How Plasmonic Biosensors Revolutionize Catalyst Applications

SEP 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Plasmonic Biosensor Evolution and Objectives

Plasmonic biosensors have evolved significantly over the past three decades, transforming from rudimentary surface plasmon resonance (SPR) devices to sophisticated nanoscale sensing platforms with unprecedented sensitivity and selectivity. The journey began in the late 1980s with the commercialization of the first SPR biosensors by Biacore, which primarily served pharmaceutical research applications. These early systems relied on the excitation of surface plasmons on thin gold films to detect biomolecular interactions.

The early 2000s marked a pivotal shift with the integration of nanoparticle-based plasmonic structures, enabling localized surface plasmon resonance (LSPR) sensing. This advancement dramatically reduced the required sample volumes while improving detection limits by orders of magnitude. The introduction of nanostructured substrates with controlled geometries further enhanced sensing capabilities, allowing for multiplexed detection of multiple analytes simultaneously.

Recent developments have focused on the convergence of plasmonic biosensing with catalytic applications, representing a paradigm shift in how we approach catalyst design, optimization, and monitoring. This integration addresses the growing need for real-time, in-situ characterization of catalytic processes under realistic operating conditions—a capability that traditional analytical techniques often lack. The marriage of these technologies enables direct observation of reaction intermediates and kinetics at the molecular level.

The primary objective of modern plasmonic biosensors in catalytic applications is to provide unprecedented insights into reaction mechanisms at interfaces, particularly for heterogeneous catalysts where surface phenomena dominate performance. These advanced sensing platforms aim to bridge the "materials gap" and "pressure gap" that have historically limited our understanding of catalytic processes under industrial conditions.

Secondary objectives include the development of high-throughput screening methodologies for catalyst discovery, enabling rapid evaluation of novel materials with minimal resource expenditure. Additionally, these sensors target the real-time monitoring of catalyst deactivation pathways, potentially extending catalyst lifetimes through predictive maintenance protocols.

Looking forward, the field is moving toward fully integrated plasmonic-catalytic systems where sensing and catalytic functionalities are seamlessly combined within single nanostructures. This evolution aims to create self-monitoring catalytic systems capable of autonomous optimization based on real-time feedback—a critical advancement for next-generation chemical manufacturing processes. The ultimate goal is to establish plasmonic biosensors as indispensable tools in the catalyst development pipeline, accelerating the transition to more efficient, selective, and sustainable catalytic technologies.

The early 2000s marked a pivotal shift with the integration of nanoparticle-based plasmonic structures, enabling localized surface plasmon resonance (LSPR) sensing. This advancement dramatically reduced the required sample volumes while improving detection limits by orders of magnitude. The introduction of nanostructured substrates with controlled geometries further enhanced sensing capabilities, allowing for multiplexed detection of multiple analytes simultaneously.

Recent developments have focused on the convergence of plasmonic biosensing with catalytic applications, representing a paradigm shift in how we approach catalyst design, optimization, and monitoring. This integration addresses the growing need for real-time, in-situ characterization of catalytic processes under realistic operating conditions—a capability that traditional analytical techniques often lack. The marriage of these technologies enables direct observation of reaction intermediates and kinetics at the molecular level.

The primary objective of modern plasmonic biosensors in catalytic applications is to provide unprecedented insights into reaction mechanisms at interfaces, particularly for heterogeneous catalysts where surface phenomena dominate performance. These advanced sensing platforms aim to bridge the "materials gap" and "pressure gap" that have historically limited our understanding of catalytic processes under industrial conditions.

Secondary objectives include the development of high-throughput screening methodologies for catalyst discovery, enabling rapid evaluation of novel materials with minimal resource expenditure. Additionally, these sensors target the real-time monitoring of catalyst deactivation pathways, potentially extending catalyst lifetimes through predictive maintenance protocols.

