Why Plasmonic Biosensors Lead in EV Battery Performance Testing

SEP 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Plasmonic Biosensor Technology Background and Objectives

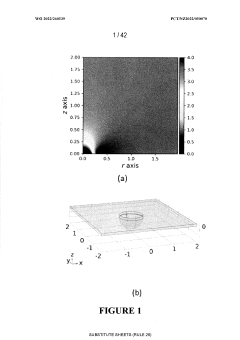

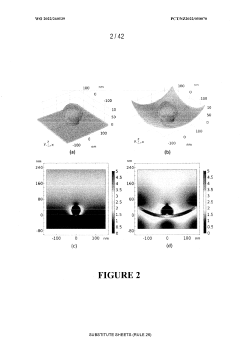

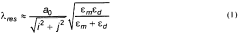

Plasmonic biosensors represent a revolutionary convergence of nanotechnology, photonics, and biochemistry that has evolved significantly over the past two decades. These sensors exploit the unique optical properties of metallic nanostructures, particularly the phenomenon of surface plasmon resonance (SPR), which occurs when light interacts with conduction electrons at the interface between a negative and positive permittivity material.

The historical trajectory of plasmonic biosensor development began in the early 1990s with basic SPR sensors, progressing through significant milestones including localized surface plasmon resonance (LSPR) discovery, nanofabrication advancements, and most recently, integration with electrochemical systems specifically designed for energy storage applications. This technological evolution has positioned plasmonic biosensors at the forefront of advanced diagnostic tools across multiple industries.

In the context of electric vehicle (EV) battery performance testing, plasmonic biosensors offer unprecedented capabilities for real-time, label-free detection of critical electrochemical processes and degradation mechanisms. The fundamental principle leverages the extreme sensitivity of plasmonic structures to their local environment, enabling detection of minute changes in electrolyte composition, electrode surface modifications, and interfacial reactions that directly impact battery performance and longevity.

The primary technical objectives for plasmonic biosensors in EV battery applications include achieving sub-nanomolar detection limits for critical battery degradation markers, developing robust sensor platforms capable of withstanding harsh electrochemical environments, and creating integrated sensing systems that provide continuous, non-destructive monitoring throughout battery lifecycle. These objectives address the pressing industry need for more sophisticated diagnostic tools to enhance battery reliability, safety, and performance.

Current research trends indicate accelerating development of multiplexed plasmonic sensing platforms capable of simultaneously monitoring multiple battery health parameters, including lithium-ion transport dynamics, solid-electrolyte interphase (SEI) formation, and dendrite growth. The integration of artificial intelligence with plasmonic sensing data is emerging as a powerful approach for predictive battery health management.

The technological trajectory suggests plasmonic biosensors will continue to evolve toward miniaturized, cost-effective platforms with enhanced specificity and sensitivity. Industry projections indicate that by 2025, plasmonic biosensor technology could become standard in premium EV battery management systems, with broader market penetration expected by 2030 as manufacturing costs decrease and performance advantages become more widely recognized.

The ultimate goal of this technology development is to establish plasmonic biosensors as the gold standard for battery performance testing, enabling a new generation of safer, longer-lasting, and more efficient energy storage solutions for the rapidly expanding electric vehicle market.

The historical trajectory of plasmonic biosensor development began in the early 1990s with basic SPR sensors, progressing through significant milestones including localized surface plasmon resonance (LSPR) discovery, nanofabrication advancements, and most recently, integration with electrochemical systems specifically designed for energy storage applications. This technological evolution has positioned plasmonic biosensors at the forefront of advanced diagnostic tools across multiple industries.

In the context of electric vehicle (EV) battery performance testing, plasmonic biosensors offer unprecedented capabilities for real-time, label-free detection of critical electrochemical processes and degradation mechanisms. The fundamental principle leverages the extreme sensitivity of plasmonic structures to their local environment, enabling detection of minute changes in electrolyte composition, electrode surface modifications, and interfacial reactions that directly impact battery performance and longevity.

