Comparing FTIR Sample Preparation: Techniques & Outcomes

SEP 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

FTIR Spectroscopy Background and Objectives

Fourier Transform Infrared (FTIR) spectroscopy has evolved significantly since its inception in the mid-20th century, becoming an indispensable analytical technique across numerous scientific and industrial domains. The technology leverages the interaction between infrared radiation and matter to provide detailed molecular composition information, enabling researchers to identify and quantify chemical compounds with remarkable precision. Initially developed as a simpler alternative to dispersive spectroscopy, FTIR has undergone substantial technological advancements, particularly in instrumentation sensitivity, data processing capabilities, and sampling methodologies.

The evolution of FTIR technology has been characterized by continuous improvements in spectral resolution, signal-to-noise ratios, and acquisition speeds. Modern FTIR systems incorporate sophisticated interferometers, advanced detectors, and powerful computational algorithms that have dramatically enhanced analytical capabilities. These developments have expanded FTIR applications from traditional laboratory settings to portable field instruments, enabling real-time analysis in diverse environments.

Sample preparation techniques represent a critical aspect of FTIR spectroscopy that significantly impacts measurement accuracy, reproducibility, and overall analytical success. Historically, sample preparation methods have ranged from simple transmission techniques using pressed KBr pellets to more sophisticated approaches such as Attenuated Total Reflection (ATR), diffuse reflectance, and microsampling. Each technique offers distinct advantages and limitations depending on the sample type, physical state, and analytical objectives.

The primary objective of this technical research report is to comprehensively evaluate and compare various FTIR sample preparation techniques, assessing their relative merits, limitations, and optimal application scenarios. By examining factors such as sample throughput, ease of preparation, spectral quality, quantitative accuracy, and reproducibility, this analysis aims to provide evidence-based guidance for selecting appropriate sample preparation methodologies across different analytical contexts.

Additionally, this report seeks to identify emerging trends in FTIR sample preparation, including innovations in microfluidic sampling, automated sample handling systems, and novel accessory designs that address traditional challenges in sample presentation. These developments are evaluated within the broader context of evolving analytical requirements across pharmaceutical, environmental, materials science, and biomedical applications.

Understanding the intricate relationship between sample preparation techniques and spectral outcomes is essential for maximizing the analytical potential of FTIR spectroscopy. This report will establish a framework for systematic comparison of preparation methods, enabling researchers and analysts to make informed decisions that optimize analytical performance while minimizing artifacts and interferences that can compromise data integrity.

The evolution of FTIR technology has been characterized by continuous improvements in spectral resolution, signal-to-noise ratios, and acquisition speeds. Modern FTIR systems incorporate sophisticated interferometers, advanced detectors, and powerful computational algorithms that have dramatically enhanced analytical capabilities. These developments have expanded FTIR applications from traditional laboratory settings to portable field instruments, enabling real-time analysis in diverse environments.

Sample preparation techniques represent a critical aspect of FTIR spectroscopy that significantly impacts measurement accuracy, reproducibility, and overall analytical success. Historically, sample preparation methods have ranged from simple transmission techniques using pressed KBr pellets to more sophisticated approaches such as Attenuated Total Reflection (ATR), diffuse reflectance, and microsampling. Each technique offers distinct advantages and limitations depending on the sample type, physical state, and analytical objectives.

The primary objective of this technical research report is to comprehensively evaluate and compare various FTIR sample preparation techniques, assessing their relative merits, limitations, and optimal application scenarios. By examining factors such as sample throughput, ease of preparation, spectral quality, quantitative accuracy, and reproducibility, this analysis aims to provide evidence-based guidance for selecting appropriate sample preparation methodologies across different analytical contexts.

Additionally, this report seeks to identify emerging trends in FTIR sample preparation, including innovations in microfluidic sampling, automated sample handling systems, and novel accessory designs that address traditional challenges in sample presentation. These developments are evaluated within the broader context of evolving analytical requirements across pharmaceutical, environmental, materials science, and biomedical applications.

Understanding the intricate relationship between sample preparation techniques and spectral outcomes is essential for maximizing the analytical potential of FTIR spectroscopy. This report will establish a framework for systematic comparison of preparation methods, enabling researchers and analysts to make informed decisions that optimize analytical performance while minimizing artifacts and interferences that can compromise data integrity.

Market Applications and Analytical Demands

The FTIR spectroscopy market has experienced significant growth across various industries, driven by increasing demands for precise molecular analysis and quality control. The global FTIR market was valued at approximately 1.2 billion USD in 2022, with projections indicating a compound annual growth rate of 6.8% through 2030. This growth is primarily fueled by expanding applications in pharmaceutical development, environmental monitoring, food safety, and materials science.

In the pharmaceutical sector, FTIR has become indispensable for drug formulation analysis, raw material verification, and quality assurance processes. The technique's ability to provide detailed molecular fingerprints makes it particularly valuable for identifying counterfeit medications and ensuring batch-to-batch consistency. Regulatory requirements from agencies like the FDA and EMA have further cemented FTIR's position as a standard analytical tool in pharmaceutical manufacturing.

