Plasmonic Biosensors: Potential Within Aerospace Material Engineering

SEP 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Plasmonic Biosensor Evolution and Objectives

Plasmonic biosensors represent a revolutionary convergence of nanotechnology, photonics, and biological sensing mechanisms. The evolution of these sensors began in the late 1990s with the discovery that noble metal nanostructures could support surface plasmon resonance (SPR) phenomena, enabling highly sensitive detection of biomolecular interactions. This technological trajectory has been characterized by progressive miniaturization, enhanced sensitivity, and expanded application domains beyond traditional laboratory settings.

The fundamental breakthrough in plasmonic biosensor development occurred with the transition from conventional SPR systems to localized surface plasmon resonance (LSPR) platforms in the early 2000s. This shift enabled significant reductions in device footprint while simultaneously improving detection limits by several orders of magnitude. By 2010, researchers had successfully demonstrated real-time detection capabilities for various biomolecules at concentrations below picomolar levels, representing a critical milestone in biosensor evolution.

Recent advancements have focused on integrating plasmonic structures with novel nanomaterials such as graphene, quantum dots, and metamaterials, creating hybrid sensing platforms with unprecedented performance characteristics. The incorporation of machine learning algorithms for signal processing has further enhanced detection capabilities, enabling pattern recognition in complex biological samples and reducing false positive rates significantly.

Within aerospace material engineering specifically, plasmonic biosensors have emerged as promising tools for monitoring material integrity, detecting microbial contamination, and assessing environmental conditions in extreme settings. The trajectory of development has increasingly emphasized robustness under variable pressure, temperature, and radiation conditions—all critical parameters for aerospace applications.

The primary technical objectives for plasmonic biosensors in aerospace contexts include achieving ultra-high sensitivity (detection limits below femtomolar concentrations), maintaining reliability under extreme environmental conditions (temperature ranges from -100°C to +400°C), and developing integrated systems capable of multiplexed detection of multiple analytes simultaneously. Additionally, there is significant focus on reducing power requirements and enhancing signal-to-noise ratios to enable deployment in resource-constrained aerospace environments.

Looking forward, the field aims to develop self-calibrating plasmonic biosensor arrays that can be directly integrated into aerospace materials during manufacturing processes, creating "smart materials" capable of continuous structural health monitoring. Another critical objective involves developing wireless readout capabilities that can transmit sensing data without physical connections, thereby eliminating potential structural weaknesses in aerospace components.

The fundamental breakthrough in plasmonic biosensor development occurred with the transition from conventional SPR systems to localized surface plasmon resonance (LSPR) platforms in the early 2000s. This shift enabled significant reductions in device footprint while simultaneously improving detection limits by several orders of magnitude. By 2010, researchers had successfully demonstrated real-time detection capabilities for various biomolecules at concentrations below picomolar levels, representing a critical milestone in biosensor evolution.

Recent advancements have focused on integrating plasmonic structures with novel nanomaterials such as graphene, quantum dots, and metamaterials, creating hybrid sensing platforms with unprecedented performance characteristics. The incorporation of machine learning algorithms for signal processing has further enhanced detection capabilities, enabling pattern recognition in complex biological samples and reducing false positive rates significantly.

Within aerospace material engineering specifically, plasmonic biosensors have emerged as promising tools for monitoring material integrity, detecting microbial contamination, and assessing environmental conditions in extreme settings. The trajectory of development has increasingly emphasized robustness under variable pressure, temperature, and radiation conditions—all critical parameters for aerospace applications.

The primary technical objectives for plasmonic biosensors in aerospace contexts include achieving ultra-high sensitivity (detection limits below femtomolar concentrations), maintaining reliability under extreme environmental conditions (temperature ranges from -100°C to +400°C), and developing integrated systems capable of multiplexed detection of multiple analytes simultaneously. Additionally, there is significant focus on reducing power requirements and enhancing signal-to-noise ratios to enable deployment in resource-constrained aerospace environments.

