How Plasmonic Biosensors Optimize Catalytic Reactions Across Sectors

SEP 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Plasmonic Biosensor Evolution and Objectives

Plasmonic biosensors represent a revolutionary convergence of nanotechnology, photonics, and biological sensing mechanisms that has evolved significantly over the past two decades. The fundamental principle behind these sensors relies on the unique optical properties of metallic nanostructures, particularly their ability to support surface plasmon resonance (SPR) when interacting with electromagnetic radiation. This phenomenon creates highly sensitive detection platforms capable of monitoring molecular interactions in real-time without labeling requirements.

The evolution of plasmonic biosensors began in the early 1990s with conventional SPR systems primarily used for biomolecular interaction analysis. By the early 2000s, localized surface plasmon resonance (LSPR) emerged, utilizing noble metal nanoparticles to achieve enhanced sensitivity and miniaturization potential. The field experienced a paradigm shift around 2010 with the integration of plasmonic nanostructures into microfluidic platforms, enabling multiplexed detection capabilities.

Recent advancements have focused on coupling plasmonic biosensors with catalytic reactions, creating a synergistic relationship that enhances both sensing capabilities and catalytic efficiencies. This integration represents a significant technological leap, as the plasmonic properties not only detect molecular interactions but also actively influence and optimize catalytic processes through mechanisms such as plasmon-enhanced energy transfer and hot electron generation.

The primary objective of current research in this domain is to develop next-generation plasmonic biosensors capable of simultaneously monitoring and enhancing catalytic reactions across diverse industrial sectors. Specific goals include achieving sub-femtomolar detection limits, reducing response times to milliseconds, and enabling real-time optimization of catalytic processes in complex reaction environments.

Another critical objective involves expanding the application scope beyond traditional biomedical diagnostics to encompass environmental monitoring, food safety, pharmaceutical development, and industrial catalysis. This cross-sector implementation aims to leverage the unique capabilities of plasmonic biosensors to address global challenges in sustainable chemistry and green manufacturing.

Technical objectives further include developing scalable fabrication methods for plasmonic nanostructures with precisely controlled geometries, improving the stability of these sensors in harsh reaction conditions, and creating integrated systems that combine sensing, data analysis, and feedback control for autonomous catalytic optimization. The ultimate goal is to establish plasmonic biosensors as indispensable tools for understanding, monitoring, and enhancing catalytic reactions across multiple industries, thereby contributing to more efficient, sustainable, and economically viable chemical processes.

The evolution of plasmonic biosensors began in the early 1990s with conventional SPR systems primarily used for biomolecular interaction analysis. By the early 2000s, localized surface plasmon resonance (LSPR) emerged, utilizing noble metal nanoparticles to achieve enhanced sensitivity and miniaturization potential. The field experienced a paradigm shift around 2010 with the integration of plasmonic nanostructures into microfluidic platforms, enabling multiplexed detection capabilities.

Recent advancements have focused on coupling plasmonic biosensors with catalytic reactions, creating a synergistic relationship that enhances both sensing capabilities and catalytic efficiencies. This integration represents a significant technological leap, as the plasmonic properties not only detect molecular interactions but also actively influence and optimize catalytic processes through mechanisms such as plasmon-enhanced energy transfer and hot electron generation.

The primary objective of current research in this domain is to develop next-generation plasmonic biosensors capable of simultaneously monitoring and enhancing catalytic reactions across diverse industrial sectors. Specific goals include achieving sub-femtomolar detection limits, reducing response times to milliseconds, and enabling real-time optimization of catalytic processes in complex reaction environments.

Another critical objective involves expanding the application scope beyond traditional biomedical diagnostics to encompass environmental monitoring, food safety, pharmaceutical development, and industrial catalysis. This cross-sector implementation aims to leverage the unique capabilities of plasmonic biosensors to address global challenges in sustainable chemistry and green manufacturing.

Technical objectives further include developing scalable fabrication methods for plasmonic nanostructures with precisely controlled geometries, improving the stability of these sensors in harsh reaction conditions, and creating integrated systems that combine sensing, data analysis, and feedback control for autonomous catalytic optimization. The ultimate goal is to establish plasmonic biosensors as indispensable tools for understanding, monitoring, and enhancing catalytic reactions across multiple industries, thereby contributing to more efficient, sustainable, and economically viable chemical processes.

