Comparatively Measure Ultrafiltration and Membrane Distillation Performances

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ultrafiltration and Membrane Distillation Background and Objectives

Water scarcity has become a critical global challenge, driving the development of advanced water treatment technologies. Among these, membrane-based separation processes have emerged as efficient solutions for water purification and reuse. Ultrafiltration (UF) and Membrane Distillation (MD) represent two distinct yet complementary approaches that have evolved significantly over the past decades, each with unique historical trajectories and technological foundations.

Ultrafiltration technology dates back to the 1960s when asymmetric cellulose acetate membranes were first developed. The technology has since progressed through multiple generations, evolving from simple polymeric membranes to advanced composite structures with enhanced selectivity and flux characteristics. The primary driving force behind UF development has been the need for efficient removal of suspended solids, bacteria, and macromolecules from water sources without the high energy demands associated with reverse osmosis.

Membrane Distillation, by contrast, emerged in the 1980s as a thermal-driven separation process combining the principles of thermal distillation with membrane technology. MD development has been motivated by its potential to treat highly concentrated solutions and utilize low-grade heat sources, making it particularly attractive for specialized applications where conventional technologies face limitations.

The technological evolution of both UF and MD has accelerated in recent years due to advancements in material science, process engineering, and computational modeling. Novel membrane materials including nanocomposites, biomimetic structures, and stimuli-responsive polymers have expanded the performance envelope of these technologies, while improved module designs have enhanced operational efficiency and reduced fouling tendencies.

The primary objective of this technical research is to establish a comprehensive comparative framework for measuring and evaluating the performance of Ultrafiltration and Membrane Distillation technologies across diverse applications and operational conditions. This comparison aims to identify the specific advantages, limitations, and optimal application scenarios for each technology, thereby informing strategic technology selection decisions.

Secondary objectives include: quantifying the energy efficiency profiles of both technologies under standardized conditions; evaluating membrane fouling mechanisms and mitigation strategies; assessing long-term operational stability and maintenance requirements; and exploring hybrid system configurations that leverage the complementary strengths of both technologies.

The technological trajectory suggests continued innovation in both fields, with UF evolving toward higher selectivity and lower energy consumption, while MD development focuses on thermal efficiency improvements and specialized applications where conventional technologies face limitations. Understanding the comparative performance metrics of these technologies is essential for predicting future development pathways and identifying promising research directions.

Ultrafiltration technology dates back to the 1960s when asymmetric cellulose acetate membranes were first developed. The technology has since progressed through multiple generations, evolving from simple polymeric membranes to advanced composite structures with enhanced selectivity and flux characteristics. The primary driving force behind UF development has been the need for efficient removal of suspended solids, bacteria, and macromolecules from water sources without the high energy demands associated with reverse osmosis.

Membrane Distillation, by contrast, emerged in the 1980s as a thermal-driven separation process combining the principles of thermal distillation with membrane technology. MD development has been motivated by its potential to treat highly concentrated solutions and utilize low-grade heat sources, making it particularly attractive for specialized applications where conventional technologies face limitations.

The technological evolution of both UF and MD has accelerated in recent years due to advancements in material science, process engineering, and computational modeling. Novel membrane materials including nanocomposites, biomimetic structures, and stimuli-responsive polymers have expanded the performance envelope of these technologies, while improved module designs have enhanced operational efficiency and reduced fouling tendencies.

The primary objective of this technical research is to establish a comprehensive comparative framework for measuring and evaluating the performance of Ultrafiltration and Membrane Distillation technologies across diverse applications and operational conditions. This comparison aims to identify the specific advantages, limitations, and optimal application scenarios for each technology, thereby informing strategic technology selection decisions.

Secondary objectives include: quantifying the energy efficiency profiles of both technologies under standardized conditions; evaluating membrane fouling mechanisms and mitigation strategies; assessing long-term operational stability and maintenance requirements; and exploring hybrid system configurations that leverage the complementary strengths of both technologies.

The technological trajectory suggests continued innovation in both fields, with UF evolving toward higher selectivity and lower energy consumption, while MD development focuses on thermal efficiency improvements and specialized applications where conventional technologies face limitations. Understanding the comparative performance metrics of these technologies is essential for predicting future development pathways and identifying promising research directions.