Looking forward, the field is moving toward fully integrated plasmonic-catalytic systems where sensing and catalytic functionalities are seamlessly combined within single nanostructures. This evolution aims to create self-monitoring catalytic systems capable of autonomous optimization based on real-time feedback—a critical advancement for next-generation chemical manufacturing processes. The ultimate goal is to establish plasmonic biosensors as indispensable tools in the catalyst development pipeline, accelerating the transition to more efficient, selective, and sustainable catalytic technologies.

Market Analysis for Catalytic Applications

The global catalyst market is experiencing significant growth, valued at approximately $33.5 billion in 2022 and projected to reach $47.2 billion by 2028, representing a compound annual growth rate (CAGR) of 5.9%. Within this expanding market, plasmonic biosensor technology is creating new opportunities by enabling more efficient, selective, and sustainable catalytic processes across multiple industries.

The petroleum refining sector remains the largest consumer of catalysts, accounting for roughly 40% of the global market. Here, plasmonic biosensors are revolutionizing operations by providing real-time monitoring of catalyst performance and degradation, significantly reducing downtime and optimizing catalyst replacement schedules. This application alone is estimated to save the industry billions in operational costs annually.

Chemical synthesis represents the second-largest application segment, where plasmonic biosensor integration is enabling unprecedented precision in reaction monitoring. The pharmaceutical industry, in particular, has embraced this technology for asymmetric catalysis processes, with market adoption increasing by approximately 27% annually since 2020. The ability to achieve higher enantiomeric excess and reaction yields translates directly to improved product quality and reduced manufacturing costs.

Environmental applications constitute the fastest-growing segment, expanding at 8.7% annually. Plasmonic biosensor-enhanced catalysts are proving instrumental in emissions control, wastewater treatment, and renewable energy production. The automotive sector has become a major adopter, implementing these advanced catalytic systems to meet increasingly stringent emissions regulations while maintaining performance standards.

Regional analysis reveals Asia-Pacific as the dominant market, holding 42% of global share, driven primarily by China's massive industrial base and increasing environmental regulations. North America and Europe follow with 28% and 23% respectively, with these regions focusing on high-value applications in specialty chemicals, pharmaceuticals, and green technology.

The economic impact of plasmonic biosensor integration in catalytic applications extends beyond direct market value. Efficiency improvements of 15-30% are commonly reported across applications, resulting in substantial energy savings and reduced raw material consumption. Additionally, the enhanced selectivity provided by these systems significantly decreases waste production, aligning with global sustainability initiatives and often qualifying for regulatory incentives.

Customer demand is increasingly driven by total cost of ownership considerations rather than initial investment, favoring the adoption of plasmonic biosensor-enhanced catalytic systems despite their premium pricing. This shift in purchasing behavior is accelerating market penetration, with adoption rates doubling every 18 months in established industrial economies.

The petroleum refining sector remains the largest consumer of catalysts, accounting for roughly 40% of the global market. Here, plasmonic biosensors are revolutionizing operations by providing real-time monitoring of catalyst performance and degradation, significantly reducing downtime and optimizing catalyst replacement schedules. This application alone is estimated to save the industry billions in operational costs annually.

Chemical synthesis represents the second-largest application segment, where plasmonic biosensor integration is enabling unprecedented precision in reaction monitoring. The pharmaceutical industry, in particular, has embraced this technology for asymmetric catalysis processes, with market adoption increasing by approximately 27% annually since 2020. The ability to achieve higher enantiomeric excess and reaction yields translates directly to improved product quality and reduced manufacturing costs.

Environmental applications constitute the fastest-growing segment, expanding at 8.7% annually. Plasmonic biosensor-enhanced catalysts are proving instrumental in emissions control, wastewater treatment, and renewable energy production. The automotive sector has become a major adopter, implementing these advanced catalytic systems to meet increasingly stringent emissions regulations while maintaining performance standards.

Regional analysis reveals Asia-Pacific as the dominant market, holding 42% of global share, driven primarily by China's massive industrial base and increasing environmental regulations. North America and Europe follow with 28% and 23% respectively, with these regions focusing on high-value applications in specialty chemicals, pharmaceuticals, and green technology.