The primary technical objectives for plasmonic biosensors in EV battery applications include achieving sub-nanomolar detection limits for critical battery degradation markers, developing robust sensor platforms capable of withstanding harsh electrochemical environments, and creating integrated sensing systems that provide continuous, non-destructive monitoring throughout battery lifecycle. These objectives address the pressing industry need for more sophisticated diagnostic tools to enhance battery reliability, safety, and performance.

Current research trends indicate accelerating development of multiplexed plasmonic sensing platforms capable of simultaneously monitoring multiple battery health parameters, including lithium-ion transport dynamics, solid-electrolyte interphase (SEI) formation, and dendrite growth. The integration of artificial intelligence with plasmonic sensing data is emerging as a powerful approach for predictive battery health management.

The technological trajectory suggests plasmonic biosensors will continue to evolve toward miniaturized, cost-effective platforms with enhanced specificity and sensitivity. Industry projections indicate that by 2025, plasmonic biosensor technology could become standard in premium EV battery management systems, with broader market penetration expected by 2030 as manufacturing costs decrease and performance advantages become more widely recognized.

The ultimate goal of this technology development is to establish plasmonic biosensors as the gold standard for battery performance testing, enabling a new generation of safer, longer-lasting, and more efficient energy storage solutions for the rapidly expanding electric vehicle market.

Market Analysis for EV Battery Testing Solutions

The global market for electric vehicle (EV) battery testing solutions is experiencing unprecedented growth, driven by the rapid expansion of the EV industry. Current market valuations indicate that the EV battery testing segment reached approximately $2.8 billion in 2022 and is projected to grow at a CAGR of 18.5% through 2030. This growth trajectory is directly linked to increasing EV adoption rates worldwide, with global EV sales surpassing 10 million units in 2022, representing a 55% year-over-year increase.

Within this expanding market, plasmonic biosensor technology is emerging as a disruptive force, capturing significant attention from industry stakeholders. Traditional battery testing methods, including electrochemical impedance spectroscopy and cyclic voltammetry, currently dominate with approximately 65% market share. However, plasmonic biosensor solutions are projected to grow at twice the rate of conventional technologies over the next five years.

The market segmentation reveals distinct testing solution categories: laboratory-grade equipment (40% market share), production line testing systems (35%), and portable diagnostic tools (25%). Plasmonic biosensors are making particularly strong inroads in the high-precision laboratory segment, where their superior sensitivity provides competitive advantage for manufacturers requiring detailed performance analytics.

Geographically, Asia Pacific leads the market with 45% share, driven by China's dominant position in both EV production and battery manufacturing. North America and Europe follow with 25% and 20% respectively, with both regions showing accelerated investment in advanced testing technologies as they attempt to reduce dependency on Asian battery supply chains.

Customer segmentation analysis reveals three primary buyer categories: battery manufacturers seeking production quality control solutions, EV manufacturers requiring performance validation tools, and research institutions demanding high-precision analytical capabilities. Plasmonic biosensor technologies are uniquely positioned to serve all three segments due to their versatility and scalability.

Market barriers include high initial investment costs for advanced testing equipment, with plasmonic systems typically commanding a 30-40% premium over conventional alternatives. However, total cost of ownership analysis demonstrates that the enhanced precision and reduced testing time can deliver ROI within 18-24 months for high-volume testing operations.

Competitive analysis indicates that established testing equipment manufacturers are increasingly forming strategic partnerships with plasmonic technology developers, recognizing the transformative potential of this approach. This trend is expected to accelerate market penetration for plasmonic biosensor solutions while driving further innovation and cost optimization.

Within this expanding market, plasmonic biosensor technology is emerging as a disruptive force, capturing significant attention from industry stakeholders. Traditional battery testing methods, including electrochemical impedance spectroscopy and cyclic voltammetry, currently dominate with approximately 65% market share. However, plasmonic biosensor solutions are projected to grow at twice the rate of conventional technologies over the next five years.

The market segmentation reveals distinct testing solution categories: laboratory-grade equipment (40% market share), production line testing systems (35%), and portable diagnostic tools (25%). Plasmonic biosensors are making particularly strong inroads in the high-precision laboratory segment, where their superior sensitivity provides competitive advantage for manufacturers requiring detailed performance analytics.

