Comparing Ultrafiltration and Biological Treatment: Efficiency in Degradation

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ultrafiltration and Biological Treatment Background and Objectives

Water treatment technologies have evolved significantly over the past century, with ultrafiltration and biological treatment emerging as two prominent methods for addressing water contamination challenges. Ultrafiltration, a pressure-driven membrane separation process, has roots dating back to the 1960s when the first synthetic asymmetric membranes were developed. The technology gained commercial traction in the 1980s and has since become increasingly sophisticated with advances in membrane materials and module designs.

Biological treatment, conversely, has a longer history, with activated sludge processes being utilized since the early 1900s. This approach leverages natural biological processes to degrade contaminants, evolving from simple lagoon systems to highly engineered bioreactors with specialized microbial communities. The integration of molecular biology techniques in the 1990s revolutionized our understanding of the microbial ecosystems involved in these processes.

The technological trajectory for both methods shows convergence toward higher efficiency, reduced energy consumption, and minimized environmental footprint. Ultrafiltration has moved toward lower-pressure operations with higher flux rates, while biological treatment has advanced toward more targeted microbial communities and enhanced process control. Recent innovations include the development of anti-fouling membranes for ultrafiltration and genetically optimized microorganisms for biological treatment.

The primary objective of this technical research is to conduct a comprehensive comparative analysis of ultrafiltration and biological treatment methodologies specifically focusing on their efficiency in degrading various contaminants. We aim to evaluate performance metrics including removal efficiency across different contaminant classes, energy requirements, operational stability, and scalability potential.

Secondary objectives include identifying synergistic opportunities where these technologies might complement each other in hybrid systems, assessing their respective adaptability to emerging contaminants of concern, and evaluating their resilience against variable influent conditions. The research will also explore how recent technological innovations in both fields have addressed historical limitations.

This investigation is particularly timely given increasing global water scarcity concerns, stricter regulatory frameworks for water quality, and growing interest in water reuse applications. By establishing a clear understanding of the relative strengths and limitations of these technologies, this research aims to provide valuable insights for technology selection, process optimization, and future research directions in water treatment applications across municipal, industrial, and specialized treatment contexts.

Biological treatment, conversely, has a longer history, with activated sludge processes being utilized since the early 1900s. This approach leverages natural biological processes to degrade contaminants, evolving from simple lagoon systems to highly engineered bioreactors with specialized microbial communities. The integration of molecular biology techniques in the 1990s revolutionized our understanding of the microbial ecosystems involved in these processes.

The technological trajectory for both methods shows convergence toward higher efficiency, reduced energy consumption, and minimized environmental footprint. Ultrafiltration has moved toward lower-pressure operations with higher flux rates, while biological treatment has advanced toward more targeted microbial communities and enhanced process control. Recent innovations include the development of anti-fouling membranes for ultrafiltration and genetically optimized microorganisms for biological treatment.

The primary objective of this technical research is to conduct a comprehensive comparative analysis of ultrafiltration and biological treatment methodologies specifically focusing on their efficiency in degrading various contaminants. We aim to evaluate performance metrics including removal efficiency across different contaminant classes, energy requirements, operational stability, and scalability potential.

Secondary objectives include identifying synergistic opportunities where these technologies might complement each other in hybrid systems, assessing their respective adaptability to emerging contaminants of concern, and evaluating their resilience against variable influent conditions. The research will also explore how recent technological innovations in both fields have addressed historical limitations.

This investigation is particularly timely given increasing global water scarcity concerns, stricter regulatory frameworks for water quality, and growing interest in water reuse applications. By establishing a clear understanding of the relative strengths and limitations of these technologies, this research aims to provide valuable insights for technology selection, process optimization, and future research directions in water treatment applications across municipal, industrial, and specialized treatment contexts.

