Comparing Linear Hall Effect Sensors vs Switch Sensors

SEP 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hall Effect Sensing Technology Background and Objectives

Hall Effect sensing technology, discovered by Edwin Hall in 1879, represents one of the most significant advancements in non-contact position and current sensing. The technology is based on the Hall Effect principle, where a voltage difference is generated across an electrical conductor transverse to an electric current when exposed to a magnetic field. This fundamental physical phenomenon has evolved from a laboratory curiosity to a cornerstone of modern sensing applications across numerous industries.

The evolution of Hall Effect technology has been marked by several key milestones. Early implementations in the mid-20th century were primarily focused on laboratory applications due to limitations in semiconductor manufacturing. The 1970s saw the first commercial Hall Effect sensors, though these were relatively simple switch-type devices with binary outputs. The 1980s and 1990s brought significant advancements with the introduction of integrated circuits that combined Hall Effect elements with signal processing capabilities, enabling more sophisticated applications.

In recent years, the technology has bifurcated into two primary categories: Linear Hall Effect sensors and Switch sensors. Linear sensors provide an analog or digital output proportional to the magnetic field strength, offering continuous measurement capabilities. In contrast, Switch sensors provide binary outputs based on magnetic threshold detection, functioning essentially as contactless switches. This divergence has expanded the application landscape dramatically, from automotive systems to industrial automation and consumer electronics.

The current technological trajectory is moving toward higher precision, increased integration, and enhanced reliability. Modern Hall Effect sensors now incorporate temperature compensation, digital interfaces, and programmable features that were unimaginable in earlier generations. The miniaturization trend has also been significant, with sensors now available in extremely compact packages suitable for space-constrained applications.

The primary objectives of current Hall Effect sensing technology development include improving sensitivity to detect weaker magnetic fields, enhancing signal-to-noise ratios for more accurate measurements, and reducing power consumption for battery-powered and energy-efficient applications. Additionally, there is a strong focus on developing sensors with broader operating temperature ranges and improved immunity to external interference.

Another critical objective is the integration of Hall Effect sensors with IoT and Industry 4.0 ecosystems, requiring advancements in digital interfaces, wireless connectivity, and data processing capabilities. This integration aims to enable predictive maintenance, real-time monitoring, and advanced control systems that leverage the unique non-contact measurement capabilities of Hall Effect technology.

The comparison between Linear Hall Effect sensors and Switch sensors represents a fundamental choice in system design, with each offering distinct advantages depending on the application requirements, measurement precision needs, and environmental constraints.

The evolution of Hall Effect technology has been marked by several key milestones. Early implementations in the mid-20th century were primarily focused on laboratory applications due to limitations in semiconductor manufacturing. The 1970s saw the first commercial Hall Effect sensors, though these were relatively simple switch-type devices with binary outputs. The 1980s and 1990s brought significant advancements with the introduction of integrated circuits that combined Hall Effect elements with signal processing capabilities, enabling more sophisticated applications.

In recent years, the technology has bifurcated into two primary categories: Linear Hall Effect sensors and Switch sensors. Linear sensors provide an analog or digital output proportional to the magnetic field strength, offering continuous measurement capabilities. In contrast, Switch sensors provide binary outputs based on magnetic threshold detection, functioning essentially as contactless switches. This divergence has expanded the application landscape dramatically, from automotive systems to industrial automation and consumer electronics.

The current technological trajectory is moving toward higher precision, increased integration, and enhanced reliability. Modern Hall Effect sensors now incorporate temperature compensation, digital interfaces, and programmable features that were unimaginable in earlier generations. The miniaturization trend has also been significant, with sensors now available in extremely compact packages suitable for space-constrained applications.

The primary objectives of current Hall Effect sensing technology development include improving sensitivity to detect weaker magnetic fields, enhancing signal-to-noise ratios for more accurate measurements, and reducing power consumption for battery-powered and energy-efficient applications. Additionally, there is a strong focus on developing sensors with broader operating temperature ranges and improved immunity to external interference.

