avenues for sensor design, allowing for direct electronic coupling between the plasmonic elements and detection systems.

The global research landscape shows varying approaches to polymer utilization in plasmonic biosensor construction. European research institutions have predominantly focused on biodegradable polymer systems, while North American researchers have emphasized high-performance synthetic polymers. Asian research groups, particularly in Japan and South Korea, have made significant contributions in hybrid polymer-nanoparticle systems that demonstrate enhanced sensitivity.

The primary objectives of current research in this field include enhancing detection limits to reach single-molecule sensitivity, improving the stability and shelf-life of polymer-based sensors, and developing cost-effective manufacturing processes for large-scale production. There is also a growing emphasis on creating multiplexed sensing platforms capable of detecting multiple analytes simultaneously, which represents a significant technological challenge requiring innovative polymer engineering approaches.

Another critical research goal involves addressing the limitations of current polymer-based systems, particularly regarding non-specific binding issues and performance degradation in complex biological matrices. Researchers aim to develop new polymer formulations and surface modification strategies that maintain sensitivity while improving selectivity in real-world applications.

The convergence of polymer science, plasmonics, and biosensing technologies presents unprecedented opportunities for creating next-generation diagnostic and monitoring tools. As this field continues to evolve, the comparative analysis of different polymer systems in plasmonic biosensor construction will be instrumental in identifying optimal materials and designs for specific applications.

Market Analysis of Polymer Plasmonic Biosensor Applications

The global market for plasmonic biosensors is experiencing significant growth, driven by increasing demand for rapid, sensitive, and portable diagnostic tools across healthcare, environmental monitoring, and food safety sectors. The polymer-based plasmonic biosensor segment specifically is projected to grow at a compound annual growth rate of 9.2% through 2028, outpacing the overall biosensor market growth rate of 7.8%.

Healthcare applications currently dominate the polymer plasmonic biosensor market, accounting for approximately 65% of total revenue. This dominance stems from the critical need for early disease detection, point-of-care diagnostics, and continuous health monitoring systems. The COVID-19 pandemic has further accelerated this trend, highlighting the necessity for rapid diagnostic tools that can be deployed in resource-limited settings.

Environmental monitoring represents the fastest-growing application segment, with increasing regulatory pressure driving adoption across industrial and municipal sectors. Water quality monitoring alone is expected to generate market opportunities exceeding $2.3 billion by 2027, as governments worldwide implement stricter environmental protection policies.

Food safety applications are gaining traction particularly in developed economies, where consumer awareness regarding foodborne pathogens and contaminants has heightened. The market for polymer plasmonic biosensors in this segment is anticipated to double within the next five years, particularly for detecting bacterial contamination and chemical residues.

Regionally, North America leads the market with approximately 38% share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is demonstrating the highest growth rate, fueled by increasing healthcare expenditure, expanding industrial base, and government initiatives to improve diagnostic infrastructure.

A key market driver is the cost advantage offered by polymer-based plasmonic biosensors compared to traditional gold or silver-based alternatives. The average production cost reduction ranges between 30-45%, making these sensors particularly attractive for mass deployment in emerging economies.

Consumer electronics integration represents an emerging opportunity, with wearable health monitoring devices incorporating polymer plasmonic biosensor technology expected to create a new market segment worth approximately $1.8 billion by 2030. This convergence of biosensing with consumer technology is attracting non-traditional players from the electronics industry into the biosensor market.

Market challenges include standardization issues, regulatory approval timelines, and competition from alternative sensing technologies. However, the unique combination of sensitivity, specificity, and cost-effectiveness positions polymer-based plasmonic biosensors favorably against competing technologies in most application scenarios.

Healthcare applications currently dominate the polymer plasmonic biosensor market, accounting for approximately 65% of total revenue. This dominance stems from the critical need for early disease detection, point-of-care diagnostics, and continuous health monitoring systems. The COVID-19 pandemic has further accelerated this trend, highlighting the necessity for rapid diagnostic tools that can be deployed in resource-limited settings.

