Compare FTIR vs Pyrolysis-Gas Chromatography: Analytical Power

SEP 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

FTIR and Py-GC Analytical Evolution and Objectives

Fourier Transform Infrared Spectroscopy (FTIR) and Pyrolysis-Gas Chromatography (Py-GC) have evolved significantly since their inception, transforming analytical chemistry capabilities across multiple industries. FTIR technology emerged in the 1960s as an advancement over dispersive IR spectroscopy, utilizing mathematical Fourier transforms to convert interferometric data into spectral information. This innovation dramatically improved signal-to-noise ratios and data acquisition speeds, making real-time analysis possible.

The 1970s and 1980s witnessed substantial miniaturization and computerization of FTIR systems, transitioning from room-sized equipment to benchtop instruments. By the 1990s, the integration of advanced detectors and sampling accessories expanded FTIR applications into previously challenging areas such as microanalysis and in-situ measurements. Modern FTIR systems now feature portable and handheld configurations, enabling field analysis capabilities that were once confined to laboratory settings.

Pyrolysis-Gas Chromatography developed along a parallel but distinct trajectory. Initially conceived in the 1950s for analyzing polymeric materials, Py-GC combines thermal decomposition with chromatographic separation. The 1980s marked a turning point with the introduction of capillary columns and improved pyrolysis interfaces, significantly enhancing separation efficiency and reproducibility.

The coupling of Py-GC with mass spectrometry (Py-GC/MS) in the 1990s represented a revolutionary advancement, enabling precise identification of pyrolysis products and expanding analytical capabilities for complex matrices. Recent developments include microwave-assisted pyrolysis and ultra-fast pyrolysis techniques, which have further refined the temporal resolution and sensitivity of the method.

The primary objective in comparing these technologies is to establish their respective analytical strengths, limitations, and complementary aspects. Specifically, this assessment aims to determine optimal applications for each technique across various sample types, concentration ranges, and analytical requirements. Additionally, the evaluation seeks to identify scenarios where combined or sequential application of both methods might yield superior analytical outcomes.

Future technical goals include developing integrated analytical platforms that leverage the molecular structural information from FTIR with the compositional specificity of Py-GC. Such integration would address current analytical gaps in complex material characterization, particularly for emerging materials in renewable energy, advanced composites, and biodegradable polymers. The ultimate objective is to establish comprehensive analytical protocols that maximize information extraction while minimizing sample requirements and analysis time.

The 1970s and 1980s witnessed substantial miniaturization and computerization of FTIR systems, transitioning from room-sized equipment to benchtop instruments. By the 1990s, the integration of advanced detectors and sampling accessories expanded FTIR applications into previously challenging areas such as microanalysis and in-situ measurements. Modern FTIR systems now feature portable and handheld configurations, enabling field analysis capabilities that were once confined to laboratory settings.

Pyrolysis-Gas Chromatography developed along a parallel but distinct trajectory. Initially conceived in the 1950s for analyzing polymeric materials, Py-GC combines thermal decomposition with chromatographic separation. The 1980s marked a turning point with the introduction of capillary columns and improved pyrolysis interfaces, significantly enhancing separation efficiency and reproducibility.

The coupling of Py-GC with mass spectrometry (Py-GC/MS) in the 1990s represented a revolutionary advancement, enabling precise identification of pyrolysis products and expanding analytical capabilities for complex matrices. Recent developments include microwave-assisted pyrolysis and ultra-fast pyrolysis techniques, which have further refined the temporal resolution and sensitivity of the method.

The primary objective in comparing these technologies is to establish their respective analytical strengths, limitations, and complementary aspects. Specifically, this assessment aims to determine optimal applications for each technique across various sample types, concentration ranges, and analytical requirements. Additionally, the evaluation seeks to identify scenarios where combined or sequential application of both methods might yield superior analytical outcomes.

Future technical goals include developing integrated analytical platforms that leverage the molecular structural information from FTIR with the compositional specificity of Py-GC. Such integration would address current analytical gaps in complex material characterization, particularly for emerging materials in renewable energy, advanced composites, and biodegradable polymers. The ultimate objective is to establish comprehensive analytical protocols that maximize information extraction while minimizing sample requirements and analysis time.

Market Applications and Demand Analysis

The market for analytical instrumentation continues to expand as industries increasingly rely on precise chemical analysis for quality control, research, and regulatory compliance. FTIR (Fourier Transform Infrared Spectroscopy) and Pyrolysis-Gas Chromatography (Py-GC) represent two distinct yet complementary analytical approaches with different market applications and demand drivers.

