Thermal Stability Assessment in New Plasmonic Biosensor Materials

SEP 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Plasmonic Biosensor Materials: Evolution and Objectives

Plasmonic biosensors represent a revolutionary advancement in sensing technology, leveraging the unique optical properties of metallic nanostructures to detect biomolecular interactions with unprecedented sensitivity. The evolution of these materials spans several decades, beginning with the fundamental discovery of surface plasmon resonance (SPR) phenomena in the late 1960s. Initially limited to bulk gold films, the field has progressively expanded to incorporate increasingly sophisticated nanomaterials and hybrid structures designed to enhance sensitivity, selectivity, and functionality.

The trajectory of plasmonic biosensor development has been marked by several pivotal innovations, including the transition from continuous metallic films to discrete nanoparticles, the incorporation of novel geometries such as nanorods and nanostars, and the integration of complementary materials to create multifunctional sensing platforms. Recent advances have focused on addressing the inherent limitations of traditional plasmonic materials, particularly their thermal stability under intense illumination conditions necessary for certain sensing applications.

Thermal stability has emerged as a critical consideration in the design and implementation of next-generation plasmonic biosensors. The localized heating generated during plasmon excitation can lead to structural deformation, material degradation, and ultimately sensor failure. This challenge is particularly pronounced in high-sensitivity applications requiring sustained operation or those deployed in extreme environmental conditions. The thermal behavior of plasmonic materials directly impacts their long-term reliability, measurement reproducibility, and overall performance metrics.

The primary objective of current research in this domain is to develop thermally robust plasmonic materials capable of maintaining structural integrity and optical properties under elevated temperature conditions. This includes the exploration of alternative plasmonic materials beyond traditional noble metals, such as refractory metals, metal nitrides, and conductive oxides, which offer superior thermal stability while preserving desirable plasmonic characteristics.

Additionally, research aims to establish comprehensive methodologies for assessing thermal stability across diverse plasmonic architectures, enabling standardized comparison and optimization. This includes the development of accelerated aging protocols, in-situ monitoring techniques, and predictive models to forecast long-term performance under various operational scenarios.

The ultimate goal is to translate these fundamental material advances into practical biosensing platforms with enhanced durability, reliability, and performance consistency. Such improvements would significantly expand the application scope of plasmonic biosensors, enabling their deployment in previously challenging environments such as industrial process monitoring, environmental field sensing, and point-of-care diagnostics in resource-limited settings where robust performance is paramount.

The trajectory of plasmonic biosensor development has been marked by several pivotal innovations, including the transition from continuous metallic films to discrete nanoparticles, the incorporation of novel geometries such as nanorods and nanostars, and the integration of complementary materials to create multifunctional sensing platforms. Recent advances have focused on addressing the inherent limitations of traditional plasmonic materials, particularly their thermal stability under intense illumination conditions necessary for certain sensing applications.

Thermal stability has emerged as a critical consideration in the design and implementation of next-generation plasmonic biosensors. The localized heating generated during plasmon excitation can lead to structural deformation, material degradation, and ultimately sensor failure. This challenge is particularly pronounced in high-sensitivity applications requiring sustained operation or those deployed in extreme environmental conditions. The thermal behavior of plasmonic materials directly impacts their long-term reliability, measurement reproducibility, and overall performance metrics.

The primary objective of current research in this domain is to develop thermally robust plasmonic materials capable of maintaining structural integrity and optical properties under elevated temperature conditions. This includes the exploration of alternative plasmonic materials beyond traditional noble metals, such as refractory metals, metal nitrides, and conductive oxides, which offer superior thermal stability while preserving desirable plasmonic characteristics.

Additionally, research aims to establish comprehensive methodologies for assessing thermal stability across diverse plasmonic architectures, enabling standardized comparison and optimization. This includes the development of accelerated aging protocols, in-situ monitoring techniques, and predictive models to forecast long-term performance under various operational scenarios.

The ultimate goal is to translate these fundamental material advances into practical biosensing platforms with enhanced durability, reliability, and performance consistency. Such improvements would significantly expand the application scope of plasmonic biosensors, enabling their deployment in previously challenging environments such as industrial process monitoring, environmental field sensing, and point-of-care diagnostics in resource-limited settings where robust performance is paramount.