Another critical objective is the integration of Hall Effect sensors with IoT and Industry 4.0 ecosystems, requiring advancements in digital interfaces, wireless connectivity, and data processing capabilities. This integration aims to enable predictive maintenance, real-time monitoring, and advanced control systems that leverage the unique non-contact measurement capabilities of Hall Effect technology.

The comparison between Linear Hall Effect sensors and Switch sensors represents a fundamental choice in system design, with each offering distinct advantages depending on the application requirements, measurement precision needs, and environmental constraints.

Market Applications and Demand Analysis for Hall Sensors

The global Hall sensor market has witnessed substantial growth, valued at approximately $2.1 billion in 2022 and projected to reach $3.5 billion by 2028, with a compound annual growth rate of 8.9%. This growth is primarily driven by increasing demand across automotive, industrial, consumer electronics, and aerospace sectors, where precise position sensing and contactless measurement capabilities are essential.

In the automotive industry, Hall sensors have become indispensable components in modern vehicles, with an average of 15-25 sensors per vehicle. They are utilized in critical applications including throttle position sensing, crankshaft position detection, wheel speed monitoring, and power steering systems. The transition toward electric and autonomous vehicles has further accelerated demand, as these vehicles require even more sophisticated sensing solutions for motor control and battery management systems.

Industrial automation represents another significant market segment, where Hall sensors enable precise motion control, speed detection, and position monitoring in manufacturing equipment. The Industry 4.0 revolution has intensified the need for reliable, high-precision sensors that can operate in harsh industrial environments while providing digital output compatible with modern control systems.

Consumer electronics constitutes a rapidly expanding application area, with Hall sensors incorporated into smartphones, tablets, laptops, and wearable devices. These sensors enable features such as lid closure detection, screen rotation, and power management. The miniaturization trend in consumer electronics has created demand for smaller, more energy-efficient Hall sensor solutions with enhanced sensitivity.

When comparing market demand between linear Hall effect sensors and switch sensors, distinct patterns emerge. Linear Hall sensors command premium pricing (typically 30-50% higher than switch variants) due to their ability to provide proportional output relative to magnetic field strength. This capability makes them preferred in applications requiring precise measurement and control, such as automotive throttle position sensing and industrial robotics.

Switch-type Hall sensors dominate in terms of unit volume, accounting for approximately 65% of total Hall sensor shipments. Their binary output (on/off) makes them ideal for simple presence detection, proximity sensing, and limit switches. The consumer electronics sector particularly favors these sensors due to their lower cost and simplified integration requirements.

Regional analysis reveals Asia-Pacific as the dominant market, accounting for over 45% of global demand, driven by the region's strong manufacturing base in automotive and consumer electronics. North America and Europe follow with approximately 25% and 20% market share respectively, with particular strength in high-precision industrial and aerospace applications.

In the automotive industry, Hall sensors have become indispensable components in modern vehicles, with an average of 15-25 sensors per vehicle. They are utilized in critical applications including throttle position sensing, crankshaft position detection, wheel speed monitoring, and power steering systems. The transition toward electric and autonomous vehicles has further accelerated demand, as these vehicles require even more sophisticated sensing solutions for motor control and battery management systems.

Industrial automation represents another significant market segment, where Hall sensors enable precise motion control, speed detection, and position monitoring in manufacturing equipment. The Industry 4.0 revolution has intensified the need for reliable, high-precision sensors that can operate in harsh industrial environments while providing digital output compatible with modern control systems.

Consumer electronics constitutes a rapidly expanding application area, with Hall sensors incorporated into smartphones, tablets, laptops, and wearable devices. These sensors enable features such as lid closure detection, screen rotation, and power management. The miniaturization trend in consumer electronics has created demand for smaller, more energy-efficient Hall sensor solutions with enhanced sensitivity.

When comparing market demand between linear Hall effect sensors and switch sensors, distinct patterns emerge. Linear Hall sensors command premium pricing (typically 30-50% higher than switch variants) due to their ability to provide proportional output relative to magnetic field strength. This capability makes them preferred in applications requiring precise measurement and control, such as automotive throttle position sensing and industrial robotics.