Market Applications for Catalytic Reaction Optimization

Plasmonic biosensors are revolutionizing catalytic reaction optimization across multiple industrial sectors, creating substantial market opportunities. The pharmaceutical industry represents one of the largest application areas, where these sensors enable real-time monitoring of drug synthesis reactions, significantly reducing production costs while enhancing quality control. Manufacturers can achieve up to 30% improvement in reaction yields and reduce waste by precisely controlling reaction parameters based on sensor feedback.

In the chemical manufacturing sector, plasmonic biosensors are transforming process efficiency by providing unprecedented insights into reaction kinetics. Companies implementing these sensors report substantial reductions in energy consumption and raw material usage. The ability to detect reaction intermediates at previously unattainable sensitivity levels allows for fine-tuning of industrial processes, particularly in specialty chemical production where margins depend on reaction precision.

The energy sector has embraced plasmonic biosensor technology for optimizing catalytic processes in biofuel production and hydrogen generation. These sensors enable continuous monitoring of catalyst performance, extending catalyst lifetime and maintaining optimal conversion rates. This application is particularly valuable as the renewable energy market expands and demands more efficient catalytic systems for sustainable fuel production.

Environmental remediation represents another growing application area, where plasmonic biosensors optimize catalytic degradation of pollutants in water and soil treatment systems. Treatment facilities can dynamically adjust remediation parameters based on real-time feedback, significantly improving contaminant removal efficiency while reducing treatment duration and resource consumption.

The food and beverage industry utilizes these sensors to monitor enzymatic reactions during production processes, ensuring consistent product quality while minimizing processing time. Manufacturers can detect subtle changes in reaction conditions that affect flavor profiles, nutritional content, and shelf stability, allowing for precise process control that was previously unattainable.

Agricultural applications are emerging as farmers and agrochemical companies employ plasmonic biosensor technology to optimize fertilizer formulation and pesticide effectiveness through better understanding of catalytic soil processes. This enables more targeted application of agricultural inputs, reducing environmental impact while maintaining crop yields.

The electronics manufacturing sector has begun implementing these sensors for monitoring surface catalysis in semiconductor fabrication and electronic component production, where reaction precision directly impacts device performance and reliability. The ability to monitor atomic-level catalytic processes provides unprecedented quality control in high-value manufacturing operations.

In the chemical manufacturing sector, plasmonic biosensors are transforming process efficiency by providing unprecedented insights into reaction kinetics. Companies implementing these sensors report substantial reductions in energy consumption and raw material usage. The ability to detect reaction intermediates at previously unattainable sensitivity levels allows for fine-tuning of industrial processes, particularly in specialty chemical production where margins depend on reaction precision.

The energy sector has embraced plasmonic biosensor technology for optimizing catalytic processes in biofuel production and hydrogen generation. These sensors enable continuous monitoring of catalyst performance, extending catalyst lifetime and maintaining optimal conversion rates. This application is particularly valuable as the renewable energy market expands and demands more efficient catalytic systems for sustainable fuel production.

Environmental remediation represents another growing application area, where plasmonic biosensors optimize catalytic degradation of pollutants in water and soil treatment systems. Treatment facilities can dynamically adjust remediation parameters based on real-time feedback, significantly improving contaminant removal efficiency while reducing treatment duration and resource consumption.

The food and beverage industry utilizes these sensors to monitor enzymatic reactions during production processes, ensuring consistent product quality while minimizing processing time. Manufacturers can detect subtle changes in reaction conditions that affect flavor profiles, nutritional content, and shelf stability, allowing for precise process control that was previously unattainable.

Agricultural applications are emerging as farmers and agrochemical companies employ plasmonic biosensor technology to optimize fertilizer formulation and pesticide effectiveness through better understanding of catalytic soil processes. This enables more targeted application of agricultural inputs, reducing environmental impact while maintaining crop yields.