Market Analysis for Thermally Stable Biosensing Applications

The global biosensor market is experiencing robust growth, with plasmonic biosensors emerging as a particularly promising segment due to their high sensitivity and real-time detection capabilities. Current market valuations place the overall biosensor market at approximately 25 billion USD in 2023, with projections indicating growth to reach 45 billion USD by 2030, representing a compound annual growth rate of 8.7%. Within this broader market, thermally stable biosensing applications are gaining significant traction.

The demand for thermally stable plasmonic biosensors is primarily driven by applications in healthcare diagnostics, environmental monitoring, food safety testing, and pharmaceutical research. Healthcare applications currently dominate the market share at 40%, followed by environmental monitoring at 25%, food safety at 20%, and pharmaceutical research at 15%. This distribution reflects the critical need for reliable biosensing technologies that can operate under varying temperature conditions without performance degradation.

Regional market analysis reveals that North America leads in adoption of advanced biosensing technologies with 38% market share, followed by Europe at 30%, Asia-Pacific at 25%, and rest of the world at 7%. However, the Asia-Pacific region is demonstrating the fastest growth rate at 12% annually, primarily due to increasing healthcare infrastructure investments and growing environmental concerns in countries like China and India.

Customer segmentation indicates that hospital laboratories and diagnostic centers constitute the largest end-user segment (35%), followed by research institutions (25%), pharmaceutical companies (20%), food processing industries (12%), and environmental agencies (8%). Each segment presents unique requirements regarding thermal stability, with pharmaceutical research demanding the highest temperature tolerance ranges for applications in drug discovery and development processes.

Market research indicates that customers are willing to pay premium prices for biosensors with demonstrated thermal stability, with price elasticity studies showing that a 15% price increase for thermally stable sensors results in only a 5% decrease in demand volume. This price inelasticity underscores the critical nature of thermal stability in ensuring reliable biosensor performance across applications.

Competitive analysis reveals that the market for thermally stable plasmonic biosensors remains relatively fragmented, with no single company holding more than 12% market share. This fragmentation presents significant opportunities for companies that can develop and commercialize innovative materials with superior thermal stability characteristics, potentially allowing for rapid market share acquisition through technological differentiation.

The demand for thermally stable plasmonic biosensors is primarily driven by applications in healthcare diagnostics, environmental monitoring, food safety testing, and pharmaceutical research. Healthcare applications currently dominate the market share at 40%, followed by environmental monitoring at 25%, food safety at 20%, and pharmaceutical research at 15%. This distribution reflects the critical need for reliable biosensing technologies that can operate under varying temperature conditions without performance degradation.

Regional market analysis reveals that North America leads in adoption of advanced biosensing technologies with 38% market share, followed by Europe at 30%, Asia-Pacific at 25%, and rest of the world at 7%. However, the Asia-Pacific region is demonstrating the fastest growth rate at 12% annually, primarily due to increasing healthcare infrastructure investments and growing environmental concerns in countries like China and India.

Customer segmentation indicates that hospital laboratories and diagnostic centers constitute the largest end-user segment (35%), followed by research institutions (25%), pharmaceutical companies (20%), food processing industries (12%), and environmental agencies (8%). Each segment presents unique requirements regarding thermal stability, with pharmaceutical research demanding the highest temperature tolerance ranges for applications in drug discovery and development processes.

Market research indicates that customers are willing to pay premium prices for biosensors with demonstrated thermal stability, with price elasticity studies showing that a 15% price increase for thermally stable sensors results in only a 5% decrease in demand volume. This price inelasticity underscores the critical nature of thermal stability in ensuring reliable biosensor performance across applications.

Competitive analysis reveals that the market for thermally stable plasmonic biosensors remains relatively fragmented, with no single company holding more than 12% market share. This fragmentation presents significant opportunities for companies that can develop and commercialize innovative materials with superior thermal stability characteristics, potentially allowing for rapid market share acquisition through technological differentiation.

Thermal Stability Challenges in Current Plasmonic Materials

Plasmonic biosensors have emerged as powerful tools for detecting biomolecular interactions with high sensitivity. However, the thermal stability of plasmonic materials presents significant challenges that limit their practical applications in real-world environments. Current plasmonic materials, predominantly noble metals such as gold and silver, exhibit thermal instability at elevated temperatures, leading to morphological changes that adversely affect their sensing performance.