Market Analysis for Advanced Membrane Separation Technologies

The global market for advanced membrane separation technologies has witnessed substantial growth in recent years, driven by increasing water scarcity, stringent environmental regulations, and growing industrial demand for efficient separation processes. The membrane separation market was valued at approximately $5.4 billion in 2020 and is projected to reach $8.3 billion by 2026, growing at a CAGR of 7.2% during the forecast period.

Ultrafiltration (UF) technology holds a significant market share, accounting for about 28% of the total membrane separation market. Its applications span across water treatment, food and beverage processing, biotechnology, and pharmaceutical industries. The UF market segment is expected to grow at 8.1% annually through 2026, fueled by increasing adoption in municipal water treatment and industrial process water recycling.

Membrane Distillation (MD), while currently occupying a smaller market share (approximately 12%), is experiencing the fastest growth rate among membrane technologies at 9.5% annually. This growth is primarily attributed to its unique ability to operate with low-grade thermal energy and handle high-salinity feeds, making it particularly valuable for desalination applications and industrial wastewater treatment where conventional methods struggle.

Regional analysis reveals that North America and Europe currently dominate the advanced membrane market, collectively accounting for 58% of global revenue. However, the Asia-Pacific region is emerging as the fastest-growing market with a projected CAGR of 9.8% through 2026, driven by rapid industrialization, urbanization, and increasing water stress in countries like China, India, and Southeast Asian nations.

End-user segmentation shows that municipal water treatment remains the largest application sector (36% market share), followed by industrial processes (29%), food and beverage (18%), and pharmaceutical applications (12%). The remaining 5% is distributed across various niche applications including electronics manufacturing and laboratory research.

Key market drivers include increasing water reuse initiatives, growing demand for high-purity water in various industries, and the shift toward sustainable manufacturing processes. Additionally, the integration of membrane technologies with renewable energy sources is creating new market opportunities, particularly for energy-intensive processes like membrane distillation.

Market challenges include high initial capital costs, membrane fouling issues that affect performance longevity, and competition from conventional separation technologies. The comparative performance metrics between UF and MD technologies are becoming increasingly important as end-users seek optimal solutions for specific separation challenges, balancing factors such as energy consumption, separation efficiency, and operational costs.

Ultrafiltration (UF) technology holds a significant market share, accounting for about 28% of the total membrane separation market. Its applications span across water treatment, food and beverage processing, biotechnology, and pharmaceutical industries. The UF market segment is expected to grow at 8.1% annually through 2026, fueled by increasing adoption in municipal water treatment and industrial process water recycling.

Membrane Distillation (MD), while currently occupying a smaller market share (approximately 12%), is experiencing the fastest growth rate among membrane technologies at 9.5% annually. This growth is primarily attributed to its unique ability to operate with low-grade thermal energy and handle high-salinity feeds, making it particularly valuable for desalination applications and industrial wastewater treatment where conventional methods struggle.

Regional analysis reveals that North America and Europe currently dominate the advanced membrane market, collectively accounting for 58% of global revenue. However, the Asia-Pacific region is emerging as the fastest-growing market with a projected CAGR of 9.8% through 2026, driven by rapid industrialization, urbanization, and increasing water stress in countries like China, India, and Southeast Asian nations.

End-user segmentation shows that municipal water treatment remains the largest application sector (36% market share), followed by industrial processes (29%), food and beverage (18%), and pharmaceutical applications (12%). The remaining 5% is distributed across various niche applications including electronics manufacturing and laboratory research.

Key market drivers include increasing water reuse initiatives, growing demand for high-purity water in various industries, and the shift toward sustainable manufacturing processes. Additionally, the integration of membrane technologies with renewable energy sources is creating new market opportunities, particularly for energy-intensive processes like membrane distillation.

Market challenges include high initial capital costs, membrane fouling issues that affect performance longevity, and competition from conventional separation technologies. The comparative performance metrics between UF and MD technologies are becoming increasingly important as end-users seek optimal solutions for specific separation challenges, balancing factors such as energy consumption, separation efficiency, and operational costs.

Current Technical Challenges in Membrane Performance Evaluation

The evaluation of membrane performance faces significant challenges that hinder accurate comparison between different membrane technologies such as ultrafiltration (UF) and membrane distillation (MD). One primary challenge is the lack of standardized testing protocols across the membrane industry. Different manufacturers employ varying testing conditions, making direct performance comparisons problematic and often misleading for end-users seeking optimal solutions.