The food and beverage industry represents another significant market segment, where FTIR is increasingly utilized for compositional analysis, adulteration detection, and quality control. Manufacturers face mounting pressure to verify product authenticity and nutritional content, driving adoption of rapid and reliable analytical methods like FTIR. The technique's non-destructive nature and minimal sample preparation requirements make it particularly attractive for routine quality testing.

Environmental monitoring applications have expanded considerably, with FTIR becoming a preferred method for analyzing air pollutants, soil contaminants, and water quality parameters. Government agencies and environmental consultancies require techniques that can detect trace compounds with high sensitivity and specificity, often in complex matrices. This has led to innovations in sample preparation methods tailored to environmental samples.

The materials science and polymer industries demand sophisticated analytical capabilities for research, development, and quality control. FTIR's ability to characterize chemical structures, identify functional groups, and monitor polymerization reactions makes it essential for these applications. As advanced materials become increasingly complex, the need for optimized sample preparation techniques has grown proportionally.

Academic and research institutions constitute another significant market segment, where FTIR is employed across diverse scientific disciplines. The analytical demands in this sector focus on versatility, accuracy, and the ability to analyze novel compounds or materials with minimal reference data. Sample preparation innovations often originate in academic settings before being adopted by industrial users.

The healthcare diagnostics market represents an emerging application area, with FTIR being explored for rapid disease screening and biomarker identification. This sector demands highly sensitive and specific analytical methods capable of detecting subtle biochemical changes in biological samples, driving research into specialized sample preparation techniques for tissues, cells, and biofluids.

In the pharmaceutical sector, FTIR has become indispensable for drug formulation analysis, raw material verification, and quality assurance processes. The technique's ability to provide detailed molecular fingerprints makes it particularly valuable for identifying counterfeit medications and ensuring batch-to-batch consistency. Regulatory requirements from agencies like the FDA and EMA have further cemented FTIR's position as a standard analytical tool in pharmaceutical manufacturing.

The food and beverage industry represents another significant market segment, where FTIR is increasingly utilized for compositional analysis, adulteration detection, and quality control. Manufacturers face mounting pressure to verify product authenticity and nutritional content, driving adoption of rapid and reliable analytical methods like FTIR. The technique's non-destructive nature and minimal sample preparation requirements make it particularly attractive for routine quality testing.

Environmental monitoring applications have expanded considerably, with FTIR becoming a preferred method for analyzing air pollutants, soil contaminants, and water quality parameters. Government agencies and environmental consultancies require techniques that can detect trace compounds with high sensitivity and specificity, often in complex matrices. This has led to innovations in sample preparation methods tailored to environmental samples.

The materials science and polymer industries demand sophisticated analytical capabilities for research, development, and quality control. FTIR's ability to characterize chemical structures, identify functional groups, and monitor polymerization reactions makes it essential for these applications. As advanced materials become increasingly complex, the need for optimized sample preparation techniques has grown proportionally.

Academic and research institutions constitute another significant market segment, where FTIR is employed across diverse scientific disciplines. The analytical demands in this sector focus on versatility, accuracy, and the ability to analyze novel compounds or materials with minimal reference data. Sample preparation innovations often originate in academic settings before being adopted by industrial users.

The healthcare diagnostics market represents an emerging application area, with FTIR being explored for rapid disease screening and biomarker identification. This sector demands highly sensitive and specific analytical methods capable of detecting subtle biochemical changes in biological samples, driving research into specialized sample preparation techniques for tissues, cells, and biofluids.

Current Sample Preparation Challenges

Despite significant advancements in FTIR spectroscopy, sample preparation remains a critical bottleneck that affects analytical accuracy, reproducibility, and efficiency. Current FTIR sample preparation faces several persistent challenges that limit the technique's full potential across various applications. The most fundamental issue is sample heterogeneity, which continues to plague analysts working with complex matrices such as biological tissues, polymer blends, and environmental samples. Achieving representative sampling while maintaining molecular integrity presents a delicate balance that often requires compromise.

Contamination control represents another significant challenge, particularly as detection limits push into lower concentrations. Even trace contaminants from laboratory environments, preparation tools, or storage containers can introduce spectral artifacts that complicate interpretation. This issue becomes especially problematic when analyzing samples with subtle spectral features or when conducting quantitative analysis where baseline accuracy is paramount.

The time-intensive nature of traditional sample preparation methods creates workflow inefficiencies that limit throughput in both research and industrial settings. Manual preparation steps introduce variability between operators and laboratories, contributing to reproducibility issues that undermine confidence in results. This variability becomes particularly problematic in regulated environments where method validation and transfer between facilities are required.

For solid samples, achieving optimal particle size distribution remains challenging. Inconsistent grinding or milling processes lead to variable path lengths and scattering effects that distort spectral features. Meanwhile, liquid sample preparation struggles with solvent selection that minimizes spectral interference while maintaining analyte solubility and stability.

The KBr pellet technique, though widely used, continues to suffer from moisture sensitivity issues that affect baseline stability and spectral quality. Hygroscopic samples require specialized handling protocols that are difficult to standardize across different laboratory environments. Additionally, pressure-induced polymorphic changes during pellet formation can alter molecular structures, leading to misinterpretation of results.