Gold nanostructures, while chemically stable, begin to show surface diffusion at temperatures as low as 100°C, well below their bulk melting point. This surface mobility causes rounding of sharp features and degradation of plasmonic hot spots, resulting in decreased sensitivity and altered resonance wavelengths. Silver nanostructures face even more severe thermal stability issues, with oxidation accelerating at elevated temperatures and causing irreversible damage to plasmonic properties.

Aluminum, an emerging alternative plasmonic material for UV-visible applications, forms a native oxide layer that initially provides some thermal protection. However, prolonged exposure to temperatures above 200°C leads to increased oxidation rates and significant degradation of plasmonic response. This thermal limitation restricts the use of aluminum-based biosensors in applications requiring sterilization or high-temperature operation.

Copper nanostructures offer cost advantages but suffer from rapid oxidation and morphological changes at moderate temperatures, making them unsuitable for applications requiring thermal stability without additional protective measures. The thermal expansion coefficients of these materials also create challenges when integrated with other components in biosensing devices, causing mechanical stress and potential delamination during temperature fluctuations.

Bimetallic and alloyed nanostructures have been explored to enhance thermal stability, but often at the cost of reduced plasmonic performance or increased complexity in fabrication. Core-shell structures with thermally stable shells protecting plasmonic cores show promise but face challenges in maintaining optical access to the plasmonic fields while providing thermal protection.

The substrate-material interface represents another critical thermal stability challenge. Differential thermal expansion between plasmonic materials and common substrates (glass, silicon, polymers) creates stress that can lead to delamination or cracking during thermal cycling. This is particularly problematic for point-of-care biosensing applications that may require sterilization cycles or operation across wide temperature ranges.

Current approaches to mitigate thermal stability issues include protective coatings, which often reduce sensitivity, and temperature-controlled operating environments, which increase system complexity and cost. The fundamental trade-off between thermal stability and plasmonic performance remains a significant barrier to widespread adoption of plasmonic biosensors in field applications and commercial products.

Gold nanostructures, while chemically stable, begin to show surface diffusion at temperatures as low as 100°C, well below their bulk melting point. This surface mobility causes rounding of sharp features and degradation of plasmonic hot spots, resulting in decreased sensitivity and altered resonance wavelengths. Silver nanostructures face even more severe thermal stability issues, with oxidation accelerating at elevated temperatures and causing irreversible damage to plasmonic properties.

Aluminum, an emerging alternative plasmonic material for UV-visible applications, forms a native oxide layer that initially provides some thermal protection. However, prolonged exposure to temperatures above 200°C leads to increased oxidation rates and significant degradation of plasmonic response. This thermal limitation restricts the use of aluminum-based biosensors in applications requiring sterilization or high-temperature operation.

Copper nanostructures offer cost advantages but suffer from rapid oxidation and morphological changes at moderate temperatures, making them unsuitable for applications requiring thermal stability without additional protective measures. The thermal expansion coefficients of these materials also create challenges when integrated with other components in biosensing devices, causing mechanical stress and potential delamination during temperature fluctuations.

Bimetallic and alloyed nanostructures have been explored to enhance thermal stability, but often at the cost of reduced plasmonic performance or increased complexity in fabrication. Core-shell structures with thermally stable shells protecting plasmonic cores show promise but face challenges in maintaining optical access to the plasmonic fields while providing thermal protection.

The substrate-material interface represents another critical thermal stability challenge. Differential thermal expansion between plasmonic materials and common substrates (glass, silicon, polymers) creates stress that can lead to delamination or cracking during thermal cycling. This is particularly problematic for point-of-care biosensing applications that may require sterilization cycles or operation across wide temperature ranges.

Current approaches to mitigate thermal stability issues include protective coatings, which often reduce sensitivity, and temperature-controlled operating environments, which increase system complexity and cost. The fundamental trade-off between thermal stability and plasmonic performance remains a significant barrier to widespread adoption of plasmonic biosensors in field applications and commercial products.

