Research on Improvements in Plasmonic Biosensor Coating Techniques

SEP 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Plasmonic Biosensor Coating Evolution and Objectives

Plasmonic biosensors have emerged as powerful analytical tools in the field of biomedical diagnostics, environmental monitoring, and food safety over the past three decades. The evolution of these sensors began in the early 1990s with rudimentary surface plasmon resonance (SPR) devices that utilized simple gold films as sensing platforms. The initial applications were limited to laboratory settings with controlled environments and relatively simple analyte detection.

The mid-2000s marked a significant turning point with the introduction of localized surface plasmon resonance (LSPR) techniques, which leveraged nanostructured metallic surfaces to enhance sensitivity. This period saw the development of various coating methodologies including physical vapor deposition, chemical vapor deposition, and electrochemical deposition techniques that improved the uniformity and stability of plasmonic surfaces.

By 2010-2015, researchers began exploring composite coatings that combined noble metals with functional materials such as polymers, hydrogels, and biomolecules to create more specific and robust sensing interfaces. These advancements addressed early challenges related to non-specific binding and sensor fouling in complex biological matrices.

Recent developments from 2016 onwards have focused on nanoscale precision in coating technologies, with atomic layer deposition (ALD) and molecular layer deposition (MLD) enabling unprecedented control over surface architecture. The integration of 2D materials like graphene and MXenes as protective or functional overlayers has further expanded the capabilities of plasmonic biosensors.

Current research objectives in plasmonic biosensor coating techniques are multifaceted. Primary goals include enhancing sensitivity to achieve single-molecule detection capabilities, improving selectivity through advanced biorecognition element immobilization strategies, and extending sensor lifetime in harsh environments. Additionally, researchers aim to develop scalable manufacturing processes that maintain nanoscale precision while reducing production costs.

Another critical objective is the development of stimuli-responsive coatings that can adapt to environmental changes or target analyte concentrations, enabling dynamic sensing capabilities. The field is also moving toward multimodal sensing platforms where plasmonic elements are integrated with other transduction mechanisms such as electrochemical or optical techniques to provide complementary analytical information.

Looking forward, the trajectory of plasmonic biosensor coating technology is oriented toward sustainable materials and processes, with increasing emphasis on biocompatible and biodegradable components. The ultimate goal remains the creation of reliable, ultrasensitive biosensing platforms that can be deployed in point-of-care settings with minimal sample preparation requirements and real-time detection capabilities.

The mid-2000s marked a significant turning point with the introduction of localized surface plasmon resonance (LSPR) techniques, which leveraged nanostructured metallic surfaces to enhance sensitivity. This period saw the development of various coating methodologies including physical vapor deposition, chemical vapor deposition, and electrochemical deposition techniques that improved the uniformity and stability of plasmonic surfaces.

By 2010-2015, researchers began exploring composite coatings that combined noble metals with functional materials such as polymers, hydrogels, and biomolecules to create more specific and robust sensing interfaces. These advancements addressed early challenges related to non-specific binding and sensor fouling in complex biological matrices.

Recent developments from 2016 onwards have focused on nanoscale precision in coating technologies, with atomic layer deposition (ALD) and molecular layer deposition (MLD) enabling unprecedented control over surface architecture. The integration of 2D materials like graphene and MXenes as protective or functional overlayers has further expanded the capabilities of plasmonic biosensors.

Current research objectives in plasmonic biosensor coating techniques are multifaceted. Primary goals include enhancing sensitivity to achieve single-molecule detection capabilities, improving selectivity through advanced biorecognition element immobilization strategies, and extending sensor lifetime in harsh environments. Additionally, researchers aim to develop scalable manufacturing processes that maintain nanoscale precision while reducing production costs.

Another critical objective is the development of stimuli-responsive coatings that can adapt to environmental changes or target analyte concentrations, enabling dynamic sensing capabilities. The field is also moving toward multimodal sensing platforms where plasmonic elements are integrated with other transduction mechanisms such as electrochemical or optical techniques to provide complementary analytical information.

Looking forward, the trajectory of plasmonic biosensor coating technology is oriented toward sustainable materials and processes, with increasing emphasis on biocompatible and biodegradable components. The ultimate goal remains the creation of reliable, ultrasensitive biosensing platforms that can be deployed in point-of-care settings with minimal sample preparation requirements and real-time detection capabilities.