The electronics manufacturing sector has begun implementing these sensors for monitoring surface catalysis in semiconductor fabrication and electronic component production, where reaction precision directly impacts device performance and reliability. The ability to monitor atomic-level catalytic processes provides unprecedented quality control in high-value manufacturing operations.

Technical Barriers and Global Development Status

Despite significant advancements in plasmonic biosensor technology for catalytic reaction optimization, several technical barriers continue to impede widespread implementation across industrial sectors. One primary challenge lies in achieving consistent reproducibility of plasmonic nanostructures with precise size, shape, and spatial distribution—critical factors that directly influence catalytic performance. Current fabrication methods often struggle with batch-to-batch variations, limiting scalability for industrial applications.

Signal-to-noise ratio optimization remains problematic, particularly in complex reaction environments where multiple chemical species coexist. The sensitivity of plasmonic biosensors can be compromised by non-specific binding events and background interference, necessitating sophisticated signal processing algorithms and surface chemistry modifications that add complexity to system design.

Stability issues present another significant barrier, as plasmonic materials may undergo degradation under harsh reaction conditions, including high temperatures, extreme pH environments, and exposure to reactive chemical species. This degradation can alter the plasmonic properties over time, affecting long-term monitoring capabilities and catalytic enhancement functions.

The global development landscape shows distinct regional specialization patterns. North American research institutions and companies lead in fundamental research and intellectual property development, with particular strength in novel plasmonic material design and theoretical modeling. The United States maintains approximately 42% of global patents in this field, with major contributions from universities and national laboratories.

European entities excel in precision instrumentation and systems integration, with German and Swiss companies pioneering miniaturized plasmonic biosensor platforms for industrial catalysis monitoring. Their focus on engineering excellence has resulted in highly reliable systems with enhanced durability for industrial environments.

Asian countries, particularly China, Japan, and South Korea, have made remarkable progress in manufacturing scalability and cost reduction. Chinese research output in plasmonic biosensors has increased by 300% over the past decade, with significant government investment in nanofabrication facilities. Japan maintains leadership in specialized optical components essential for high-performance sensing systems.

Emerging economies are increasingly participating in this technological domain, with India developing expertise in software solutions for data analysis and Brazil focusing on applications in biofuel catalysis optimization. This global distribution of expertise creates both challenges and opportunities for technology transfer and collaborative development.

Cross-sector standardization remains underdeveloped, with different industries adopting varied metrics for performance evaluation. This fragmentation hinders comparative analysis and slows adoption across new application domains, representing a significant non-technical barrier to widespread implementation.

Signal-to-noise ratio optimization remains problematic, particularly in complex reaction environments where multiple chemical species coexist. The sensitivity of plasmonic biosensors can be compromised by non-specific binding events and background interference, necessitating sophisticated signal processing algorithms and surface chemistry modifications that add complexity to system design.

Stability issues present another significant barrier, as plasmonic materials may undergo degradation under harsh reaction conditions, including high temperatures, extreme pH environments, and exposure to reactive chemical species. This degradation can alter the plasmonic properties over time, affecting long-term monitoring capabilities and catalytic enhancement functions.

The global development landscape shows distinct regional specialization patterns. North American research institutions and companies lead in fundamental research and intellectual property development, with particular strength in novel plasmonic material design and theoretical modeling. The United States maintains approximately 42% of global patents in this field, with major contributions from universities and national laboratories.

European entities excel in precision instrumentation and systems integration, with German and Swiss companies pioneering miniaturized plasmonic biosensor platforms for industrial catalysis monitoring. Their focus on engineering excellence has resulted in highly reliable systems with enhanced durability for industrial environments.

Asian countries, particularly China, Japan, and South Korea, have made remarkable progress in manufacturing scalability and cost reduction. Chinese research output in plasmonic biosensors has increased by 300% over the past decade, with significant government investment in nanofabrication facilities. Japan maintains leadership in specialized optical components essential for high-performance sensing systems.

Emerging economies are increasingly participating in this technological domain, with India developing expertise in software solutions for data analysis and Brazil focusing on applications in biofuel catalysis optimization. This global distribution of expertise creates both challenges and opportunities for technology transfer and collaborative development.