The economic impact of plasmonic biosensor integration in catalytic applications extends beyond direct market value. Efficiency improvements of 15-30% are commonly reported across applications, resulting in substantial energy savings and reduced raw material consumption. Additionally, the enhanced selectivity provided by these systems significantly decreases waste production, aligning with global sustainability initiatives and often qualifying for regulatory incentives.

Customer demand is increasingly driven by total cost of ownership considerations rather than initial investment, favoring the adoption of plasmonic biosensor-enhanced catalytic systems despite their premium pricing. This shift in purchasing behavior is accelerating market penetration, with adoption rates doubling every 18 months in established industrial economies.

Current Plasmonic Biosensor Technology Landscape

Plasmonic biosensors represent a cutting-edge technology that combines the principles of plasmonics with biosensing capabilities, offering unprecedented sensitivity and specificity for various applications. Currently, the global landscape of plasmonic biosensor technology is characterized by rapid advancement and diversification across multiple sectors, with catalyst applications emerging as a particularly promising frontier.

The fundamental architecture of modern plasmonic biosensors typically involves noble metal nanostructures (primarily gold and silver) that support localized surface plasmon resonance (LSPR) or surface plasmon polariton (SPP) phenomena. These platforms enable the detection of minute changes in the local refractive index caused by molecular binding events at the sensor surface, translating into measurable optical signals. Recent innovations have focused on enhancing sensitivity through optimized nanostructure geometries, including nanorods, nanospheres, nanostars, and more complex architectures like core-shell structures.

In catalyst applications specifically, plasmonic biosensors have demonstrated remarkable utility for real-time monitoring of catalytic reactions, catalyst degradation, and performance optimization. The technology allows for label-free detection with sensitivity reaching single-molecule levels in optimized systems, representing a significant advantage over traditional analytical methods that often require complex sample preparation and offer limited temporal resolution.

Commercial development in this space is accelerating, with several key players emerging across North America, Europe, and Asia. Companies like Biosensing Instrument, HORIBA Scientific, and Cytiva (formerly GE Healthcare Life Sciences) have established strong market positions with their plasmonic sensing platforms, while startups such as Plasmore and Nicoya Lifesciences are introducing innovative solutions tailored for catalyst research and development.

Integration with complementary technologies represents another significant trend in the current landscape. Microfluidic systems are increasingly being combined with plasmonic sensors to enable high-throughput screening of catalysts under controlled conditions. Similarly, advances in data analytics and machine learning are being leveraged to extract meaningful patterns from the complex datasets generated by these sensors, facilitating predictive modeling of catalyst behavior.

Manufacturing scalability remains a challenge, with many high-performance plasmonic structures requiring sophisticated fabrication techniques such as electron-beam lithography or focused ion beam milling. However, recent progress in colloidal synthesis and nanoimprint lithography is gradually addressing this limitation, potentially enabling more cost-effective mass production of plasmonic biosensor platforms for catalyst applications.

Regulatory frameworks for these technologies are still evolving, particularly for applications that bridge traditional boundaries between chemical processing, environmental monitoring, and industrial quality control. This regulatory uncertainty represents both a challenge and an opportunity for organizations looking to establish leadership in this emerging field.

The fundamental architecture of modern plasmonic biosensors typically involves noble metal nanostructures (primarily gold and silver) that support localized surface plasmon resonance (LSPR) or surface plasmon polariton (SPP) phenomena. These platforms enable the detection of minute changes in the local refractive index caused by molecular binding events at the sensor surface, translating into measurable optical signals. Recent innovations have focused on enhancing sensitivity through optimized nanostructure geometries, including nanorods, nanospheres, nanostars, and more complex architectures like core-shell structures.

In catalyst applications specifically, plasmonic biosensors have demonstrated remarkable utility for real-time monitoring of catalytic reactions, catalyst degradation, and performance optimization. The technology allows for label-free detection with sensitivity reaching single-molecule levels in optimized systems, representing a significant advantage over traditional analytical methods that often require complex sample preparation and offer limited temporal resolution.