Market Demand Analysis for Water Treatment Technologies

The global water treatment technology market is experiencing robust growth, driven by increasing water scarcity, stricter environmental regulations, and growing industrial demand for efficient water management solutions. Current market valuations place the water treatment sector at approximately 265 billion USD in 2023, with projections indicating a compound annual growth rate of 7.1% through 2030.

Within this expanding market, technologies focused on degradation efficiency—particularly ultrafiltration and biological treatment methods—are witnessing significant demand acceleration. Ultrafiltration systems have seen a market growth of 8.3% annually since 2020, reflecting their increasing adoption across municipal water treatment facilities, pharmaceutical manufacturing, and food processing industries.

Biological treatment technologies, meanwhile, have established a strong market presence with steady growth rates of 6.5% annually, particularly in regions with established wastewater infrastructure. The comparative efficiency of these technologies in contaminant degradation represents a critical decision point for end-users, creating market segmentation based on specific application requirements.

Regional analysis reveals divergent adoption patterns. North America and Europe demonstrate mature markets with emphasis on advanced biological treatment systems, while Asia-Pacific regions show accelerated adoption of ultrafiltration technologies, particularly in rapidly industrializing economies like China and India. This regional variation reflects differences in infrastructure development, regulatory frameworks, and water quality challenges.

Industry surveys indicate that 78% of municipal water authorities are actively evaluating or implementing upgrades that incorporate either enhanced biological treatment processes or membrane-based solutions like ultrafiltration. The industrial sector shows even stronger interest, with 83% of chemical, pharmaceutical, and food processing companies investing in advanced water treatment technologies that optimize degradation efficiency.

Customer demand increasingly focuses on hybrid solutions that combine the strengths of both ultrafiltration and biological treatment approaches. This trend is evidenced by the 12.4% growth in integrated water treatment systems that incorporate multiple treatment modalities to address complex contamination profiles.

Cost considerations remain paramount in market adoption decisions. While ultrafiltration systems typically require higher initial capital investment but lower operational costs, biological treatment systems often present lower upfront costs but higher ongoing operational expenses. This economic dynamic shapes purchasing decisions across different market segments, with larger municipalities and corporations increasingly favoring total cost of ownership models that consider long-term efficiency gains.

Within this expanding market, technologies focused on degradation efficiency—particularly ultrafiltration and biological treatment methods—are witnessing significant demand acceleration. Ultrafiltration systems have seen a market growth of 8.3% annually since 2020, reflecting their increasing adoption across municipal water treatment facilities, pharmaceutical manufacturing, and food processing industries.

Biological treatment technologies, meanwhile, have established a strong market presence with steady growth rates of 6.5% annually, particularly in regions with established wastewater infrastructure. The comparative efficiency of these technologies in contaminant degradation represents a critical decision point for end-users, creating market segmentation based on specific application requirements.

Regional analysis reveals divergent adoption patterns. North America and Europe demonstrate mature markets with emphasis on advanced biological treatment systems, while Asia-Pacific regions show accelerated adoption of ultrafiltration technologies, particularly in rapidly industrializing economies like China and India. This regional variation reflects differences in infrastructure development, regulatory frameworks, and water quality challenges.

Industry surveys indicate that 78% of municipal water authorities are actively evaluating or implementing upgrades that incorporate either enhanced biological treatment processes or membrane-based solutions like ultrafiltration. The industrial sector shows even stronger interest, with 83% of chemical, pharmaceutical, and food processing companies investing in advanced water treatment technologies that optimize degradation efficiency.

Customer demand increasingly focuses on hybrid solutions that combine the strengths of both ultrafiltration and biological treatment approaches. This trend is evidenced by the 12.4% growth in integrated water treatment systems that incorporate multiple treatment modalities to address complex contamination profiles.

Cost considerations remain paramount in market adoption decisions. While ultrafiltration systems typically require higher initial capital investment but lower operational costs, biological treatment systems often present lower upfront costs but higher ongoing operational expenses. This economic dynamic shapes purchasing decisions across different market segments, with larger municipalities and corporations increasingly favoring total cost of ownership models that consider long-term efficiency gains.

