Comparing FTIR and UV-Vis for Chemical Analysis

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

FTIR and UV-Vis Spectroscopy Background and Objectives

Fourier Transform Infrared (FTIR) and Ultraviolet-Visible (UV-Vis) spectroscopy represent two cornerstone analytical techniques in modern chemical analysis, each with distinct historical development trajectories. FTIR spectroscopy evolved from traditional infrared spectroscopy in the mid-20th century, with significant advancements occurring in the 1960s through the application of Fourier transform mathematics to infrared analysis. This innovation dramatically improved signal-to-noise ratios and data acquisition speeds, revolutionizing molecular structure determination capabilities.

UV-Vis spectroscopy, conversely, traces its origins to the early 20th century, with fundamental principles established by Beer and Lambert. The technique experienced substantial refinement during the 1940s-1950s with the development of photoelectric detectors and double-beam instruments, enabling more precise quantitative analysis of compounds that absorb light in the ultraviolet and visible regions.

The technological evolution of both techniques has accelerated in recent decades, with miniaturization, automation, and integration with computational systems significantly expanding their applications across diverse scientific and industrial domains. Modern FTIR systems feature enhanced resolution, broader spectral ranges, and advanced sampling accessories, while UV-Vis instruments have evolved to incorporate diode array detectors and fiber optic probes for remote sensing capabilities.

Current research trends indicate continued convergence of these technologies with other analytical methods, particularly through hyphenated techniques that combine spectroscopic analysis with separation methods. Additionally, portable and field-deployable versions of both instruments represent a significant direction in technological development, responding to growing demands for on-site and real-time analysis capabilities.

The primary objective of comparing FTIR and UV-Vis spectroscopy is to establish a comprehensive understanding of their respective strengths, limitations, and complementary aspects for chemical analysis applications. This comparison aims to optimize analytical strategy selection based on specific requirements including sensitivity, selectivity, sample preparation needs, and data interpretation complexity.

Furthermore, this technical assessment seeks to identify emerging applications where the combined or sequential use of both techniques may yield superior analytical outcomes compared to either method alone. The evaluation will consider factors such as detection limits, structural information depth, quantification accuracy, and operational efficiency across various sample types and analytical contexts.

The ultimate goal is to develop a strategic framework for analytical method selection that maximizes information yield while minimizing resource expenditure, thereby enhancing overall analytical efficiency in both research and industrial settings. This framework will incorporate considerations of recent technological advancements and anticipated future developments in both spectroscopic platforms.

UV-Vis spectroscopy, conversely, traces its origins to the early 20th century, with fundamental principles established by Beer and Lambert. The technique experienced substantial refinement during the 1940s-1950s with the development of photoelectric detectors and double-beam instruments, enabling more precise quantitative analysis of compounds that absorb light in the ultraviolet and visible regions.

The technological evolution of both techniques has accelerated in recent decades, with miniaturization, automation, and integration with computational systems significantly expanding their applications across diverse scientific and industrial domains. Modern FTIR systems feature enhanced resolution, broader spectral ranges, and advanced sampling accessories, while UV-Vis instruments have evolved to incorporate diode array detectors and fiber optic probes for remote sensing capabilities.

Current research trends indicate continued convergence of these technologies with other analytical methods, particularly through hyphenated techniques that combine spectroscopic analysis with separation methods. Additionally, portable and field-deployable versions of both instruments represent a significant direction in technological development, responding to growing demands for on-site and real-time analysis capabilities.

The primary objective of comparing FTIR and UV-Vis spectroscopy is to establish a comprehensive understanding of their respective strengths, limitations, and complementary aspects for chemical analysis applications. This comparison aims to optimize analytical strategy selection based on specific requirements including sensitivity, selectivity, sample preparation needs, and data interpretation complexity.

Furthermore, this technical assessment seeks to identify emerging applications where the combined or sequential use of both techniques may yield superior analytical outcomes compared to either method alone. The evaluation will consider factors such as detection limits, structural information depth, quantification accuracy, and operational efficiency across various sample types and analytical contexts.