The pharmaceutical industry demonstrates strong demand for both technologies, with FTIR being particularly valued for its rapid identification of raw materials and finished products. The global pharmaceutical analytical testing market is projected to grow at a compound annual growth rate of 8.6% through 2028, with spectroscopy techniques accounting for approximately one-third of this market. FTIR's non-destructive testing capability makes it especially attractive for quality control applications where sample preservation is critical.

Environmental monitoring represents another significant market segment, where Py-GC techniques have gained substantial traction. The ability to analyze complex environmental samples, particularly microplastics and polymer degradation products in marine environments, has positioned Py-GC as an essential tool for environmental scientists and regulatory bodies. This application area has seen demand growth of nearly 12% annually as global focus on plastic pollution intensifies.

The polymer and materials science sector utilizes both technologies extensively, with FTIR dominating routine quality control while Py-GC provides deeper compositional analysis. Market research indicates that approximately 65% of polymer manufacturers employ FTIR for daily quality assurance, while 40% utilize Py-GC for more complex formulation and failure analysis.

Food and beverage industry applications have created a rapidly expanding market segment, particularly for FTIR technology. Its ability to rapidly analyze nutritional components, detect adulterants, and verify authenticity has driven adoption rates up by 15% annually in this sector. Meanwhile, Py-GC finds specialized applications in flavor and fragrance analysis, though with a smaller market footprint.

The forensic science field represents a niche but growing market for both technologies. Py-GC's superior ability to analyze trace evidence like paint chips, fibers, and adhesives has made it indispensable in criminal investigations, while FTIR provides complementary data for material identification.

Regional market analysis reveals that North America and Europe currently dominate demand for both technologies, accounting for approximately 60% of global market share. However, the Asia-Pacific region is experiencing the fastest growth rate, driven by expanding pharmaceutical manufacturing, environmental regulations, and materials research initiatives in China, India, and South Korea.

The pharmaceutical industry demonstrates strong demand for both technologies, with FTIR being particularly valued for its rapid identification of raw materials and finished products. The global pharmaceutical analytical testing market is projected to grow at a compound annual growth rate of 8.6% through 2028, with spectroscopy techniques accounting for approximately one-third of this market. FTIR's non-destructive testing capability makes it especially attractive for quality control applications where sample preservation is critical.

Environmental monitoring represents another significant market segment, where Py-GC techniques have gained substantial traction. The ability to analyze complex environmental samples, particularly microplastics and polymer degradation products in marine environments, has positioned Py-GC as an essential tool for environmental scientists and regulatory bodies. This application area has seen demand growth of nearly 12% annually as global focus on plastic pollution intensifies.

The polymer and materials science sector utilizes both technologies extensively, with FTIR dominating routine quality control while Py-GC provides deeper compositional analysis. Market research indicates that approximately 65% of polymer manufacturers employ FTIR for daily quality assurance, while 40% utilize Py-GC for more complex formulation and failure analysis.

Food and beverage industry applications have created a rapidly expanding market segment, particularly for FTIR technology. Its ability to rapidly analyze nutritional components, detect adulterants, and verify authenticity has driven adoption rates up by 15% annually in this sector. Meanwhile, Py-GC finds specialized applications in flavor and fragrance analysis, though with a smaller market footprint.

The forensic science field represents a niche but growing market for both technologies. Py-GC's superior ability to analyze trace evidence like paint chips, fibers, and adhesives has made it indispensable in criminal investigations, while FTIR provides complementary data for material identification.

Regional market analysis reveals that North America and Europe currently dominate demand for both technologies, accounting for approximately 60% of global market share. However, the Asia-Pacific region is experiencing the fastest growth rate, driven by expanding pharmaceutical manufacturing, environmental regulations, and materials research initiatives in China, India, and South Korea.

Current Capabilities and Technical Limitations

FTIR spectroscopy currently offers rapid analysis capabilities with minimal sample preparation requirements. Modern FTIR instruments can complete scans in seconds to minutes, providing immediate molecular structure information through characteristic absorption bands. The technique excels in identifying functional groups and can detect compounds at concentrations as low as parts per million in optimal conditions. Its non-destructive nature preserves samples for further analysis, making it particularly valuable for rare or limited specimens.

However, FTIR faces significant limitations in complex mixture analysis. The technique struggles with spectral overlap in multi-component samples, where absorption bands from different compounds may coincide, complicating interpretation. Quantitative analysis remains challenging, especially for minor components in complex matrices. Additionally, FTIR shows reduced sensitivity compared to chromatographic methods, typically operating in the parts per million range rather than parts per billion.