Switch-type Hall sensors dominate in terms of unit volume, accounting for approximately 65% of total Hall sensor shipments. Their binary output (on/off) makes them ideal for simple presence detection, proximity sensing, and limit switches. The consumer electronics sector particularly favors these sensors due to their lower cost and simplified integration requirements.

Regional analysis reveals Asia-Pacific as the dominant market, accounting for over 45% of global demand, driven by the region's strong manufacturing base in automotive and consumer electronics. North America and Europe follow with approximately 25% and 20% market share respectively, with particular strength in high-precision industrial and aerospace applications.

Current State and Technical Challenges in Hall Effect Sensing

Hall Effect sensing technology has evolved significantly over the past decades, with both linear Hall Effect sensors and switch sensors gaining widespread adoption across various industries. Currently, the global Hall Effect sensors market is valued at approximately $2.2 billion and is projected to reach $3.5 billion by 2026, growing at a CAGR of around 8.5%. This growth is primarily driven by increasing demand in automotive applications, industrial automation, and consumer electronics.

Linear Hall Effect sensors dominate in applications requiring precise measurement of magnetic field strength, offering analog output proportional to the magnetic field intensity. These sensors currently achieve resolution capabilities as fine as 0.1 mT, with the most advanced models featuring temperature stability of ±50 ppm/°C. However, they face challenges in power consumption, typically requiring 5-10 mA during operation, which limits their application in battery-powered devices.

Switch-type Hall Effect sensors, conversely, have achieved significant miniaturization, with some models now available in packages as small as 1.5 × 1.5 mm. These binary output sensors have improved switching speeds, with response times reduced to under 10 μs in premium models. Their power consumption advantage is substantial, with some ultra-low-power variants consuming less than 1.5 μA in standby mode.

A significant technical challenge facing both sensor types is magnetic hysteresis, which affects measurement repeatability. Current generation sensors exhibit hysteresis values ranging from 0.5% to 3% of the full-scale range, impacting precision in applications requiring high accuracy. Temperature drift remains another critical challenge, particularly in automotive and industrial environments where operating conditions can vary widely.

Interference from external magnetic fields presents an ongoing challenge, with current shielding technologies offering only partial solutions. Cross-axis sensitivity in linear sensors typically ranges from 1% to 5%, affecting measurement accuracy in multi-dimensional magnetic field environments.

Geographically, North America and Europe lead in sensor development and production of high-precision Hall Effect sensors, while Asia-Pacific dominates manufacturing volume, particularly for switch-type sensors. Japan and Germany maintain leadership in automotive-grade Hall Effect sensing technologies, with companies focusing on enhanced reliability under extreme conditions.

Recent advancements include the integration of temperature compensation algorithms directly into sensor ICs, reducing drift to below 0.01%/°C in premium models. MEMS-based Hall Effect sensors are emerging as a promising direction, offering improved sensitivity while reducing form factor. However, these innovations face challenges in manufacturing scalability and cost-effectiveness for mass-market applications.

Linear Hall Effect sensors dominate in applications requiring precise measurement of magnetic field strength, offering analog output proportional to the magnetic field intensity. These sensors currently achieve resolution capabilities as fine as 0.1 mT, with the most advanced models featuring temperature stability of ±50 ppm/°C. However, they face challenges in power consumption, typically requiring 5-10 mA during operation, which limits their application in battery-powered devices.

Switch-type Hall Effect sensors, conversely, have achieved significant miniaturization, with some models now available in packages as small as 1.5 × 1.5 mm. These binary output sensors have improved switching speeds, with response times reduced to under 10 μs in premium models. Their power consumption advantage is substantial, with some ultra-low-power variants consuming less than 1.5 μA in standby mode.

A significant technical challenge facing both sensor types is magnetic hysteresis, which affects measurement repeatability. Current generation sensors exhibit hysteresis values ranging from 0.5% to 3% of the full-scale range, impacting precision in applications requiring high accuracy. Temperature drift remains another critical challenge, particularly in automotive and industrial environments where operating conditions can vary widely.