The ultimate goal is to develop a strategic framework for analytical method selection that maximizes information yield while minimizing resource expenditure, thereby enhancing overall analytical efficiency in both research and industrial settings. This framework will incorporate considerations of recent technological advancements and anticipated future developments in both spectroscopic platforms.

Market Applications and Demand Analysis for Spectroscopic Techniques

The global spectroscopy market has witnessed substantial growth in recent years, driven by increasing applications across pharmaceutical, chemical, food, and environmental sectors. The market for spectroscopic techniques, particularly FTIR and UV-Vis, was valued at approximately 14.2 billion USD in 2022 and is projected to reach 20.5 billion USD by 2027, representing a compound annual growth rate of 7.6%.

Pharmaceutical and biotechnology industries constitute the largest market segment for spectroscopic techniques, accounting for nearly 35% of the total market share. These industries utilize FTIR and UV-Vis extensively for drug discovery, formulation development, and quality control processes. The stringent regulatory requirements for pharmaceutical products have further accelerated the adoption of advanced analytical techniques.

The chemical industry represents the second-largest market segment, where spectroscopic techniques are employed for raw material testing, process monitoring, and final product quality assurance. Environmental monitoring applications have shown the fastest growth rate at 9.2% annually, driven by increasing regulatory pressure and public awareness regarding pollution control and water quality management.

Regional analysis reveals that North America dominates the spectroscopy market with approximately 40% share, followed by Europe at 30% and Asia-Pacific at 25%. However, the Asia-Pacific region is experiencing the highest growth rate due to rapid industrialization, increasing R&D investments, and growing awareness about quality control in emerging economies like China and India.

The demand for portable and handheld spectroscopic devices has surged significantly, with market growth exceeding 12% annually. This trend reflects the increasing need for on-site analysis in various applications including environmental monitoring, food safety testing, and pharmaceutical counterfeit detection. FTIR has gained particular traction in this segment due to its versatility and reliability in field conditions.

Cloud-connected spectroscopic systems represent an emerging market trend, with integration capabilities allowing real-time data analysis and remote monitoring. This development aligns with Industry 4.0 initiatives and has created new market opportunities, particularly in manufacturing quality control and process optimization applications.

Customer demand analysis indicates a growing preference for multi-functional analytical instruments that combine different spectroscopic techniques. This trend is particularly evident in research institutions and analytical service providers seeking to maximize analytical capabilities while optimizing capital investment. The total cost of ownership has become a critical factor in purchasing decisions, with customers increasingly evaluating long-term operational costs alongside initial acquisition expenses.

Pharmaceutical and biotechnology industries constitute the largest market segment for spectroscopic techniques, accounting for nearly 35% of the total market share. These industries utilize FTIR and UV-Vis extensively for drug discovery, formulation development, and quality control processes. The stringent regulatory requirements for pharmaceutical products have further accelerated the adoption of advanced analytical techniques.

The chemical industry represents the second-largest market segment, where spectroscopic techniques are employed for raw material testing, process monitoring, and final product quality assurance. Environmental monitoring applications have shown the fastest growth rate at 9.2% annually, driven by increasing regulatory pressure and public awareness regarding pollution control and water quality management.

Regional analysis reveals that North America dominates the spectroscopy market with approximately 40% share, followed by Europe at 30% and Asia-Pacific at 25%. However, the Asia-Pacific region is experiencing the highest growth rate due to rapid industrialization, increasing R&D investments, and growing awareness about quality control in emerging economies like China and India.

The demand for portable and handheld spectroscopic devices has surged significantly, with market growth exceeding 12% annually. This trend reflects the increasing need for on-site analysis in various applications including environmental monitoring, food safety testing, and pharmaceutical counterfeit detection. FTIR has gained particular traction in this segment due to its versatility and reliability in field conditions.

Cloud-connected spectroscopic systems represent an emerging market trend, with integration capabilities allowing real-time data analysis and remote monitoring. This development aligns with Industry 4.0 initiatives and has created new market opportunities, particularly in manufacturing quality control and process optimization applications.