Pyrolysis-Gas Chromatography (Py-GC) demonstrates superior capabilities in complex mixture separation and identification. The technique can effectively analyze high molecular weight compounds that are difficult to examine with traditional GC methods. Modern Py-GC systems achieve detection limits in the parts per billion range, significantly outperforming FTIR in sensitivity. When coupled with mass spectrometry (Py-GC/MS), the technique provides detailed structural information and precise compound identification.

Despite these advantages, Py-GC presents several technical challenges. The technique is inherently destructive, consuming the entire sample during analysis and preventing subsequent testing. Pyrolysis conditions must be carefully controlled, as variations in temperature, heating rate, and residence time can significantly affect results and reproducibility. The complex data interpretation requires specialized expertise and reference libraries, creating a steeper learning curve compared to FTIR.

Both techniques face common limitations in standardization. Method development remains highly application-specific, requiring extensive optimization for each new sample type. Reference databases, while expanding, still contain gaps for novel compounds or specific material combinations. Quantitative analysis in both techniques requires careful calibration and validation, often necessitating complementary analytical methods for comprehensive characterization.

Recent technological advances have partially addressed these limitations through hybrid approaches and enhanced data processing. AI-assisted spectral interpretation has improved FTIR's ability to deconvolute complex spectra, while advanced pyrolysis interfaces have enhanced Py-GC reproducibility. However, significant technical challenges remain in achieving comprehensive single-method analysis for complex materials.

However, FTIR faces significant limitations in complex mixture analysis. The technique struggles with spectral overlap in multi-component samples, where absorption bands from different compounds may coincide, complicating interpretation. Quantitative analysis remains challenging, especially for minor components in complex matrices. Additionally, FTIR shows reduced sensitivity compared to chromatographic methods, typically operating in the parts per million range rather than parts per billion.

Pyrolysis-Gas Chromatography (Py-GC) demonstrates superior capabilities in complex mixture separation and identification. The technique can effectively analyze high molecular weight compounds that are difficult to examine with traditional GC methods. Modern Py-GC systems achieve detection limits in the parts per billion range, significantly outperforming FTIR in sensitivity. When coupled with mass spectrometry (Py-GC/MS), the technique provides detailed structural information and precise compound identification.

Despite these advantages, Py-GC presents several technical challenges. The technique is inherently destructive, consuming the entire sample during analysis and preventing subsequent testing. Pyrolysis conditions must be carefully controlled, as variations in temperature, heating rate, and residence time can significantly affect results and reproducibility. The complex data interpretation requires specialized expertise and reference libraries, creating a steeper learning curve compared to FTIR.

Both techniques face common limitations in standardization. Method development remains highly application-specific, requiring extensive optimization for each new sample type. Reference databases, while expanding, still contain gaps for novel compounds or specific material combinations. Quantitative analysis in both techniques requires careful calibration and validation, often necessitating complementary analytical methods for comprehensive characterization.

Recent technological advances have partially addressed these limitations through hybrid approaches and enhanced data processing. AI-assisted spectral interpretation has improved FTIR's ability to deconvolute complex spectra, while advanced pyrolysis interfaces have enhanced Py-GC reproducibility. However, significant technical challenges remain in achieving comprehensive single-method analysis for complex materials.

Comparative Methodologies and Implementation Approaches

01 FTIR spectroscopy for material analysis and characterization

Fourier Transform Infrared (FTIR) spectroscopy is used for analyzing and characterizing various materials by measuring the absorption of infrared radiation. This technique helps identify chemical bonds and functional groups in samples, providing valuable information about material composition. FTIR can be applied to analyze polymers, organic compounds, and other materials, offering high sensitivity and accuracy in detecting chemical structures.- FTIR spectroscopy for material analysis: Fourier Transform Infrared (FTIR) spectroscopy is used for analyzing the chemical composition of various materials by measuring the absorption of infrared radiation. This technique helps identify functional groups and molecular structures in samples. FTIR provides detailed information about chemical bonds and can be used for both qualitative and quantitative analysis, making it valuable for material characterization, quality control, and research applications.

- Pyrolysis-Gas Chromatography techniques: Pyrolysis-Gas Chromatography (Py-GC) involves the thermal decomposition of samples followed by gas chromatographic separation of the resulting fragments. This analytical technique is particularly useful for analyzing complex polymers, composites, and organic materials that cannot be directly analyzed by conventional gas chromatography. The method provides detailed compositional information and can identify trace components in complex matrices.

- Combined analytical systems for enhanced characterization: Integration of multiple analytical techniques, particularly FTIR with Pyrolysis-Gas Chromatography, creates powerful systems for comprehensive material characterization. These combined approaches allow for both structural and compositional analysis in a single workflow. The synergistic use of these techniques provides more complete information about complex samples than either method alone, enabling better identification of unknown materials and more accurate quality control.