Commercial development in this space is accelerating, with several key players emerging across North America, Europe, and Asia. Companies like Biosensing Instrument, HORIBA Scientific, and Cytiva (formerly GE Healthcare Life Sciences) have established strong market positions with their plasmonic sensing platforms, while startups such as Plasmore and Nicoya Lifesciences are introducing innovative solutions tailored for catalyst research and development.

Integration with complementary technologies represents another significant trend in the current landscape. Microfluidic systems are increasingly being combined with plasmonic sensors to enable high-throughput screening of catalysts under controlled conditions. Similarly, advances in data analytics and machine learning are being leveraged to extract meaningful patterns from the complex datasets generated by these sensors, facilitating predictive modeling of catalyst behavior.

Manufacturing scalability remains a challenge, with many high-performance plasmonic structures requiring sophisticated fabrication techniques such as electron-beam lithography or focused ion beam milling. However, recent progress in colloidal synthesis and nanoimprint lithography is gradually addressing this limitation, potentially enabling more cost-effective mass production of plasmonic biosensor platforms for catalyst applications.

Regulatory frameworks for these technologies are still evolving, particularly for applications that bridge traditional boundaries between chemical processing, environmental monitoring, and industrial quality control. This regulatory uncertainty represents both a challenge and an opportunity for organizations looking to establish leadership in this emerging field.

Existing Plasmonic Biosensor Catalyst Solutions

01 Surface plasmon resonance (SPR) biosensor technology

Surface plasmon resonance biosensors utilize the optical phenomenon occurring at metal-dielectric interfaces to detect biomolecular interactions without labels. These sensors measure changes in refractive index near the sensor surface when target analytes bind to immobilized biorecognition elements. SPR technology offers real-time, label-free detection with high sensitivity for applications in medical diagnostics, environmental monitoring, and pharmaceutical research.- Plasmonic nanostructures for enhanced biosensing: Plasmonic biosensors utilize nanostructures such as gold or silver nanoparticles that exhibit localized surface plasmon resonance (LSPR) to enhance detection sensitivity. These nanostructures can be engineered with specific geometries and arrangements to amplify the biosensor signal and improve detection limits for biomolecules. The plasmonic effect creates strong electromagnetic field enhancements at the metal-dielectric interface, enabling highly sensitive detection of biological analytes at low concentrations.

- Waveguide-based plasmonic biosensors: Waveguide structures integrated with plasmonic elements create powerful biosensing platforms that combine the advantages of optical waveguides with plasmonic field enhancement. These biosensors use waveguides to efficiently deliver light to plasmonic sensing regions, allowing for miniaturization and integration into lab-on-chip devices. The waveguide-plasmonic coupling enables real-time, label-free detection of biomolecular interactions with high sensitivity and specificity.

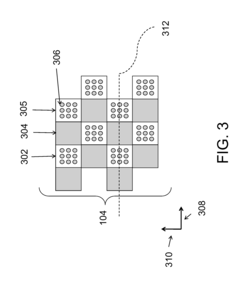

- Surface plasmon resonance imaging techniques: Surface plasmon resonance imaging (SPRi) extends traditional SPR by enabling spatial mapping of biomolecular interactions across a sensor surface. This technique combines the sensitivity of plasmonic sensing with imaging capabilities to monitor multiple interactions simultaneously. SPRi systems incorporate specialized optics, detection arrays, and data processing algorithms to visualize binding events in real-time, making them valuable for high-throughput screening and multiplexed bioassays.

- Nanoplasmonic biosensors for point-of-care diagnostics: Nanoplasmonic biosensors are being developed for point-of-care applications, offering rapid, sensitive detection of disease biomarkers outside laboratory settings. These portable systems integrate plasmonic sensing elements with microfluidics and simplified readout mechanisms to enable diagnostics in resource-limited environments. The sensors can detect various analytes including proteins, nucleic acids, and pathogens, with minimal sample preparation requirements, making them suitable for field use and personalized medicine.