Customer demand analysis indicates a growing preference for multi-functional analytical instruments that combine different spectroscopic techniques. This trend is particularly evident in research institutions and analytical service providers seeking to maximize analytical capabilities while optimizing capital investment. The total cost of ownership has become a critical factor in purchasing decisions, with customers increasingly evaluating long-term operational costs alongside initial acquisition expenses.

Current Technological Status and Challenges in Spectroscopic Analysis

Spectroscopic analysis techniques have evolved significantly over the past decades, with Fourier Transform Infrared (FTIR) and Ultraviolet-Visible (UV-Vis) spectroscopy emerging as two predominant methodologies in chemical analysis. Currently, FTIR technology has reached a high level of sophistication, with modern instruments offering resolution capabilities down to 0.1 cm^-1 and scan speeds of less than one second per scan. The integration of advanced computational algorithms has further enhanced data processing capabilities, allowing for more accurate spectral interpretation.

UV-Vis spectroscopy has similarly progressed, with current systems capable of measuring across wavelengths from 190 to 1100 nm with precision of ±0.1 nm. The development of diode array detectors has significantly improved acquisition speeds, enabling real-time monitoring of fast chemical reactions and processes.

Despite these advancements, both technologies face substantial challenges. FTIR spectroscopy struggles with water interference, as water's strong absorption bands can mask important spectral features in aqueous samples. This limitation is particularly problematic for biological and environmental analyses. Additionally, the complexity of spectral interpretation remains a significant hurdle, often requiring extensive reference libraries and expert knowledge.

UV-Vis spectroscopy, while simpler to operate, suffers from lower specificity compared to FTIR. The broad absorption bands characteristic of UV-Vis spectra make it difficult to distinguish between similar compounds in complex mixtures. Furthermore, the technique is limited to compounds with chromophores or conjugated systems, restricting its applicability across the full spectrum of chemical analysis needs.

The geographical distribution of technological development shows concentration in North America, Europe, and East Asia, with companies like Thermo Fisher Scientific, Bruker, and Shimadzu leading innovation. Recent trends indicate growing interest in miniaturization and portability of both technologies, with handheld and field-deployable instruments gaining market share, though these compact versions still face sensitivity and resolution limitations.

A significant current challenge is the integration of artificial intelligence and machine learning algorithms for automated spectral interpretation. While promising, these approaches require extensive training datasets and face difficulties with novel compounds or unexpected interferences. The development of standardized protocols for data processing and interpretation remains an ongoing challenge in the field.

Another emerging issue is the need for multi-technique approaches that combine the strengths of both FTIR and UV-Vis with other analytical methods. This integration presents technical challenges in terms of hardware compatibility, data fusion, and unified software platforms capable of processing diverse spectral information simultaneously.

UV-Vis spectroscopy has similarly progressed, with current systems capable of measuring across wavelengths from 190 to 1100 nm with precision of ±0.1 nm. The development of diode array detectors has significantly improved acquisition speeds, enabling real-time monitoring of fast chemical reactions and processes.

Despite these advancements, both technologies face substantial challenges. FTIR spectroscopy struggles with water interference, as water's strong absorption bands can mask important spectral features in aqueous samples. This limitation is particularly problematic for biological and environmental analyses. Additionally, the complexity of spectral interpretation remains a significant hurdle, often requiring extensive reference libraries and expert knowledge.

UV-Vis spectroscopy, while simpler to operate, suffers from lower specificity compared to FTIR. The broad absorption bands characteristic of UV-Vis spectra make it difficult to distinguish between similar compounds in complex mixtures. Furthermore, the technique is limited to compounds with chromophores or conjugated systems, restricting its applicability across the full spectrum of chemical analysis needs.

The geographical distribution of technological development shows concentration in North America, Europe, and East Asia, with companies like Thermo Fisher Scientific, Bruker, and Shimadzu leading innovation. Recent trends indicate growing interest in miniaturization and portability of both technologies, with handheld and field-deployable instruments gaining market share, though these compact versions still face sensitivity and resolution limitations.