Environmental monitoring represents the fastest-growing application segment, with increasing regulatory pressure driving adoption across industrial and municipal sectors. Water quality monitoring alone is expected to generate market opportunities exceeding $2.3 billion by 2027, as governments worldwide implement stricter environmental protection policies.

Food safety applications are gaining traction particularly in developed economies, where consumer awareness regarding foodborne pathogens and contaminants has heightened. The market for polymer plasmonic biosensors in this segment is anticipated to double within the next five years, particularly for detecting bacterial contamination and chemical residues.

Regionally, North America leads the market with approximately 38% share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is demonstrating the highest growth rate, fueled by increasing healthcare expenditure, expanding industrial base, and government initiatives to improve diagnostic infrastructure.

A key market driver is the cost advantage offered by polymer-based plasmonic biosensors compared to traditional gold or silver-based alternatives. The average production cost reduction ranges between 30-45%, making these sensors particularly attractive for mass deployment in emerging economies.

Consumer electronics integration represents an emerging opportunity, with wearable health monitoring devices incorporating polymer plasmonic biosensor technology expected to create a new market segment worth approximately $1.8 billion by 2030. This convergence of biosensing with consumer technology is attracting non-traditional players from the electronics industry into the biosensor market.

Market challenges include standardization issues, regulatory approval timelines, and competition from alternative sensing technologies. However, the unique combination of sensitivity, specificity, and cost-effectiveness positions polymer-based plasmonic biosensors favorably against competing technologies in most application scenarios.

Current Polymer Integration Challenges in Plasmonic Biosensing

Despite significant advancements in plasmonic biosensor technology, polymer integration remains a critical challenge that limits widespread commercial adoption. Current polymer-based plasmonic biosensors face several fundamental obstacles that require innovative solutions. The primary challenge involves achieving consistent molecular immobilization on polymer surfaces while maintaining the plasmonic properties essential for sensing applications. Conventional polymers often exhibit non-specific binding characteristics that reduce sensor specificity and increase false positive rates in complex biological samples.

Surface modification techniques for polymers in plasmonic applications present another significant hurdle. Unlike glass or metal substrates, polymers require specialized treatment protocols to achieve stable functionalization without compromising their structural integrity or optical properties. Current methods often result in heterogeneous surface coverage, leading to inconsistent sensor performance across manufacturing batches and limiting reproducibility in clinical settings.

The interface between metallic nanostructures and polymer substrates represents a particularly challenging aspect of integration. Adhesion issues frequently arise due to the inherent incompatibility between hydrophobic polymer surfaces and metallic nanoparticles or films. This incompatibility leads to delamination during operation, especially in aqueous environments typical of biological testing, severely limiting sensor lifespan and reliability.

Thermal management presents another significant obstacle in polymer-based plasmonic biosensors. The localized surface plasmon resonance phenomenon generates considerable heat that can deform polymer substrates, altering critical optical parameters and sensor geometry. Current thermal management solutions add complexity and cost to device fabrication without fully resolving the issue.

Mass production scalability remains problematic for polymer-plasmonic hybrid systems. While polymers offer cost advantages for high-volume manufacturing, current fabrication techniques struggle to maintain nanoscale precision across large production runs. Techniques like nanoimprint lithography show promise but face challenges in achieving consistent plasmonic structures with the required dimensional accuracy at industrial scales.

Biodegradation and biofouling of polymer surfaces in biological media constitute another significant challenge. Many polymers used in biosensor construction gradually degrade when exposed to biological samples, changing their optical properties and compromising sensor performance over time. Additionally, protein adsorption on polymer surfaces can mask the plasmonic signal, necessitating complex surface passivation strategies that add to manufacturing complexity and cost.

These integration challenges collectively represent a significant barrier to the widespread adoption of polymer-based plasmonic biosensors in clinical and point-of-care applications, despite their theoretical advantages in terms of cost and manufacturability.