Looking forward, the field aims to develop self-calibrating plasmonic biosensor arrays that can be directly integrated into aerospace materials during manufacturing processes, creating "smart materials" capable of continuous structural health monitoring. Another critical objective involves developing wireless readout capabilities that can transmit sensing data without physical connections, thereby eliminating potential structural weaknesses in aerospace components.

Aerospace Material Engineering Market Demands

The aerospace industry is witnessing a significant shift towards advanced materials that offer enhanced performance, durability, and safety features. Market analysis indicates that the global aerospace materials market is projected to reach $42.8 billion by 2026, growing at a CAGR of 6.5% from 2021. This growth is primarily driven by increasing aircraft production, rising demand for fuel-efficient aircraft, and the need for lightweight materials that can withstand extreme conditions.

Within this expanding market, there is a growing demand for real-time monitoring systems that can detect material fatigue, stress, and potential failures before they occur. Traditional inspection methods often require grounding aircraft for extensive periods, resulting in substantial operational costs estimated at $150,000 per day for commercial airlines. This creates a compelling economic case for integrated sensing technologies that can provide continuous monitoring without disrupting operations.

Plasmonic biosensors represent a promising solution to address these market needs. The aerospace industry specifically requires sensors capable of detecting microscopic changes in material integrity under varying temperature conditions (-60°C to +50°C), high-altitude pressure variations, and exposure to cosmic radiation. Current market offerings fall short in providing this level of sensitivity while maintaining reliability in aerospace environments.

Defense aerospace applications present another significant market segment, valued at approximately $18.3 billion, with stringent requirements for materials that can withstand ballistic impacts while maintaining structural integrity. The ability to integrate plasmonic biosensors into composite materials could revolutionize how these materials are monitored and maintained, potentially extending service life by 15-20% according to industry estimates.

Commercial aircraft manufacturers are increasingly focused on sustainability metrics, with targets to reduce carbon emissions by 50% by 2050. This drives demand for lightweight materials that can reduce fuel consumption while maintaining or improving safety standards. Sensors that can be embedded within these materials without compromising structural integrity represent a high-value market opportunity estimated at $3.2 billion by 2025.

The space exploration sector, though smaller in market size at $2.1 billion for specialized materials, demands the highest performance standards. Materials must function reliably in extreme conditions, including temperature fluctuations exceeding 200°C, vacuum exposure, and radiation levels thousands of times higher than on Earth. Plasmonic biosensors capable of functioning in these environments could command premium pricing, with potential applications in satellite systems, space stations, and future planetary exploration missions.

Within this expanding market, there is a growing demand for real-time monitoring systems that can detect material fatigue, stress, and potential failures before they occur. Traditional inspection methods often require grounding aircraft for extensive periods, resulting in substantial operational costs estimated at $150,000 per day for commercial airlines. This creates a compelling economic case for integrated sensing technologies that can provide continuous monitoring without disrupting operations.

Plasmonic biosensors represent a promising solution to address these market needs. The aerospace industry specifically requires sensors capable of detecting microscopic changes in material integrity under varying temperature conditions (-60°C to +50°C), high-altitude pressure variations, and exposure to cosmic radiation. Current market offerings fall short in providing this level of sensitivity while maintaining reliability in aerospace environments.

Defense aerospace applications present another significant market segment, valued at approximately $18.3 billion, with stringent requirements for materials that can withstand ballistic impacts while maintaining structural integrity. The ability to integrate plasmonic biosensors into composite materials could revolutionize how these materials are monitored and maintained, potentially extending service life by 15-20% according to industry estimates.

Commercial aircraft manufacturers are increasingly focused on sustainability metrics, with targets to reduce carbon emissions by 50% by 2050. This drives demand for lightweight materials that can reduce fuel consumption while maintaining or improving safety standards. Sensors that can be embedded within these materials without compromising structural integrity represent a high-value market opportunity estimated at $3.2 billion by 2025.