A significant current challenge is the integration of artificial intelligence and machine learning algorithms for automated spectral interpretation. While promising, these approaches require extensive training datasets and face difficulties with novel compounds or unexpected interferences. The development of standardized protocols for data processing and interpretation remains an ongoing challenge in the field.

Another emerging issue is the need for multi-technique approaches that combine the strengths of both FTIR and UV-Vis with other analytical methods. This integration presents technical challenges in terms of hardware compatibility, data fusion, and unified software platforms capable of processing diverse spectral information simultaneously.

Comparative Analysis of FTIR and UV-Vis Methodologies

01 FTIR and UV-Vis spectroscopy for material characterization

The combined use of FTIR (Fourier Transform Infrared) and UV-Vis (Ultraviolet-Visible) spectroscopy techniques provides comprehensive characterization of materials by analyzing both molecular structure and electronic transitions. This dual approach enables identification of functional groups, chemical bonds, and chromophores in various substances. The complementary nature of these techniques allows for more accurate material identification and quality control in industries such as pharmaceuticals, polymers, and nanomaterials.- FTIR and UV-Vis spectroscopy for material characterization: The combination of FTIR (Fourier Transform Infrared) and UV-Vis (Ultraviolet-Visible) spectroscopy techniques provides comprehensive characterization of materials by analyzing both molecular structure and electronic transitions. FTIR identifies functional groups and molecular bonds through infrared absorption patterns, while UV-Vis measures electronic transitions and chromophores. Together, these complementary techniques enable detailed analysis of organic compounds, polymers, and various materials for quality control, research, and development applications.

- Portable and integrated spectroscopic systems: Advancements in spectroscopic technology have led to the development of portable and integrated systems that combine FTIR and UV-Vis capabilities in a single device. These systems feature miniaturized components, improved detectors, and specialized software for real-time analysis. The integration enables field-based measurements, on-site quality control, and rapid analysis without requiring separate laboratory equipment, making chemical analysis more accessible and efficient for various industries and research applications.

- Spectroscopic analysis for pharmaceutical applications: FTIR and UV-Vis spectroscopy are widely used in pharmaceutical research and quality control to analyze drug formulations, identify active pharmaceutical ingredients, and detect impurities. These techniques enable non-destructive testing of pharmaceutical compounds, verification of raw materials, quantification of active ingredients, and monitoring of stability and degradation processes. The combination of both spectroscopic methods provides comprehensive chemical fingerprinting for drug development, manufacturing, and regulatory compliance.

- Environmental and water quality monitoring: FTIR and UV-Vis spectroscopy techniques are employed for environmental monitoring and water quality assessment. These methods can detect and quantify pollutants, organic contaminants, heavy metals, and microplastics in water and soil samples. The spectroscopic approach allows for rapid screening of environmental samples, continuous monitoring of industrial effluents, and identification of trace contaminants without extensive sample preparation, supporting environmental protection efforts and regulatory compliance.

- Advanced data processing and chemometric methods: Modern FTIR and UV-Vis spectroscopic analysis incorporates advanced data processing and chemometric methods to enhance analytical capabilities. These include multivariate statistical analysis, machine learning algorithms, and pattern recognition techniques that improve spectral interpretation, reduce noise, and enable automated identification of chemical components. The integration of computational methods with spectroscopic data allows for more accurate quantification, detection of subtle spectral differences, and handling of complex sample matrices in various analytical applications.