Surface modification techniques for polymers in plasmonic applications present another significant hurdle. Unlike glass or metal substrates, polymers require specialized treatment protocols to achieve stable functionalization without compromising their structural integrity or optical properties. Current methods often result in heterogeneous surface coverage, leading to inconsistent sensor performance across manufacturing batches and limiting reproducibility in clinical settings.

The interface between metallic nanostructures and polymer substrates represents a particularly challenging aspect of integration. Adhesion issues frequently arise due to the inherent incompatibility between hydrophobic polymer surfaces and metallic nanoparticles or films. This incompatibility leads to delamination during operation, especially in aqueous environments typical of biological testing, severely limiting sensor lifespan and reliability.

Thermal management presents another significant obstacle in polymer-based plasmonic biosensors. The localized surface plasmon resonance phenomenon generates considerable heat that can deform polymer substrates, altering critical optical parameters and sensor geometry. Current thermal management solutions add complexity and cost to device fabrication without fully resolving the issue.

Mass production scalability remains problematic for polymer-plasmonic hybrid systems. While polymers offer cost advantages for high-volume manufacturing, current fabrication techniques struggle to maintain nanoscale precision across large production runs. Techniques like nanoimprint lithography show promise but face challenges in achieving consistent plasmonic structures with the required dimensional accuracy at industrial scales.

Biodegradation and biofouling of polymer surfaces in biological media constitute another significant challenge. Many polymers used in biosensor construction gradually degrade when exposed to biological samples, changing their optical properties and compromising sensor performance over time. Additionally, protein adsorption on polymer surfaces can mask the plasmonic signal, necessitating complex surface passivation strategies that add to manufacturing complexity and cost.

These integration challenges collectively represent a significant barrier to the widespread adoption of polymer-based plasmonic biosensors in clinical and point-of-care applications, despite their theoretical advantages in terms of cost and manufacturability.

Comparative Analysis of Current Polymer-Plasmonic Integration Methods

01 Polymer-based plasmonic nanostructures for biosensing

Polymer materials can be used as substrates or matrices for plasmonic nanostructures in biosensors. These polymers provide structural support while maintaining the optical properties necessary for plasmonic sensing. The integration of polymers with plasmonic materials enhances the construction efficiency of biosensors by offering flexibility, biocompatibility, and ease of fabrication. These structures can detect biological analytes with high sensitivity through localized surface plasmon resonance.- Polymer-based plasmonic nanostructures for biosensing: Polymer materials can be used as substrates or matrices for plasmonic nanostructures in biosensors. These polymers provide structural support while allowing for the integration of metallic nanoparticles that exhibit plasmonic properties. The combination enhances detection sensitivity and enables more efficient biosensor construction. Polymers offer advantages such as flexibility, biocompatibility, and ease of fabrication, making them ideal for creating plasmonic biosensing platforms with improved efficiency.

- Conductive polymers for signal enhancement in plasmonic biosensors: Conductive polymers can be incorporated into plasmonic biosensors to enhance signal transduction and improve detection efficiency. These polymers facilitate electron transfer between the plasmonic elements and the detection system, resulting in amplified signals and lower detection limits. The integration of conductive polymers with plasmonic nanostructures creates synergistic effects that improve the overall performance and construction efficiency of biosensors for various biomedical applications.

- Polymer-metal nanocomposites for enhanced plasmonic sensing: Polymer-metal nanocomposites combine the advantages of polymeric materials with the plasmonic properties of metallic nanoparticles. These nanocomposites can be engineered to optimize light-matter interactions, resulting in enhanced sensitivity and selectivity for biosensing applications. The polymer matrix provides stability to the metallic nanostructures while allowing for functionalization with biomolecules. This approach improves the construction efficiency of plasmonic biosensors by simplifying fabrication processes and enhancing sensor performance.

- Stimuli-responsive polymers for dynamic plasmonic biosensing: Stimuli-responsive polymers can be integrated into plasmonic biosensors to create dynamic sensing platforms that respond to environmental changes. These smart polymers undergo conformational changes in response to stimuli such as pH, temperature, or specific biomolecules, which modulates the plasmonic properties of the sensor. This approach enables real-time monitoring and improves the specificity of detection. The responsive nature of these polymers enhances the construction efficiency by incorporating multiple functionalities into a single biosensing platform.