Geographically, Asia Pacific leads the market with 45% share, driven by China's dominant position in both EV production and battery manufacturing. North America and Europe follow with 25% and 20% respectively, with both regions showing accelerated investment in advanced testing technologies as they attempt to reduce dependency on Asian battery supply chains.

Customer segmentation analysis reveals three primary buyer categories: battery manufacturers seeking production quality control solutions, EV manufacturers requiring performance validation tools, and research institutions demanding high-precision analytical capabilities. Plasmonic biosensor technologies are uniquely positioned to serve all three segments due to their versatility and scalability.

Market barriers include high initial investment costs for advanced testing equipment, with plasmonic systems typically commanding a 30-40% premium over conventional alternatives. However, total cost of ownership analysis demonstrates that the enhanced precision and reduced testing time can deliver ROI within 18-24 months for high-volume testing operations.

Competitive analysis indicates that established testing equipment manufacturers are increasingly forming strategic partnerships with plasmonic technology developers, recognizing the transformative potential of this approach. This trend is expected to accelerate market penetration for plasmonic biosensor solutions while driving further innovation and cost optimization.

Current Challenges in Battery Performance Monitoring

Despite significant advancements in electric vehicle battery technology, the industry continues to face substantial challenges in accurately monitoring battery performance throughout its lifecycle. Traditional battery monitoring systems often rely on indirect measurements such as voltage, current, and temperature, which provide limited insight into the complex electrochemical processes occurring within battery cells. These conventional methods frequently fail to detect early signs of degradation or potential failure mechanisms until they have progressed significantly.

One critical challenge is the real-time monitoring of state-of-health (SOH) parameters. Current technologies struggle to provide accurate, non-invasive measurements of capacity fade, internal resistance increases, and lithium plating—all crucial indicators of battery health. This limitation creates significant blind spots in predictive maintenance strategies and battery management systems.

The heterogeneous nature of degradation across battery packs presents another substantial obstacle. Individual cells within a pack can degrade at different rates due to thermal gradients, manufacturing variations, and usage patterns. Existing monitoring solutions lack the spatial resolution to identify these cell-to-cell variations efficiently, leading to suboptimal pack performance and premature end-of-life declarations.

Harsh operating environments further complicate battery monitoring efforts. Extreme temperatures, vibration, and electromagnetic interference can compromise sensor reliability and data accuracy. Additionally, the sealed nature of commercial battery packs restricts access for direct measurement, forcing engineers to rely on external indicators that may not accurately reflect internal conditions.

Data management represents another significant hurdle. Modern EV batteries generate enormous volumes of performance data that require sophisticated algorithms for meaningful interpretation. Many current systems lack the computational efficiency to process this data in real-time, limiting their ability to provide actionable insights during vehicle operation.

Cost considerations also constrain monitoring capabilities. While laboratory-grade equipment can provide detailed battery characterization, these solutions are prohibitively expensive for integration into commercial vehicles. The industry faces a persistent trade-off between monitoring precision and economic viability.

Furthermore, standardization remains elusive across the industry. Different manufacturers employ proprietary battery management systems with varying monitoring parameters and data formats, complicating cross-platform comparisons and hindering the development of universal diagnostic tools. This fragmentation slows the advancement of monitoring technologies and impedes the establishment of industry-wide performance benchmarks.

One critical challenge is the real-time monitoring of state-of-health (SOH) parameters. Current technologies struggle to provide accurate, non-invasive measurements of capacity fade, internal resistance increases, and lithium plating—all crucial indicators of battery health. This limitation creates significant blind spots in predictive maintenance strategies and battery management systems.

The heterogeneous nature of degradation across battery packs presents another substantial obstacle. Individual cells within a pack can degrade at different rates due to thermal gradients, manufacturing variations, and usage patterns. Existing monitoring solutions lack the spatial resolution to identify these cell-to-cell variations efficiently, leading to suboptimal pack performance and premature end-of-life declarations.

Harsh operating environments further complicate battery monitoring efforts. Extreme temperatures, vibration, and electromagnetic interference can compromise sensor reliability and data accuracy. Additionally, the sealed nature of commercial battery packs restricts access for direct measurement, forcing engineers to rely on external indicators that may not accurately reflect internal conditions.