02 Portable and integrated spectroscopic systems

Development of portable and integrated systems that combine FTIR and UV-Vis spectroscopy capabilities in a single device. These systems enable on-site, real-time chemical analysis without requiring separate laboratory equipment. The integration of multiple spectroscopic techniques into compact, field-deployable instruments facilitates rapid analysis in various environments, including industrial settings, environmental monitoring, and forensic investigations. These systems often incorporate advanced data processing algorithms for immediate interpretation of results.Expand Specific Solutions03 Spectroscopic analysis for pharmaceutical applications

Application of FTIR and UV-Vis spectroscopy for quality control, formulation development, and counterfeit detection in pharmaceutical products. These techniques enable rapid identification of active pharmaceutical ingredients, excipients, and potential contaminants. The non-destructive nature of these spectroscopic methods allows for efficient batch testing and process monitoring during drug manufacturing. Additionally, these techniques can detect subtle chemical differences between authentic medications and counterfeits, providing valuable tools for regulatory compliance and patient safety.Expand Specific Solutions04 Environmental and water quality monitoring

Utilization of FTIR and UV-Vis spectroscopy for environmental analysis and water quality assessment. These techniques enable detection and quantification of pollutants, organic compounds, and microplastics in environmental samples. The spectroscopic methods provide rapid screening capabilities for monitoring contaminants in water sources, soil samples, and air quality. The combination of these complementary techniques allows for comprehensive characterization of complex environmental matrices and identification of multiple pollutants simultaneously.Expand Specific Solutions05 Advanced data processing and machine learning integration

Implementation of advanced data processing techniques and machine learning algorithms to enhance the analytical capabilities of FTIR and UV-Vis spectroscopy. These computational approaches enable automated pattern recognition, multivariate analysis, and spectral deconvolution for complex mixtures. Machine learning models trained on spectroscopic data can predict material properties, identify unknown compounds, and detect subtle spectral changes indicative of specific chemical characteristics. This integration of spectroscopy with artificial intelligence significantly improves the speed and accuracy of chemical analysis across various applications.Expand Specific Solutions

Key Manufacturers and Research Institutions in Spectroscopy

The FTIR and UV-Vis spectroscopy market for chemical analysis is in a mature growth phase with established technologies experiencing continuous refinement. The global market size is estimated at $3-4 billion, growing at 5-7% annually due to increasing demand in pharmaceutical, environmental, and materials science applications. Technologically, FTIR has reached high maturity with companies like Thermo Fisher Scientific, Spectra Analysis, and HORIBA leading innovation in hyphenated techniques and miniaturization. UV-Vis technology, while mature, is seeing advancements in sensitivity and portability from players like Nicoya Lifesciences and Spectromics. Academic institutions (Heriot-Watt, McGill, EPFL) collaborate with industry leaders to develop next-generation spectroscopic methods, while oil companies (Saudi Aramco, Halliburton) drive specialized applications for energy sector analysis.

Spectra Analysis Instruments, Inc.

Technical Solution: Spectra Analysis Instruments has developed specialized solutions focusing on the complementary nature of FTIR and UV-Vis for comprehensive chemical characterization. Their DiscovIR-GC™ system integrates FTIR detection with gas chromatography, achieving detection limits in the nanogram range for complex mixtures. The company's proprietary solid-phase deposition technology allows for direct FTIR analysis of GC effluents by condensing analytes onto an infrared-transparent substrate. This approach overcomes traditional limitations of gas-phase FTIR detection, improving sensitivity by approximately 100-fold compared to conventional flow cells. For UV-Vis applications, Spectra Analysis has developed specialized flow cells with patented optical path designs that minimize stray light and maximize signal-to-noise ratios. Their software platform enables direct correlation between FTIR structural information and UV-Vis spectral features, providing enhanced identification capabilities for unknown compounds. The company has also pioneered automated chemometric models that leverage data from both techniques to improve quantitative accuracy for complex mixtures.

Strengths: Exceptional integration of chromatographic and spectroscopic techniques; specialized expertise in difficult sample types; innovative sample handling approaches that maximize sensitivity. Weaknesses: More focused on specialized applications rather than general-purpose analysis; smaller company with more limited global support infrastructure; systems require more expertise to operate compared to mainstream alternatives.