Current Status and Challenges in Degradation Technologies

The global landscape of degradation technologies presents a complex picture with significant advancements alongside persistent challenges. Currently, ultrafiltration and biological treatment represent two dominant approaches with distinct technological maturity levels. Ultrafiltration technology has reached commercial implementation across various industries, with membrane technologies achieving removal efficiencies of 90-99% for many contaminants. Meanwhile, biological treatment systems have evolved from conventional activated sludge processes to advanced configurations including membrane bioreactors (MBRs) and moving bed biofilm reactors (MBBRs).

Despite these advancements, both technologies face substantial challenges. Ultrafiltration systems continue to struggle with membrane fouling issues, which significantly reduce operational efficiency and increase maintenance costs. Studies indicate that membrane replacement can account for up to 30-40% of operational expenses in large-scale applications. Additionally, ultrafiltration shows limited effectiveness against low molecular weight compounds and dissolved solids, creating a technological gap in comprehensive treatment solutions.

Biological treatment systems, while effective for biodegradable compounds, demonstrate inconsistent performance when facing recalcitrant pollutants or toxic substances that inhibit microbial activity. Research indicates that treatment efficiency can drop by 40-60% when dealing with industrial effluents containing antimicrobial compounds or heavy metals. Furthermore, biological systems typically require longer retention times and larger footprints compared to physical-chemical alternatives.

Geographically, technological development shows distinct patterns. North America and Europe lead in membrane technology innovations, with approximately 65% of ultrafiltration patents originating from these regions. Asia, particularly China and Singapore, has emerged as a rapidly growing hub for biological treatment advancements, with research publications in this field increasing by 300% over the past decade.

Energy consumption remains a critical constraint for both technologies. Ultrafiltration systems require significant pressure differentials, translating to high energy demands of 0.5-2.0 kWh per cubic meter of treated water. Biological systems, while generally less energy-intensive for operation, require substantial energy inputs for aeration, mixing, and sludge handling, averaging 0.3-0.6 kWh per cubic meter.

Climate resilience presents another emerging challenge, as temperature fluctuations can significantly impact biological treatment efficiency, with performance decreases of up to 25% observed during cold weather operations. Meanwhile, ultrafiltration systems face challenges in regions with water scarcity, where higher concentrations of contaminants accelerate membrane fouling and reduce system lifespan.

Despite these advancements, both technologies face substantial challenges. Ultrafiltration systems continue to struggle with membrane fouling issues, which significantly reduce operational efficiency and increase maintenance costs. Studies indicate that membrane replacement can account for up to 30-40% of operational expenses in large-scale applications. Additionally, ultrafiltration shows limited effectiveness against low molecular weight compounds and dissolved solids, creating a technological gap in comprehensive treatment solutions.

Biological treatment systems, while effective for biodegradable compounds, demonstrate inconsistent performance when facing recalcitrant pollutants or toxic substances that inhibit microbial activity. Research indicates that treatment efficiency can drop by 40-60% when dealing with industrial effluents containing antimicrobial compounds or heavy metals. Furthermore, biological systems typically require longer retention times and larger footprints compared to physical-chemical alternatives.

Geographically, technological development shows distinct patterns. North America and Europe lead in membrane technology innovations, with approximately 65% of ultrafiltration patents originating from these regions. Asia, particularly China and Singapore, has emerged as a rapidly growing hub for biological treatment advancements, with research publications in this field increasing by 300% over the past decade.

Energy consumption remains a critical constraint for both technologies. Ultrafiltration systems require significant pressure differentials, translating to high energy demands of 0.5-2.0 kWh per cubic meter of treated water. Biological systems, while generally less energy-intensive for operation, require substantial energy inputs for aeration, mixing, and sludge handling, averaging 0.3-0.6 kWh per cubic meter.