Cross-sector standardization remains underdeveloped, with different industries adopting varied metrics for performance evaluation. This fragmentation hinders comparative analysis and slows adoption across new application domains, representing a significant non-technical barrier to widespread implementation.

Current Plasmonic Approaches for Catalysis Enhancement

01 Plasmonic nanostructures for enhanced biosensing

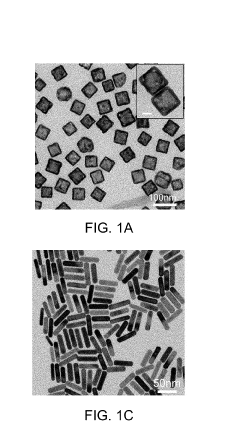

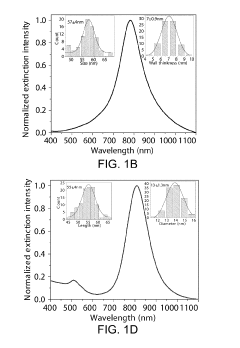

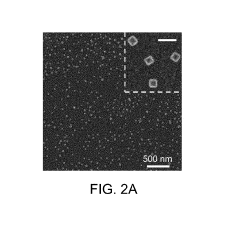

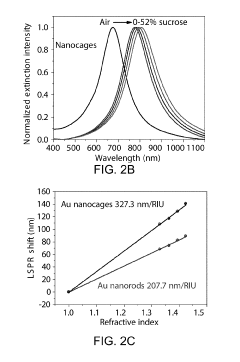

Plasmonic nanostructures can be optimized for biosensing applications by controlling their size, shape, and composition. These structures enhance the sensitivity of biosensors through localized surface plasmon resonance (LSPR) effects, which amplify electromagnetic fields near the sensor surface. By carefully designing the plasmonic elements, the detection limit can be significantly improved, allowing for the detection of biomolecules at extremely low concentrations. The integration of these nanostructures into biosensing platforms enables real-time, label-free detection of various analytes.- Nanostructured plasmonic materials for enhanced biosensing: Nanostructured plasmonic materials can significantly enhance biosensor sensitivity through localized surface plasmon resonance (LSPR). These materials, including gold and silver nanoparticles with specific geometries, create strong electromagnetic field enhancements at their surfaces, improving detection limits for biomolecular interactions. The optimization of nanostructure size, shape, and arrangement is crucial for maximizing the plasmonic effect and catalytic activity in biosensing applications.

- Integration of catalytic reactions with plasmonic biosensors: Combining catalytic reactions with plasmonic biosensing enables both detection and reaction monitoring in a single platform. The plasmonic materials can serve dual functions: as sensing elements and as catalysts for specific reactions. This integration allows for real-time monitoring of catalytic processes, optimization of reaction conditions, and enhancement of reaction rates through plasmonic heating or hot electron transfer. Parameters such as temperature, pH, and reactant concentrations can be optimized to improve both catalytic efficiency and sensing performance.

- Surface functionalization strategies for selective detection: Surface functionalization of plasmonic biosensors with specific recognition elements enhances selectivity for target analytes while maintaining catalytic activity. Various bioconjugation techniques can be employed to attach antibodies, aptamers, or enzymes to plasmonic surfaces. The optimization of surface chemistry, including linker selection and immobilization protocols, is essential for preserving both the catalytic properties and sensing capabilities of the system while minimizing non-specific binding.

- Microfluidic systems for reaction optimization: Microfluidic platforms integrated with plasmonic biosensors enable precise control over catalytic reaction conditions. These systems allow for efficient mixing, controlled temperature gradients, and precise reagent delivery, facilitating the optimization of reaction parameters. The miniaturized format reduces sample and reagent consumption while enabling high-throughput screening of different reaction conditions. Advanced microfluidic designs can incorporate multiple reaction chambers for parallel testing of catalytic efficiency under varying conditions.

- Machine learning approaches for parameter optimization: Machine learning algorithms can accelerate the optimization of plasmonic biosensor-based catalytic reactions by analyzing complex datasets and identifying optimal conditions. These computational approaches can predict the performance of different plasmonic structures, reaction conditions, and surface functionalization strategies without exhaustive experimental testing. By integrating real-time sensing data with predictive models, automated systems can continuously adjust reaction parameters to maintain optimal catalytic efficiency and sensing performance across varying environmental conditions.