Thermo Electron Scientific Instruments LLC

Technical Solution: Thermo Electron has developed comprehensive solutions for both FTIR and UV-Vis spectroscopy with their Nicolet™ FTIR and Evolution™ UV-Vis product lines. Their FTIR systems feature patented optical designs achieving spectral resolution down to 0.09 cm⁻¹ and signal-to-noise ratios exceeding 50,000:1. For chemical analysis applications, they've implemented advanced ATR (Attenuated Total Reflectance) accessories that enable direct analysis of liquids, pastes, and solids without sample preparation. Their OMNIC™ software platform integrates both technologies, providing unified spectral libraries containing over 100,000 reference compounds. Thermo's UV-Vis systems offer wavelength accuracy of ±0.1nm and photometric precision of ±0.0002A. Their dual-beam optical designs compensate for source fluctuations, improving baseline stability for quantitative analysis. The company has also pioneered hyphenated techniques combining FTIR with TGA (Thermogravimetric Analysis) and GC (Gas Chromatography) for complex mixture characterization.

Strengths: Exceptional instrument sensitivity and stability; comprehensive software integration; extensive application support and method development resources; robust validation protocols for regulated industries. Weaknesses: Premium pricing positions products beyond reach of smaller laboratories; some advanced features require significant user expertise; hardware upgrades can be costly and complex.

Critical Patents and Innovations in Spectroscopic Techniques

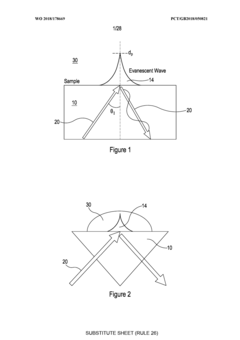

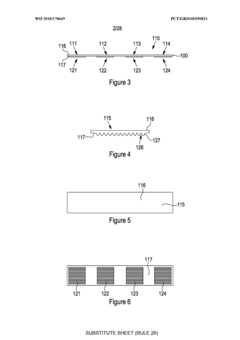

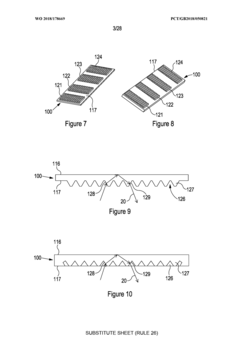

Infra-red spectroscopy system

PatentWO2018178669A2

Innovation

- A sample slide with multiple sample-receiving portions and integrated beam-receiving portions acting as internal reflection elements, allowing for multiple measurements without removing and replacing the slide, and the use of a disposable silicon slide to reduce costs and eliminate cleaning and drying requirements.

Spectrometer with built-in ATR and accessory compartment

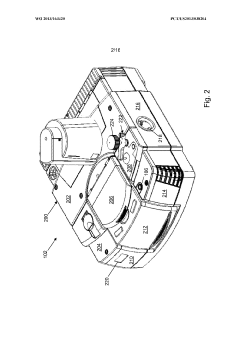

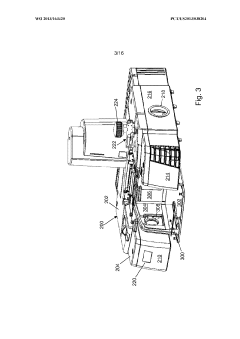

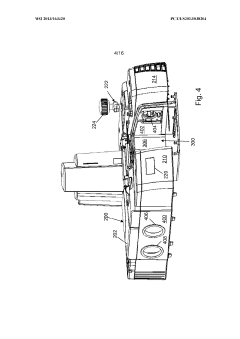

PatentWO2013163420A1

Innovation

- A spectrometer design incorporating a base plate with a light source, interferometer, accessory compartment, sample analysis device, and optical elements, including a crystal for ATR analysis, allows for modular sample analysis using an actuator to switch between positions for ATR and other measurement modes.

Sample Preparation and Handling Considerations

Sample preparation and handling represent critical factors that significantly influence the reliability and accuracy of both FTIR and UV-Vis spectroscopic analyses. These techniques, while powerful, require different approaches to sample preparation due to their distinct operational principles and sensitivity characteristics.