Interference from external magnetic fields presents an ongoing challenge, with current shielding technologies offering only partial solutions. Cross-axis sensitivity in linear sensors typically ranges from 1% to 5%, affecting measurement accuracy in multi-dimensional magnetic field environments.

Geographically, North America and Europe lead in sensor development and production of high-precision Hall Effect sensors, while Asia-Pacific dominates manufacturing volume, particularly for switch-type sensors. Japan and Germany maintain leadership in automotive-grade Hall Effect sensing technologies, with companies focusing on enhanced reliability under extreme conditions.

Recent advancements include the integration of temperature compensation algorithms directly into sensor ICs, reducing drift to below 0.01%/°C in premium models. MEMS-based Hall Effect sensors are emerging as a promising direction, offering improved sensitivity while reducing form factor. However, these innovations face challenges in manufacturing scalability and cost-effectiveness for mass-market applications.

Technical Comparison Between Linear and Switch Hall Sensors

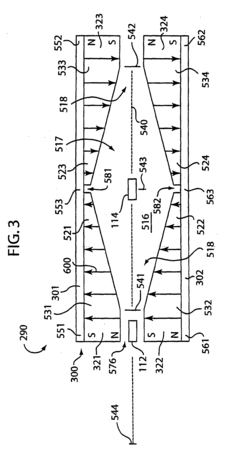

01 Hall Effect Sensor Design and Structure

Hall effect sensors are designed with specific structures to detect magnetic fields. These sensors operate based on the Hall effect principle, where a voltage is generated perpendicular to the current flow when a magnetic field is applied. The design includes semiconductor materials that respond to magnetic fields, and various structural configurations to enhance sensitivity and performance. Advanced designs incorporate features for improved accuracy, reduced size, and increased durability in various operating conditions.- Hall Effect Sensor Design and Structure: Hall effect sensors are designed with specific structures to detect magnetic fields. These sensors typically consist of a semiconductor material with current flowing through it. When exposed to a magnetic field, the charge carriers in the semiconductor experience a force perpendicular to both the current and magnetic field, creating a measurable voltage difference. Various structural designs and materials are used to optimize sensitivity, stability, and performance across different applications.

- Magnetic Field Detection and Measurement Applications: Hall effect sensors are widely used for detecting and measuring magnetic fields in various applications. These sensors can accurately determine the strength and direction of magnetic fields, making them suitable for position sensing, speed detection, and current measurement. The sensors can be integrated into systems that require precise magnetic field measurements, such as automotive systems, industrial equipment, and consumer electronics.

- Switch Sensor Mechanisms and Activation: Switch sensors utilize various mechanisms for activation and control. These mechanisms can include magnetic triggers, mechanical contacts, or electronic thresholds. When the activation condition is met, the switch changes state from open to closed or vice versa. Switch sensors can be designed with different sensitivity levels, hysteresis characteristics, and response times to suit specific application requirements.

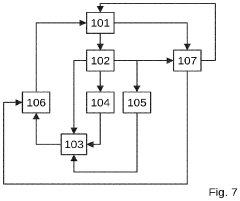

- Integration in Electronic Systems and Control Circuits: Hall effect and switch sensors are integrated into various electronic systems and control circuits. These sensors provide input signals that can be processed to control system operations. The integration involves interface circuitry, signal conditioning, and often digital processing to interpret the sensor outputs. Advanced systems may incorporate multiple sensors with sophisticated algorithms to enhance reliability and functionality.

- Automotive and Industrial Applications: Hall effect and switch sensors find extensive use in automotive and industrial applications. In automotive systems, these sensors are used for wheel speed detection, throttle position sensing, and ignition timing. Industrial applications include motor control, position detection in machinery, and safety systems. The sensors are designed to withstand harsh environments, temperature variations, and electromagnetic interference while maintaining reliable operation.