- Polymer-based fabrication techniques for plasmonic biosensor arrays: Advanced polymer-based fabrication techniques enable the efficient construction of plasmonic biosensor arrays with high reproducibility and scalability. Methods such as nanoimprint lithography, soft lithography, and polymer templating allow for precise control over the spatial arrangement of plasmonic structures. These techniques facilitate the mass production of biosensor devices with consistent performance characteristics. The use of polymers in these fabrication processes improves construction efficiency by reducing costs and complexity while maintaining high-quality plasmonic structures for biosensing applications.

02 Conductive polymers for enhanced plasmonic coupling

Conductive polymers can be incorporated into plasmonic biosensors to improve signal transduction and enhance plasmonic coupling efficiency. These polymers facilitate electron transfer between the plasmonic nanostructures and the sensing interface, resulting in improved sensitivity and detection limits. The electrical properties of conductive polymers can be tuned to optimize the performance of plasmonic biosensors for specific applications, making them valuable components in efficient biosensor construction.Expand Specific Solutions03 Polymer-based surface functionalization techniques

Surface functionalization of plasmonic biosensors using polymers improves their specificity and sensitivity. Polymers can be modified with functional groups that selectively bind to target analytes, reducing non-specific binding and background noise. These functionalization techniques enhance the construction efficiency of plasmonic biosensors by providing a versatile platform for immobilizing various biorecognition elements such as antibodies, aptamers, or enzymes, while maintaining the plasmonic properties of the underlying substrate.Expand Specific Solutions04 Stimuli-responsive polymers for dynamic plasmonic sensing

Stimuli-responsive polymers that change their properties in response to environmental factors can be integrated into plasmonic biosensors to create dynamic sensing platforms. These smart polymers undergo conformational changes in response to temperature, pH, light, or other stimuli, which can modulate the plasmonic response of the sensor. This approach improves construction efficiency by enabling multi-parameter sensing and self-calibrating capabilities in plasmonic biosensors, reducing the complexity of sensor design while enhancing functionality.Expand Specific Solutions05 Polymer nanocomposites with plasmonic nanoparticles

Polymer nanocomposites incorporating plasmonic nanoparticles offer enhanced optical properties and improved construction efficiency for biosensors. These nanocomposites combine the processability and versatility of polymers with the unique optical properties of plasmonic nanoparticles. The polymer matrix provides stability to the nanoparticles while allowing for efficient fabrication methods such as spin-coating, 3D printing, or injection molding. This approach enables cost-effective mass production of plasmonic biosensors with consistent performance characteristics.Expand Specific Solutions

Leading Research Groups and Companies in Polymer Plasmonic Biosensors

The plasmonic biosensor market is in a growth phase, characterized by increasing research activities and commercial applications. The global market size for biosensors is expanding rapidly, driven by healthcare demands and technological advancements. In terms of technical maturity, polymer-based plasmonic biosensors are evolving from experimental to practical applications. Leading academic institutions like Rutgers University, University of California, and Arizona State University are advancing fundamental research, while commercial players demonstrate varying levels of technological readiness. Companies like Roche, Philips, and Abbott Diabetes Care represent established manufacturers with mature biosensor technologies, while specialized firms such as Biolinq and Opteev Technologies are developing innovative polymer-based approaches. Asian manufacturers including Shenzhen Sisensing and Shanghai MicroPort Lifesciences are rapidly advancing their technical capabilities in this competitive landscape.

Rutgers State University of New Jersey

Technical Solution: Rutgers has developed innovative polymer-based plasmonic biosensors utilizing molecularly imprinted polymers (MIPs) combined with gold nanoparticles for enhanced sensitivity. Their approach involves creating polymer matrices with specific molecular recognition sites that interact with target analytes, causing measurable changes in the plasmonic properties. The research team has demonstrated detection limits in the picomolar range for various biomarkers by optimizing the polymer composition and nanostructure geometry. Their platform incorporates hydrogel-based polymers that maintain biocompatibility while providing stable immobilization of plasmonic nanostructures. Recent advancements include the development of stimuli-responsive polymers that change their conformation upon analyte binding, amplifying the plasmonic signal and improving detection sensitivity[1]. The integration of these smart polymers with surface plasmon resonance (SPR) technology has enabled real-time, label-free detection of various biomolecules.