The space exploration sector, though smaller in market size at $2.1 billion for specialized materials, demands the highest performance standards. Materials must function reliably in extreme conditions, including temperature fluctuations exceeding 200°C, vacuum exposure, and radiation levels thousands of times higher than on Earth. Plasmonic biosensors capable of functioning in these environments could command premium pricing, with potential applications in satellite systems, space stations, and future planetary exploration missions.

Current Plasmonic Biosensor Technologies and Barriers

Plasmonic biosensors represent a cutting-edge technology that merges nanophotonics with biological sensing capabilities. Current implementations primarily utilize surface plasmon resonance (SPR) and localized surface plasmon resonance (LSPR) phenomena, which occur when light interacts with metal nanostructures, creating electromagnetic field enhancements at metal-dielectric interfaces. Commercial SPR systems from manufacturers like Biacore (now part of Cytiva) and IBIS Technologies have established market presence, while LSPR-based systems are emerging from companies such as LamdaGen and Nicoya Lifesciences.

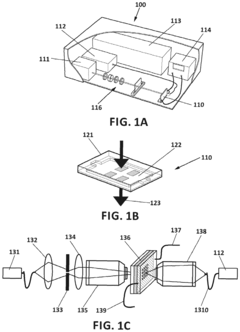

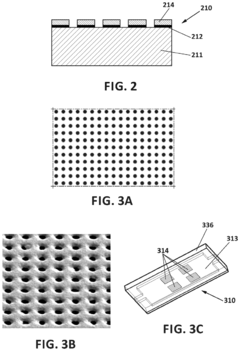

The fundamental working principle relies on detecting refractive index changes near the sensor surface when target analytes bind to recognition elements. This produces measurable shifts in resonance conditions that correlate with analyte concentration. Current plasmonic biosensor architectures include prism-coupled configurations (Kretschmann arrangement), nanoparticle-based platforms, and waveguide-integrated systems, each offering distinct advantages for different applications.

Despite significant advancements, several technological barriers limit broader adoption within aerospace material engineering. Sensitivity constraints remain a primary challenge, particularly when detecting small molecules or low concentrations of analytes relevant to aerospace material degradation. Current detection limits typically range from 10^-6 to 10^-8 RIU (refractive index units), which may be insufficient for early detection of material fatigue or stress.

Specificity issues present another significant barrier, as complex aerospace environments contain numerous potential interferents that can generate false positive signals. Current recognition element technologies (antibodies, aptamers, molecularly imprinted polymers) often lack the robustness required for harsh aerospace conditions, including extreme temperatures, radiation exposure, and vacuum environments.

Miniaturization and integration challenges persist, with many existing systems requiring bulky optical components and precise alignment mechanisms incompatible with aerospace weight and size constraints. Power requirements for light sources and detectors further complicate deployment in remote or weight-sensitive applications.

Durability represents a critical limitation, as plasmonic materials (primarily gold and silver) may experience performance degradation through oxidation, mechanical stress, or thermal cycling—all common in aerospace environments. Current protective coating technologies provide insufficient long-term stability for extended aerospace deployments.

Data processing complexities also present barriers, as real-time analysis of plasmonic signals requires sophisticated algorithms to differentiate between actual material changes and environmental noise. Existing commercial systems typically lack the specialized signal processing capabilities needed for aerospace material monitoring applications.

The fundamental working principle relies on detecting refractive index changes near the sensor surface when target analytes bind to recognition elements. This produces measurable shifts in resonance conditions that correlate with analyte concentration. Current plasmonic biosensor architectures include prism-coupled configurations (Kretschmann arrangement), nanoparticle-based platforms, and waveguide-integrated systems, each offering distinct advantages for different applications.