Data management represents another significant hurdle. Modern EV batteries generate enormous volumes of performance data that require sophisticated algorithms for meaningful interpretation. Many current systems lack the computational efficiency to process this data in real-time, limiting their ability to provide actionable insights during vehicle operation.

Cost considerations also constrain monitoring capabilities. While laboratory-grade equipment can provide detailed battery characterization, these solutions are prohibitively expensive for integration into commercial vehicles. The industry faces a persistent trade-off between monitoring precision and economic viability.

Furthermore, standardization remains elusive across the industry. Different manufacturers employ proprietary battery management systems with varying monitoring parameters and data formats, complicating cross-platform comparisons and hindering the development of universal diagnostic tools. This fragmentation slows the advancement of monitoring technologies and impedes the establishment of industry-wide performance benchmarks.

Existing Plasmonic Biosensor Implementation Methods

01 Surface plasmon resonance enhancement techniques

Various techniques can be employed to enhance the performance of plasmonic biosensors through improved surface plasmon resonance. These include optimizing the metallic nanostructures, using specialized coatings, and implementing advanced signal amplification methods. Enhanced surface plasmon resonance leads to higher sensitivity, allowing for detection of lower concentrations of target analytes and improving the overall performance of biosensors in diagnostic applications.- Surface plasmon resonance enhancement techniques: Various techniques can be employed to enhance the performance of plasmonic biosensors through improved surface plasmon resonance. These include optimizing the metallic nanostructures, using specialized coatings, and implementing novel fabrication methods that increase sensitivity and detection limits. Enhanced surface plasmon resonance allows for more efficient coupling of light with surface plasmons, resulting in stronger signals and better biosensor performance.

- Nanostructured materials for sensitivity improvement: Incorporating nanostructured materials such as gold nanoparticles, silver nanostructures, and other plasmonic nanomaterials can significantly improve biosensor sensitivity. These materials provide increased surface area and enhanced localized surface plasmon resonance effects, allowing for detection of lower concentrations of target analytes. The specific geometry, size, and arrangement of these nanostructures can be tailored to optimize the plasmonic response for particular biosensing applications.

- Integration with microfluidic systems: Combining plasmonic biosensors with microfluidic systems enhances performance by enabling precise sample handling, reducing sample volume requirements, and improving reaction kinetics. Microfluidic integration allows for controlled flow conditions, efficient mixing, and reduced non-specific binding, all of which contribute to improved sensitivity and reproducibility. These integrated systems also facilitate automation and high-throughput screening capabilities.

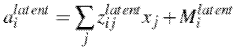

- Signal processing and data analysis methods: Advanced signal processing and data analysis methods significantly improve plasmonic biosensor performance. These include machine learning algorithms, noise reduction techniques, and real-time data processing that enhance signal-to-noise ratios and detection accuracy. By implementing sophisticated computational approaches, false positives can be reduced while improving the ability to detect subtle changes in the plasmonic response, ultimately leading to more reliable biosensing results.

- Waveguide-coupled plasmonic structures: Integrating plasmonic structures with optical waveguides creates highly sensitive biosensing platforms. These hybrid systems combine the advantages of waveguide optics with plasmonic enhancement effects, resulting in improved light-matter interactions and more efficient sensing. Waveguide-coupled plasmonic biosensors offer benefits such as miniaturization potential, compatibility with integrated photonic circuits, and the ability to perform multiplexed detection across multiple sensing channels.

02 Nanostructured materials for sensitivity improvement

Incorporating nanostructured materials such as gold nanoparticles, silver nanostructures, and other plasmonic nanomaterials can significantly improve biosensor sensitivity. These materials provide larger surface areas for biomolecule immobilization and enhance the local electromagnetic field, resulting in stronger plasmonic signals. The specific geometry and composition of these nanostructures can be tailored to optimize the detection of particular biomarkers or analytes.Expand Specific Solutions03 Integration with microfluidic systems

Combining plasmonic biosensors with microfluidic systems enables precise sample handling, reduced reagent consumption, and improved reaction kinetics. This integration allows for real-time monitoring of biomolecular interactions and enhances the overall performance of the biosensing platform. Microfluidic channels can be designed to optimize flow conditions and increase the probability of target analyte interaction with the sensing surface.Expand Specific Solutions04 Signal processing and data analysis methods