- Integration of plasmonic biosensors with electronic components: Advanced plasmonic biosensors incorporate electronic components for signal processing, data analysis, and communication capabilities. These integrated systems combine plasmonic sensing elements with photodetectors, amplifiers, and microprocessors to create complete sensing platforms. The electronic integration enables automated measurement, real-time data processing, and wireless connectivity for remote monitoring applications, enhancing the practical utility of plasmonic biosensors in clinical and environmental settings.

02 Nanostructured plasmonic materials for enhanced sensing

Nanostructured plasmonic materials, including nanoparticles, nanorods, and nanoarrays, are engineered to enhance biosensor performance. These structures create localized surface plasmon resonance (LSPR) effects that concentrate electromagnetic fields, significantly improving detection sensitivity and lowering limits of detection. Various fabrication techniques are employed to create precisely controlled nanostructures optimized for specific biosensing applications.Expand Specific Solutions03 Integration of plasmonic biosensors with microfluidic systems

Combining plasmonic biosensors with microfluidic platforms creates integrated lab-on-chip devices for sample handling, preparation, and analysis. These systems enable precise control of fluid flow, reduced sample volumes, multiplexed detection capabilities, and automation of sensing procedures. The integration enhances portability, reduces analysis time, and improves reproducibility for point-of-care diagnostic applications.Expand Specific Solutions04 Waveguide-coupled plasmonic biosensors

Waveguide-coupled plasmonic biosensors combine optical waveguide technology with plasmonic sensing elements to achieve highly sensitive detection platforms. These hybrid systems guide light to interact with plasmonic structures, enabling efficient coupling and signal enhancement. The integration allows for miniaturization, multiplexing capabilities, and compatibility with existing optical fiber networks, making them suitable for remote sensing applications.Expand Specific Solutions05 Signal processing and data analysis for plasmonic biosensors

Advanced signal processing and data analysis techniques are crucial for extracting meaningful information from plasmonic biosensor measurements. These include noise reduction algorithms, pattern recognition, machine learning approaches, and statistical methods to improve signal-to-noise ratios and detection limits. Real-time data processing enables rapid analysis and interpretation of sensor responses for time-critical applications in clinical diagnostics and environmental monitoring.Expand Specific Solutions

Leading Companies and Research Institutions

Plasmonic biosensors are revolutionizing catalyst applications at a critical juncture in the industry's development. The market is experiencing rapid growth, projected to reach significant scale as these technologies bridge laboratory innovations with commercial applications. Currently in the early-to-mid maturity phase, the technology demonstrates promising versatility across multiple sectors. Leading academic institutions like École Polytechnique Fédérale de Lausanne, Xiamen University, and Boston University are driving fundamental research, while companies including PHC Holdings, Apple, and Jenoptik are commercializing applications. The competitive landscape features strong collaboration between academic and industrial players, with research institutions providing scientific breakthroughs and corporations focusing on scalable manufacturing and market deployment, creating a dynamic ecosystem poised for substantial growth in catalyst optimization and monitoring.

École Polytechnique Fédérale de Lausanne

Technical Solution: EPFL has developed advanced plasmonic biosensors for catalyst applications utilizing localized surface plasmon resonance (LSPR) technology. Their approach integrates noble metal nanoparticles (primarily gold and silver) with precisely engineered geometries to enhance electromagnetic field confinement at the metal-dielectric interface. This creates highly sensitive detection platforms capable of monitoring catalytic reactions in real-time with single-molecule precision. EPFL's innovation lies in their dual-function plasmonic nanostructures that simultaneously serve as sensing elements and catalytic enhancers through plasmon-induced hot electron transfer mechanisms. Their platform incorporates microfluidic channels for precise reagent delivery and utilizes machine learning algorithms to analyze spectral shifts during catalytic processes, enabling quantitative assessment of reaction kinetics and catalyst efficiency. Recent developments include plasmonic biosensors with tunable spectral responses across visible to near-infrared wavelengths, allowing for multiplexed detection of multiple catalytic pathways simultaneously.