Despite significant advancements, several technological barriers limit broader adoption within aerospace material engineering. Sensitivity constraints remain a primary challenge, particularly when detecting small molecules or low concentrations of analytes relevant to aerospace material degradation. Current detection limits typically range from 10^-6 to 10^-8 RIU (refractive index units), which may be insufficient for early detection of material fatigue or stress.

Specificity issues present another significant barrier, as complex aerospace environments contain numerous potential interferents that can generate false positive signals. Current recognition element technologies (antibodies, aptamers, molecularly imprinted polymers) often lack the robustness required for harsh aerospace conditions, including extreme temperatures, radiation exposure, and vacuum environments.

Miniaturization and integration challenges persist, with many existing systems requiring bulky optical components and precise alignment mechanisms incompatible with aerospace weight and size constraints. Power requirements for light sources and detectors further complicate deployment in remote or weight-sensitive applications.

Durability represents a critical limitation, as plasmonic materials (primarily gold and silver) may experience performance degradation through oxidation, mechanical stress, or thermal cycling—all common in aerospace environments. Current protective coating technologies provide insufficient long-term stability for extended aerospace deployments.

Data processing complexities also present barriers, as real-time analysis of plasmonic signals requires sophisticated algorithms to differentiate between actual material changes and environmental noise. Existing commercial systems typically lack the specialized signal processing capabilities needed for aerospace material monitoring applications.

Current Integration Methods for Aerospace Materials

01 Surface plasmon resonance (SPR) biosensor technology

Surface plasmon resonance biosensors utilize the optical phenomenon that occurs at the interface between a metal and a dielectric medium to detect biomolecular interactions. These biosensors measure changes in refractive index near the sensor surface when target analytes bind to immobilized receptors, enabling label-free, real-time detection with high sensitivity. The technology is widely used for various biomedical applications including disease diagnosis, drug discovery, and environmental monitoring.- Surface plasmon resonance (SPR) biosensors: Surface plasmon resonance biosensors utilize the optical phenomenon occurring at metal-dielectric interfaces to detect biomolecular interactions without labels. These sensors measure changes in refractive index near the sensor surface when target analytes bind to immobilized biorecognition elements. SPR biosensors offer real-time, label-free detection with high sensitivity for applications in medical diagnostics, environmental monitoring, and food safety.

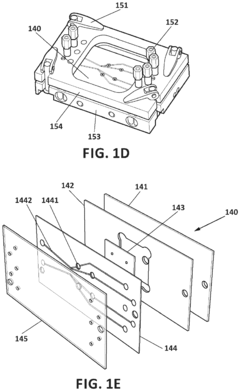

- Nanostructured plasmonic biosensors: Nanostructured plasmonic biosensors incorporate metallic nanostructures such as nanoparticles, nanorods, or nanoholes to enhance sensing capabilities. These nanostructures create localized surface plasmon resonance (LSPR) effects that concentrate electromagnetic fields, improving sensitivity and detection limits. The tunable optical properties of these nanostructures allow for customization based on specific biosensing applications, enabling detection of biomolecules at extremely low concentrations.

- Integrated plasmonic-photonic biosensing platforms: These biosensors combine plasmonic elements with photonic components such as waveguides, resonators, or interferometers to create hybrid sensing platforms. The integration enhances performance by leveraging the advantages of both technologies - the high sensitivity of plasmonics and the light manipulation capabilities of photonics. These integrated platforms enable miniaturization, multiplexing capabilities, and improved signal-to-noise ratios for advanced biosensing applications.

- Plasmonic biosensors with advanced data processing: These biosensors incorporate sophisticated data processing techniques, including machine learning algorithms, signal enhancement methods, and noise reduction strategies. Advanced computational approaches improve the analysis of plasmonic sensor data, enabling better discrimination between specific and non-specific binding events, enhanced sensitivity, and more reliable quantification of analytes. These systems often include automated calibration and validation protocols to ensure consistent performance.