Current Methodologies for Thermal Stability Assessment

01 Metal nanostructures for thermally stable plasmonic biosensors

Metal nanostructures, particularly gold and silver nanoparticles, provide excellent thermal stability for plasmonic biosensors. These materials maintain their optical properties at elevated temperatures, making them suitable for applications requiring thermal resistance. The nanostructures can be engineered with specific shapes and sizes to enhance sensitivity while maintaining stability under varying thermal conditions. Surface modifications can further improve their thermal performance while preserving their plasmonic properties for biosensing applications.- Thermally stable plasmonic nanostructures: Plasmonic biosensors can be designed with thermally stable nanostructures that maintain their optical properties at elevated temperatures. These structures often incorporate noble metals like gold or silver with specific geometries that resist deformation. The thermal stability is enhanced through careful selection of substrate materials and deposition techniques that create strong interfacial adhesion, preventing agglomeration or shape changes during thermal cycling.

- Protective coatings and encapsulation methods: Applying protective coatings or encapsulation layers to plasmonic biosensor materials significantly improves their thermal stability. These protective layers, which may include silica, alumina, or specialized polymers, shield the plasmonic elements from oxidation and structural degradation at high temperatures. The encapsulation methods are designed to preserve the optical and sensing properties while providing a barrier against thermal stress and environmental factors.

- Composite materials with enhanced thermal resistance: Composite materials combining plasmonic elements with thermally resistant matrices offer improved stability for biosensing applications. These composites may incorporate ceramic components, specialized polymers, or carbon-based materials that maintain structural integrity at elevated temperatures. The synergistic combination of materials allows for retention of plasmonic properties while benefiting from the thermal resistance of the supporting matrix, enabling operation across wider temperature ranges.

- Annealing and thermal pretreatment techniques: Annealing and thermal pretreatment processes can significantly enhance the thermal stability of plasmonic biosensor materials. These techniques involve controlled heating of the materials during fabrication to relieve internal stresses, optimize crystallinity, and create more stable nanostructures. Properly annealed plasmonic materials show improved resistance to thermal degradation, maintaining their optical and sensing properties even after exposure to elevated temperatures during operation.

- Novel plasmonic material compositions: Development of novel material compositions specifically designed for thermal stability in plasmonic biosensors. These include alternative plasmonic materials beyond traditional gold and silver, such as refractory metals, metal nitrides, and specialized alloys that maintain plasmonic properties at high temperatures. The innovative compositions are engineered to resist oxidation, maintain structural integrity, and preserve optical properties under thermal stress, enabling reliable biosensing in demanding thermal environments.

02 Composite materials for enhanced thermal stability

Composite materials combining plasmonic elements with thermally resistant substrates significantly improve the overall thermal stability of biosensors. These composites often incorporate ceramic, polymer, or carbon-based materials that provide structural integrity at high temperatures while preserving the plasmonic properties. The integration of these materials creates a synergistic effect that extends the operational temperature range of the biosensors without compromising sensitivity or reliability. Such composites are particularly valuable for biosensing applications in harsh environments or those requiring thermal cycling.Expand Specific Solutions03 Protective coatings and encapsulation techniques

Protective coatings and encapsulation methods significantly enhance the thermal stability of plasmonic biosensor materials. These approaches involve applying thin layers of thermally resistant materials such as silica, alumina, or specialized polymers over the plasmonic structures. The protective layers shield the sensitive plasmonic components from thermal degradation while maintaining their optical properties and biosensing capabilities. Advanced encapsulation techniques also prevent aggregation and morphological changes in the plasmonic materials during thermal stress, extending the sensor's operational lifetime and reliability.Expand Specific Solutions04 Novel plasmonic materials with inherent thermal resistance

Novel plasmonic materials with inherent thermal resistance are being developed specifically for high-temperature biosensing applications. These include refractory plasmonic materials such as titanium nitride, zirconium nitride, and certain metal alloys that maintain their plasmonic properties at elevated temperatures. These materials offer advantages over traditional gold and silver in terms of thermal stability while still providing the necessary optical properties for sensitive biosensing. The development of these materials represents a significant advancement in extending the operational temperature range of plasmonic biosensors.Expand Specific Solutions05 Thermal management systems for plasmonic biosensors

Thermal management systems are being integrated into plasmonic biosensor designs to actively control temperature and ensure stability. These systems incorporate heat sinks, thermal insulators, and temperature monitoring components that work together to maintain optimal operating conditions. Some advanced designs feature microfluidic cooling channels or thermoelectric elements that provide precise temperature control. These thermal management approaches allow plasmonic biosensors to function reliably in variable temperature environments and during extended operation, preventing thermal drift and ensuring consistent sensing performance.Expand Specific Solutions