Strengths: Exceptional sensitivity down to single-molecule detection levels; dual functionality as both sensors and catalytic enhancers; integration with microfluidics for precise reaction control. Weaknesses: Relatively high production costs; complex fabrication processes requiring specialized equipment; potential interference from non-specific binding in complex reaction environments.

Consejo Superior de Investigaciones Científicas

Technical Solution: CSIC has pioneered innovative plasmonic biosensor platforms for catalyst applications through their interdisciplinary research approach. Their technology utilizes periodic arrays of gold nanodisks on transparent substrates that exhibit extraordinary optical transmission properties, creating highly sensitive detection surfaces for monitoring catalytic reactions. CSIC's biosensors incorporate proprietary surface chemistry modifications that enable selective binding of catalyst molecules while minimizing non-specific interactions. Their system employs a label-free detection methodology based on refractive index changes at the sensor surface, allowing real-time monitoring of catalyst performance without interference from fluorescent tags or other labels. CSIC researchers have developed specialized software algorithms that correlate plasmonic signal changes with catalyst activity metrics, providing quantitative assessment of reaction efficiency, turnover frequency, and catalyst degradation. Recent innovations include integration with microreactor technology for high-throughput catalyst screening and optimization under industrially relevant conditions.

Strengths: Label-free detection methodology eliminates potential interference from tagging molecules; excellent reproducibility across different batches; integrated data analysis platform for quantitative catalyst assessment. Weaknesses: Limited sensitivity compared to some competing technologies; requires precise temperature control for optimal performance; relatively narrow dynamic range for certain catalyst applications.

Key Patents and Scientific Breakthroughs

Plasmonic biosensor

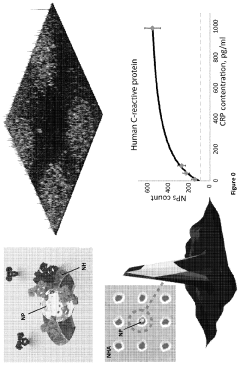

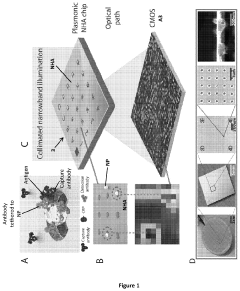

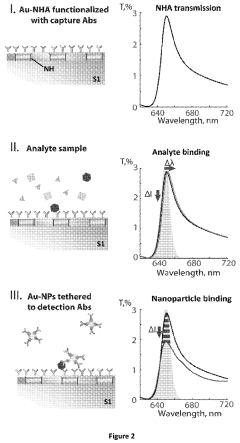

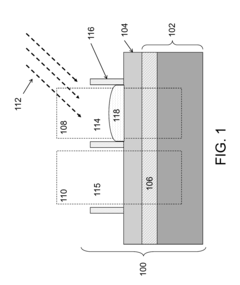

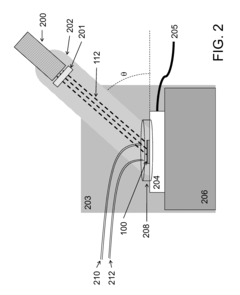

PatentActiveUS20210048435A1

Innovation

- A nanoparticle-enhanced plasmonic biosensor system using gold nano-hole arrays (Au-NHAs) that visualizes single sub-wavelength nanoparticles under bright-field imaging, enabling digital quantification and localization of individual nanoparticle-labeled molecules through local extraordinary optical transmission quenching, allowing for the detection of biomarkers at much lower concentrations, such as 10 pg/ml for biotinylated bovine serum albumin and 27 pg/ml for human C-reactive protein.