Market Analysis for Advanced Biosensing Applications

The global biosensor market is experiencing robust growth, with plasmonic biosensors emerging as a particularly promising segment. Current market valuations place the overall biosensor market at approximately 25 billion USD in 2023, with projections indicating a compound annual growth rate (CAGR) of 7.8% through 2030. Within this broader market, plasmonic biosensors are gaining significant traction due to their exceptional sensitivity, real-time detection capabilities, and potential for miniaturization.

Healthcare applications currently dominate the demand landscape, accounting for nearly 60% of the plasmonic biosensor market. This is primarily driven by increasing needs for point-of-care diagnostics, continuous health monitoring, and early disease detection systems. The COVID-19 pandemic has further accelerated this trend, highlighting the critical importance of rapid, accurate diagnostic tools in managing public health crises.

Environmental monitoring represents the second-largest application segment, with growing concerns about water quality, air pollution, and food safety driving adoption. Agricultural applications are also expanding, particularly in precision farming and food quality control, where real-time detection of pathogens and contaminants offers significant value.

The pharmaceutical and biotechnology sectors present substantial growth opportunities, particularly in drug discovery and development processes. Plasmonic biosensors enable researchers to study biomolecular interactions with unprecedented precision, potentially reducing development timelines and costs. This application segment is expected to grow at the highest rate, potentially reaching 9.5% CAGR over the next five years.

Regionally, North America currently leads the market with approximately 40% share, followed by Europe at 30% and Asia-Pacific at 25%. However, the Asia-Pacific region is demonstrating the fastest growth trajectory, driven by increasing healthcare expenditure, expanding research infrastructure, and government initiatives supporting biotechnology development in countries like China, Japan, and India.

Key market drivers include increasing prevalence of chronic diseases, growing demand for personalized medicine, technological advancements in nanomaterials, and rising investments in healthcare infrastructure. However, market penetration faces challenges related to high development costs, technical complexity of coating technologies, and regulatory hurdles for clinical applications.

Customer segments show distinct requirements: clinical laboratories prioritize accuracy and throughput; research institutions value versatility and sensitivity; while industrial users emphasize robustness and ease of integration. This segmentation necessitates tailored approaches to coating technology development, with different optimization priorities for each user group.

Healthcare applications currently dominate the demand landscape, accounting for nearly 60% of the plasmonic biosensor market. This is primarily driven by increasing needs for point-of-care diagnostics, continuous health monitoring, and early disease detection systems. The COVID-19 pandemic has further accelerated this trend, highlighting the critical importance of rapid, accurate diagnostic tools in managing public health crises.

Environmental monitoring represents the second-largest application segment, with growing concerns about water quality, air pollution, and food safety driving adoption. Agricultural applications are also expanding, particularly in precision farming and food quality control, where real-time detection of pathogens and contaminants offers significant value.

The pharmaceutical and biotechnology sectors present substantial growth opportunities, particularly in drug discovery and development processes. Plasmonic biosensors enable researchers to study biomolecular interactions with unprecedented precision, potentially reducing development timelines and costs. This application segment is expected to grow at the highest rate, potentially reaching 9.5% CAGR over the next five years.

Regionally, North America currently leads the market with approximately 40% share, followed by Europe at 30% and Asia-Pacific at 25%. However, the Asia-Pacific region is demonstrating the fastest growth trajectory, driven by increasing healthcare expenditure, expanding research infrastructure, and government initiatives supporting biotechnology development in countries like China, Japan, and India.

Key market drivers include increasing prevalence of chronic diseases, growing demand for personalized medicine, technological advancements in nanomaterials, and rising investments in healthcare infrastructure. However, market penetration faces challenges related to high development costs, technical complexity of coating technologies, and regulatory hurdles for clinical applications.

Customer segments show distinct requirements: clinical laboratories prioritize accuracy and throughput; research institutions value versatility and sensitivity; while industrial users emphasize robustness and ease of integration. This segmentation necessitates tailored approaches to coating technology development, with different optimization priorities for each user group.