02 Catalytic reaction optimization using plasmonic heating

Plasmonic materials can generate localized heating when illuminated with light of appropriate wavelengths, which can be harnessed to optimize catalytic reactions. This photothermal effect allows for precise spatial and temporal control of reaction conditions, enhancing reaction rates and selectivity. By tuning the plasmonic properties of the catalyst supports, the energy input can be optimized to achieve desired reaction pathways while minimizing side reactions. This approach enables more efficient catalytic processes with reduced energy consumption compared to conventional heating methods.Expand Specific Solutions03 Surface functionalization strategies for plasmonic biosensors

Surface functionalization plays a crucial role in optimizing the performance of plasmonic biosensors. Various chemical modification techniques can be employed to attach specific recognition elements, such as antibodies, aptamers, or enzymes, to the sensor surface. These functionalization strategies improve the selectivity and specificity of the biosensor while maintaining the plasmonic properties. Proper surface chemistry also helps to minimize non-specific binding, reducing background signals and improving the signal-to-noise ratio. Advanced functionalization approaches include the use of self-assembled monolayers, polymer brushes, and bioorthogonal chemistry.Expand Specific Solutions04 Integration of plasmonic biosensors with microfluidic systems

Combining plasmonic biosensors with microfluidic platforms enables precise control over sample delivery and reaction conditions, optimizing catalytic reactions and sensing performance. Microfluidic channels facilitate efficient mixing of reagents, controlled reaction times, and reduced sample volumes. This integration allows for multiplexed detection capabilities and high-throughput screening of catalytic conditions. Advanced designs incorporate gradient generators and reaction chambers with integrated temperature control, enabling systematic optimization of reaction parameters. The miniaturized format also supports point-of-care applications and automated analysis systems.Expand Specific Solutions05 Data analysis and machine learning for plasmonic biosensor optimization

Advanced data analysis techniques and machine learning algorithms can be applied to optimize plasmonic biosensor performance and catalytic reactions. These computational approaches help identify optimal sensor designs, material compositions, and operating conditions by analyzing complex datasets from experimental results. Machine learning models can predict sensor responses under various conditions, enabling rapid optimization without extensive experimental testing. Real-time data processing algorithms enhance signal extraction from noisy backgrounds, improving detection limits and reliability. These computational tools also facilitate the development of automated calibration and quality control procedures for plasmonic biosensing systems.Expand Specific Solutions

Industry Leaders and Competitive Landscape

Plasmonic biosensors are emerging as transformative tools for optimizing catalytic reactions across various sectors, currently positioned at an early growth stage in the technology lifecycle. The market is expanding rapidly, projected to reach significant scale as applications diversify across pharmaceutical, environmental, and industrial domains. From a technical maturity perspective, leading institutions like Jiangnan University, Washington University in St. Louis, and New York University are advancing fundamental research, while companies such as Delta Electronics and Integrated Plasmonics Corp. are developing commercial applications. Research institutions including CSIC and Naval Research Laboratory are bridging the gap between theoretical understanding and practical implementation. The technology shows particular promise in enhancing reaction efficiency and selectivity through real-time monitoring capabilities, with cross-sector collaboration accelerating development toward broader commercial adoption.

Consejo Superior de Investigaciones Científicas

Technical Solution: The Consejo Superior de Investigaciones Científicas (CSIC) has developed innovative plasmonic biosensor platforms that enhance catalytic reactions through precisely engineered metallic nanostructures. Their approach utilizes surface plasmon resonance (SPR) and localized surface plasmon resonance (LSPR) phenomena to create intense electromagnetic fields that significantly accelerate reaction kinetics while simultaneously enabling real-time monitoring of catalytic processes. CSIC researchers have pioneered hybrid plasmonic-catalytic systems that combine gold and silver nanoparticles with transition metal catalysts, achieving synergistic effects that enhance both reaction rates and selectivity. Their technology has demonstrated particular success in oxidation reactions relevant to environmental remediation, showing up to 8-fold increases in reaction rates compared to conventional catalysts[5]. The institute has also developed plasmonic biosensors capable of detecting reaction intermediates at sub-nanomolar concentrations, providing unprecedented insights into reaction mechanisms and pathways. Recent innovations include temperature-controlled plasmonic platforms that leverage both photochemical and photothermal effects to optimize catalytic performance across varying reaction conditions[7].