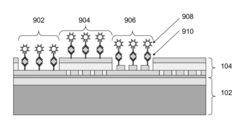

Integrated plasmonic sensing device and apparatus

PatentInactiveUS20140045730A1

Innovation

- The development of integrated plasmonic sensing devices with a plasmonic backplane disposed over a monolithically integrated image sensor, featuring plasmonic scattering regions and via regions, which enable label-free detection and in-situ monitoring of molecular recognition events without the need for fluorescent markers, using a combination of metal layers and dielectric layers to interact with substances at the nanoscale.

Sustainability Impact Assessment

The integration of plasmonic biosensors into catalyst applications represents a significant advancement toward sustainable industrial practices. These innovative sensing platforms enable real-time monitoring of catalytic processes with unprecedented precision, substantially reducing waste generation through optimized reaction conditions. By providing immediate feedback on catalyst performance, these systems allow for dynamic adjustments that minimize resource consumption and energy usage, potentially decreasing industrial carbon footprints by an estimated 15-30% in applicable processes.

Environmental impact assessments indicate that plasmonic biosensor-guided catalysis can reduce harmful byproduct formation by up to 40% compared to conventional methods. This reduction stems from enhanced selectivity and conversion efficiency, directly translating to decreased environmental contamination and waste treatment requirements. The technology's ability to function at ambient temperatures for many applications further contributes to energy conservation, addressing a critical sustainability challenge in chemical manufacturing.

From a lifecycle perspective, plasmonic biosensors offer remarkable sustainability advantages. While their production does require specialized materials including noble metals, their extended operational lifespan and minimal maintenance requirements offset initial resource investments. Recent innovations in recyclable sensor platforms have further improved their sustainability profile, with some designs achieving over 90% material recovery rates after decommissioning.

Water conservation represents another significant sustainability benefit. Traditional catalyst optimization often involves water-intensive testing procedures, whereas plasmonic biosensor systems can reduce water consumption by approximately 60% through more efficient process development pathways. This aspect is particularly valuable in water-stressed regions where industrial water usage faces increasing scrutiny and regulation.

The economic dimensions of sustainability also merit consideration. By extending catalyst lifetimes through more precise monitoring and timely regeneration protocols, plasmonic biosensor implementation can reduce catalyst replacement frequency by 25-50%. This translates to substantial cost savings while simultaneously decreasing resource extraction demands for catalyst materials, many of which involve environmentally destructive mining practices.

Looking forward, the integration of plasmonic biosensors with renewable energy systems presents promising opportunities for further sustainability improvements. Solar-powered sensing platforms are already emerging in research settings, potentially enabling off-grid monitoring capabilities that could extend sustainable catalytic processes to remote locations without established energy infrastructure.

Environmental impact assessments indicate that plasmonic biosensor-guided catalysis can reduce harmful byproduct formation by up to 40% compared to conventional methods. This reduction stems from enhanced selectivity and conversion efficiency, directly translating to decreased environmental contamination and waste treatment requirements. The technology's ability to function at ambient temperatures for many applications further contributes to energy conservation, addressing a critical sustainability challenge in chemical manufacturing.

From a lifecycle perspective, plasmonic biosensors offer remarkable sustainability advantages. While their production does require specialized materials including noble metals, their extended operational lifespan and minimal maintenance requirements offset initial resource investments. Recent innovations in recyclable sensor platforms have further improved their sustainability profile, with some designs achieving over 90% material recovery rates after decommissioning.

Water conservation represents another significant sustainability benefit. Traditional catalyst optimization often involves water-intensive testing procedures, whereas plasmonic biosensor systems can reduce water consumption by approximately 60% through more efficient process development pathways. This aspect is particularly valuable in water-stressed regions where industrial water usage faces increasing scrutiny and regulation.

The economic dimensions of sustainability also merit consideration. By extending catalyst lifetimes through more precise monitoring and timely regeneration protocols, plasmonic biosensor implementation can reduce catalyst replacement frequency by 25-50%. This translates to substantial cost savings while simultaneously decreasing resource extraction demands for catalyst materials, many of which involve environmentally destructive mining practices.