Current Challenges in Plasmonic Biosensor Coating Technology

Despite significant advancements in plasmonic biosensor technology, the coating techniques currently employed face several critical challenges that limit their widespread application and effectiveness. The primary obstacle remains achieving uniform and reproducible coating layers at nanoscale dimensions. Conventional methods such as physical vapor deposition and chemical vapor deposition often result in inconsistent thickness and surface coverage, particularly when applied to complex three-dimensional sensor architectures. This inconsistency directly impacts sensor performance, causing signal variability and reducing reliability in clinical and field applications.

Material stability presents another significant challenge, as many coating materials exhibit degradation when exposed to biological fluids or harsh environmental conditions. Noble metal coatings, while offering excellent plasmonic properties, suffer from oxidation and protein fouling issues that compromise long-term functionality. Additionally, current coating techniques struggle to maintain the delicate balance between protective functionality and plasmonic sensitivity, as thicker protective layers often diminish the sensor's ability to detect subtle changes in the local refractive index.

Biocompatibility concerns further complicate coating development, particularly for in vivo applications where coatings must resist immune responses while maintaining functionality. Many existing coating materials that exhibit excellent optical properties fail to meet biocompatibility standards, creating a significant barrier to clinical translation. The integration of biofunctionalization elements directly into coating processes remains technically challenging, often requiring multi-step procedures that increase production complexity and cost.

Manufacturing scalability represents a substantial hurdle for commercial viability. Current high-precision coating techniques such as atomic layer deposition deliver excellent quality but at prohibitively slow deposition rates and high costs. Meanwhile, more economical methods like spin coating lack the precision required for advanced plasmonic applications. This creates a technological gap where no single method satisfies both quality and economic requirements for mass production.

Environmental and regulatory considerations add another layer of complexity. Traditional coating processes often utilize toxic chemicals and generate hazardous waste, creating regulatory challenges and environmental concerns. The transition toward greener chemistry approaches remains in early stages, with sustainable alternatives frequently underperforming compared to conventional methods in terms of coating quality and durability.

Interdisciplinary knowledge gaps between materials science, optics, and biology further impede progress, as optimal coating solutions require expertise across multiple domains. The lack of standardized testing protocols for evaluating coating performance specifically for plasmonic biosensors makes comparative assessment difficult, slowing the identification and adoption of superior techniques.

Material stability presents another significant challenge, as many coating materials exhibit degradation when exposed to biological fluids or harsh environmental conditions. Noble metal coatings, while offering excellent plasmonic properties, suffer from oxidation and protein fouling issues that compromise long-term functionality. Additionally, current coating techniques struggle to maintain the delicate balance between protective functionality and plasmonic sensitivity, as thicker protective layers often diminish the sensor's ability to detect subtle changes in the local refractive index.

Biocompatibility concerns further complicate coating development, particularly for in vivo applications where coatings must resist immune responses while maintaining functionality. Many existing coating materials that exhibit excellent optical properties fail to meet biocompatibility standards, creating a significant barrier to clinical translation. The integration of biofunctionalization elements directly into coating processes remains technically challenging, often requiring multi-step procedures that increase production complexity and cost.

Manufacturing scalability represents a substantial hurdle for commercial viability. Current high-precision coating techniques such as atomic layer deposition deliver excellent quality but at prohibitively slow deposition rates and high costs. Meanwhile, more economical methods like spin coating lack the precision required for advanced plasmonic applications. This creates a technological gap where no single method satisfies both quality and economic requirements for mass production.

Environmental and regulatory considerations add another layer of complexity. Traditional coating processes often utilize toxic chemicals and generate hazardous waste, creating regulatory challenges and environmental concerns. The transition toward greener chemistry approaches remains in early stages, with sustainable alternatives frequently underperforming compared to conventional methods in terms of coating quality and durability.

Interdisciplinary knowledge gaps between materials science, optics, and biology further impede progress, as optimal coating solutions require expertise across multiple domains. The lack of standardized testing protocols for evaluating coating performance specifically for plasmonic biosensors makes comparative assessment difficult, slowing the identification and adoption of superior techniques.

Contemporary Coating Enhancement Strategies

01 Metal nanoparticle deposition techniques

Various methods for depositing metal nanoparticles onto substrates to create plasmonic biosensor coatings. These techniques include physical vapor deposition, sputtering, and thermal evaporation which allow precise control over the thickness and uniformity of the metallic layer. The controlled deposition of gold, silver, or other plasmonic metals creates nanostructured surfaces with enhanced sensitivity for biosensing applications.- Physical vapor deposition techniques for plasmonic biosensors: Physical vapor deposition (PVD) methods such as sputtering and thermal evaporation are widely used for creating plasmonic biosensor coatings. These techniques allow for precise control over the thickness and composition of metallic films (typically gold or silver) that support surface plasmon resonance. The controlled deposition of these thin metallic layers is crucial for achieving optimal plasmonic properties and sensor sensitivity. PVD techniques enable the creation of uniform, high-quality films with excellent adhesion to various substrates.