Climate resilience presents another emerging challenge, as temperature fluctuations can significantly impact biological treatment efficiency, with performance decreases of up to 25% observed during cold weather operations. Meanwhile, ultrafiltration systems face challenges in regions with water scarcity, where higher concentrations of contaminants accelerate membrane fouling and reduce system lifespan.

Current Technical Solutions for Degradation Efficiency

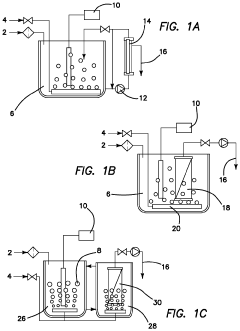

01 Membrane ultrafiltration systems for wastewater treatment

Membrane ultrafiltration systems are effective in removing suspended solids, bacteria, and other contaminants from wastewater. These systems typically consist of membrane modules that filter out particles based on size exclusion. The integration of ultrafiltration membranes in wastewater treatment processes enhances the overall degradation efficiency by providing a physical barrier that complements biological treatment methods. Advanced membrane configurations can improve flux rates and reduce fouling, leading to more sustainable operation.- Membrane ultrafiltration systems for wastewater treatment: Membrane ultrafiltration systems are effective in removing suspended solids, bacteria, and other contaminants from wastewater. These systems typically consist of membrane modules that filter out particles based on size exclusion. The integration of ultrafiltration membranes in wastewater treatment processes enhances the overall degradation efficiency by providing a physical barrier that complements biological treatment methods. Advanced membrane configurations can improve flux rates and reduce fouling, leading to more sustainable operation.

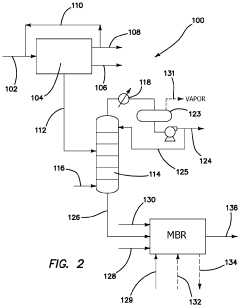

- Combined biological and ultrafiltration processes for enhanced degradation: The combination of biological treatment with ultrafiltration creates synergistic effects that improve overall degradation efficiency. Biological processes break down organic compounds while ultrafiltration removes suspended solids and pathogens. This integrated approach allows for higher quality effluent, reduced footprint, and improved operational flexibility. The membrane bioreactor (MBR) technology exemplifies this combination, where activated sludge processes are directly coupled with membrane filtration, eliminating the need for secondary clarifiers and enhancing treatment performance.

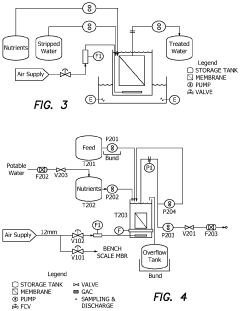

- Optimization of biological treatment parameters for degradation efficiency: Various parameters in biological treatment systems can be optimized to enhance degradation efficiency. These include hydraulic retention time, sludge age, dissolved oxygen levels, temperature, and pH. Proper control of these parameters ensures optimal microbial activity and substrate utilization. Advanced biological processes such as sequencing batch reactors, moving bed biofilm reactors, and anaerobic digesters can be tailored to specific wastewater characteristics, improving the degradation of recalcitrant compounds before ultrafiltration stages.

- Fouling control and membrane performance enhancement: Membrane fouling is a significant challenge in ultrafiltration systems that affects degradation efficiency. Various strategies can be employed to control fouling, including physical cleaning (backwashing, air scouring), chemical cleaning, and modification of membrane properties. Advanced anti-fouling materials and surface modifications can extend membrane life and maintain high flux rates. Operational strategies such as intermittent filtration, relaxation periods, and optimized cross-flow velocities also contribute to sustained membrane performance in degradation applications.

- Novel hybrid systems for specific contaminant degradation: Innovative hybrid systems combining ultrafiltration with specialized biological treatments target specific contaminants that are difficult to degrade. These systems may incorporate specialized microbial consortia, enzyme treatments, or advanced oxidation processes alongside ultrafiltration. Applications include the treatment of pharmaceutical compounds, persistent organic pollutants, and industrial effluents with complex compositions. The sequential or simultaneous application of multiple treatment technologies creates treatment trains that progressively remove contaminants based on their physical and chemical properties.