Membrane fouling represents another critical challenge in performance evaluation. The progressive accumulation of particles, colloids, and biological matter on membrane surfaces alters performance characteristics over time. Current evaluation methods often fail to adequately simulate long-term fouling scenarios, leading to discrepancies between laboratory test results and real-world operational performance.

The complex interplay between operating parameters further complicates performance assessment. Factors such as transmembrane pressure, cross-flow velocity, temperature, and feed composition significantly influence membrane performance. The multivariable nature of these parameters makes it difficult to establish consistent baseline conditions for comparative analysis between UF and MD technologies.

Temperature polarization effects present unique challenges specifically for membrane distillation performance evaluation. The temperature gradient across the membrane creates boundary layers that reduce effective driving force. Current measurement techniques struggle to accurately quantify this phenomenon, leading to overestimation of MD performance in laboratory settings compared to field applications.

Scaling and concentration polarization phenomena similarly affect ultrafiltration performance evaluation. As filtration progresses, rejected solutes accumulate near the membrane surface, creating concentration gradients that reduce effective separation capability. Existing evaluation methods often fail to account for these dynamic changes during extended operation periods.

The diversity of potential feed streams presents another significant challenge. Laboratory evaluations typically use model solutions with well-defined compositions, whereas real-world applications involve complex, variable mixtures. This discrepancy limits the transferability of performance data from controlled testing to practical implementation scenarios.

Energy efficiency metrics remain inconsistently applied across different membrane technologies. While UF processes are primarily evaluated based on permeate flux and rejection rates, MD performance assessment must additionally consider thermal efficiency and energy consumption. This fundamental difference complicates direct technology comparison and often leads to incomplete performance evaluation.

Membrane fouling represents another critical challenge in performance evaluation. The progressive accumulation of particles, colloids, and biological matter on membrane surfaces alters performance characteristics over time. Current evaluation methods often fail to adequately simulate long-term fouling scenarios, leading to discrepancies between laboratory test results and real-world operational performance.

The complex interplay between operating parameters further complicates performance assessment. Factors such as transmembrane pressure, cross-flow velocity, temperature, and feed composition significantly influence membrane performance. The multivariable nature of these parameters makes it difficult to establish consistent baseline conditions for comparative analysis between UF and MD technologies.

Temperature polarization effects present unique challenges specifically for membrane distillation performance evaluation. The temperature gradient across the membrane creates boundary layers that reduce effective driving force. Current measurement techniques struggle to accurately quantify this phenomenon, leading to overestimation of MD performance in laboratory settings compared to field applications.

Scaling and concentration polarization phenomena similarly affect ultrafiltration performance evaluation. As filtration progresses, rejected solutes accumulate near the membrane surface, creating concentration gradients that reduce effective separation capability. Existing evaluation methods often fail to account for these dynamic changes during extended operation periods.

The diversity of potential feed streams presents another significant challenge. Laboratory evaluations typically use model solutions with well-defined compositions, whereas real-world applications involve complex, variable mixtures. This discrepancy limits the transferability of performance data from controlled testing to practical implementation scenarios.

Energy efficiency metrics remain inconsistently applied across different membrane technologies. While UF processes are primarily evaluated based on permeate flux and rejection rates, MD performance assessment must additionally consider thermal efficiency and energy consumption. This fundamental difference complicates direct technology comparison and often leads to incomplete performance evaluation.

Methodologies for Comparative Performance Assessment

01 Membrane material selection and modification

The selection and modification of membrane materials significantly impact ultrafiltration and membrane distillation performance. Advanced materials such as composite membranes, hydrophobic polymers, and surface-modified membranes can enhance separation efficiency, reduce fouling, and improve flux rates. Modifications may include incorporating nanoparticles, applying hydrophobic coatings, or creating hierarchical structures to optimize pore size distribution and surface properties for specific applications.- Membrane material innovations for enhanced performance: Advanced membrane materials significantly improve ultrafiltration and membrane distillation performance. Novel composite membranes with specialized coatings or modified surface properties demonstrate superior flux rates, fouling resistance, and separation efficiency. These innovations include hydrophobic/hydrophilic modifications, nanoparticle incorporation, and polymer blends that optimize pore size distribution and mechanical strength while maintaining thermal stability under operational conditions.