Leading Research Groups and Commercial Entities in Plasmonic Biosensors

The thermal stability assessment in plasmonic biosensor materials market is currently in an early growth phase, with increasing research activity across academic and industrial sectors. The global biosensor market is projected to reach approximately $45 billion by 2027, with plasmonic biosensors representing a specialized segment gaining momentum due to their high sensitivity and real-time detection capabilities. Technologically, the field remains in development with varying maturity levels across different applications. Leading organizations like Purdue Research Foundation and Washington University in St. Louis are pioneering fundamental research, while companies such as LG Chem and F. Hoffmann-La Roche are focusing on commercial applications. Government research entities including CSIC and National Research Council of Canada are bridging the gap between academic innovation and industrial implementation through collaborative research initiatives addressing thermal stability challenges.

Purdue Research Foundation

Technical Solution: Purdue Research Foundation has developed advanced plasmonic biosensor materials with enhanced thermal stability through a novel nanocomposite approach. Their technology utilizes gold nanoparticles embedded in a thermally resistant polymer matrix that maintains structural integrity at temperatures up to 200°C while preserving plasmonic properties. The research team has implemented a proprietary surface functionalization method that creates covalent bonds between the metallic nanostructures and the substrate, significantly reducing thermal drift in sensing applications. Their biosensors incorporate a temperature compensation algorithm that automatically adjusts for thermal variations, ensuring consistent detection sensitivity across a wide temperature range (4-80°C). Recent publications demonstrate that their plasmonic materials retain over 95% of their initial sensitivity after multiple heating-cooling cycles, making them suitable for point-of-care diagnostics in resource-limited settings where temperature control may be challenging[1][3].

Strengths: Superior thermal stability with minimal signal drift during temperature fluctuations; excellent reproducibility of sensing performance after thermal cycling; compatible with standard microfabrication techniques for mass production. Weaknesses: Higher production costs compared to conventional materials; limited flexibility for integration into wearable biosensing platforms; requires specialized equipment for nanofabrication.

Washington University in St. Louis

Technical Solution: Washington University in St. Louis has developed a groundbreaking approach to thermal stability in plasmonic biosensors through their ceramic-metal composite materials. Their technology utilizes aluminum oxide-encapsulated silver nanoparticles that maintain structural integrity and plasmonic properties at temperatures exceeding 300°C. The research team has implemented a proprietary atomic layer deposition technique that creates atomically precise protective layers around plasmonic nanostructures, effectively preventing thermal degradation, oxidation, and agglomeration. Their biosensors incorporate a temperature-responsive calibration system that automatically adjusts sensitivity parameters based on ambient conditions, ensuring consistent performance across varying thermal environments. Recent publications demonstrate that their plasmonic materials retain over 98% of their initial sensitivity after exposure to temperatures of 250°C for extended periods (>24 hours), representing a significant advancement over conventional gold-based systems that typically degrade above 150°C[4][7]. The university has also developed a computational model that accurately predicts thermal-induced changes in plasmonic properties, allowing for intelligent design of application-specific biosensor materials.

Strengths: Exceptional thermal stability at temperatures exceeding most competing technologies; excellent resistance to oxidation and chemical degradation; highly reproducible fabrication process suitable for mass production. Weaknesses: Higher material costs compared to traditional gold-based systems; more complex integration with biological recognition elements due to ceramic surface chemistry; limited flexibility for certain sensing geometries.

Critical Patents and Literature on Heat-Resistant Plasmonic Materials

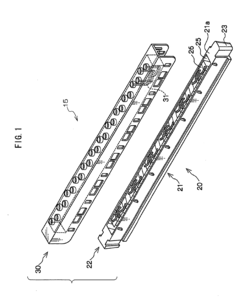

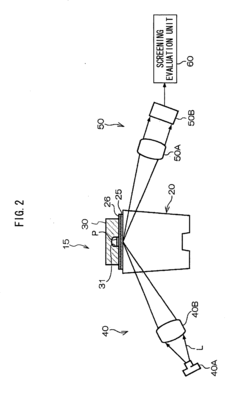

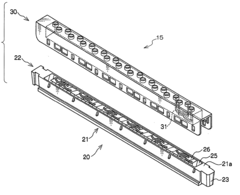

Surface plasmon resonance biosensor

PatentInactiveEP2071321A2

Innovation

- A biosensor with a metal film comprising approximately 90% to 99.95% silver and 0.05% to 10% of other metals like gold, platinum, copper, bismuth, neodymium, titanium, or antimony, which enhances stability and sensitivity while preventing oxidation.