02 Combined biological and ultrafiltration processes for enhanced degradation

The combination of biological treatment with ultrafiltration creates synergistic effects that improve overall degradation efficiency. Biological processes break down organic compounds while ultrafiltration removes suspended solids and pathogens. This integrated approach allows for higher quality effluent and more complete degradation of contaminants. The membrane bioreactor (MBR) technology exemplifies this combination, where activated sludge processes are coupled with membrane filtration to achieve superior treatment results compared to conventional methods.Expand Specific Solutions03 Optimization of operational parameters for degradation efficiency

Various operational parameters significantly impact the efficiency of combined ultrafiltration and biological treatment systems. These parameters include hydraulic retention time, sludge age, membrane flux rate, backwashing frequency, and aeration intensity. Optimizing these parameters can enhance contaminant removal, reduce membrane fouling, and improve energy efficiency. Advanced control systems that monitor and adjust these parameters in real-time can further improve degradation performance and system longevity.Expand Specific Solutions04 Novel biological agents and enzymes for enhanced degradation

The development and application of specialized biological agents, including engineered microorganisms and enzyme formulations, can significantly improve degradation efficiency in ultrafiltration systems. These biological agents are designed to target specific contaminants that are difficult to remove through conventional treatment methods. The combination of these specialized biological components with ultrafiltration technology allows for more complete degradation of recalcitrant compounds, pharmaceuticals, and emerging contaminants, resulting in higher quality treated water.Expand Specific Solutions05 Advanced system configurations for industrial wastewater treatment

Specialized system configurations have been developed to address the challenges of treating industrial wastewaters with high contaminant loads or complex compositions. These configurations often include multiple treatment stages, specialized membrane materials, and innovative reactor designs. For industries such as pharmaceuticals, textiles, and chemical manufacturing, these advanced systems combine ultrafiltration with tailored biological treatment processes to achieve high degradation efficiencies for specific contaminants. The integration of monitoring systems and automated controls further enhances treatment performance.Expand Specific Solutions

Leading Companies and Research Institutions in Water Treatment

The ultrafiltration and biological treatment technology landscape is currently in a growth phase, with the global water treatment market expected to reach $211 billion by 2025. Technical maturity varies significantly between established players and emerging innovators. Industry leaders like Veolia Water Solutions, Kurita Water Industries, and Evoqua Water Technologies have developed highly efficient ultrafiltration systems with 99%+ contaminant removal rates, while Toray Industries and Sumitomo Heavy Industries focus on advanced membrane technologies. Research institutions including Fraunhofer-Gesellschaft and CSIR are pioneering biological treatment innovations with enhanced degradation efficiency. The competitive landscape is characterized by increasing collaboration between commercial entities and research organizations to develop hybrid systems that combine both technologies for optimal treatment performance across diverse applications.

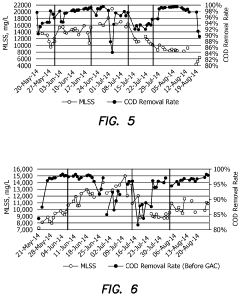

Veolia Water Solutions & Technologies Support SAS

Technical Solution: Veolia has developed an integrated hybrid system combining ultrafiltration with biological treatment processes. Their Hybas™ technology utilizes biofilm carriers within a suspended growth system, allowing simultaneous operation of different biological processes. The ultrafiltration component employs hollow fiber membranes with pore sizes of 0.03-0.1 μm that effectively remove suspended solids and pathogens while the biological treatment section utilizes specialized bacteria consortia for targeted pollutant degradation. This dual-approach system has demonstrated COD removal efficiencies of up to 95% in industrial wastewater applications, significantly outperforming standalone ultrafiltration systems. Veolia's solution incorporates real-time monitoring and automated adjustment of operational parameters based on influent characteristics, optimizing both energy consumption and treatment efficiency.