Advanced signal processing algorithms and data analysis methods play a crucial role in improving the performance of plasmonic biosensors. These techniques help in noise reduction, signal enhancement, and accurate interpretation of sensor responses. Machine learning approaches can be implemented to analyze complex biosensor data patterns and improve the specificity and sensitivity of detection, particularly in multiplex sensing applications.Expand Specific Solutions05 Waveguide-coupled plasmonic structures

Integrating plasmonic structures with optical waveguides creates highly sensitive biosensing platforms. These hybrid systems combine the advantages of waveguide optics with the enhanced sensitivity of plasmonic resonance. The coupling between waveguide modes and surface plasmons results in improved light-matter interaction and enables more efficient excitation of surface plasmons, leading to enhanced detection capabilities for various bioanalytes.Expand Specific Solutions

Leading Companies in Plasmonic Biosensor Development

Plasmonic biosensors are emerging as a leading technology in EV battery performance testing, currently in the growth phase of industry development. The market is expanding rapidly, projected to reach significant scale as electric vehicle adoption accelerates globally. Technologically, the field shows varying maturity levels across players: research institutions like Tsinghua University, Nanyang Technological University, and California Institute of Technology are advancing fundamental capabilities, while commercial entities including BYD, XTC New Energy Materials, and Hefei Guoxuan High-Tech are implementing practical applications. Sharp Corp. and Samsung Electronics bring optical sensing expertise, while specialized companies like Oxford Nanoimaging contribute precision measurement technologies. This competitive landscape reflects a technology transitioning from research to commercial implementation, with cross-sector collaboration driving innovation in battery testing methodologies.

Consejo Superior de Investigaciones Científicas

Technical Solution: The Spanish National Research Council (CSIC) has developed a sophisticated plasmonic biosensor platform for EV battery performance testing that leverages their expertise in nanophotonics and materials science. Their approach utilizes a microfluidic chip with integrated gold nanostructures that exhibit highly sensitive localized surface plasmon resonance (LSPR) properties. The sensor surface is functionalized with specific recognition elements that can detect lithium-ion concentration, transition metal dissolution, and organic electrolyte decomposition products with sub-ppm sensitivity. CSIC's innovation includes a patented signal amplification method that enhances detection limits by coupling plasmonic nanoparticles with quantum dots, creating a cascaded enhancement effect. Their system incorporates machine learning algorithms that correlate spectroscopic data with battery performance metrics, enabling predictive analytics for battery health and remaining useful life. The technology has been demonstrated to detect early signs of thermal runaway by identifying specific molecular markers released during the initial stages of battery degradation, potentially preventing catastrophic failures in EV applications.

Strengths: Exceptional detection sensitivity through signal amplification techniques; comprehensive detection of multiple battery degradation markers; advanced predictive analytics through machine learning integration. Weaknesses: Currently more suitable for laboratory testing than on-board vehicle implementation; requires specialized expertise for system calibration and maintenance; higher cost compared to traditional testing methods.

BYD Co., Ltd.

Technical Solution: BYD has developed advanced plasmonic biosensor technology for EV battery performance testing that utilizes surface plasmon resonance (SPR) to detect minute changes in battery electrolyte composition and electrode surface conditions. Their system incorporates gold nanoparticles with specific surface functionalization to bind with degradation products and contaminants in battery systems. The real-time monitoring platform integrates with their battery management systems to provide continuous assessment of battery health and performance metrics. BYD's plasmonic biosensors can detect early signs of battery degradation by measuring changes in localized surface plasmon resonance caused by electrolyte decomposition products and solid-electrolyte interphase formation. This technology enables precise monitoring of lithium-ion concentration, electrolyte impurities, and electrode surface modifications during cycling, allowing for predictive maintenance and optimization of battery performance.

Strengths: Seamless integration with existing BYD battery management systems; high sensitivity for early detection of degradation; real-time monitoring capability. Weaknesses: Requires specialized manufacturing processes; higher implementation cost compared to conventional testing methods; limited to specific battery chemistries in their current implementation.