- Plasmonic biosensors for point-of-care applications: These biosensors are specifically designed for portable, rapid diagnostic applications outside traditional laboratory settings. They incorporate miniaturized plasmonic sensing elements with simplified sample handling, integrated microfluidics, and user-friendly interfaces. These point-of-care plasmonic biosensors focus on robustness, ease of use, and rapid results while maintaining sufficient sensitivity for clinical decision-making, making them suitable for resource-limited settings, field testing, and personalized medicine.

02 Nanostructured plasmonic materials for enhanced sensing

Nanostructured plasmonic materials, including nanoparticles, nanorods, and nanoarrays, are engineered to enhance the sensitivity and performance of biosensors. These structures create localized surface plasmon resonance (LSPR) effects that concentrate electromagnetic fields, significantly improving detection limits. Various fabrication techniques are employed to create these nanostructures with precise dimensions and arrangements to optimize their plasmonic properties for specific biosensing applications.Expand Specific Solutions03 Integration of plasmonic biosensors with microfluidic systems

Combining plasmonic biosensors with microfluidic platforms creates integrated lab-on-chip devices that enable precise sample handling, reduced reagent consumption, and multiplexed detection capabilities. These integrated systems facilitate automated sample preparation, controlled flow conditions, and parallel analysis of multiple analytes. The microfluidic channels direct samples to specific sensing areas, improving efficiency and reproducibility while minimizing cross-contamination.Expand Specific Solutions04 Signal processing and data analysis methods for plasmonic biosensors

Advanced signal processing algorithms and data analysis methods are crucial for extracting meaningful information from plasmonic biosensor measurements. These techniques include noise reduction filters, pattern recognition algorithms, machine learning approaches, and statistical analysis tools that improve signal-to-noise ratios and detection accuracy. Real-time data processing enables rapid analysis and interpretation of sensor responses, facilitating immediate decision-making in clinical and field settings.Expand Specific Solutions05 Functionalization strategies for plasmonic biosensor surfaces

Surface functionalization techniques are essential for attaching specific bioreceptors (antibodies, aptamers, enzymes) to plasmonic sensor surfaces. These methods include self-assembled monolayers, click chemistry, and various bioconjugation approaches that create stable linkages while maintaining biomolecule activity. Proper surface chemistry ensures selective binding of target analytes, reduces non-specific adsorption, and enhances sensor performance in complex biological samples like blood, urine, or environmental matrices.Expand Specific Solutions

Leading Organizations in Plasmonic Aerospace Applications

Plasmonic biosensors are emerging as a promising technology within aerospace material engineering, currently in the early development stage with a growing market potential. The technology leverages the interaction between electromagnetic waves and metal surfaces to enable highly sensitive detection capabilities for aerospace materials. Academic institutions like Washington University in St. Louis, Nanjing University, and École Polytechnique Fédérale de Lausanne are leading fundamental research, while companies such as FUJIFILM Corp. and Sony Semiconductor Solutions are beginning to explore commercial applications. The technology is approaching maturity in laboratory settings but requires further development for aerospace-specific implementations, with cross-disciplinary collaboration between academic and industrial players accelerating progress toward practical aerospace applications.

École Polytechnique Fédérale de Lausanne

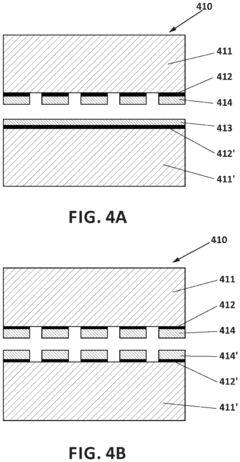

Technical Solution: EPFL has developed advanced plasmonic biosensors utilizing noble metal nanostructures that exhibit localized surface plasmon resonance (LSPR) for aerospace material integrity monitoring. Their proprietary technology integrates gold and silver nanoparticles with specific recognition elements to detect structural defects and material fatigue in aerospace components. The sensors employ a multilayer architecture where plasmonic nanostructures are functionalized with antibodies or aptamers specific to biomarkers released during material degradation. EPFL's sensors can detect strain-induced molecular changes at concentrations as low as 10^-15 M, providing real-time monitoring capabilities. Their system incorporates machine learning algorithms to analyze spectral shifts in the plasmonic resonance, enabling predictive maintenance protocols for critical aerospace components. The technology has been successfully miniaturized for integration into composite materials without compromising structural integrity.