For FTIR analysis, samples can be prepared in various forms including solids, liquids, gases, and thin films. Solid samples typically require grinding with KBr to form pellets, which must be prepared under controlled humidity conditions to prevent moisture interference. Alternatively, attenuated total reflectance (ATR) accessories allow direct analysis of solid and liquid samples with minimal preparation, though surface contact quality becomes crucial for reproducible results.

Liquid samples for FTIR analysis often require specialized cells with infrared-transparent windows made of materials like CaF₂, ZnSe, or NaCl. These windows are susceptible to damage from aggressive solvents and humidity, necessitating careful handling and storage. Sample thickness must be precisely controlled, typically between 0.01-0.1 mm, to achieve optimal absorbance levels without signal saturation.

UV-Vis spectroscopy, conversely, primarily analyzes liquid samples in solution form. Sample preparation involves dissolution in appropriate solvents that do not absorb in the wavelength region of interest. Quartz cuvettes are standard for UV-Vis analysis, as they provide excellent transparency across the UV-visible spectrum, unlike glass which absorbs in the UV region.

Concentration management represents a critical difference between the techniques. UV-Vis typically requires dilute solutions (10⁻⁵ to 10⁻³ M) to maintain linearity according to Beer-Lambert law, while FTIR can accommodate higher concentrations. This difference impacts sample handling protocols and dilution requirements.

Environmental factors affect both techniques differently. FTIR is particularly sensitive to atmospheric water vapor and CO₂, often requiring purging with dry nitrogen or background correction. UV-Vis, while less affected by atmospheric conditions, is more susceptible to particulate contamination and requires filtration of turbid samples.

Sample stability considerations also differ. UV-Vis samples may be subject to photodegradation during analysis, particularly with UV radiation exposure. FTIR samples, especially those in KBr pellets, can absorb atmospheric moisture over time, altering spectral characteristics. Both techniques benefit from standardized handling protocols to ensure reproducibility across analyses.

For FTIR analysis, samples can be prepared in various forms including solids, liquids, gases, and thin films. Solid samples typically require grinding with KBr to form pellets, which must be prepared under controlled humidity conditions to prevent moisture interference. Alternatively, attenuated total reflectance (ATR) accessories allow direct analysis of solid and liquid samples with minimal preparation, though surface contact quality becomes crucial for reproducible results.

Liquid samples for FTIR analysis often require specialized cells with infrared-transparent windows made of materials like CaF₂, ZnSe, or NaCl. These windows are susceptible to damage from aggressive solvents and humidity, necessitating careful handling and storage. Sample thickness must be precisely controlled, typically between 0.01-0.1 mm, to achieve optimal absorbance levels without signal saturation.

UV-Vis spectroscopy, conversely, primarily analyzes liquid samples in solution form. Sample preparation involves dissolution in appropriate solvents that do not absorb in the wavelength region of interest. Quartz cuvettes are standard for UV-Vis analysis, as they provide excellent transparency across the UV-visible spectrum, unlike glass which absorbs in the UV region.

Concentration management represents a critical difference between the techniques. UV-Vis typically requires dilute solutions (10⁻⁵ to 10⁻³ M) to maintain linearity according to Beer-Lambert law, while FTIR can accommodate higher concentrations. This difference impacts sample handling protocols and dilution requirements.

Environmental factors affect both techniques differently. FTIR is particularly sensitive to atmospheric water vapor and CO₂, often requiring purging with dry nitrogen or background correction. UV-Vis, while less affected by atmospheric conditions, is more susceptible to particulate contamination and requires filtration of turbid samples.

Sample stability considerations also differ. UV-Vis samples may be subject to photodegradation during analysis, particularly with UV radiation exposure. FTIR samples, especially those in KBr pellets, can absorb atmospheric moisture over time, altering spectral characteristics. Both techniques benefit from standardized handling protocols to ensure reproducibility across analyses.