- Fouling mitigation strategies in membrane processes: Various techniques have been developed to address membrane fouling, which is a critical factor affecting ultrafiltration and membrane distillation performance. These include pretreatment methods, hydrodynamic modifications, periodic backwashing protocols, and chemical cleaning regimes. Advanced anti-fouling strategies incorporate air scouring, vibration-assisted systems, and specialized feed spacer designs that create turbulence to minimize concentration polarization and scaling on membrane surfaces.

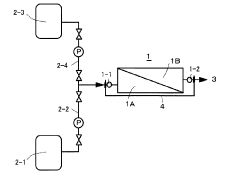

- Process optimization and operational parameters: Optimizing operational parameters significantly impacts the efficiency of ultrafiltration and membrane distillation systems. Key parameters include transmembrane pressure, cross-flow velocity, temperature gradient, feed concentration, and recovery ratio. Research demonstrates that precise control of these variables can maximize permeate flux while minimizing energy consumption. Advanced process configurations such as multi-stage operations and hybrid systems further enhance performance by optimizing mass and heat transfer across membranes.

- Energy efficiency improvements in membrane systems: Energy consumption is a critical factor in membrane-based separation processes. Innovations focus on reducing the energy footprint through heat recovery systems, renewable energy integration, and optimized module designs. Novel approaches include utilizing waste heat sources, implementing pressure recovery devices, and developing low-temperature membrane distillation configurations. These advancements significantly improve the economic viability and sustainability of ultrafiltration and membrane distillation technologies for various applications.

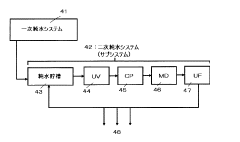

- Novel system configurations and hybrid processes: Innovative system configurations and hybrid processes combine ultrafiltration and membrane distillation with other separation technologies to achieve superior performance. These include integrated membrane bioreactors, forward osmosis-membrane distillation systems, and ultrafiltration-nanofiltration cascades. Such hybrid approaches leverage the complementary strengths of different separation mechanisms to overcome individual process limitations, resulting in enhanced contaminant removal, improved water recovery rates, and extended membrane lifespans.

02 Fouling prevention and membrane cleaning strategies

Fouling is a major challenge affecting membrane performance in both ultrafiltration and membrane distillation processes. Various strategies have been developed to prevent or mitigate fouling, including pretreatment of feed solutions, optimization of operating conditions, and implementation of periodic cleaning protocols. Advanced anti-fouling approaches involve surface modifications, air scouring, backwashing techniques, and the use of chemical cleaning agents to restore membrane performance and extend operational lifetime.Expand Specific Solutions03 Process optimization and operating parameters

The performance of ultrafiltration and membrane distillation systems is highly dependent on operating parameters such as temperature, pressure, flow rate, and concentration gradients. Optimization of these parameters can significantly enhance separation efficiency, permeate flux, and energy consumption. Advanced process control strategies, including feed pretreatment, temperature polarization mitigation, and module configuration improvements, can be implemented to achieve optimal performance under various operating conditions.Expand Specific Solutions04 Hybrid and integrated membrane systems

Combining ultrafiltration with membrane distillation or other separation technologies in hybrid or integrated systems can overcome limitations of individual processes and achieve enhanced overall performance. These integrated approaches can improve water recovery rates, reduce energy consumption, and enable treatment of complex feed streams. Examples include ultrafiltration as pretreatment for membrane distillation, or coupling with other technologies such as reverse osmosis, nanofiltration, or electrochemical processes for specialized applications.Expand Specific Solutions05 Energy efficiency and sustainable operation

Improving energy efficiency is crucial for the economic viability and sustainability of ultrafiltration and membrane distillation processes. Innovations in this area include waste heat utilization, solar-powered systems, energy recovery devices, and optimized module designs. Sustainable operation also involves minimizing chemical usage, reducing waste generation, and implementing renewable energy sources to power membrane systems, thereby decreasing the environmental footprint while maintaining high separation performance.Expand Specific Solutions

Leading Companies and Research Institutions in Membrane Technology

The ultrafiltration and membrane distillation technology market is currently in a growth phase, with increasing adoption across water treatment, pharmaceutical, and chemical processing industries. The global market size is estimated to exceed $5 billion, driven by water scarcity concerns and stringent environmental regulations. Technologically, membrane distillation remains less mature than ultrafiltration, with companies at different development stages. Industry leaders like EMD Millipore, Fresenius Medical Care, and Sartorius Stedim Biotech have established robust ultrafiltration portfolios, while WILO SE, Doosan Enerbility, and Saudi Aramco are advancing membrane distillation technologies. Academic institutions including NJIT, Cranfield University, and King Fahd University collaborate with industry players to bridge performance gaps between these complementary technologies, focusing on energy efficiency and membrane fouling reduction.