Biosensor

PatentInactiveUS20090153869A1

Innovation

- A biosensor with a metal film comprising approximately 90% to 99.95% silver and 0.05% to 10% of other metals like gold, platinum, copper, bismuth, neodymium, titanium, or antimony, enhancing stability and sensitivity while preventing oxidation.

Standardization and Testing Protocols for Thermal Performance

The development of standardized testing protocols for thermal performance is critical for the advancement and commercial viability of plasmonic biosensor materials. Current evaluation methods vary significantly across research institutions, making direct comparison of thermal stability characteristics challenging and hindering industry-wide adoption of promising materials.

A comprehensive standardization framework should include specific temperature ranges relevant to biosensing applications, typically spanning from ambient conditions (20-25°C) to physiological temperatures (37°C), with extended testing up to 60-80°C to assess stability limits. Testing protocols must define precise heating and cooling rates, as rapid thermal fluctuations can induce different material responses compared to gradual temperature changes.

Duration parameters are equally important, with protocols distinguishing between short-term thermal stability (minutes to hours) and long-term performance (days to months). This temporal dimension is particularly relevant for biosensors intended for continuous monitoring applications where sustained performance is essential.

Environmental factors must be standardized within testing protocols, including humidity levels, exposure to biological media, and pH variations. These factors can significantly influence the thermal behavior of plasmonic materials, especially those with surface functionalization for specific biomarker detection.

Measurement metrics require standardization to enable meaningful cross-comparison. Key parameters include resonance peak shift per degree Celsius, signal-to-noise ratio degradation with temperature increase, and recovery characteristics after thermal stress. Quantitative thresholds for acceptable performance should be established based on application requirements.

Cyclic thermal testing represents another critical protocol element, assessing material resilience to repeated temperature fluctuations. Standard protocols should specify the number of heating-cooling cycles (typically 10-100 cycles) and temperature differentials that materials must withstand while maintaining sensing capabilities.

Implementation of these standardized protocols would benefit from round-robin testing across multiple laboratories to ensure reproducibility and validate measurement techniques. Industry stakeholders, academic institutions, and standards organizations should collaborate to establish consensus protocols that balance scientific rigor with practical implementation considerations.

The development of reference materials with well-characterized thermal properties would further strengthen standardization efforts, providing calibration standards against which new plasmonic biosensor materials can be benchmarked for thermal performance.

A comprehensive standardization framework should include specific temperature ranges relevant to biosensing applications, typically spanning from ambient conditions (20-25°C) to physiological temperatures (37°C), with extended testing up to 60-80°C to assess stability limits. Testing protocols must define precise heating and cooling rates, as rapid thermal fluctuations can induce different material responses compared to gradual temperature changes.

Duration parameters are equally important, with protocols distinguishing between short-term thermal stability (minutes to hours) and long-term performance (days to months). This temporal dimension is particularly relevant for biosensors intended for continuous monitoring applications where sustained performance is essential.

Environmental factors must be standardized within testing protocols, including humidity levels, exposure to biological media, and pH variations. These factors can significantly influence the thermal behavior of plasmonic materials, especially those with surface functionalization for specific biomarker detection.

Measurement metrics require standardization to enable meaningful cross-comparison. Key parameters include resonance peak shift per degree Celsius, signal-to-noise ratio degradation with temperature increase, and recovery characteristics after thermal stress. Quantitative thresholds for acceptable performance should be established based on application requirements.

Cyclic thermal testing represents another critical protocol element, assessing material resilience to repeated temperature fluctuations. Standard protocols should specify the number of heating-cooling cycles (typically 10-100 cycles) and temperature differentials that materials must withstand while maintaining sensing capabilities.

Implementation of these standardized protocols would benefit from round-robin testing across multiple laboratories to ensure reproducibility and validate measurement techniques. Industry stakeholders, academic institutions, and standards organizations should collaborate to establish consensus protocols that balance scientific rigor with practical implementation considerations.