02 Magnetic Field Detection and Measurement Applications

Hall effect sensors are widely used for detecting and measuring magnetic fields in various applications. These sensors can accurately measure the strength and direction of magnetic fields, making them suitable for position sensing, speed detection, and current measurement. The technology allows for non-contact sensing, which is advantageous in harsh environments or where mechanical wear is a concern. Applications include automotive systems, industrial equipment, consumer electronics, and medical devices.Expand Specific Solutions03 Switch Sensor Mechanisms and Activation

Switch sensors utilize various mechanisms for activation, including magnetic, mechanical, and electronic triggers. These sensors can be designed to respond to specific thresholds or conditions, providing binary on/off signals or more complex outputs. The activation mechanisms can be tailored for different applications, such as proximity detection, position sensing, or safety interlocks. Advanced switch sensors may incorporate features like hysteresis to prevent rapid switching near threshold values, improving reliability and reducing wear.Expand Specific Solutions04 Integration with Electronic Systems and Signal Processing

Hall effect and switch sensors are integrated into electronic systems with signal processing capabilities to enhance functionality. These integrated systems can include amplification circuits, filtering components, and digital interfaces for communication with microcontrollers or other devices. Signal processing techniques improve sensor accuracy, reduce noise, and enable advanced features like self-calibration and diagnostics. The integration allows for compact designs and efficient power management, making these sensors suitable for battery-powered and IoT applications.Expand Specific Solutions05 Specialized Applications in Automotive and Industrial Settings

Hall effect and switch sensors are specially designed for automotive and industrial applications, where they must withstand harsh environments and provide reliable operation. In automotive systems, these sensors are used for wheel speed detection, throttle position sensing, and transmission control. Industrial applications include motor control, position feedback in automation systems, and safety interlocks. These specialized sensors feature robust packaging, extended temperature ranges, and protection against electromagnetic interference to ensure long-term reliability in demanding conditions.Expand Specific Solutions

Key Manufacturers and Competitive Landscape Analysis

The Hall Effect sensor market is currently in a growth phase, with linear sensors gaining traction over traditional switch sensors due to their superior precision and broader application range. The global market is projected to reach approximately $2 billion by 2025, driven by automotive, industrial, and consumer electronics applications. Technologically, major players exhibit varying maturity levels: Infineon Technologies, Texas Instruments, and Microchip Technology lead with comprehensive sensor portfolios and advanced manufacturing capabilities, while companies like Honeywell and CTS offer specialized solutions. Continental Automotive and Siemens are integrating these sensors into broader systems, particularly for automotive applications. Asian manufacturers such as Shanghai Awinic and Orient-Chip are rapidly advancing their technological capabilities, challenging established Western players through cost-effective solutions and growing R&D investments.

Infineon Technologies AG

Technical Solution: Infineon has developed advanced linear Hall effect sensors that utilize integrated circuit technology to provide precise analog output proportional to magnetic field strength. Their TLE4998 series features digital signal processing capabilities with programmable characteristics, allowing for customized transfer functions and temperature compensation. Infineon's sensors incorporate chopper stabilization techniques to minimize offset drift and achieve high accuracy (±1% full scale) across wide temperature ranges (-40°C to +170°C)[1]. Their XENSIV™ TLE4964 family combines linear and switch functionality in a single package, offering both threshold detection and proportional output modes. The sensors feature integrated protection circuits against overvoltage, reverse polarity, and ESD events up to 4kV, making them suitable for harsh automotive environments[2]. Infineon's approach focuses on miniaturization with packages as small as SOT23 while maintaining high sensitivity (typically 100-300 mV/mT) and low current consumption (typically 1.6mA)[3].

Strengths: Superior accuracy with digital signal processing and temperature compensation; versatile programmability allowing customization for specific applications; excellent reliability in harsh environments. Weaknesses: Higher cost compared to basic switch sensors; requires more complex implementation with additional signal conditioning; higher power consumption than simple Hall switches.