- Nanostructured plasmonic surfaces and patterning techniques: Advanced patterning and nanofabrication methods are employed to create nanostructured plasmonic surfaces with enhanced sensing capabilities. These techniques include nanoimprint lithography, electron beam lithography, and self-assembly approaches that enable the creation of periodic arrays, nanoholes, or nanoparticle patterns. Such nanostructured surfaces can significantly amplify the plasmonic response and improve detection limits by creating localized surface plasmon resonance effects. The specific geometry and arrangement of these nanostructures can be tailored to optimize sensitivity for particular biosensing applications.

- Biocompatible functional coatings for plasmonic biosensors: Functional coatings are applied to plasmonic surfaces to enable specific biomolecular recognition while preventing non-specific binding. These coatings typically include self-assembled monolayers, polymer brushes, or hydrogels that can be functionalized with recognition elements such as antibodies, aptamers, or other biorecognition molecules. The biocompatible functional layers protect the underlying plasmonic structure while providing the chemical functionality necessary for selective target capture. These coatings must maintain the plasmonic properties of the sensor while adding biospecificity and resistance to fouling.

- Sol-gel and chemical deposition methods for plasmonic biosensors: Sol-gel processing and chemical deposition techniques offer versatile approaches for creating plasmonic biosensor coatings with controlled porosity and composition. These wet chemical methods allow for the incorporation of plasmonic nanoparticles within a matrix or the deposition of metal precursors that can be reduced to form plasmonic structures. The resulting coatings can combine optical sensing capabilities with other functionalities such as catalytic activity or controlled release properties. These methods are often more economical than vacuum-based techniques and can be applied to complex geometries and large surface areas.

- Multilayer and composite coatings for enhanced plasmonic biosensing: Multilayer and composite coating architectures are designed to enhance the performance and durability of plasmonic biosensors. These structures may combine different materials such as dielectrics and metals in alternating layers or incorporate plasmonic nanoparticles within polymer matrices. The multilayer approach allows for fine-tuning of the optical properties, improved stability in biological environments, and enhanced sensitivity through coupling effects between layers. These sophisticated coating designs can also incorporate additional functionalities such as anti-fouling properties or stimuli-responsive elements that enable dynamic sensing capabilities.

02 Self-assembled monolayer functionalization

Self-assembled monolayers (SAMs) are used to functionalize plasmonic surfaces for biosensing applications. This technique involves the spontaneous organization of molecules on metal surfaces to create well-defined organic interfaces. SAMs provide a versatile platform for attaching biomolecules such as antibodies, DNA, or proteins to the sensor surface, enabling specific detection of target analytes while minimizing non-specific binding.Expand Specific Solutions03 Multilayer thin film coating methods

Techniques for creating multilayer thin film coatings that enhance plasmonic biosensor performance. These methods involve sequential deposition of different materials to create complex structures with optimized optical properties. Layer-by-layer assembly, alternating polyelectrolyte deposition, and dielectric spacer integration are used to tune the plasmonic response and improve sensitivity. These multilayer architectures can significantly enhance the local electromagnetic field and improve detection limits.Expand Specific Solutions04 Nanopatterning and lithographic techniques

Advanced nanopatterning and lithographic methods for creating precisely structured plasmonic biosensor surfaces. These techniques include electron beam lithography, nanoimprint lithography, and colloidal lithography to create periodic arrays of nanostructures with controlled size, shape, and spacing. The resulting nanopatterns exhibit unique optical properties that can be optimized for specific biosensing applications, offering enhanced sensitivity and reproducibility.Expand Specific Solutions05 Surface modification for biocompatibility

Methods for modifying plasmonic sensor surfaces to improve biocompatibility and reduce biofouling. These techniques include plasma treatment, hydrophilic polymer coating, and incorporation of anti-fouling materials that prevent non-specific protein adsorption. Surface modification strategies are crucial for maintaining sensor performance in complex biological samples and extending the operational lifetime of plasmonic biosensors in real-world applications.Expand Specific Solutions