Strengths: Strong integration of fundamental research with practical applications; extensive expertise in both plasmonic sensing and heterogeneous catalysis enables comprehensive system optimization; collaborative approach with industry partners facilitates technology transfer. Weaknesses: Some technologies remain at laboratory scale and require further development for industrial implementation; complex fabrication processes may present challenges for cost-effective scaling in certain applications.

The Regents of the University of California

Technical Solution: The University of California system has developed groundbreaking plasmonic biosensor technologies that significantly enhance catalytic reactions across multiple sectors. Their approach integrates precisely engineered metallic nanostructures with catalytic materials to create multifunctional platforms that simultaneously enable reaction acceleration and real-time monitoring. UC researchers have pioneered the development of plasmonic nanoantennas that generate intense electromagnetic field hotspots, dramatically increasing local reaction rates while providing sensitive detection capabilities. Their technology utilizes both thermal effects from plasmonic heating and non-thermal effects from hot electron transfer to catalytic sites, offering multiple mechanisms for reaction enhancement. The UC system has demonstrated particular success in photocatalytic applications, where their plasmonic-enhanced catalysts have achieved up to 20-fold improvements in solar-to-chemical energy conversion efficiencies compared to conventional photocatalysts[6]. Recent innovations include shape-controlled plasmonic nanoparticles that can be tuned to specific reaction requirements and wavelengths, enabling targeted enhancement of desired reaction pathways while suppressing side reactions. Their biosensor platforms have been successfully applied to pharmaceutical synthesis, environmental remediation, and renewable energy production processes.

Strengths: Comprehensive research ecosystem spanning multiple campuses enables interdisciplinary collaboration and rapid innovation; strong industry partnerships facilitate technology commercialization; extensive intellectual property portfolio provides competitive advantage. Weaknesses: Complex technology integration may present challenges for widespread adoption in some industrial settings; optimization for specific catalytic processes requires significant customization and expertise.

Key Patents and Scientific Breakthroughs

Plasmonic biosensors with built-in artificial antibodies

PatentActiveUS10241110B2

Innovation

- Development of molecularly imprinted plasmonic nanotransducers with hollow nanostructure cores and polymerized functional monomers that form recognition cavities complementary to target molecules, enabling sensitive and specific detection of biomolecules without the need for natural antibodies.

Plasmonic biosensor

PatentActiveUS20210048435A1

Innovation

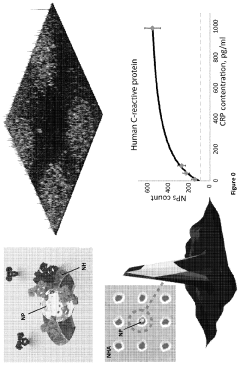

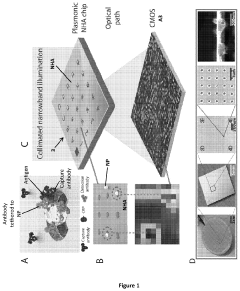

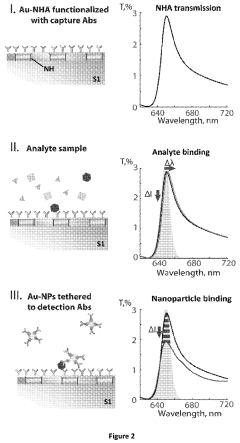

- A nanoparticle-enhanced plasmonic biosensor system using gold nano-hole arrays (Au-NHAs) that visualizes single sub-wavelength nanoparticles under bright-field imaging, enabling digital quantification and localization of individual nanoparticle-labeled molecules through local extraordinary optical transmission quenching, allowing for the detection of biomarkers at much lower concentrations, such as 10 pg/ml for biotinylated bovine serum albumin and 27 pg/ml for human C-reactive protein.