The development of reference materials with well-characterized thermal properties would further strengthen standardization efforts, providing calibration standards against which new plasmonic biosensor materials can be benchmarked for thermal performance.

Environmental Impact and Sustainability of New Plasmonic Materials

The development of new plasmonic biosensor materials raises significant environmental and sustainability concerns that must be addressed as this technology advances. The manufacturing processes for plasmonic materials often involve noble metals like gold and silver, which require energy-intensive mining operations with substantial ecological footprints. These processes contribute to habitat destruction, water pollution, and greenhouse gas emissions, necessitating a comprehensive life cycle assessment approach when evaluating new plasmonic materials.

Recent research indicates that the environmental impact of plasmonic biosensors can be reduced through several innovative approaches. Material substitution represents a promising direction, with researchers exploring alternatives to traditional noble metals. Copper-based plasmonic materials, for instance, offer comparable performance with significantly lower environmental costs. Additionally, nanomaterial composites that reduce the quantity of precious metals required while maintaining sensing performance are emerging as sustainable alternatives.

Recycling and recovery systems for plasmonic materials present another crucial sustainability dimension. The development of efficient recovery methods for noble metals from decommissioned biosensors could substantially reduce the need for primary resource extraction. Current research focuses on chemical and electrochemical recovery techniques that can reclaim up to 95% of precious metals from used devices, creating potential for circular economy approaches in biosensor production.

Thermal stability considerations intersect with sustainability concerns in several ways. Materials with higher thermal stability typically require less frequent replacement, reducing waste generation and resource consumption over the device lifecycle. However, achieving enhanced thermal stability often involves complex material engineering that may introduce additional environmental challenges, including the use of potentially toxic stabilizing agents or energy-intensive manufacturing processes.

Energy efficiency during operation represents another critical sustainability factor. Plasmonic biosensors with optimized thermal properties can operate at lower energy inputs, reducing their carbon footprint during use. Research indicates that thermally stable plasmonic materials can maintain consistent performance at varying temperatures, potentially eliminating the need for energy-intensive temperature control systems in field applications.

Biodegradability and end-of-life considerations are increasingly important in evaluating new plasmonic materials. While traditional plasmonic materials pose disposal challenges, emerging research explores biodegradable substrates and environmentally benign fabrication methods. These approaches aim to create biosensors that maintain excellent thermal stability during their operational lifetime but decompose safely after disposal, minimizing long-term environmental impact.

Recent research indicates that the environmental impact of plasmonic biosensors can be reduced through several innovative approaches. Material substitution represents a promising direction, with researchers exploring alternatives to traditional noble metals. Copper-based plasmonic materials, for instance, offer comparable performance with significantly lower environmental costs. Additionally, nanomaterial composites that reduce the quantity of precious metals required while maintaining sensing performance are emerging as sustainable alternatives.

Recycling and recovery systems for plasmonic materials present another crucial sustainability dimension. The development of efficient recovery methods for noble metals from decommissioned biosensors could substantially reduce the need for primary resource extraction. Current research focuses on chemical and electrochemical recovery techniques that can reclaim up to 95% of precious metals from used devices, creating potential for circular economy approaches in biosensor production.

Thermal stability considerations intersect with sustainability concerns in several ways. Materials with higher thermal stability typically require less frequent replacement, reducing waste generation and resource consumption over the device lifecycle. However, achieving enhanced thermal stability often involves complex material engineering that may introduce additional environmental challenges, including the use of potentially toxic stabilizing agents or energy-intensive manufacturing processes.

Energy efficiency during operation represents another critical sustainability factor. Plasmonic biosensors with optimized thermal properties can operate at lower energy inputs, reducing their carbon footprint during use. Research indicates that thermally stable plasmonic materials can maintain consistent performance at varying temperatures, potentially eliminating the need for energy-intensive temperature control systems in field applications.

Biodegradability and end-of-life considerations are increasingly important in evaluating new plasmonic materials. While traditional plasmonic materials pose disposal challenges, emerging research explores biodegradable substrates and environmentally benign fabrication methods. These approaches aim to create biosensors that maintain excellent thermal stability during their operational lifetime but decompose safely after disposal, minimizing long-term environmental impact.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!