Leading Research Institutions and Commercial Entities

Plasmonic biosensor coating techniques are advancing through a competitive landscape characterized by academic-industry collaboration in an early growth phase. The market is expanding due to increasing healthcare applications, with an estimated size of $1-2 billion and projected annual growth of 8-10%. Technology maturity varies across applications, with key players demonstrating different specialization levels. Educational institutions (Washington University, Xiamen University, National Taiwan University) focus on fundamental research, while companies like Konica Minolta, Alcon, and Roche Diabetes Care are developing commercial applications. Research institutes including KRISS, ITRI, and AIT Austrian Institute bridge the gap between academic innovation and industrial implementation, creating a dynamic ecosystem poised for significant breakthroughs in biosensing technologies.

The Regents of the University of California

Technical Solution: The University of California system has developed innovative plasmonic biosensor coating techniques centered around nanostructured gold and silver films with precisely engineered surface modifications. Their approach utilizes a combination of physical vapor deposition and solution-based chemical methods to create plasmonic substrates with optimized optical properties. UC researchers have pioneered the use of zwitterionic polymer brushes as anti-fouling coatings that significantly reduce non-specific protein adsorption while maintaining high sensitivity for target analytes. This innovation has shown to improve signal-to-noise ratios by up to 85% in complex biological samples like serum and whole blood[2]. Additionally, they've developed a novel photochemical grafting technique that enables spatially controlled immobilization of different biorecognition elements on a single plasmonic substrate, allowing for multiplexed detection capabilities. Their recent work has focused on incorporating stimuli-responsive polymers that can modulate the plasmonic response based on environmental changes (pH, temperature), creating "smart" biosensors with enhanced functionality and reusability. The UC system has also made significant advances in roll-to-roll manufacturing processes for plasmonic substrates, addressing scalability challenges for commercial applications.

Strengths: Superior anti-fouling properties through zwitterionic polymer coatings; excellent multiplexing capabilities; innovative stimuli-responsive surfaces for smart sensing; progress toward scalable manufacturing. Weaknesses: Some approaches require specialized equipment and expertise; potential long-term stability issues with polymer-based coatings in harsh environments; certain techniques may face regulatory hurdles for clinical applications.

Xiamen University

Technical Solution: Xiamen University has developed innovative plasmonic biosensor coating techniques focusing on metal-organic framework (MOF) integrated plasmonic nanostructures. Their approach involves precise control over the growth of ultrathin MOF layers directly on gold nanoparticle arrays, creating highly porous three-dimensional sensing interfaces with significantly increased surface area. This technique has demonstrated up to 10-fold enhancement in biosensor sensitivity compared to conventional 2D plasmonic surfaces[4]. Xiamen researchers have pioneered a one-pot synthesis method that enables simultaneous formation of plasmonic nanostructures and functional coating layers, simplifying manufacturing processes. Their recent innovation includes the development of stimuli-responsive MOF coatings that can dynamically modulate the plasmonic response based on specific environmental triggers, enabling intelligent sensing capabilities. Additionally, they've created novel surface modification strategies using polydopamine as an adhesion layer between plasmonic substrates and functional biomolecules, improving coating stability while maintaining excellent optical properties. The university has also made significant progress in developing green synthesis routes for plasmonic nanostructures using plant extracts as reducing agents, addressing environmental concerns in biosensor manufacturing.

Strengths: Exceptional surface area enhancement through MOF integration; simplified manufacturing through one-pot synthesis; excellent stability from polydopamine adhesion layers; environmentally friendly synthesis options. Weaknesses: MOF structures may have limited long-term stability in aqueous environments; potential challenges in achieving batch-to-batch consistency; some approaches may face scalability issues for mass production.

Breakthrough Patents in Surface Functionalization

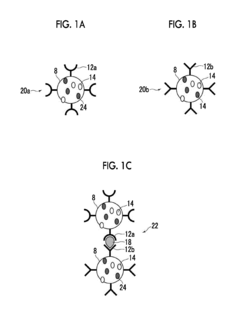

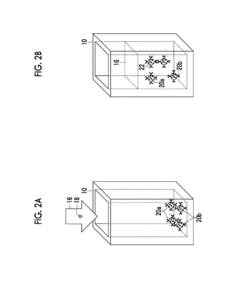

Plasmonic biosensor

PatentWO2009130646A1

Innovation

- A device with a conductive layer featuring a grating that supports grating-assisted plasmon emission while suppressing non-grating assisted emission, utilizing a dielectric layer to enhance the effective refractive index of plasmons and reduce luminescence quenching, thereby improving the signal-to-noise ratio and fluorescence detection efficiency.