Strengths: Exceptional molecular recognition specificity through MIP technology; excellent sensitivity with detection limits reaching picomolar ranges; stimuli-responsive polymer systems that amplify detection signals. Weaknesses: Potential batch-to-batch variation in polymer synthesis affecting reproducibility; relatively complex fabrication process compared to traditional biosensors; limited long-term stability in certain biological environments.

The Regents of the University of California

Technical Solution: The University of California has pioneered advanced polymer-plasmonic hybrid biosensing platforms that leverage the unique properties of conducting polymers integrated with metallic nanostructures. Their proprietary approach utilizes electropolymerized films of polypyrrole and PEDOT:PSS as active sensing layers on gold nanorod arrays, creating highly sensitive detection interfaces. Research teams have demonstrated multiplex detection capabilities by patterning different polymer compositions onto a single chip, each optimized for specific biomarker recognition. The technology incorporates precisely controlled polymer thickness (10-100 nm) to optimize the plasmonic field enhancement effect while maintaining rapid diffusion of target analytes[2]. Their recent innovations include the development of biodegradable polymer scaffolds that support plasmonic nanoparticles while offering environmentally friendly disposal options. The platform has been successfully applied to detect various disease biomarkers with sensitivity improvements of 2-3 orders of magnitude compared to conventional methods, and response times under 5 minutes for point-of-care applications.

Strengths: Exceptional sensitivity through optimized polymer-plasmonic coupling; versatile multiplex detection capabilities; rapid response times suitable for point-of-care applications; environmentally conscious design with biodegradable components. Weaknesses: Higher production costs compared to traditional biosensors; potential signal interference in complex biological samples; requires specialized equipment for fabrication and measurement.

Key Patents and Publications on Polymer-Enhanced Plasmonic Sensing

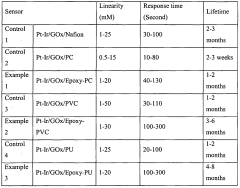

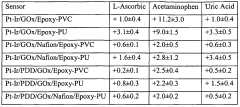

Epoxy enhanced polymer membrane to increase durability of biosensors

PatentInactiveEP1782062A2

Innovation

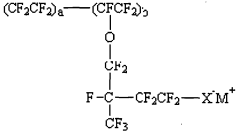

- An epoxy-enhanced polymer membrane is developed as a protective layer for biosensors, comprising a mixture of polymers and epoxy resin, which forms a durable coating that enhances adhesion to the enzyme layer and acts as a diffusion barrier, significantly extending the sensor's lifespan by preventing enzyme loss and membrane degradation.

Epoxy enhanced polymer membrane to increase durability of biosensors

PatentWO2006127023A2

Innovation

- An epoxy-enhanced polymer membrane is developed as a protective layer for biosensors, comprising a mixture of polymers and epoxy resin, which forms a durable coating that enhances adhesion to the enzyme layer and electrode, reducing enzyme loss and membrane degradation, while also serving as a diffusion barrier and interference eliminator.

Biocompatibility and Sustainability Considerations

In the development of plasmonic biosensors, biocompatibility and sustainability considerations have become increasingly critical factors that influence both research directions and commercial applications. Polymer materials used in these biosensors must demonstrate compatibility with biological systems to ensure accurate detection without causing adverse reactions when in contact with biological fluids, tissues, or cells.

The biocompatibility of polymers in plasmonic biosensor construction varies significantly across different polymer types. Natural polymers such as chitosan, alginate, and cellulose derivatives generally exhibit excellent biocompatibility and biodegradability, making them suitable for in vivo applications. Synthetic polymers like polyethylene glycol (PEG), poly(methyl methacrylate) (PMMA), and polydimethylsiloxane (PDMS) have also demonstrated good biocompatibility profiles, though their degradation pathways differ substantially from natural alternatives.