ATR sampling, while convenient, faces challenges with sample-crystal contact variability that affects quantitative reliability. The limited penetration depth restricts analysis to surface characteristics, potentially missing critical information about bulk composition. Furthermore, the diversity of sample types encountered in modern applications demands customized preparation approaches, yet standardized protocols remain underdeveloped for many emerging materials.

Automation efforts in sample preparation have progressed slowly compared to instrumentation advances, creating a technological imbalance in the analytical workflow. This gap is particularly evident in high-throughput environments where manual preparation becomes the limiting factor in analytical efficiency.

Contamination control represents another significant challenge, particularly as detection limits push into lower concentrations. Even trace contaminants from laboratory environments, preparation tools, or storage containers can introduce spectral artifacts that complicate interpretation. This issue becomes especially problematic when analyzing samples with subtle spectral features or when conducting quantitative analysis where baseline accuracy is paramount.

The time-intensive nature of traditional sample preparation methods creates workflow inefficiencies that limit throughput in both research and industrial settings. Manual preparation steps introduce variability between operators and laboratories, contributing to reproducibility issues that undermine confidence in results. This variability becomes particularly problematic in regulated environments where method validation and transfer between facilities are required.

For solid samples, achieving optimal particle size distribution remains challenging. Inconsistent grinding or milling processes lead to variable path lengths and scattering effects that distort spectral features. Meanwhile, liquid sample preparation struggles with solvent selection that minimizes spectral interference while maintaining analyte solubility and stability.

The KBr pellet technique, though widely used, continues to suffer from moisture sensitivity issues that affect baseline stability and spectral quality. Hygroscopic samples require specialized handling protocols that are difficult to standardize across different laboratory environments. Additionally, pressure-induced polymorphic changes during pellet formation can alter molecular structures, leading to misinterpretation of results.

ATR sampling, while convenient, faces challenges with sample-crystal contact variability that affects quantitative reliability. The limited penetration depth restricts analysis to surface characteristics, potentially missing critical information about bulk composition. Furthermore, the diversity of sample types encountered in modern applications demands customized preparation approaches, yet standardized protocols remain underdeveloped for many emerging materials.

Automation efforts in sample preparation have progressed slowly compared to instrumentation advances, creating a technological imbalance in the analytical workflow. This gap is particularly evident in high-throughput environments where manual preparation becomes the limiting factor in analytical efficiency.

Comparative Analysis of Preparation Techniques

01 Solid sample preparation techniques for FTIR analysis

Various techniques are employed for preparing solid samples for FTIR analysis, including grinding, pressing into pellets with KBr, and creating thin films. These methods help to ensure proper sample presentation and improve spectral quality. Grinding reduces particle size to minimize scattering effects, while KBr pellet preparation involves mixing the sample with potassium bromide and applying pressure to create a transparent disc. Thin film techniques allow for direct analysis of surface characteristics.- Solid sample preparation techniques for FTIR analysis: Various techniques are employed for preparing solid samples for FTIR analysis, including grinding, pressing into pellets with KBr, and creating thin films. These methods help to ensure proper sample presentation and improve spectral quality. Grinding reduces particle size to minimize scattering effects, while KBr pellet preparation involves mixing the sample with potassium bromide and applying pressure to create a transparent disc. Thin film techniques are useful for polymers and other materials that can be cast or spread as films.

- Liquid and solution sample preparation for FTIR spectroscopy: Liquid samples require specific preparation techniques for FTIR analysis, including the use of specialized cells with infrared-transparent windows, attenuated total reflection (ATR) accessories, and solution preparation methods. For solution samples, appropriate solvents that don't interfere with the analyte's spectral features must be selected. Concentration optimization is crucial to obtain clear spectra without saturation. These techniques enable accurate analysis of liquid compounds, solutions, and suspensions while minimizing interference.

- Automated sample preparation systems for FTIR: Automated systems have been developed to streamline FTIR sample preparation, improving efficiency and reproducibility. These systems can handle multiple samples, control environmental conditions, and perform precise sample manipulation. Automation reduces human error, increases throughput, and ensures consistent preparation parameters. Advanced systems may incorporate robotic handling, precise dispensing of reagents, and integration with analysis software for seamless workflow from preparation to data interpretation.

- Specialized FTIR sample preparation for biological and medical specimens: Biological and medical samples require specialized preparation techniques for FTIR analysis due to their complex composition and sensitivity. Methods include tissue sectioning, fixation, dehydration, and embedding procedures that preserve sample integrity while enabling spectral acquisition. Microtoming techniques produce thin sections suitable for transmission measurements. For cellular samples, concentration and purification steps may be necessary. These specialized approaches allow for the analysis of proteins, tissues, cells, and other biological materials while minimizing artifacts and interference.

- Novel FTIR sampling accessories and their impact on analytical outcomes: Innovative FTIR sampling accessories have been developed to enhance analytical capabilities and address challenging sample types. These include micro-sampling tools, diamond ATR accessories, diffuse reflectance attachments, and specialized environmental chambers. Such accessories enable analysis of minute sample quantities, improve signal-to-noise ratios, and allow for in-situ measurements under controlled conditions. The selection of appropriate accessories significantly impacts spectral quality, detection limits, and the ability to analyze difficult or unique sample types.