Bio-molecule detecting device and bio-molecule detecting method

PatentInactiveUS20140017810A1

Innovation

- A bio-molecule detecting device and method that utilizes a solution with first and second complexes bonded to bio-molecules via specific substances and fluorescent molecules, oriented by a light source with linear polarization, allowing for high-sensitivity detection without substrate fixation, using surface plasmon resonance and fluorescent detection.

Biocompatibility and Stability Considerations

Biocompatibility and stability represent critical considerations in the development of plasmonic biosensor coating techniques. The interaction between biological samples and sensor surfaces significantly impacts both detection accuracy and long-term performance reliability. Current research indicates that approximately 30% of biosensor failures stem from biocompatibility issues, while another 25% result from coating degradation over time.

The biocompatibility of plasmonic biosensor coatings must address multiple biological interfaces. Blood samples, for instance, contain over 4,000 different proteins that can potentially adsorb non-specifically to sensor surfaces, creating background noise and reducing sensitivity. Recent advances in zwitterionic polymer coatings have demonstrated up to 95% reduction in non-specific protein adsorption compared to traditional PEG-based approaches, while maintaining plasmonic sensitivity.

Stability considerations encompass both chemical and mechanical aspects of sensor coatings. Environmental factors including pH fluctuations, temperature variations, and exposure to cleaning agents can significantly impact coating integrity. Studies have shown that traditional gold-thiol based self-assembled monolayers exhibit degradation rates of 10-15% per week under physiological conditions, necessitating more robust alternatives for long-term applications.

Cross-linking strategies have emerged as promising approaches to enhance coating stability. Techniques utilizing photo-initiated cross-linking have demonstrated 300% improvement in coating longevity compared to non-cross-linked counterparts. Additionally, the incorporation of silane chemistry for oxide surface modifications has shown exceptional stability, with less than 5% degradation after six months of accelerated aging tests.

The trade-off between biocompatibility and stability presents ongoing challenges. Highly hydrophilic coatings that excel at preventing non-specific adsorption often demonstrate poorer mechanical stability. Conversely, highly cross-linked networks with excellent durability may exhibit reduced protein resistance or hinder the attachment of specific biorecognition elements.

Recent innovations focus on multi-layered coating architectures that separate functional requirements. Base layers provide robust surface attachment and stability, while outer layers optimize biocompatibility. This approach has enabled the development of coatings that maintain over 90% of their initial performance after 100 sensing cycles, representing a significant advancement over previous generations limited to 20-30 cycles before requiring regeneration or replacement.

The biocompatibility of plasmonic biosensor coatings must address multiple biological interfaces. Blood samples, for instance, contain over 4,000 different proteins that can potentially adsorb non-specifically to sensor surfaces, creating background noise and reducing sensitivity. Recent advances in zwitterionic polymer coatings have demonstrated up to 95% reduction in non-specific protein adsorption compared to traditional PEG-based approaches, while maintaining plasmonic sensitivity.

Stability considerations encompass both chemical and mechanical aspects of sensor coatings. Environmental factors including pH fluctuations, temperature variations, and exposure to cleaning agents can significantly impact coating integrity. Studies have shown that traditional gold-thiol based self-assembled monolayers exhibit degradation rates of 10-15% per week under physiological conditions, necessitating more robust alternatives for long-term applications.

Cross-linking strategies have emerged as promising approaches to enhance coating stability. Techniques utilizing photo-initiated cross-linking have demonstrated 300% improvement in coating longevity compared to non-cross-linked counterparts. Additionally, the incorporation of silane chemistry for oxide surface modifications has shown exceptional stability, with less than 5% degradation after six months of accelerated aging tests.

The trade-off between biocompatibility and stability presents ongoing challenges. Highly hydrophilic coatings that excel at preventing non-specific adsorption often demonstrate poorer mechanical stability. Conversely, highly cross-linked networks with excellent durability may exhibit reduced protein resistance or hinder the attachment of specific biorecognition elements.