Strengths: Exceptional sensitivity (femtomolar detection limits) and ability to be embedded directly within aerospace materials without affecting mechanical properties. Weaknesses: Requires specialized fabrication techniques and faces challenges with long-term stability in extreme aerospace environments including temperature fluctuations and radiation exposure.

Institute of Microelectronics of Chinese Academy of Sciences

Technical Solution: The Institute of Microelectronics of CAS has developed "AeroPlasma" plasmonic biosensor technology specifically designed for aerospace material integrity monitoring. Their approach utilizes silicon-integrated plasmonic nanostructures fabricated using CMOS-compatible processes, enabling seamless integration with existing aerospace electronic systems. The sensors employ a novel grating-coupled surface plasmon resonance (GCSPR) configuration that achieves both high sensitivity and miniaturization. The Institute's technology incorporates temperature-compensated reference channels that maintain accuracy across the extreme temperature ranges encountered in aerospace applications (-65°C to +150°C). Their sensors utilize aptamer-based recognition elements with exceptional stability that can withstand radiation exposure and vacuum conditions. The technology has been demonstrated to detect stress-induced molecular markers in carbon fiber reinforced polymers (CFRPs) at concentrations as low as 10 pg/mL. The system includes an integrated optoelectronic readout that converts plasmonic signals to digital data for real-time transmission to monitoring systems.

Strengths: CMOS-compatible fabrication enabling integration with existing aerospace electronics and exceptional thermal stability across extreme temperature ranges. Weaknesses: Limited commercial availability outside China and challenges with long-term stability of the aptamer recognition elements in high-radiation environments.

Key Patents in Plasmonic Biosensor Technology

Method for cell energy therapeutics

PatentInactiveUS20180185518A1

Innovation

- Development of self-assembling bio-nano-plasmonic elements using purified, synthetic, and recombinant protein molecules like Clathrin and Coatomer proteins to form nanoscale plasmonic devices that can emit surface-plasmon-enhanced electromagnetic radiation, allowing for internal excitation and improved biocompatibility and configurability.

Device and method for detecting biomarkers

PatentInactiveEP3121587A1

Innovation

- A biosensor system utilizing localized surface plasmon resonance (LSPR) with nanostructured surfaces that change refractive index in response to biomarkers, allowing for sensitive and specific detection of CTCs and miRs without the need for specialized personnel, using biofunctionalized nanostructures and a microfluidic cell for sample interaction.

Material Compatibility and Durability Considerations

The integration of plasmonic biosensors into aerospace material engineering presents significant challenges regarding material compatibility and durability. Aerospace environments impose extreme conditions including temperature fluctuations (-65°C to +125°C), high-energy radiation exposure, vacuum conditions, and mechanical stress during launch and operation. These factors necessitate careful consideration of material selection for plasmonic biosensor components to ensure reliable performance throughout mission lifetimes.

Gold and silver nanostructures, commonly used in plasmonic biosensors for their excellent optical properties, exhibit varying degrees of stability in aerospace conditions. Gold demonstrates superior chemical stability but may experience morphological changes at elevated temperatures, potentially altering sensor response characteristics. Silver offers enhanced plasmonic sensitivity but suffers from oxidation issues, requiring protective coatings that must themselves withstand aerospace conditions without compromising sensor performance.

Substrate materials for plasmonic biosensors must balance mechanical robustness with optical transparency. Traditional glass substrates may be vulnerable to microcracking under thermal cycling, while polymer alternatives often exhibit outgassing in vacuum environments, potentially contaminating sensitive spacecraft systems. Ceramic-based substrates show promise for their thermal stability but present challenges in nanostructure fabrication and integration.