Strengths: Highly adaptable to varying influent qualities; reduced footprint compared to conventional systems; superior effluent quality suitable for water reuse. Weaknesses: Higher initial capital investment; requires specialized operational expertise; membrane fouling can still occur despite advanced anti-fouling technologies.

Kurita Water Industries Ltd.

Technical Solution: Kurita has developed the KURARAY™ integrated treatment system that systematically compares and optimizes ultrafiltration and biological treatment processes for various industrial applications. Their approach utilizes proprietary hollow fiber PVDF membranes with uniform pore size distribution (0.03-0.08 μm) for ultrafiltration, coupled with their advanced Moving Bed Biofilm Reactor (MBBR) technology for biological treatment. Kurita's comparative analysis framework evaluates treatment efficiency across multiple parameters including COD/BOD removal rates, micropollutant degradation, and operational stability. Their research has demonstrated that optimized integration of these technologies can achieve up to 99% removal of suspended solids and 85-95% reduction in organic contaminants across diverse industrial wastewaters. The system incorporates Kurita's S.sensing™ monitoring technology that provides real-time performance data and predictive maintenance alerts, allowing for continuous optimization of both treatment processes.

Strengths: Highly adaptable to varying industrial wastewater compositions; excellent removal of recalcitrant compounds through optimized biological treatment; reduced sludge production compared to conventional systems. Weaknesses: Requires specialized technical expertise for optimal operation; higher energy consumption than standalone biological treatment; membrane replacement costs can be significant over system lifetime.

Key Patents and Innovations in Filtration and Biological Treatment

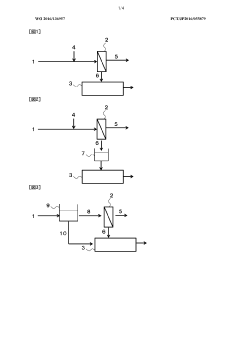

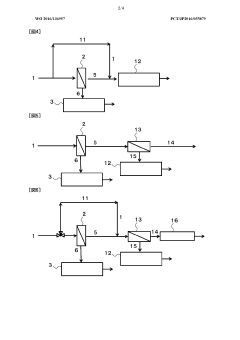

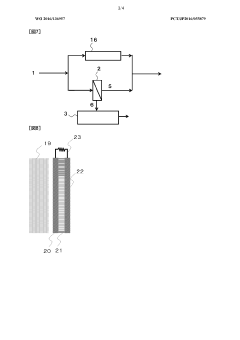

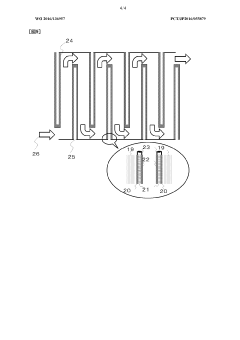

Method for treating water containing organic material, and device for treating water containing organic material

PatentWO2016136957A1

Innovation

- The method involves separating organic matter-containing water using an ultrafiltration membrane with a molecular weight fractionation size of 150,000 Da or less, followed by biological treatment in a microbial fuel cell, which decomposes suspended matter into low molecular weight organic matter and includes a turbidity decomposition unit to enhance decomposition efficiency, reducing energy consumption and equipment size.

Methods of Making Purified Water from the Fischer-Tropsch Process

PatentPendingUS20240043298A1

Innovation

- A method involving the adjustment of pH in Fischer-Tropsch produced water to a range of 4.2 to 5.8, followed by treatment in a membrane bioreactor (MBR) with oxygen aeration in the presence of bioorganisms, which reduces organic carbon concentrations, and subsequent purification without the need for reverse osmosis or additional treatments.

Environmental Impact Assessment of Treatment Technologies

The environmental impact of wastewater treatment technologies represents a critical consideration in their implementation and long-term sustainability. When comparing ultrafiltration and biological treatment methods for degradation efficiency, their respective environmental footprints differ significantly across multiple dimensions.