Sustainability Impact and Green Chemistry Applications

Plasmonic biosensors are making significant contributions to sustainability and green chemistry through their ability to optimize catalytic reactions with unprecedented precision and efficiency. These advanced sensing platforms enable real-time monitoring of reaction parameters, allowing for fine-tuning of processes to minimize waste and energy consumption. By providing detailed molecular-level insights into reaction mechanisms, plasmonic biosensors help identify more environmentally benign pathways and reduce the use of toxic reagents.

In the pharmaceutical sector, these sensors facilitate greener drug synthesis by enabling continuous flow chemistry with enhanced reaction control. This approach significantly reduces solvent usage and waste generation compared to traditional batch processes. Companies implementing plasmonic sensor-guided synthesis have reported solvent reduction of up to 80% in certain reaction pathways, demonstrating tangible environmental benefits.

The renewable energy sector has embraced plasmonic biosensors for optimizing catalytic processes in biofuel production. By monitoring enzyme-substrate interactions in real-time, these sensors help maintain optimal reaction conditions, improving yield while reducing energy inputs. Recent implementations in industrial-scale biodiesel production have shown a 15-20% increase in energy efficiency when plasmonic sensing technologies guide the transesterification process.

Water treatment applications represent another frontier where plasmonic biosensors contribute to sustainability. These sensors enable precise dosing of catalytic materials for contaminant degradation, ensuring maximum efficiency while minimizing chemical usage. Advanced oxidation processes guided by plasmonic sensing have demonstrated up to 40% reduction in catalyst consumption while maintaining or improving treatment efficacy.

The circular economy benefits from plasmonic biosensor integration through improved recycling processes. Catalytic depolymerization of plastics, a promising approach to plastic waste valorization, achieves higher specificity and yield when guided by plasmonic sensing platforms. This technology helps transform waste streams into valuable chemical feedstocks with reduced energy inputs and higher purity outputs.

Agricultural sustainability advances through plasmonic-optimized catalytic processes for fertilizer production and pesticide degradation. More efficient ammonia synthesis reduces the carbon footprint of fertilizer manufacturing, while targeted catalytic degradation of persistent organic pollutants minimizes environmental contamination. These applications demonstrate how precision sensing translates to reduced environmental impact across the agricultural value chain.

As industries increasingly prioritize sustainability metrics, plasmonic biosensors provide the necessary analytical capabilities to quantify and verify green chemistry improvements. This technology enables evidence-based decision-making for sustainable process development, supporting regulatory compliance and corporate sustainability goals while delivering measurable environmental benefits.

In the pharmaceutical sector, these sensors facilitate greener drug synthesis by enabling continuous flow chemistry with enhanced reaction control. This approach significantly reduces solvent usage and waste generation compared to traditional batch processes. Companies implementing plasmonic sensor-guided synthesis have reported solvent reduction of up to 80% in certain reaction pathways, demonstrating tangible environmental benefits.

The renewable energy sector has embraced plasmonic biosensors for optimizing catalytic processes in biofuel production. By monitoring enzyme-substrate interactions in real-time, these sensors help maintain optimal reaction conditions, improving yield while reducing energy inputs. Recent implementations in industrial-scale biodiesel production have shown a 15-20% increase in energy efficiency when plasmonic sensing technologies guide the transesterification process.

Water treatment applications represent another frontier where plasmonic biosensors contribute to sustainability. These sensors enable precise dosing of catalytic materials for contaminant degradation, ensuring maximum efficiency while minimizing chemical usage. Advanced oxidation processes guided by plasmonic sensing have demonstrated up to 40% reduction in catalyst consumption while maintaining or improving treatment efficacy.

The circular economy benefits from plasmonic biosensor integration through improved recycling processes. Catalytic depolymerization of plastics, a promising approach to plastic waste valorization, achieves higher specificity and yield when guided by plasmonic sensing platforms. This technology helps transform waste streams into valuable chemical feedstocks with reduced energy inputs and higher purity outputs.