Recent studies have highlighted the importance of surface modifications to enhance biocompatibility. Techniques such as plasma treatment, UV-ozone exposure, and chemical functionalization can significantly improve the interaction between polymer surfaces and biological entities. These modifications can reduce non-specific protein adsorption, which is a common challenge in biosensor applications that can lead to decreased sensitivity and false readings.

From a sustainability perspective, the environmental impact of polymer-based plasmonic biosensors must be carefully evaluated. Traditional petroleum-derived polymers present end-of-life disposal challenges, contributing to persistent environmental pollution. The research community has increasingly focused on developing biosensors using biodegradable and renewable polymers, such as polylactic acid (PLA), polyhydroxyalkanoates (PHAs), and starch-based composites, which offer reduced environmental footprints.

Life cycle assessment (LCA) studies comparing different polymer materials in biosensor applications reveal significant variations in environmental impact. Factors such as raw material sourcing, manufacturing energy requirements, use-phase durability, and end-of-life management all contribute to the overall sustainability profile. For instance, while some biopolymers may offer improved end-of-life characteristics, their production may require more energy or water resources compared to conventional polymers.

The recyclability of polymer components in plasmonic biosensors presents another important consideration. Thermoset polymers, once cured, cannot be remelted and reformed, limiting their recyclability. In contrast, thermoplastic polymers offer better recycling potential, though contamination with biological materials and metallic nanoparticles can complicate recycling processes. Emerging design approaches emphasizing modular construction and material separation may help address these challenges.

Regulatory frameworks worldwide are increasingly emphasizing both biocompatibility and sustainability aspects of medical and diagnostic devices. The FDA in the United States and the European Medical Device Regulation have established stringent requirements for biocompatibility testing, while various environmental regulations are beginning to address the sustainability aspects of these technologies.

The biocompatibility of polymers in plasmonic biosensor construction varies significantly across different polymer types. Natural polymers such as chitosan, alginate, and cellulose derivatives generally exhibit excellent biocompatibility and biodegradability, making them suitable for in vivo applications. Synthetic polymers like polyethylene glycol (PEG), poly(methyl methacrylate) (PMMA), and polydimethylsiloxane (PDMS) have also demonstrated good biocompatibility profiles, though their degradation pathways differ substantially from natural alternatives.

Recent studies have highlighted the importance of surface modifications to enhance biocompatibility. Techniques such as plasma treatment, UV-ozone exposure, and chemical functionalization can significantly improve the interaction between polymer surfaces and biological entities. These modifications can reduce non-specific protein adsorption, which is a common challenge in biosensor applications that can lead to decreased sensitivity and false readings.

From a sustainability perspective, the environmental impact of polymer-based plasmonic biosensors must be carefully evaluated. Traditional petroleum-derived polymers present end-of-life disposal challenges, contributing to persistent environmental pollution. The research community has increasingly focused on developing biosensors using biodegradable and renewable polymers, such as polylactic acid (PLA), polyhydroxyalkanoates (PHAs), and starch-based composites, which offer reduced environmental footprints.

Life cycle assessment (LCA) studies comparing different polymer materials in biosensor applications reveal significant variations in environmental impact. Factors such as raw material sourcing, manufacturing energy requirements, use-phase durability, and end-of-life management all contribute to the overall sustainability profile. For instance, while some biopolymers may offer improved end-of-life characteristics, their production may require more energy or water resources compared to conventional polymers.

The recyclability of polymer components in plasmonic biosensors presents another important consideration. Thermoset polymers, once cured, cannot be remelted and reformed, limiting their recyclability. In contrast, thermoplastic polymers offer better recycling potential, though contamination with biological materials and metallic nanoparticles can complicate recycling processes. Emerging design approaches emphasizing modular construction and material separation may help address these challenges.