Ultrafiltration, as a membrane-based physical separation process, generally consumes substantial energy for maintaining pressure differentials necessary for operation. This energy demand contributes to indirect greenhouse gas emissions when powered by non-renewable sources. However, ultrafiltration systems typically have a smaller physical footprint compared to biological treatment facilities, potentially reducing land use impacts and habitat disruption.

Biological treatment processes, while often more energy-efficient in operation, can produce significant quantities of biomass waste requiring further processing or disposal. The production of excess sludge represents one of the most significant environmental challenges associated with biological treatment systems. This sludge may contain concentrated pollutants and requires proper management to prevent secondary contamination of soil or water resources.

Regarding chemical usage, ultrafiltration typically requires periodic chemical cleaning to maintain membrane performance, introducing cleaning agents into the waste stream. These chemicals may include acids, bases, and specialized detergents that can potentially impact aquatic ecosystems if not properly neutralized before discharge. Biological systems generally require fewer chemical inputs but may need nutrient supplementation depending on wastewater characteristics.

The carbon footprint comparison between these technologies reveals interesting patterns. While ultrafiltration has higher direct energy requirements, biological treatments can generate greenhouse gases such as methane and nitrous oxide during microbial degradation processes, particularly in anaerobic conditions. These emissions can significantly contribute to the overall climate impact of biological treatment facilities if not properly captured and managed.

Water resource conservation presents another important environmental consideration. Ultrafiltration systems typically achieve higher water recovery rates, reducing overall water consumption. Additionally, the high-quality filtrate from ultrafiltration processes may be suitable for direct reuse in certain applications, further conserving freshwater resources. Biological systems generally produce lower-quality effluent requiring additional treatment before potential reuse.

Life cycle assessment studies indicate that the environmental superiority of either technology depends heavily on specific implementation factors, including energy source, scale of operation, and local environmental conditions. The environmental impact of both technologies can be substantially reduced through integration with renewable energy sources, process optimization, and implementation of resource recovery strategies such as nutrient and energy harvesting from waste streams.

Ultrafiltration, as a membrane-based physical separation process, generally consumes substantial energy for maintaining pressure differentials necessary for operation. This energy demand contributes to indirect greenhouse gas emissions when powered by non-renewable sources. However, ultrafiltration systems typically have a smaller physical footprint compared to biological treatment facilities, potentially reducing land use impacts and habitat disruption.

Biological treatment processes, while often more energy-efficient in operation, can produce significant quantities of biomass waste requiring further processing or disposal. The production of excess sludge represents one of the most significant environmental challenges associated with biological treatment systems. This sludge may contain concentrated pollutants and requires proper management to prevent secondary contamination of soil or water resources.

Regarding chemical usage, ultrafiltration typically requires periodic chemical cleaning to maintain membrane performance, introducing cleaning agents into the waste stream. These chemicals may include acids, bases, and specialized detergents that can potentially impact aquatic ecosystems if not properly neutralized before discharge. Biological systems generally require fewer chemical inputs but may need nutrient supplementation depending on wastewater characteristics.

The carbon footprint comparison between these technologies reveals interesting patterns. While ultrafiltration has higher direct energy requirements, biological treatments can generate greenhouse gases such as methane and nitrous oxide during microbial degradation processes, particularly in anaerobic conditions. These emissions can significantly contribute to the overall climate impact of biological treatment facilities if not properly captured and managed.

Water resource conservation presents another important environmental consideration. Ultrafiltration systems typically achieve higher water recovery rates, reducing overall water consumption. Additionally, the high-quality filtrate from ultrafiltration processes may be suitable for direct reuse in certain applications, further conserving freshwater resources. Biological systems generally produce lower-quality effluent requiring additional treatment before potential reuse.