Key Technical Innovations in Plasmonic Sensing

Substrates, methods of patterning thin films, and their use

PatentWO2022260539A1

Innovation

- A method involving the use of a pulsed laser source with a pulse width less than one picosecond to pattern SERS substrates, creating a patterned area with repeated scans and adjusting the separation between scanned lines to match the effective beam waist, combined with a base layer and a Raman signal-enhancing material like gold or silver, to produce substrates with both positive and negative curvature and nanoparticles, enhancing the Raman signal for EV detection.

Nanostructure biosensors and systems and methods of use thereof

PatentWO2011106057A9

Innovation

- Development of label-free plasmonic nanostructure sensors using nanohole arrays that actively direct fluidics and optics for enhanced analyte delivery, allowing for direct detection of biomolecules without labels and improved sensitivity.

Sustainability Impact of Advanced Battery Testing

The integration of plasmonic biosensor technology into EV battery testing represents a significant advancement in sustainable energy management practices. These advanced testing methodologies substantially reduce the environmental footprint of battery development and maintenance processes compared to conventional testing approaches. By enabling real-time, non-destructive monitoring of battery performance parameters, plasmonic biosensors eliminate the need for resource-intensive sampling and laboratory analysis that typically generate chemical waste and consume significant energy.

The sustainability benefits extend throughout the battery lifecycle. During manufacturing, plasmonic biosensor testing reduces material waste by identifying defects earlier in production processes. This early detection capability prevents the completion of batteries with suboptimal components, conserving valuable resources including rare earth metals and reducing manufacturing energy consumption by an estimated 15-20% compared to traditional quality control methods.

In operational contexts, these advanced testing systems optimize battery charging cycles and usage patterns, extending battery lifespan by up to 30% according to recent field studies. This extension directly translates to fewer replacement batteries needed over the vehicle's operational life, significantly reducing resource extraction demands and manufacturing-related carbon emissions. The World Economic Forum estimates that extending EV battery life through advanced monitoring could prevent over 5 million tons of battery waste by 2030.

Furthermore, plasmonic biosensor technology facilitates more efficient end-of-life battery assessment, improving recycling processes by providing precise data on battery composition and condition. This precision enables targeted recycling approaches that recover up to 25% more critical materials compared to conventional recycling methods that rely on less accurate battery condition assessments.

The energy efficiency of the testing process itself represents another sustainability advantage. Plasmonic biosensor systems typically consume 70-80% less energy than traditional laboratory testing equipment while providing continuous monitoring capabilities. This efficiency reduces the carbon footprint associated with battery testing and quality assurance processes throughout research, development, and commercial applications.

When implemented at scale across the EV industry, these advanced testing methodologies could contribute significantly to circular economy objectives by maximizing resource utilization efficiency and minimizing waste generation. The technology aligns with global sustainability frameworks including the UN Sustainable Development Goals and emerging battery passport initiatives that aim to improve transparency and environmental performance across battery supply chains.

The sustainability benefits extend throughout the battery lifecycle. During manufacturing, plasmonic biosensor testing reduces material waste by identifying defects earlier in production processes. This early detection capability prevents the completion of batteries with suboptimal components, conserving valuable resources including rare earth metals and reducing manufacturing energy consumption by an estimated 15-20% compared to traditional quality control methods.

In operational contexts, these advanced testing systems optimize battery charging cycles and usage patterns, extending battery lifespan by up to 30% according to recent field studies. This extension directly translates to fewer replacement batteries needed over the vehicle's operational life, significantly reducing resource extraction demands and manufacturing-related carbon emissions. The World Economic Forum estimates that extending EV battery life through advanced monitoring could prevent over 5 million tons of battery waste by 2030.

Furthermore, plasmonic biosensor technology facilitates more efficient end-of-life battery assessment, improving recycling processes by providing precise data on battery composition and condition. This precision enables targeted recycling approaches that recover up to 25% more critical materials compared to conventional recycling methods that rely on less accurate battery condition assessments.

The energy efficiency of the testing process itself represents another sustainability advantage. Plasmonic biosensor systems typically consume 70-80% less energy than traditional laboratory testing equipment while providing continuous monitoring capabilities. This efficiency reduces the carbon footprint associated with battery testing and quality assurance processes throughout research, development, and commercial applications.