Texas Instruments Incorporated

Technical Solution: Texas Instruments has developed the DRV5000 family of Hall effect sensors that spans both linear and switch configurations. Their linear sensors utilize chopper-stabilized amplifiers and BiCMOS technology to achieve high precision magnetic field measurement with low drift characteristics. TI's approach incorporates ratiometric output scaling that automatically adjusts sensitivity based on supply voltage, maintaining consistent performance across 2.5V to 5.5V operating ranges[1]. Their linear Hall sensors feature integrated temperature compensation circuits that correct for both sensitivity and offset drift, achieving stability of less than 100ppm/°C across industrial temperature ranges[2]. TI has also implemented advanced filtering techniques to reduce noise, achieving noise density below 40 μGauss/√Hz. For automotive applications, their sensors include diagnostics features that can detect open or short circuits and provide fault indication, meeting ASIL-B functional safety requirements[3]. The DRV5055 linear Hall sensor specifically offers programmable sensitivity options and bandwidth selection to optimize performance for different applications.

Strengths: Excellent noise immunity through advanced filtering; comprehensive diagnostic capabilities for safety-critical applications; wide operating voltage range with ratiometric output. Weaknesses: More complex implementation than switch sensors; higher power consumption (typically 3.5mA vs 1.5mA for switches); requires additional signal processing for threshold detection applications.

Core Patents and Innovations in Hall Effect Sensing

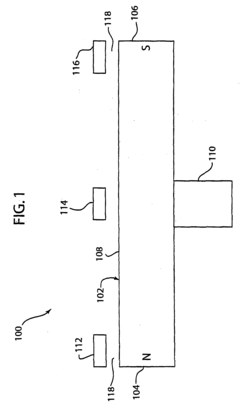

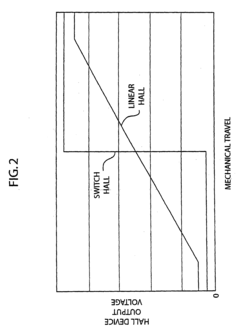

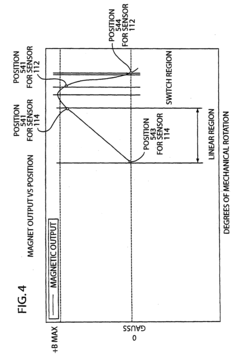

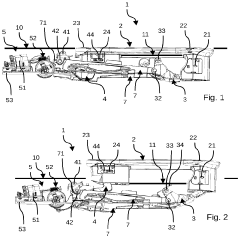

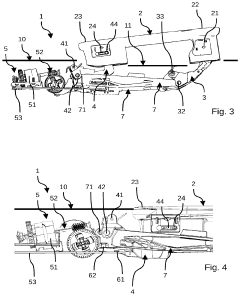

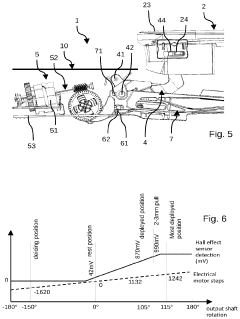

Position sensor combining hall effect sensor and switch

PatentInactiveEP1548408A2

Innovation

- A combination Hall effect position sensor and switch is integrated into a single package, using a magnet with a central and end portion, where a linear magnetic flux sensor provides positional information and a switch-type sensor indicates pre-determined positions without physical contact, enhancing precision and durability.

Vehicle door handle assembly

PatentPendingUS20240018808A1

Innovation

- A vehicle door handle assembly using a hall effect sensor or alternative position sensor in conjunction with a magnet or metallic strip, integrated with an electric motor that counts steps, allowing precise detection of the handle position without the need for multiple sensors, and a method to adjust the motor steps and angle to ensure accurate positioning.

Performance Metrics and Testing Methodologies

To effectively evaluate and compare Linear Hall Effect Sensors and Switch Sensors, standardized performance metrics and rigorous testing methodologies must be established. These frameworks enable objective assessment of sensor capabilities across various operational parameters and environmental conditions.

Sensitivity represents a critical performance metric for both sensor types, though measured differently. For Linear Hall Effect Sensors, sensitivity is typically quantified in mV/G or V/T, indicating voltage output change per unit magnetic field strength. Switch Sensors are evaluated by their operate and release points, measured in Gauss or Tesla, determining the magnetic field thresholds for state changes.