EMD Millipore Corp.

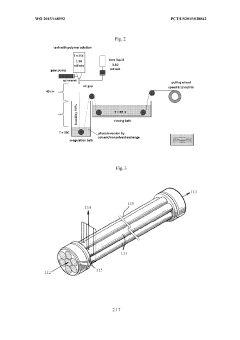

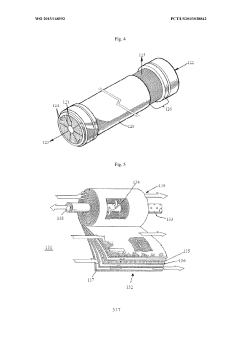

Technical Solution: EMD Millipore has developed comprehensive ultrafiltration (UF) and membrane distillation (MD) technologies for water purification and bioprocessing applications. Their UF systems utilize hollow fiber membranes with molecular weight cut-offs ranging from 1-100 kDa, achieving >99% removal of bacteria, viruses, and macromolecules. Their comparative measurement approach involves standardized testing protocols that evaluate flux rates (typically 50-150 LMH for UF), fouling resistance, and separation efficiency across different pressure conditions (1-5 bar for UF). For membrane distillation, they employ hydrophobic PTFE and PVDF membranes with pore sizes of 0.1-0.5 μm, operating at temperature differences of 10-40°C between feed and permeate sides. Their proprietary performance metrics include temperature polarization coefficients and long-term stability measurements under various feed compositions.

Strengths: Industry-leading membrane manufacturing capabilities with precise pore size control; extensive validation data across pharmaceutical and bioprocessing applications; integrated sensing and monitoring systems for real-time performance tracking. Weaknesses: Higher capital costs compared to conventional filtration; specialized maintenance requirements; membrane fouling in complex feed streams can reduce operational efficiency over time.

Gambro Lundia AB

Technical Solution: Gambro Lundia has pioneered comparative measurement methodologies for ultrafiltration and membrane distillation specifically for medical applications, particularly hemodialysis. Their approach centers on quantitative assessment of solute removal efficiency, with specialized focus on middle-molecule clearance (molecules between 500-60,000 Da) which is critical in dialysis applications. Their UF membranes achieve ultrafiltration coefficients of 20-40 mL/h/mmHg/m² while maintaining protein retention rates above 95%. For comparative analysis, they've developed standardized testing protocols that measure performance under identical operating conditions, including transmembrane pressure (typically 100-250 mmHg), temperature (37°C for medical applications), and cross-flow velocity (0.5-2 m/s). Their proprietary "Filtration Efficiency Index" combines multiple parameters including hydraulic permeability, selectivity, and fouling resistance to enable direct comparison between different membrane technologies.

Strengths: Exceptional biocompatibility of membranes; highly specialized for medical applications with validated clinical outcomes; advanced quality control systems ensuring consistent performance. Weaknesses: Limited application outside medical field; higher production costs due to medical-grade requirements; narrower operating parameter range compared to industrial filtration systems.

Critical Parameters and Metrics for Membrane Efficiency Evaluation

Asymmetric poly(phenylene ether) co-polymer membrane, separation module thereof; and methods of making

PatentWO2015168592A1

Innovation

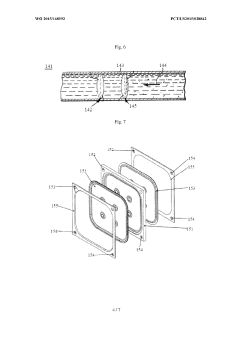

- A porous membrane made from a specific class of asymmetric poly(phenylene ether) copolymers with controlled molecular weight and surface pore size, fabricated without hydrophilic or amphiphilic polymers, using a method involving dissolution in a water-miscible polar aprotic solvent and phase inversion, which enhances selectivity and resistance to fouling.