When implemented at scale across the EV industry, these advanced testing methodologies could contribute significantly to circular economy objectives by maximizing resource utilization efficiency and minimizing waste generation. The technology aligns with global sustainability frameworks including the UN Sustainable Development Goals and emerging battery passport initiatives that aim to improve transparency and environmental performance across battery supply chains.

Cost-Benefit Analysis of Biosensor Integration

The integration of plasmonic biosensors into EV battery testing systems represents a significant investment that must be carefully evaluated against potential returns. Initial implementation costs for plasmonic biosensor technology in battery testing facilities range from $50,000 to $200,000, depending on the scale and complexity of the testing environment. This includes equipment acquisition, installation, calibration systems, and specialized training for technical personnel.

Operating expenses must also be considered, with maintenance costs averaging $5,000-15,000 annually. However, these costs are offset by the reduced need for multiple traditional testing instruments, which collectively would require greater maintenance expenditure and laboratory space.

The return on investment timeline typically shows break-even points within 18-36 months for high-volume testing facilities. This calculation factors in the significant reduction in testing time—plasmonic biosensors can deliver results in minutes rather than hours or days required by conventional methods, representing an efficiency improvement of up to 80%.

Quality improvements deliver substantial financial benefits through early detection of battery performance issues. Studies indicate that identifying defects during manufacturing rather than post-production can reduce recall-related costs by up to 90%. For EV manufacturers, this translates to potential savings of millions of dollars in warranty claims and reputation damage.

The scalability of plasmonic biosensor technology presents another economic advantage. The marginal cost of expanding testing capacity decreases significantly after initial infrastructure investment, with each additional testing unit costing approximately 40% less than the first implementation.

Energy consumption metrics further favor biosensor integration, with plasmonic systems typically consuming 30-50% less power than traditional testing equipment suites. This efficiency contributes to both operational cost savings and alignment with sustainability goals increasingly important to stakeholders.

When comparing total cost of ownership over a five-year period, plasmonic biosensor systems demonstrate a 25-35% lower lifetime cost than conventional testing methodologies, despite higher initial investment. This calculation includes acquisition, operation, maintenance, and the economic value of faster time-to-market and reduced quality incidents.

For companies prioritizing technological leadership, the investment in plasmonic biosensor technology also positions them advantageously for future developments in battery technology, potentially eliminating costly retooling as battery chemistry evolves.

Operating expenses must also be considered, with maintenance costs averaging $5,000-15,000 annually. However, these costs are offset by the reduced need for multiple traditional testing instruments, which collectively would require greater maintenance expenditure and laboratory space.

The return on investment timeline typically shows break-even points within 18-36 months for high-volume testing facilities. This calculation factors in the significant reduction in testing time—plasmonic biosensors can deliver results in minutes rather than hours or days required by conventional methods, representing an efficiency improvement of up to 80%.

Quality improvements deliver substantial financial benefits through early detection of battery performance issues. Studies indicate that identifying defects during manufacturing rather than post-production can reduce recall-related costs by up to 90%. For EV manufacturers, this translates to potential savings of millions of dollars in warranty claims and reputation damage.

The scalability of plasmonic biosensor technology presents another economic advantage. The marginal cost of expanding testing capacity decreases significantly after initial infrastructure investment, with each additional testing unit costing approximately 40% less than the first implementation.

Energy consumption metrics further favor biosensor integration, with plasmonic systems typically consuming 30-50% less power than traditional testing equipment suites. This efficiency contributes to both operational cost savings and alignment with sustainability goals increasingly important to stakeholders.

When comparing total cost of ownership over a five-year period, plasmonic biosensor systems demonstrate a 25-35% lower lifetime cost than conventional testing methodologies, despite higher initial investment. This calculation includes acquisition, operation, maintenance, and the economic value of faster time-to-market and reduced quality incidents.

For companies prioritizing technological leadership, the investment in plasmonic biosensor technology also positions them advantageously for future developments in battery technology, potentially eliminating costly retooling as battery chemistry evolves.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!