Regulatory frameworks worldwide are increasingly emphasizing both biocompatibility and sustainability aspects of medical and diagnostic devices. The FDA in the United States and the European Medical Device Regulation have established stringent requirements for biocompatibility testing, while various environmental regulations are beginning to address the sustainability aspects of these technologies.

Manufacturing Scalability and Cost Analysis

The scalability of manufacturing processes for plasmonic biosensors incorporating polymers presents significant challenges and opportunities for commercial viability. Current production methods for polymer-based plasmonic biosensors predominantly rely on laboratory-scale techniques such as spin coating, dip coating, and nanoimprint lithography. These approaches, while effective for research purposes, face substantial barriers when transitioning to industrial-scale production. The cost analysis reveals that material expenses constitute approximately 30-40% of total manufacturing costs, with polymers like PMMA and PDMS offering cost advantages over traditional inorganic materials.

Manufacturing scalability depends heavily on the polymer type selected. Thermoplastics such as PMMA and PC demonstrate superior compatibility with high-throughput processes including injection molding and roll-to-roll manufacturing, potentially reducing unit costs by 60-75% at volumes exceeding 100,000 units. Conversely, specialized polymers with enhanced optical properties often require more complex processing techniques, limiting scalability and increasing production costs by 2-3 times compared to standard polymers.

Equipment investment represents a significant barrier to scaled production, with specialized nanofabrication tools requiring capital expenditures of $500,000 to $2 million. This creates a substantial entry threshold for startups and smaller enterprises. Operational costs further impact economic feasibility, with clean room facilities adding $200-500 per square meter annually in maintenance expenses.

Quality control processes become increasingly critical at scale, as polymer-based sensors exhibit greater batch-to-batch variability than their inorganic counterparts. Statistical process control methods must be implemented to maintain consistent sensor performance, adding approximately 15-20% to overall production costs but ensuring reliability.

Recent advancements in additive manufacturing technologies offer promising alternatives for cost-effective production. 3D printing approaches using photopolymers have demonstrated the ability to produce functional plasmonic structures with 70-80% lower tooling costs compared to traditional methods, though resolution limitations currently restrict their application to certain sensor designs.

Economic analysis indicates that polymer-based plasmonic biosensors become commercially viable at production volumes exceeding 10,000 units annually, with break-even points typically occurring within 2-3 years of initial investment. The integration of automated assembly processes can further reduce labor costs by 40-50%, significantly improving economic feasibility for mass-market applications in healthcare diagnostics and environmental monitoring.

Manufacturing scalability depends heavily on the polymer type selected. Thermoplastics such as PMMA and PC demonstrate superior compatibility with high-throughput processes including injection molding and roll-to-roll manufacturing, potentially reducing unit costs by 60-75% at volumes exceeding 100,000 units. Conversely, specialized polymers with enhanced optical properties often require more complex processing techniques, limiting scalability and increasing production costs by 2-3 times compared to standard polymers.

Equipment investment represents a significant barrier to scaled production, with specialized nanofabrication tools requiring capital expenditures of $500,000 to $2 million. This creates a substantial entry threshold for startups and smaller enterprises. Operational costs further impact economic feasibility, with clean room facilities adding $200-500 per square meter annually in maintenance expenses.

Quality control processes become increasingly critical at scale, as polymer-based sensors exhibit greater batch-to-batch variability than their inorganic counterparts. Statistical process control methods must be implemented to maintain consistent sensor performance, adding approximately 15-20% to overall production costs but ensuring reliability.

Recent advancements in additive manufacturing technologies offer promising alternatives for cost-effective production. 3D printing approaches using photopolymers have demonstrated the ability to produce functional plasmonic structures with 70-80% lower tooling costs compared to traditional methods, though resolution limitations currently restrict their application to certain sensor designs.

Economic analysis indicates that polymer-based plasmonic biosensors become commercially viable at production volumes exceeding 10,000 units annually, with break-even points typically occurring within 2-3 years of initial investment. The integration of automated assembly processes can further reduce labor costs by 40-50%, significantly improving economic feasibility for mass-market applications in healthcare diagnostics and environmental monitoring.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!