Preparation method of ultrafiltration membrane, water treatment method, and ultrafiltration membrane device

PatentActiveJP2018202419A

Innovation

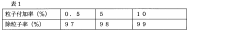

- A method involving the addition of microparticles, such as gold particles, polystyrene latex, or silica particles, to the ultrafiltration membrane surface to block large pores and improve particle removal performance.

Environmental Impact and Sustainability Considerations

The environmental footprint of water treatment technologies has become increasingly critical in the face of global water scarcity and climate change concerns. When comparing ultrafiltration (UF) and membrane distillation (MD) performances, environmental impact and sustainability considerations must be thoroughly evaluated to ensure responsible implementation.

Energy consumption represents a significant differentiating factor between these technologies. Ultrafiltration typically operates at lower energy requirements, utilizing pressure-driven mechanisms that consume approximately 0.2-0.5 kWh/m³ of treated water. In contrast, membrane distillation demands higher thermal energy inputs, often ranging from 50-80 kWh/m³, primarily due to the heating requirements to maintain vapor pressure differentials across membranes.

Chemical usage patterns also diverge substantially between these technologies. UF systems frequently require periodic chemical cleaning with agents such as sodium hypochlorite and citric acid to control membrane fouling. MD systems generally demonstrate lower chemical dependency for maintenance, potentially reducing harmful discharges to receiving water bodies. This difference translates to varying ecological footprints in operational phases.

Membrane lifespan and replacement frequency significantly impact waste generation and resource consumption. UF membranes typically require replacement every 3-7 years depending on operating conditions, while MD membranes may last 2-5 years before performance degradation necessitates replacement. The manufacturing and disposal of these membranes involve considerable environmental costs that must be factored into lifecycle assessments.

Carbon footprint calculations reveal that the greenhouse gas emissions associated with MD can be 2-4 times higher than UF when powered by conventional energy sources. However, this gap narrows significantly when renewable energy sources are integrated, particularly for MD systems that can effectively utilize low-grade waste heat from industrial processes.

Water recovery rates present another crucial sustainability metric. UF systems typically achieve 85-95% recovery rates, while MD can reach 90-98% recovery, particularly in high-salinity applications. Higher recovery translates to reduced brine discharge, mitigating potential ecological damage to aquatic ecosystems from concentrated waste streams.

The integration potential with renewable energy sources differs markedly between technologies. MD shows promising compatibility with solar thermal systems and industrial waste heat recovery, potentially offsetting its higher energy demands. UF systems, while less energy-intensive, offer fewer opportunities for renewable energy integration due to their mechanical rather than thermal energy requirements.

Energy consumption represents a significant differentiating factor between these technologies. Ultrafiltration typically operates at lower energy requirements, utilizing pressure-driven mechanisms that consume approximately 0.2-0.5 kWh/m³ of treated water. In contrast, membrane distillation demands higher thermal energy inputs, often ranging from 50-80 kWh/m³, primarily due to the heating requirements to maintain vapor pressure differentials across membranes.

Chemical usage patterns also diverge substantially between these technologies. UF systems frequently require periodic chemical cleaning with agents such as sodium hypochlorite and citric acid to control membrane fouling. MD systems generally demonstrate lower chemical dependency for maintenance, potentially reducing harmful discharges to receiving water bodies. This difference translates to varying ecological footprints in operational phases.

Membrane lifespan and replacement frequency significantly impact waste generation and resource consumption. UF membranes typically require replacement every 3-7 years depending on operating conditions, while MD membranes may last 2-5 years before performance degradation necessitates replacement. The manufacturing and disposal of these membranes involve considerable environmental costs that must be factored into lifecycle assessments.

Carbon footprint calculations reveal that the greenhouse gas emissions associated with MD can be 2-4 times higher than UF when powered by conventional energy sources. However, this gap narrows significantly when renewable energy sources are integrated, particularly for MD systems that can effectively utilize low-grade waste heat from industrial processes.

Water recovery rates present another crucial sustainability metric. UF systems typically achieve 85-95% recovery rates, while MD can reach 90-98% recovery, particularly in high-salinity applications. Higher recovery translates to reduced brine discharge, mitigating potential ecological damage to aquatic ecosystems from concentrated waste streams.