02 Liquid and solution sample preparation for FTIR spectroscopy

Liquid samples require specific preparation techniques for FTIR analysis, including the use of specialized cells, attenuated total reflection (ATR) accessories, and solution dilution methods. Liquid cells with specific path lengths and window materials are selected based on the sample properties. ATR techniques allow for direct analysis of liquids without extensive preparation. Solution preparation often involves selecting appropriate solvents that don't interfere with the spectral regions of interest.Expand Specific Solutions03 Automated FTIR sample preparation systems

Automated systems have been developed to streamline FTIR sample preparation, improving efficiency and reproducibility. These systems can handle multiple samples, control environmental conditions, and standardize preparation procedures. Automation reduces human error, increases throughput, and ensures consistent sample presentation. Advanced systems may incorporate robotic handling, precise measurement of components, and integration with analysis software for seamless workflow.Expand Specific Solutions04 Specialized FTIR sample preparation for biological and medical specimens

Biological and medical samples require specialized preparation techniques for FTIR analysis due to their complex composition and sensitivity. Methods include tissue sectioning, fixation, dehydration, and embedding procedures. Preparation techniques must preserve the biochemical integrity of the samples while making them suitable for spectroscopic analysis. Specialized approaches have been developed for analyzing proteins, cells, tissues, and bodily fluids to extract meaningful diagnostic and research information.Expand Specific Solutions05 Novel materials and accessories for enhanced FTIR sample preparation

Innovative materials and accessories have been developed to improve FTIR sample preparation outcomes. These include specialized substrates, sample holders, and preparation tools designed to enhance spectral quality and simplify the preparation process. Advanced materials with optimal optical properties minimize interference and improve signal-to-noise ratios. Custom accessories address challenges with difficult sample types, enabling analysis of previously problematic materials and expanding the application range of FTIR spectroscopy.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The FTIR sample preparation technology landscape is currently in a mature growth phase, with a market size estimated to exceed $1.5 billion globally. The competitive landscape features established analytical instrument manufacturers like Horiba, JEOL, and Bruker Nano dominating with comprehensive solution portfolios, while academic institutions such as California Institute of Technology and Monash University drive innovation through fundamental research. Specialized players like Spectra Analysis Instruments and Dxcover are carving niches in application-specific FTIR preparation techniques. The technology shows varying maturity levels across sectors, with clinical applications (Singapore Health Services, Dxcover) representing emerging opportunities, while industrial applications in petrochemicals (Schlumberger, Halliburton) and materials science (Texas Instruments, Rohm & Haas) demonstrate higher technological readiness levels with standardized preparation protocols.

Spectra Analysis Instruments, Inc.

Technical Solution: Spectra Analysis Instruments has pioneered innovative FTIR sample preparation techniques through their DiscovIR-GC system, which combines gas chromatography with FTIR for complex mixture analysis. Their approach eliminates many traditional sample preparation steps by depositing separated compounds directly onto an IR-transparent substrate for immediate FTIR analysis. The company has developed specialized sample preparation accessories for their FTIR systems, including heated sample cells for volatile materials and specialized holders for thin films and coatings. Their patented sample deposition technology allows for preservation of samples post-analysis, enabling multiple analytical techniques on the same prepared sample. Spectra Analysis has also created specialized software tools that guide users through optimal sample preparation procedures based on sample type and analytical goals, reducing preparation errors[3][7].

Strengths: Innovative hyphenated techniques reduce sample preparation requirements; specialized accessories for challenging sample types; software guidance for optimal preparation procedures. Weaknesses: Specialized systems may have higher initial costs; some techniques require specific consumables from Spectra Analysis; more complex integrated systems may require additional maintenance and expertise.

Smiths Detection Ltd.

Technical Solution: Smiths Detection has developed specialized FTIR sample preparation techniques focused on security and defense applications. Their HazMatID Elite portable FTIR system features a diamond ATR sample interface requiring minimal preparation for solid and liquid samples, enabling rapid field analysis. For trace detection, they've pioneered specialized swabbing techniques and sample collection accessories optimized for their FTIR instruments. Their laboratory-based systems incorporate automated sample preparation stations with controlled environmental chambers to maintain sample integrity during analysis. Smiths Detection has also developed specialized FTIR libraries and algorithms that compensate for variations in sample preparation quality, particularly important for field applications where preparation conditions are suboptimal. Their technology enables analysis of complex mixtures with minimal separation or preparation steps through advanced chemometric algorithms[4][6].

Strengths: Ruggedized systems designed for field use with simplified sample preparation; specialized accessories for security/defense applications; advanced algorithms compensate for preparation inconsistencies. Weaknesses: Systems optimized for specific security applications may have limited flexibility for research applications; higher cost compared to general-purpose FTIR systems; some proprietary sample preparation techniques require specific training.