Recent innovations focus on multi-layered coating architectures that separate functional requirements. Base layers provide robust surface attachment and stability, while outer layers optimize biocompatibility. This approach has enabled the development of coatings that maintain over 90% of their initial performance after 100 sensing cycles, representing a significant advancement over previous generations limited to 20-30 cycles before requiring regeneration or replacement.

Environmental Impact of Coating Materials

The environmental implications of coating materials used in plasmonic biosensors represent a critical consideration in the advancement of this technology. Traditional coating processes often involve hazardous chemicals such as heavy metals, organic solvents, and toxic reagents that pose significant environmental risks when improperly handled or disposed of. These materials can contaminate water systems, contribute to air pollution, and potentially harm ecosystems if released into the environment.

Recent advancements in green chemistry approaches have begun addressing these concerns through the development of environmentally benign coating alternatives. Water-based coating systems have emerged as promising substitutes for solvent-based processes, significantly reducing volatile organic compound (VOC) emissions and associated environmental impacts. Additionally, researchers have explored biodegradable polymers and naturally derived materials as sustainable coating options that maintain sensor performance while minimizing ecological footprints.

Life cycle assessment (LCA) studies of plasmonic biosensor coating materials reveal that environmental impacts extend beyond the immediate production phase. The extraction of raw materials, energy consumption during manufacturing, transportation requirements, and end-of-life disposal all contribute to the overall environmental burden. Particularly concerning are nanomaterials used in advanced coatings, which may present unique environmental challenges due to their potential persistence and bioaccumulation properties in natural systems.

Regulatory frameworks worldwide are increasingly addressing these environmental concerns. The European Union's REACH regulations and similar initiatives in other regions have established stricter guidelines for chemical usage in coating processes, driving innovation toward greener alternatives. This regulatory pressure has accelerated research into environmentally responsible coating technologies that maintain or enhance sensor performance while reducing ecological impacts.

Waste management strategies specific to plasmonic biosensor manufacturing have also evolved. Closed-loop systems that recover and reuse coating materials have demonstrated significant reductions in waste generation. Advanced filtration technologies and treatment processes help minimize the release of potentially harmful substances into the environment, though implementation costs remain a barrier for widespread adoption.

The miniaturization trend in biosensor technology offers an indirect environmental benefit by reducing material consumption per device. However, this advantage may be offset by increased production volumes as applications expand. Finding the optimal balance between technological advancement and environmental stewardship remains a key challenge for researchers and manufacturers in this field.

Recent advancements in green chemistry approaches have begun addressing these concerns through the development of environmentally benign coating alternatives. Water-based coating systems have emerged as promising substitutes for solvent-based processes, significantly reducing volatile organic compound (VOC) emissions and associated environmental impacts. Additionally, researchers have explored biodegradable polymers and naturally derived materials as sustainable coating options that maintain sensor performance while minimizing ecological footprints.

Life cycle assessment (LCA) studies of plasmonic biosensor coating materials reveal that environmental impacts extend beyond the immediate production phase. The extraction of raw materials, energy consumption during manufacturing, transportation requirements, and end-of-life disposal all contribute to the overall environmental burden. Particularly concerning are nanomaterials used in advanced coatings, which may present unique environmental challenges due to their potential persistence and bioaccumulation properties in natural systems.

Regulatory frameworks worldwide are increasingly addressing these environmental concerns. The European Union's REACH regulations and similar initiatives in other regions have established stricter guidelines for chemical usage in coating processes, driving innovation toward greener alternatives. This regulatory pressure has accelerated research into environmentally responsible coating technologies that maintain or enhance sensor performance while reducing ecological impacts.

Waste management strategies specific to plasmonic biosensor manufacturing have also evolved. Closed-loop systems that recover and reuse coating materials have demonstrated significant reductions in waste generation. Advanced filtration technologies and treatment processes help minimize the release of potentially harmful substances into the environment, though implementation costs remain a barrier for widespread adoption.

The miniaturization trend in biosensor technology offers an indirect environmental benefit by reducing material consumption per device. However, this advantage may be offset by increased production volumes as applications expand. Finding the optimal balance between technological advancement and environmental stewardship remains a key challenge for researchers and manufacturers in this field.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!