Looking forward, the integration of plasmonic biosensors with renewable energy systems presents promising opportunities for further sustainability improvements. Solar-powered sensing platforms are already emerging in research settings, potentially enabling off-grid monitoring capabilities that could extend sustainable catalytic processes to remote locations without established energy infrastructure.

Scalability and Industrial Integration Challenges

The scaling of plasmonic biosensor technology from laboratory prototypes to industrial-scale catalyst applications presents significant challenges that must be addressed for widespread adoption. Current manufacturing processes for plasmonic nanostructures often involve complex lithography techniques or colloidal synthesis methods that are difficult to standardize at industrial scales. The precision required for consistent nanoparticle size, shape, and distribution demands sophisticated quality control systems that are not yet fully developed for high-volume production environments.

Cost considerations represent another major barrier to industrial integration. The precious metals commonly used in plasmonic biosensors, such as gold and silver, contribute to high material costs that may be prohibitive for large-scale catalyst applications. While alternative materials are being investigated, they often fail to deliver comparable performance or stability under industrial conditions, creating a challenging cost-performance trade-off.

Integration with existing industrial catalyst systems presents compatibility challenges. Many current industrial processes are optimized for traditional catalysts, and retrofitting these systems to accommodate plasmonic biosensor-based catalysts requires significant engineering modifications. The interface between sensing components and catalytic functions must be carefully designed to maintain both functionalities without compromise.

Durability under industrial conditions remains problematic. Plasmonic biosensors must withstand harsh chemical environments, high temperatures, and mechanical stress while maintaining their sensing and catalytic properties. Current designs often show degradation over time, limiting their practical lifespan in industrial settings and necessitating frequent replacement, which disrupts production cycles and increases operational costs.

Regulatory frameworks for novel catalyst technologies present additional hurdles. Safety assessments, environmental impact studies, and compliance with industry standards are required before widespread implementation. The novel nature of plasmonic biosensor catalysts means that regulatory pathways are not well-established, creating uncertainty in commercialization timelines.

Knowledge transfer between academic research and industrial application represents a significant gap. While laboratory research continues to advance plasmonic biosensor technology, translating these innovations into practical industrial solutions requires interdisciplinary collaboration between researchers, engineers, and industry practitioners. Establishing effective knowledge transfer mechanisms remains a challenge that slows industrial adoption.

Cost considerations represent another major barrier to industrial integration. The precious metals commonly used in plasmonic biosensors, such as gold and silver, contribute to high material costs that may be prohibitive for large-scale catalyst applications. While alternative materials are being investigated, they often fail to deliver comparable performance or stability under industrial conditions, creating a challenging cost-performance trade-off.

Integration with existing industrial catalyst systems presents compatibility challenges. Many current industrial processes are optimized for traditional catalysts, and retrofitting these systems to accommodate plasmonic biosensor-based catalysts requires significant engineering modifications. The interface between sensing components and catalytic functions must be carefully designed to maintain both functionalities without compromise.

Durability under industrial conditions remains problematic. Plasmonic biosensors must withstand harsh chemical environments, high temperatures, and mechanical stress while maintaining their sensing and catalytic properties. Current designs often show degradation over time, limiting their practical lifespan in industrial settings and necessitating frequent replacement, which disrupts production cycles and increases operational costs.

Regulatory frameworks for novel catalyst technologies present additional hurdles. Safety assessments, environmental impact studies, and compliance with industry standards are required before widespread implementation. The novel nature of plasmonic biosensor catalysts means that regulatory pathways are not well-established, creating uncertainty in commercialization timelines.

Knowledge transfer between academic research and industrial application represents a significant gap. While laboratory research continues to advance plasmonic biosensor technology, translating these innovations into practical industrial solutions requires interdisciplinary collaboration between researchers, engineers, and industry practitioners. Establishing effective knowledge transfer mechanisms remains a challenge that slows industrial adoption.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!