The integration potential with renewable energy sources differs markedly between technologies. MD shows promising compatibility with solar thermal systems and industrial waste heat recovery, potentially offsetting its higher energy demands. UF systems, while less energy-intensive, offer fewer opportunities for renewable energy integration due to their mechanical rather than thermal energy requirements.

Standardization and Quality Control Protocols

Standardization and quality control protocols are essential for accurate comparative assessment of ultrafiltration (UF) and membrane distillation (MD) technologies. Establishing robust protocols ensures reproducibility of results across different research facilities and enables meaningful technology benchmarking. The development of standardized testing methods must address the inherent differences between these two separation processes while maintaining scientific rigor.

For ultrafiltration performance evaluation, standardized protocols should include precise specifications for transmembrane pressure (TMP) measurement, typically ranging from 1-10 bar depending on application. Feed characterization must follow established methods such as particle size distribution analysis (ISO 13320) and total organic carbon measurement (ISO 8245). Flux measurements should be conducted under controlled temperature conditions (±0.5°C) with standardized membrane preconditioning procedures to eliminate manufacturing variability effects.

Membrane distillation quality control requires different parameters, focusing on temperature gradient maintenance across the membrane (typically 10-40°C difference) and vapor pressure monitoring. Standardized protocols should specify conductivity measurement methods for permeate quality assessment, with recommended instrumentation precision of ±0.1 μS/cm. Membrane hydrophobicity testing via contact angle measurement must follow ASTM D7334 standards to ensure consistent evaluation of membrane integrity.

Cross-technology comparison necessitates the development of normalized performance metrics. The water flux normalization approach should account for the different driving forces (pressure in UF versus temperature gradient in MD) through dimensionless parameters. Rejection/retention efficiency calculations must be standardized with certified reference materials for specific contaminants, enabling direct performance comparison despite different separation mechanisms.

Quality assurance procedures should include regular calibration of sensors (pressure transducers, thermocouples, conductivity meters) according to ISO/IEC 17025 guidelines. Statistical analysis methods must be standardized for performance data, incorporating uncertainty analysis following GUM (Guide to the Expression of Uncertainty in Measurement) principles. Minimum testing duration and sampling frequency should be established based on membrane type and application to ensure statistical significance.

Documentation requirements constitute another critical aspect of standardization. Comprehensive reporting templates should include membrane specifications (material, pore size, surface characteristics), operating conditions, feed composition, and performance metrics. This documentation enables technology comparison across different studies and facilitates meta-analysis for technology advancement assessment.

For ultrafiltration performance evaluation, standardized protocols should include precise specifications for transmembrane pressure (TMP) measurement, typically ranging from 1-10 bar depending on application. Feed characterization must follow established methods such as particle size distribution analysis (ISO 13320) and total organic carbon measurement (ISO 8245). Flux measurements should be conducted under controlled temperature conditions (±0.5°C) with standardized membrane preconditioning procedures to eliminate manufacturing variability effects.

Membrane distillation quality control requires different parameters, focusing on temperature gradient maintenance across the membrane (typically 10-40°C difference) and vapor pressure monitoring. Standardized protocols should specify conductivity measurement methods for permeate quality assessment, with recommended instrumentation precision of ±0.1 μS/cm. Membrane hydrophobicity testing via contact angle measurement must follow ASTM D7334 standards to ensure consistent evaluation of membrane integrity.

Cross-technology comparison necessitates the development of normalized performance metrics. The water flux normalization approach should account for the different driving forces (pressure in UF versus temperature gradient in MD) through dimensionless parameters. Rejection/retention efficiency calculations must be standardized with certified reference materials for specific contaminants, enabling direct performance comparison despite different separation mechanisms.

Quality assurance procedures should include regular calibration of sensors (pressure transducers, thermocouples, conductivity meters) according to ISO/IEC 17025 guidelines. Statistical analysis methods must be standardized for performance data, incorporating uncertainty analysis following GUM (Guide to the Expression of Uncertainty in Measurement) principles. Minimum testing duration and sampling frequency should be established based on membrane type and application to ensure statistical significance.

Documentation requirements constitute another critical aspect of standardization. Comprehensive reporting templates should include membrane specifications (material, pore size, surface characteristics), operating conditions, feed composition, and performance metrics. This documentation enables technology comparison across different studies and facilitates meta-analysis for technology advancement assessment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!