Response time constitutes another essential metric, measuring the interval between magnetic field application and corresponding output signal generation. Linear Hall Effect Sensors generally demonstrate faster response times (microseconds range) compared to mechanical switch sensors, though specialized electronic switch sensors can achieve comparable performance.

Hysteresis characteristics differ significantly between these sensor technologies. Linear Hall Effect Sensors exhibit minimal hysteresis, providing consistent output regardless of approach direction. Conversely, Switch Sensors intentionally incorporate hysteresis to prevent oscillation at threshold boundaries, with the difference between operate and release points typically specified as a percentage of the operate point.

Temperature stability testing reveals distinct performance profiles. Linear sensors often incorporate temperature compensation circuits, maintaining relatively stable output across wide temperature ranges. Switch sensors may demonstrate greater threshold drift with temperature variations, necessitating comprehensive thermal testing across the intended operational range.

Durability testing methodologies include accelerated life testing, involving millions of operational cycles under various environmental conditions. Linear Hall Effect Sensors, lacking mechanical components, generally demonstrate superior longevity compared to mechanical switch alternatives, though electronic switch sensors offer comparable reliability.

Signal-to-noise ratio (SNR) testing is particularly relevant for Linear Hall Effect Sensors in precision applications. Testing protocols typically involve measuring output stability under controlled magnetic field conditions, with higher-quality sensors demonstrating superior SNR characteristics.

Power consumption assessment reveals that Linear Hall Effect Sensors typically require continuous power, while certain Switch Sensor implementations can operate with minimal or intermittent power. Testing methodologies include measuring current draw across various operational states and environmental conditions.

Standardized testing environments must control for external magnetic interference, temperature variations, and mechanical vibrations to ensure reproducible results. Industry standards such as IEC 60947-5-2 provide guidelines for proximity sensor testing, applicable to magnetic sensors with appropriate modifications for specific applications.

Sensitivity represents a critical performance metric for both sensor types, though measured differently. For Linear Hall Effect Sensors, sensitivity is typically quantified in mV/G or V/T, indicating voltage output change per unit magnetic field strength. Switch Sensors are evaluated by their operate and release points, measured in Gauss or Tesla, determining the magnetic field thresholds for state changes.

Response time constitutes another essential metric, measuring the interval between magnetic field application and corresponding output signal generation. Linear Hall Effect Sensors generally demonstrate faster response times (microseconds range) compared to mechanical switch sensors, though specialized electronic switch sensors can achieve comparable performance.

Hysteresis characteristics differ significantly between these sensor technologies. Linear Hall Effect Sensors exhibit minimal hysteresis, providing consistent output regardless of approach direction. Conversely, Switch Sensors intentionally incorporate hysteresis to prevent oscillation at threshold boundaries, with the difference between operate and release points typically specified as a percentage of the operate point.

Temperature stability testing reveals distinct performance profiles. Linear sensors often incorporate temperature compensation circuits, maintaining relatively stable output across wide temperature ranges. Switch sensors may demonstrate greater threshold drift with temperature variations, necessitating comprehensive thermal testing across the intended operational range.

Durability testing methodologies include accelerated life testing, involving millions of operational cycles under various environmental conditions. Linear Hall Effect Sensors, lacking mechanical components, generally demonstrate superior longevity compared to mechanical switch alternatives, though electronic switch sensors offer comparable reliability.

Signal-to-noise ratio (SNR) testing is particularly relevant for Linear Hall Effect Sensors in precision applications. Testing protocols typically involve measuring output stability under controlled magnetic field conditions, with higher-quality sensors demonstrating superior SNR characteristics.

Power consumption assessment reveals that Linear Hall Effect Sensors typically require continuous power, while certain Switch Sensor implementations can operate with minimal or intermittent power. Testing methodologies include measuring current draw across various operational states and environmental conditions.