Cost-Benefit Analysis of Spectroscopic Instrumentation

When evaluating spectroscopic instrumentation for chemical analysis, a comprehensive cost-benefit analysis reveals significant differences between FTIR (Fourier Transform Infrared) and UV-Vis (Ultraviolet-Visible) spectroscopy technologies. The initial investment for FTIR systems typically ranges from $20,000 to $50,000, considerably higher than UV-Vis instruments which generally cost between $5,000 and $15,000. This substantial price difference reflects the greater complexity and precision of FTIR technology.

Operational expenses also differ markedly between these technologies. FTIR systems require more specialized maintenance, including regular replacement of desiccants and periodic alignment of optical components, resulting in annual maintenance costs of approximately $2,000-$4,000. In contrast, UV-Vis instruments typically incur lower maintenance expenses, averaging $500-$1,500 annually, primarily for lamp replacements and basic calibration.

Sample preparation requirements represent another important cost consideration. FTIR often demands more elaborate sample preparation, particularly for solid samples requiring KBr pellet formation or ATR accessories, adding both time and material costs. UV-Vis typically requires simpler solution-based preparations, reducing both labor and consumable expenses.

The return on investment timeline varies significantly between these technologies. UV-Vis systems generally achieve ROI within 1-2 years in routine analytical settings due to their lower initial cost and maintenance requirements. FTIR systems, while more expensive initially, may provide superior long-term value in research environments or specialized industrial applications where their broader analytical capabilities justify the higher investment, typically reaching ROI in 3-5 years.

Training requirements also impact the total cost of ownership. FTIR systems generally demand more extensive operator training (typically 20-40 hours) compared to UV-Vis instruments (8-16 hours), representing an additional hidden cost in terms of staff time and potential productivity loss during the learning period.

Laboratory space utilization and infrastructure requirements further differentiate these technologies. FTIR systems typically occupy more bench space and may require controlled environmental conditions to maintain optimal performance. UV-Vis instruments generally have smaller footprints and less stringent environmental requirements, potentially reducing facility-related costs.

When considering analytical versatility versus cost, FTIR provides broader molecular identification capabilities across numerous sample types, while UV-Vis offers more limited but highly sensitive quantitative analysis for specific applications. Organizations must carefully weigh these factors against their specific analytical needs, budget constraints, and long-term research or production objectives.

Operational expenses also differ markedly between these technologies. FTIR systems require more specialized maintenance, including regular replacement of desiccants and periodic alignment of optical components, resulting in annual maintenance costs of approximately $2,000-$4,000. In contrast, UV-Vis instruments typically incur lower maintenance expenses, averaging $500-$1,500 annually, primarily for lamp replacements and basic calibration.

Sample preparation requirements represent another important cost consideration. FTIR often demands more elaborate sample preparation, particularly for solid samples requiring KBr pellet formation or ATR accessories, adding both time and material costs. UV-Vis typically requires simpler solution-based preparations, reducing both labor and consumable expenses.

The return on investment timeline varies significantly between these technologies. UV-Vis systems generally achieve ROI within 1-2 years in routine analytical settings due to their lower initial cost and maintenance requirements. FTIR systems, while more expensive initially, may provide superior long-term value in research environments or specialized industrial applications where their broader analytical capabilities justify the higher investment, typically reaching ROI in 3-5 years.

Training requirements also impact the total cost of ownership. FTIR systems generally demand more extensive operator training (typically 20-40 hours) compared to UV-Vis instruments (8-16 hours), representing an additional hidden cost in terms of staff time and potential productivity loss during the learning period.

Laboratory space utilization and infrastructure requirements further differentiate these technologies. FTIR systems typically occupy more bench space and may require controlled environmental conditions to maintain optimal performance. UV-Vis instruments generally have smaller footprints and less stringent environmental requirements, potentially reducing facility-related costs.

When considering analytical versatility versus cost, FTIR provides broader molecular identification capabilities across numerous sample types, while UV-Vis offers more limited but highly sensitive quantitative analysis for specific applications. Organizations must carefully weigh these factors against their specific analytical needs, budget constraints, and long-term research or production objectives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!