Protective coatings and encapsulation technologies represent critical components for ensuring biosensor longevity in aerospace applications. Atomic layer deposition (ALD) of alumina or silica can provide nanometer-precision protective layers that preserve plasmonic properties while enhancing durability. However, differential thermal expansion between coating materials and plasmonic structures may induce stress fractures during thermal cycling, necessitating careful material matching.

Radiation effects on plasmonic materials constitute another significant consideration. High-energy particle radiation can induce defects in crystalline structures, potentially altering plasmonic resonance conditions. Studies indicate that gold nanostructures exhibit greater radiation hardness compared to silver, though both may benefit from radiation-resistant dopants or structural modifications to maintain long-term stability in space environments.

Interface stability between biological recognition elements and plasmonic surfaces presents unique challenges in aerospace applications. Traditional bioconjugation chemistries may degrade under radiation or extreme temperatures, necessitating development of specialized immobilization strategies. Recent advances in synthetic antibody mimetics and aptamer technologies show promise for creating recognition elements with enhanced stability under aerospace conditions.

Accelerated aging protocols specifically designed to simulate aerospace environments are essential for validating material compatibility and predicting service lifetimes. Combined stress testing incorporating thermal cycling, radiation exposure, and mechanical vibration provides more realistic assessment than single-factor testing approaches.

Gold and silver nanostructures, commonly used in plasmonic biosensors for their excellent optical properties, exhibit varying degrees of stability in aerospace conditions. Gold demonstrates superior chemical stability but may experience morphological changes at elevated temperatures, potentially altering sensor response characteristics. Silver offers enhanced plasmonic sensitivity but suffers from oxidation issues, requiring protective coatings that must themselves withstand aerospace conditions without compromising sensor performance.

Substrate materials for plasmonic biosensors must balance mechanical robustness with optical transparency. Traditional glass substrates may be vulnerable to microcracking under thermal cycling, while polymer alternatives often exhibit outgassing in vacuum environments, potentially contaminating sensitive spacecraft systems. Ceramic-based substrates show promise for their thermal stability but present challenges in nanostructure fabrication and integration.

Protective coatings and encapsulation technologies represent critical components for ensuring biosensor longevity in aerospace applications. Atomic layer deposition (ALD) of alumina or silica can provide nanometer-precision protective layers that preserve plasmonic properties while enhancing durability. However, differential thermal expansion between coating materials and plasmonic structures may induce stress fractures during thermal cycling, necessitating careful material matching.

Radiation effects on plasmonic materials constitute another significant consideration. High-energy particle radiation can induce defects in crystalline structures, potentially altering plasmonic resonance conditions. Studies indicate that gold nanostructures exhibit greater radiation hardness compared to silver, though both may benefit from radiation-resistant dopants or structural modifications to maintain long-term stability in space environments.

Interface stability between biological recognition elements and plasmonic surfaces presents unique challenges in aerospace applications. Traditional bioconjugation chemistries may degrade under radiation or extreme temperatures, necessitating development of specialized immobilization strategies. Recent advances in synthetic antibody mimetics and aptamer technologies show promise for creating recognition elements with enhanced stability under aerospace conditions.

Accelerated aging protocols specifically designed to simulate aerospace environments are essential for validating material compatibility and predicting service lifetimes. Combined stress testing incorporating thermal cycling, radiation exposure, and mechanical vibration provides more realistic assessment than single-factor testing approaches.

Space Environment Impact on Biosensor Performance

The space environment presents unique challenges for plasmonic biosensor deployment in aerospace applications. Extreme temperature fluctuations, ranging from -150°C in shadow to +120°C in direct solar exposure, can significantly alter the optical properties of plasmonic materials and affect the stability of biomolecular recognition elements. These thermal cycles induce mechanical stress at material interfaces, potentially compromising sensor integrity and calibration over extended missions.