Standardized testing environments must control for external magnetic interference, temperature variations, and mechanical vibrations to ensure reproducible results. Industry standards such as IEC 60947-5-2 provide guidelines for proximity sensor testing, applicable to magnetic sensors with appropriate modifications for specific applications.

Integration Challenges and Implementation Considerations

When implementing Hall effect sensing solutions, engineers face distinct integration challenges depending on whether they choose linear sensors or switch sensors. Linear Hall effect sensors require more complex signal conditioning circuitry, including amplification stages and analog-to-digital converters to properly process their continuous output signals. This additional circuitry increases both design complexity and component count, potentially raising system costs and power consumption. Furthermore, linear sensors are more susceptible to electromagnetic interference (EMI), necessitating careful PCB layout and appropriate shielding techniques to maintain measurement accuracy.

Switch-based Hall sensors present different integration challenges, primarily centered around hysteresis management. Engineers must carefully select devices with appropriate switching thresholds for their specific application to avoid unintended triggering from mechanical vibrations or electrical noise. The binary nature of switch sensors also requires thoughtful system design to compensate for their lack of proportional feedback, often necessitating additional sensors or mechanical components when precise position information is needed.

Temperature compensation represents a critical implementation consideration for both sensor types. Linear Hall effect sensors typically exhibit temperature drift that must be calibrated or compensated for in software, requiring additional development effort and potentially on-board temperature sensors. Switch sensors, while generally less affected by temperature variations, may still experience threshold shifts that must be accounted for in safety-critical applications.

Power management strategies differ significantly between these technologies. Linear sensors typically consume more power due to their continuous operation and associated signal processing requirements. Switch sensors offer more power-efficient operation, particularly in battery-powered applications where they can be operated in low-duty-cycle configurations. However, this advantage may be offset if the application requires frequent polling or continuous monitoring.

Mechanical integration considerations also vary between sensor types. Linear Hall effect sensors often provide more flexibility in mounting positions since they can detect field strength variations across distances. Switch sensors typically require more precise positioning relative to the magnetic source to ensure reliable triggering at the desired points. This positioning sensitivity may necessitate tighter mechanical tolerances during manufacturing and assembly.

Finally, firmware and software integration complexity differs substantially. Linear sensors require more sophisticated calibration routines and signal processing algorithms to extract meaningful measurements from their analog outputs. Switch sensors simplify software requirements with their binary outputs but may require debouncing algorithms and careful interrupt handling to prevent false triggers in noisy environments.

Switch-based Hall sensors present different integration challenges, primarily centered around hysteresis management. Engineers must carefully select devices with appropriate switching thresholds for their specific application to avoid unintended triggering from mechanical vibrations or electrical noise. The binary nature of switch sensors also requires thoughtful system design to compensate for their lack of proportional feedback, often necessitating additional sensors or mechanical components when precise position information is needed.

Temperature compensation represents a critical implementation consideration for both sensor types. Linear Hall effect sensors typically exhibit temperature drift that must be calibrated or compensated for in software, requiring additional development effort and potentially on-board temperature sensors. Switch sensors, while generally less affected by temperature variations, may still experience threshold shifts that must be accounted for in safety-critical applications.

Power management strategies differ significantly between these technologies. Linear sensors typically consume more power due to their continuous operation and associated signal processing requirements. Switch sensors offer more power-efficient operation, particularly in battery-powered applications where they can be operated in low-duty-cycle configurations. However, this advantage may be offset if the application requires frequent polling or continuous monitoring.

Mechanical integration considerations also vary between sensor types. Linear Hall effect sensors often provide more flexibility in mounting positions since they can detect field strength variations across distances. Switch sensors typically require more precise positioning relative to the magnetic source to ensure reliable triggering at the desired points. This positioning sensitivity may necessitate tighter mechanical tolerances during manufacturing and assembly.

Finally, firmware and software integration complexity differs substantially. Linear sensors require more sophisticated calibration routines and signal processing algorithms to extract meaningful measurements from their analog outputs. Switch sensors simplify software requirements with their binary outputs but may require debouncing algorithms and careful interrupt handling to prevent false triggers in noisy environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!