Key Innovations in Sample Handling Technologies

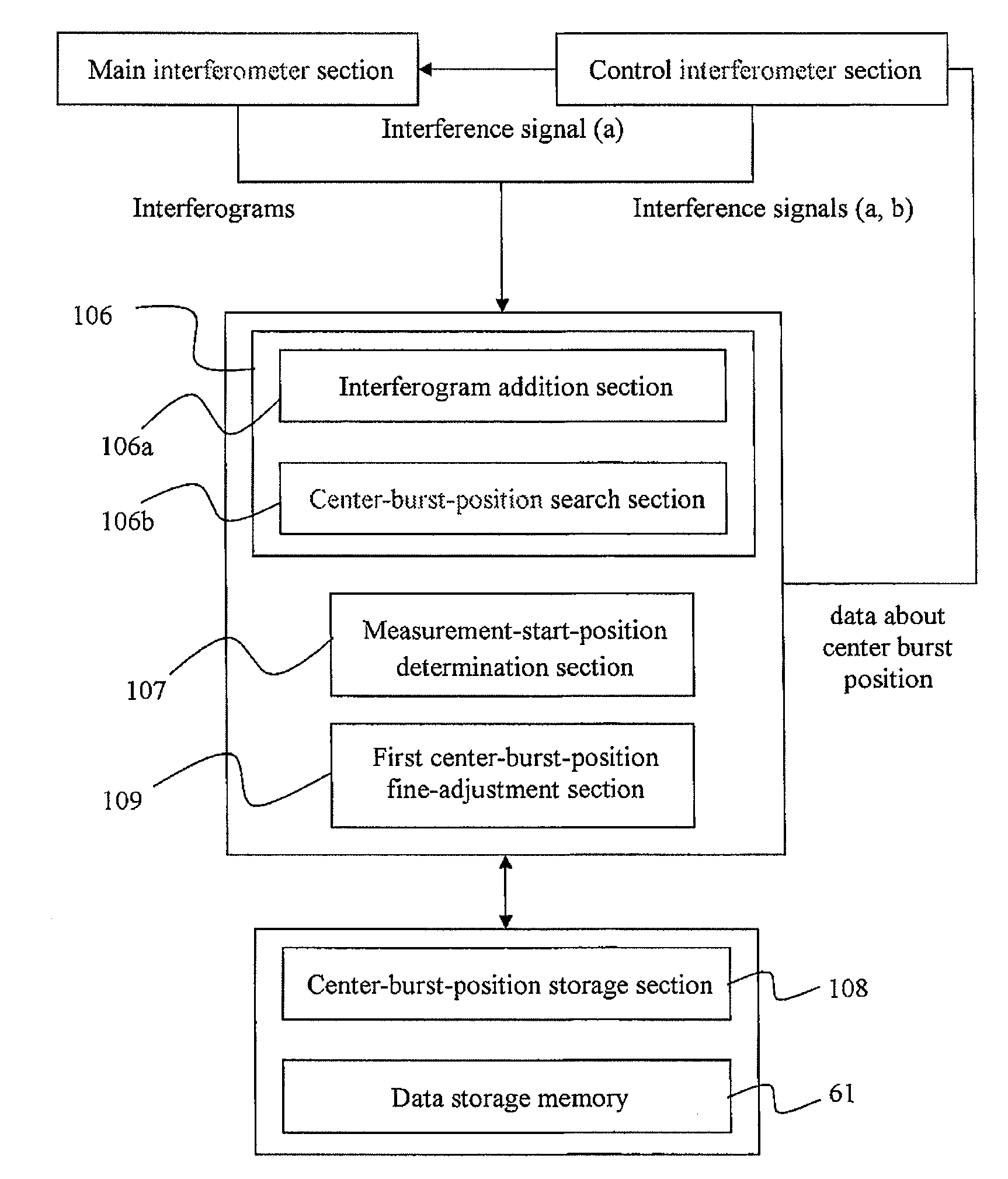

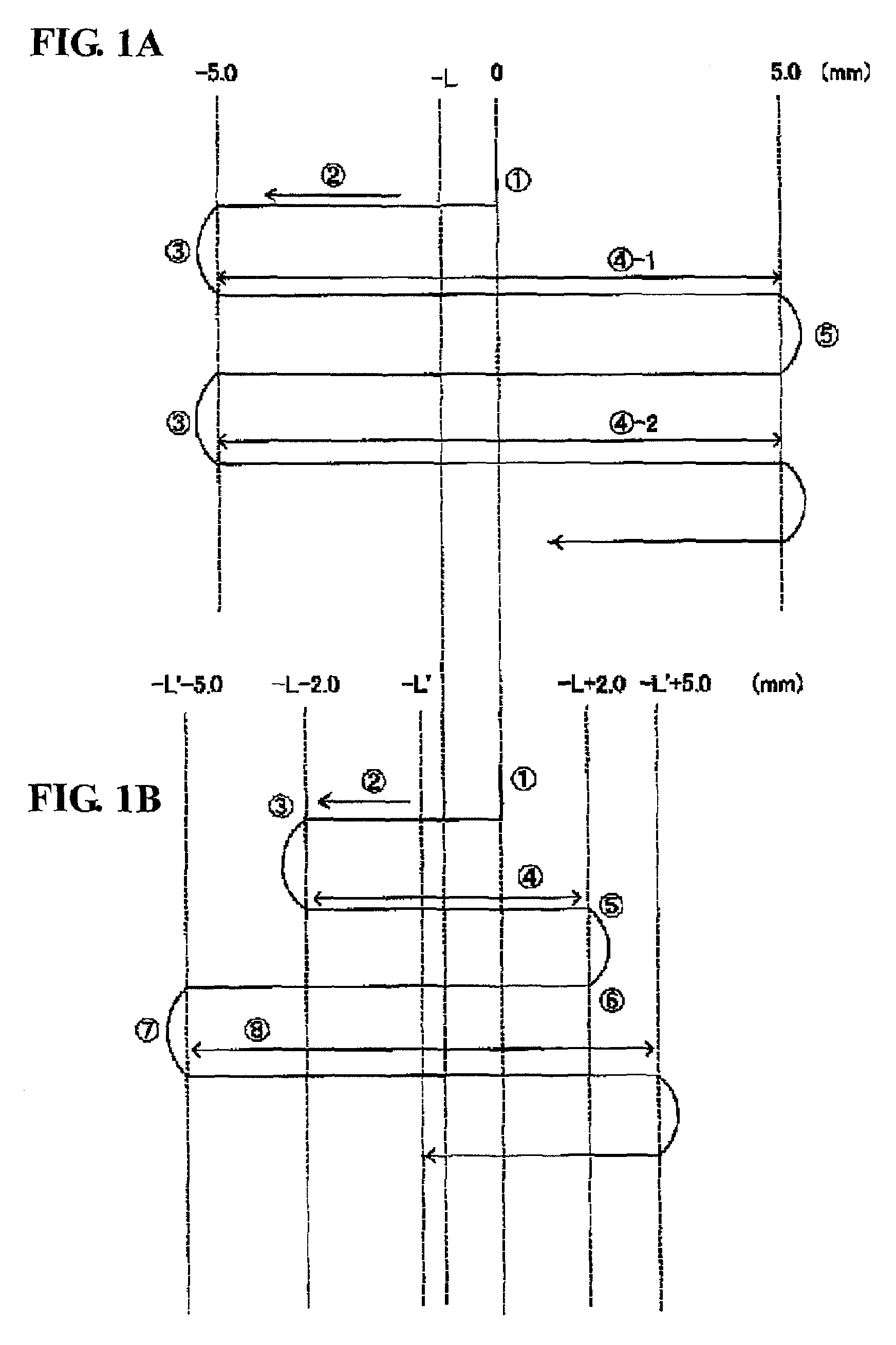

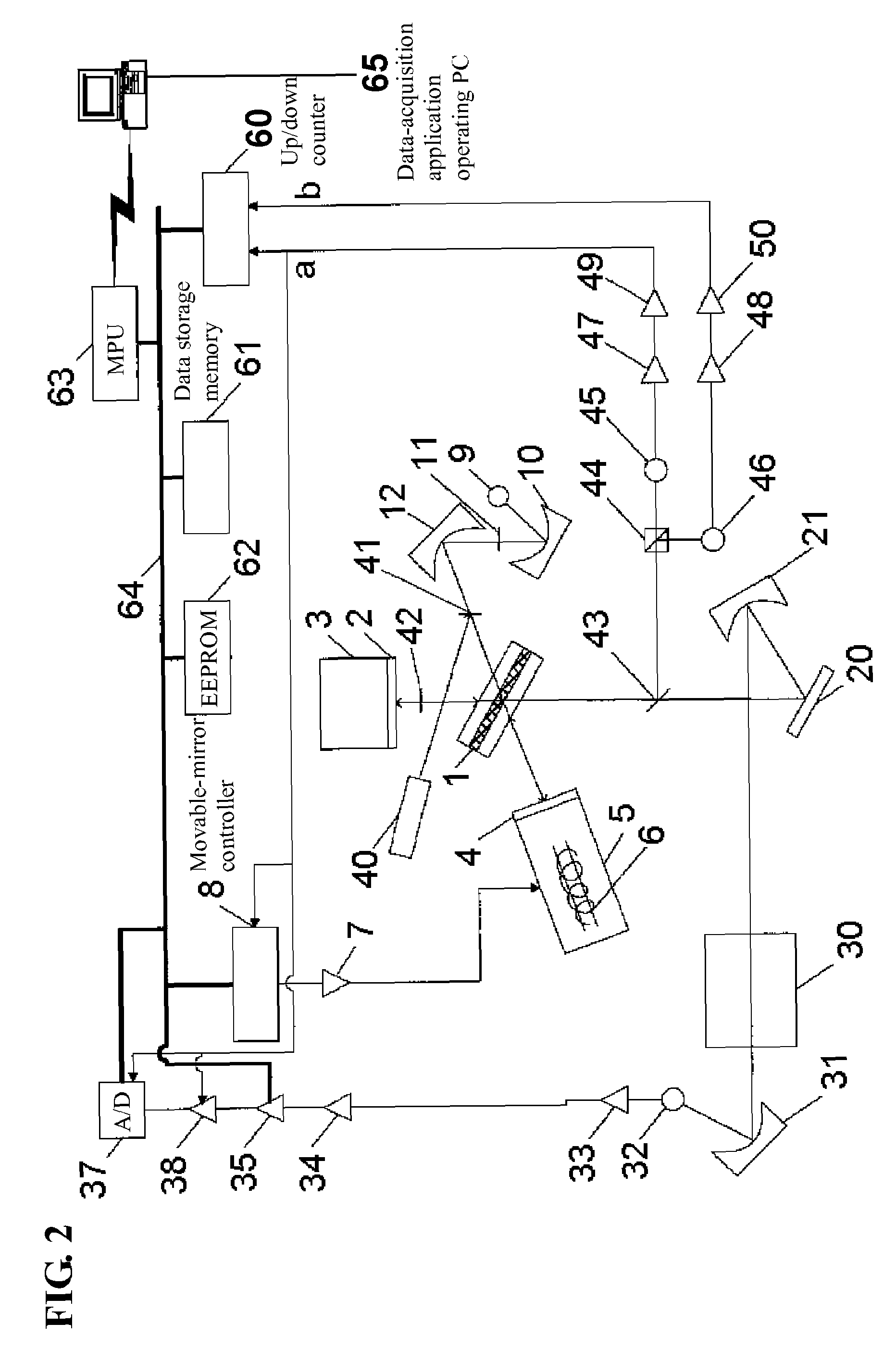

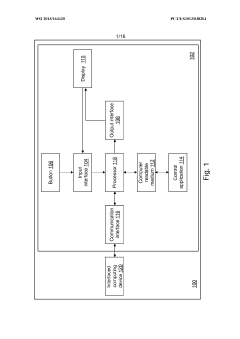

Fourier transform infrared spectrophotometer

PatentInactiveUS7535004B2

Innovation

- The implementation of a center-burst-position detection section that performs addition processing on interferogram intensities to produce a cumulative interferogram, correcting positional deviations and enhancing the detection of the center burst position by increasing the intensity of true peaks while canceling out noise peaks, thereby ensuring accurate detection even under low light conditions.

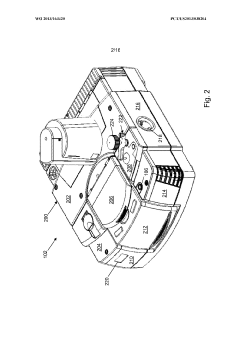

Spectrometer with built-in ATR and accessory compartment

PatentWO2013163420A1

Innovation

- A spectrometer design incorporating a base plate with a light source, interferometer, accessory compartment, sample analysis device, and optical elements, including a crystal for ATR analysis, allows for modular sample analysis using an actuator to switch between positions for ATR and other measurement modes.

Quality Control Standards for FTIR Analysis

Quality control standards are essential for ensuring the reliability and reproducibility of FTIR (Fourier Transform Infrared Spectroscopy) analysis results. Establishing robust quality control protocols begins with the implementation of standardized sample preparation techniques that minimize variability between analyses. Organizations such as ASTM International and the International Organization for Standardization (ISO) have developed comprehensive guidelines specifically for FTIR analysis, including ASTM E1252 for general sampling handling and ISO 18473 for specific material analysis protocols.