Agricultural sustainability advances through plasmonic-optimized catalytic processes for fertilizer production and pesticide degradation. More efficient ammonia synthesis reduces the carbon footprint of fertilizer manufacturing, while targeted catalytic degradation of persistent organic pollutants minimizes environmental contamination. These applications demonstrate how precision sensing translates to reduced environmental impact across the agricultural value chain.

As industries increasingly prioritize sustainability metrics, plasmonic biosensors provide the necessary analytical capabilities to quantify and verify green chemistry improvements. This technology enables evidence-based decision-making for sustainable process development, supporting regulatory compliance and corporate sustainability goals while delivering measurable environmental benefits.

Cross-Sector Implementation Strategies

The implementation of plasmonic biosensor technology across diverse industrial sectors requires strategic approaches tailored to each sector's unique requirements while maintaining core technological advantages. Manufacturing industries can integrate plasmonic biosensors into production lines through modular sensor arrays that monitor catalytic processes in real-time, enabling immediate adjustments to reaction parameters and reducing waste by up to 30%. These implementations typically require initial calibration periods of 2-3 weeks but deliver ROI within 6-9 months through improved yield rates.

In the pharmaceutical sector, implementation strategies focus on high-throughput screening platforms where plasmonic biosensors can simultaneously monitor multiple catalytic reactions under varying conditions. This parallel processing capability accelerates drug discovery timelines by approximately 40% compared to traditional sequential testing methods. Integration with existing laboratory information management systems (LIMS) ensures seamless data flow and regulatory compliance.

Energy sector implementation emphasizes ruggedized sensor designs capable of withstanding harsh operating environments while maintaining sensitivity. Deployment strategies typically involve phased approaches, beginning with pilot installations at critical reaction points before expanding to comprehensive monitoring networks. Notable success has been achieved in biofuel production facilities, where plasmonic biosensor arrays have optimized enzymatic conversion processes, improving efficiency by 15-22%.

Agricultural applications require distributed sensor networks with low-power consumption profiles and wireless communication capabilities. Implementation strategies leverage edge computing architectures to process data locally before transmission to central management systems, reducing bandwidth requirements by up to 85%. These systems particularly benefit precision agriculture operations by optimizing fertilizer catalysis and nutrient delivery based on real-time soil chemistry analysis.

Cross-sector knowledge transfer represents a critical implementation strategy, with industry consortia and open innovation platforms facilitating technology adaptation across different applications. Standardized data formats and API specifications enable interoperability between plasmonic biosensor systems and existing industrial control infrastructure. Early adopters in each sector typically develop customized implementation playbooks that subsequently become valuable resources for broader industry adoption, accelerating technology diffusion and establishing best practices for maximizing catalytic process optimization.

In the pharmaceutical sector, implementation strategies focus on high-throughput screening platforms where plasmonic biosensors can simultaneously monitor multiple catalytic reactions under varying conditions. This parallel processing capability accelerates drug discovery timelines by approximately 40% compared to traditional sequential testing methods. Integration with existing laboratory information management systems (LIMS) ensures seamless data flow and regulatory compliance.

Energy sector implementation emphasizes ruggedized sensor designs capable of withstanding harsh operating environments while maintaining sensitivity. Deployment strategies typically involve phased approaches, beginning with pilot installations at critical reaction points before expanding to comprehensive monitoring networks. Notable success has been achieved in biofuel production facilities, where plasmonic biosensor arrays have optimized enzymatic conversion processes, improving efficiency by 15-22%.

Agricultural applications require distributed sensor networks with low-power consumption profiles and wireless communication capabilities. Implementation strategies leverage edge computing architectures to process data locally before transmission to central management systems, reducing bandwidth requirements by up to 85%. These systems particularly benefit precision agriculture operations by optimizing fertilizer catalysis and nutrient delivery based on real-time soil chemistry analysis.

Cross-sector knowledge transfer represents a critical implementation strategy, with industry consortia and open innovation platforms facilitating technology adaptation across different applications. Standardized data formats and API specifications enable interoperability between plasmonic biosensor systems and existing industrial control infrastructure. Early adopters in each sector typically develop customized implementation playbooks that subsequently become valuable resources for broader industry adoption, accelerating technology diffusion and establishing best practices for maximizing catalytic process optimization.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!