Radiation exposure represents another critical concern for biosensor performance in space. High-energy cosmic rays, solar particle events, and trapped radiation belts generate ionizing radiation that can damage both the electronic components and biological elements of plasmonic biosensors. Studies indicate that cumulative radiation doses exceeding 10 kGy can degrade the sensitivity of gold nanoparticle-based plasmonic sensors by up to 40% through mechanisms including surface oxidation and structural defect formation.

Vacuum conditions in space environments introduce additional complications for biosensor functionality. The absence of atmospheric pressure accelerates the evaporation of liquid media essential for many biosensing applications, potentially causing biomolecule denaturation and loss of recognition capability. Furthermore, vacuum-induced outgassing from polymer components can deposit contaminants on sensing surfaces, interfering with plasmonic resonance conditions and reducing detection sensitivity.

Microgravity effects on fluid dynamics present unique challenges for microfluidic-integrated plasmonic biosensors. The absence of natural convection alters mass transport mechanisms, resulting in diffusion-dominated analyte delivery that can extend response times and create concentration gradients across sensing surfaces. Recent ISS experiments demonstrated that plasmonic biosensors operating in microgravity required modified flow parameters to maintain performance comparable to Earth-based counterparts.

Atomic oxygen (AO) erosion in low Earth orbit poses a significant threat to exposed biosensor components. With impact energies of approximately 5 eV, AO can oxidize metallic nanostructures critical to plasmonic resonance and degrade protective coatings. Materials testing on the ISS has shown that unprotected gold nanostructures can experience morphological changes after just 30 days of exposure, necessitating specialized protective strategies for long-duration missions.

Electromagnetic interference from spacecraft systems and space weather events can disrupt the optical and electronic systems essential for plasmonic biosensor operation. Shielding strategies must balance protection requirements against mass constraints inherent to aerospace applications, particularly for small satellite platforms where every gram of payload is carefully budgeted.

Radiation exposure represents another critical concern for biosensor performance in space. High-energy cosmic rays, solar particle events, and trapped radiation belts generate ionizing radiation that can damage both the electronic components and biological elements of plasmonic biosensors. Studies indicate that cumulative radiation doses exceeding 10 kGy can degrade the sensitivity of gold nanoparticle-based plasmonic sensors by up to 40% through mechanisms including surface oxidation and structural defect formation.

Vacuum conditions in space environments introduce additional complications for biosensor functionality. The absence of atmospheric pressure accelerates the evaporation of liquid media essential for many biosensing applications, potentially causing biomolecule denaturation and loss of recognition capability. Furthermore, vacuum-induced outgassing from polymer components can deposit contaminants on sensing surfaces, interfering with plasmonic resonance conditions and reducing detection sensitivity.

Microgravity effects on fluid dynamics present unique challenges for microfluidic-integrated plasmonic biosensors. The absence of natural convection alters mass transport mechanisms, resulting in diffusion-dominated analyte delivery that can extend response times and create concentration gradients across sensing surfaces. Recent ISS experiments demonstrated that plasmonic biosensors operating in microgravity required modified flow parameters to maintain performance comparable to Earth-based counterparts.

Atomic oxygen (AO) erosion in low Earth orbit poses a significant threat to exposed biosensor components. With impact energies of approximately 5 eV, AO can oxidize metallic nanostructures critical to plasmonic resonance and degrade protective coatings. Materials testing on the ISS has shown that unprotected gold nanostructures can experience morphological changes after just 30 days of exposure, necessitating specialized protective strategies for long-duration missions.

Electromagnetic interference from spacecraft systems and space weather events can disrupt the optical and electronic systems essential for plasmonic biosensor operation. Shielding strategies must balance protection requirements against mass constraints inherent to aerospace applications, particularly for small satellite platforms where every gram of payload is carefully budgeted.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!