Performance verification standards are critical components of quality control in FTIR analysis. These include polystyrene films with well-characterized absorption bands that serve as wavelength calibration standards. Regular calibration using these standards ensures the accuracy of the instrument's wavelength scale, which directly impacts the reliability of molecular identification. Additionally, background scans should be performed at regular intervals to account for atmospheric conditions that may affect spectral quality.

Statistical process control methods play a significant role in maintaining FTIR analysis quality. Implementing control charts to monitor key performance indicators such as signal-to-noise ratio, peak resolution, and baseline stability helps identify instrument drift or performance degradation before it affects analytical results. Laboratories should establish acceptance criteria for these parameters based on application requirements and historical performance data.

Reference materials with certified spectral properties provide another layer of quality assurance. These materials, often available from national metrology institutes like NIST, allow analysts to verify both sample preparation techniques and instrument performance simultaneously. Regular analysis of these reference materials should be incorporated into standard operating procedures, with results documented and tracked over time to identify trends or shifts in analytical performance.

Validation protocols for FTIR methods should include assessments of precision, accuracy, linearity, detection limits, and robustness. Cross-validation with complementary analytical techniques such as Raman spectroscopy or NMR can further strengthen confidence in FTIR results. For quantitative applications, multivariate calibration models should undergo rigorous validation using independent test sets to ensure their predictive capability across the expected range of sample variations.

Documentation and traceability form the foundation of effective quality control systems. All sample preparation steps, instrument parameters, calibration records, and analytical results should be thoroughly documented according to good laboratory practice guidelines. Electronic laboratory information management systems (LIMS) can facilitate this documentation process while enabling efficient data retrieval and trend analysis for continuous quality improvement.

Performance verification standards are critical components of quality control in FTIR analysis. These include polystyrene films with well-characterized absorption bands that serve as wavelength calibration standards. Regular calibration using these standards ensures the accuracy of the instrument's wavelength scale, which directly impacts the reliability of molecular identification. Additionally, background scans should be performed at regular intervals to account for atmospheric conditions that may affect spectral quality.

Statistical process control methods play a significant role in maintaining FTIR analysis quality. Implementing control charts to monitor key performance indicators such as signal-to-noise ratio, peak resolution, and baseline stability helps identify instrument drift or performance degradation before it affects analytical results. Laboratories should establish acceptance criteria for these parameters based on application requirements and historical performance data.