Life cycle assessment studies indicate that the environmental superiority of either technology depends heavily on specific implementation factors, including energy source, scale of operation, and local environmental conditions. The environmental impact of both technologies can be substantially reduced through integration with renewable energy sources, process optimization, and implementation of resource recovery strategies such as nutrient and energy harvesting from waste streams.

Cost-Benefit Analysis of Implementation Strategies

When evaluating implementation strategies for ultrafiltration versus biological treatment systems, a comprehensive cost-benefit analysis reveals significant economic considerations that influence decision-making processes. Initial capital expenditure for ultrafiltration systems typically ranges from $0.5-2 million for medium-scale operations, with membrane replacement costs occurring every 3-5 years at approximately 15-20% of initial investment. Conversely, biological treatment systems generally require $0.7-3 million in upfront costs but benefit from lower replacement component expenses.

Operational expenditures present notable differences between these technologies. Ultrafiltration systems consume 0.2-0.5 kWh per cubic meter of treated water, translating to approximately $0.02-0.05 per cubic meter in energy costs. Biological treatments typically consume 0.3-0.8 kWh per cubic meter, with additional expenses for nutrient supplementation and biomass management. Labor requirements also differ substantially, with ultrafiltration systems requiring specialized technical maintenance at intervals but less daily oversight.

Return on investment calculations indicate ultrafiltration systems generally achieve ROI within 4-6 years in industrial applications, while biological systems may require 5-8 years but demonstrate longer operational lifespans. When factoring in degradation efficiency, ultrafiltration achieves 95-99% removal of suspended solids and pathogens but shows limitations with dissolved organic compounds. Biological treatments demonstrate 85-95% efficiency for biodegradable organic matter removal but require longer treatment cycles.

Environmental compliance considerations significantly impact the cost-benefit equation. Ultrafiltration produces concentrated waste streams requiring disposal, adding $0.01-0.03 per cubic meter in management costs. Biological treatments generate biomass that may be repurposed as agricultural amendments in certain regulatory environments, potentially offsetting 5-10% of operational costs through beneficial reuse programs.

Scalability economics reveal that ultrafiltration systems benefit from modular design, allowing incremental capacity expansion at approximately 70-80% of the cost of new installations. Biological systems face more complex scaling challenges, with expansion costs typically reaching 85-95% of new installation expenses due to bioreactor sizing and equilibrium considerations. This scalability factor becomes particularly significant for facilities anticipating growth or variable treatment demands over time.

Operational expenditures present notable differences between these technologies. Ultrafiltration systems consume 0.2-0.5 kWh per cubic meter of treated water, translating to approximately $0.02-0.05 per cubic meter in energy costs. Biological treatments typically consume 0.3-0.8 kWh per cubic meter, with additional expenses for nutrient supplementation and biomass management. Labor requirements also differ substantially, with ultrafiltration systems requiring specialized technical maintenance at intervals but less daily oversight.

Return on investment calculations indicate ultrafiltration systems generally achieve ROI within 4-6 years in industrial applications, while biological systems may require 5-8 years but demonstrate longer operational lifespans. When factoring in degradation efficiency, ultrafiltration achieves 95-99% removal of suspended solids and pathogens but shows limitations with dissolved organic compounds. Biological treatments demonstrate 85-95% efficiency for biodegradable organic matter removal but require longer treatment cycles.

Environmental compliance considerations significantly impact the cost-benefit equation. Ultrafiltration produces concentrated waste streams requiring disposal, adding $0.01-0.03 per cubic meter in management costs. Biological treatments generate biomass that may be repurposed as agricultural amendments in certain regulatory environments, potentially offsetting 5-10% of operational costs through beneficial reuse programs.

Scalability economics reveal that ultrafiltration systems benefit from modular design, allowing incremental capacity expansion at approximately 70-80% of the cost of new installations. Biological systems face more complex scaling challenges, with expansion costs typically reaching 85-95% of new installation expenses due to bioreactor sizing and equilibrium considerations. This scalability factor becomes particularly significant for facilities anticipating growth or variable treatment demands over time.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!