Reference materials with certified spectral properties provide another layer of quality assurance. These materials, often available from national metrology institutes like NIST, allow analysts to verify both sample preparation techniques and instrument performance simultaneously. Regular analysis of these reference materials should be incorporated into standard operating procedures, with results documented and tracked over time to identify trends or shifts in analytical performance.

Validation protocols for FTIR methods should include assessments of precision, accuracy, linearity, detection limits, and robustness. Cross-validation with complementary analytical techniques such as Raman spectroscopy or NMR can further strengthen confidence in FTIR results. For quantitative applications, multivariate calibration models should undergo rigorous validation using independent test sets to ensure their predictive capability across the expected range of sample variations.

Documentation and traceability form the foundation of effective quality control systems. All sample preparation steps, instrument parameters, calibration records, and analytical results should be thoroughly documented according to good laboratory practice guidelines. Electronic laboratory information management systems (LIMS) can facilitate this documentation process while enabling efficient data retrieval and trend analysis for continuous quality improvement.

Cost-Benefit Analysis of Preparation Methods

When evaluating FTIR sample preparation methods, cost-benefit analysis provides crucial insights for laboratories and research facilities to optimize their analytical processes. The direct costs associated with different preparation techniques vary significantly. KBr pellet preparation requires relatively inexpensive potassium bromide, but necessitates specialized equipment like hydraulic presses and dies, representing a moderate initial investment. ATR accessories, while having higher upfront costs, offer significant long-term savings through reduced sample preparation time and minimal consumable requirements.

Labor costs constitute a substantial portion of the total expense in FTIR analysis. Traditional transmission methods like KBr pellets demand skilled technicians and approximately 10-15 minutes per sample preparation, whereas ATR techniques can reduce this time to less than 2 minutes. For high-throughput laboratories processing hundreds of samples weekly, this time differential translates to significant labor cost savings with ATR methods.

Consumable expenses also differ markedly between techniques. Nujol mull and KBr pellet methods require ongoing purchases of materials that cannot be reused, while diamond ATR crystals offer exceptional durability with thousands of analyses before requiring replacement. Laboratories must factor in these recurring costs when selecting appropriate preparation methods for their specific analytical needs.

Quality and reliability outcomes must be weighed against these cost considerations. While ATR methods offer speed and convenience, they may provide less spectral detail in certain frequency ranges compared to well-prepared KBr pellets. This quality differential may justify higher preparation costs for applications requiring maximum spectral resolution and accuracy, particularly in pharmaceutical research and forensic analysis.

Sample preservation represents another important cost-benefit consideration. Destructive techniques like KBr pellet preparation permanently alter samples, potentially necessitating additional material collection or preventing future alternative analyses. Non-destructive methods like ATR preserve sample integrity, offering significant value when analyzing rare, expensive, or irreplaceable specimens.

The environmental impact and associated compliance costs also merit consideration. Some preparation methods involve hazardous materials requiring specialized disposal procedures and safety equipment. These regulatory compliance expenses, while often overlooked in immediate cost calculations, can substantially impact the total cost of ownership for specific preparation techniques.

Return on investment timelines vary significantly between methods. High-throughput laboratories may recoup the higher initial investment in ATR accessories within months through labor savings and reduced consumable usage, while facilities with lower sample volumes might experience longer payback periods, necessitating careful financial planning and justification.

Labor costs constitute a substantial portion of the total expense in FTIR analysis. Traditional transmission methods like KBr pellets demand skilled technicians and approximately 10-15 minutes per sample preparation, whereas ATR techniques can reduce this time to less than 2 minutes. For high-throughput laboratories processing hundreds of samples weekly, this time differential translates to significant labor cost savings with ATR methods.

Consumable expenses also differ markedly between techniques. Nujol mull and KBr pellet methods require ongoing purchases of materials that cannot be reused, while diamond ATR crystals offer exceptional durability with thousands of analyses before requiring replacement. Laboratories must factor in these recurring costs when selecting appropriate preparation methods for their specific analytical needs.

Quality and reliability outcomes must be weighed against these cost considerations. While ATR methods offer speed and convenience, they may provide less spectral detail in certain frequency ranges compared to well-prepared KBr pellets. This quality differential may justify higher preparation costs for applications requiring maximum spectral resolution and accuracy, particularly in pharmaceutical research and forensic analysis.

Sample preservation represents another important cost-benefit consideration. Destructive techniques like KBr pellet preparation permanently alter samples, potentially necessitating additional material collection or preventing future alternative analyses. Non-destructive methods like ATR preserve sample integrity, offering significant value when analyzing rare, expensive, or irreplaceable specimens.

The environmental impact and associated compliance costs also merit consideration. Some preparation methods involve hazardous materials requiring specialized disposal procedures and safety equipment. These regulatory compliance expenses, while often overlooked in immediate cost calculations, can substantially impact the total cost of ownership for specific preparation techniques.

Return on investment timelines vary significantly between methods. High-throughput laboratories may recoup the higher initial investment in ATR accessories within months through labor savings and reduced consumable usage, while facilities with lower sample volumes might experience longer payback periods, necessitating careful financial planning and justification.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!