- Advanced detection methods in analytical instrumentation: Modern analytical systems incorporate advanced detection technologies to enhance sensitivity, selectivity, and reliability. These include mass spectrometry detectors, specialized infrared sensors, and multi-detector arrays that can simultaneously capture different types of analytical data. Advanced detection methods improve the limits of detection, reduce interference, and enable the analysis of increasingly complex sample matrices across various applications.

- Sample preparation and handling innovations: Innovations in sample preparation and handling techniques significantly enhance the analytical power of FTIR and Pyrolysis-Gas Chromatography. These include automated sample introduction systems, micro-sampling techniques, and specialized preparation methods for difficult materials. Proper sample preparation ensures representative results, improves reproducibility, and extends the range of materials that can be effectively analyzed using these powerful analytical techniques.

02 Pyrolysis-Gas Chromatography for complex sample analysis

Pyrolysis-Gas Chromatography (Py-GC) is a powerful analytical technique that combines thermal decomposition with gas chromatography to analyze complex samples. This method involves heating samples to high temperatures in an inert atmosphere, causing them to break down into smaller, volatile fragments that can then be separated and analyzed by gas chromatography. Py-GC is particularly useful for analyzing polymers, composites, and other materials that are difficult to analyze by conventional methods.Expand Specific Solutions03 Combined FTIR and Py-GC techniques for enhanced analytical power

The combination of FTIR spectroscopy and Pyrolysis-Gas Chromatography provides enhanced analytical capabilities for complex material characterization. This integrated approach allows for both structural identification through FTIR and detailed compositional analysis through Py-GC. The complementary nature of these techniques enables more comprehensive analysis of samples, providing information about both the chemical structure and the thermal decomposition products, which is particularly valuable for polymer analysis, forensic science, and environmental studies.Expand Specific Solutions04 Automated systems and methods for FTIR and Py-GC analysis

Automated systems have been developed to enhance the efficiency and accuracy of FTIR and Pyrolysis-Gas Chromatography analyses. These systems incorporate advanced software, robotics, and integrated hardware components to streamline sample preparation, data collection, and analysis processes. Automation reduces human error, increases throughput, and enables more consistent results across multiple samples. These systems often include features for real-time monitoring, data processing, and result interpretation.Expand Specific Solutions05 Applications of FTIR and Py-GC in environmental and industrial monitoring

FTIR and Pyrolysis-Gas Chromatography techniques are widely applied in environmental and industrial monitoring to detect and analyze pollutants, contaminants, and process materials. These analytical methods help in identifying harmful substances in air, water, and soil samples, as well as in quality control of industrial products. The high sensitivity and specificity of these techniques make them valuable tools for regulatory compliance, environmental protection, and industrial process optimization.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The FTIR and Pyrolysis-Gas Chromatography analytical techniques market is in a mature growth phase, with an estimated global analytical instrumentation market exceeding $5 billion. Technical maturity varies between the methods, with FTIR being more established and widely adopted across industries. Key players demonstrate different specialization patterns: Smiths Detection, Horiba, and Spectra Analysis Instruments focus on advanced spectroscopy solutions; Saudi Aramco, Halliburton, and Schlumberger leverage these technologies for petroleum analysis; while academic institutions like Heriot-Watt University and Southeast University drive fundamental research innovations. Pharmaceutical companies such as Roche are expanding applications in drug development, while environmental monitoring represents a growing segment with companies like Saam and Pulmonir developing specialized detection systems. The competitive landscape shows a blend of established instrumentation providers and application-specific solution developers.

Saudi Arabian Oil Co.

Technical Solution: Saudi Aramco has developed comprehensive analytical protocols comparing FTIR and Py-GC techniques for petroleum characterization and quality control applications. Their approach focuses on crude oil fingerprinting, refinery process monitoring, and petroleum product authentication. Aramco's research laboratories have established detailed correlation matrices between FTIR spectral features and Py-GC chromatographic patterns for various crude oil types and refined products. Their methodology employs FTIR as a rapid screening tool for process monitoring and quality control, while utilizing Py-GC for detailed compositional verification and contaminant identification. Aramco has pioneered the use of chemometric models that integrate data from both techniques to predict key petroleum properties and detect adulterations. Their comparative analytical framework includes specialized sample preparation protocols that minimize matrix effects when comparing results across both platforms. Aramco's research has quantified the relative analytical power of each technique for specific applications, establishing decision trees for optimal analytical method selection based on sample type and information requirements.

Strengths: Extensive experience with diverse petroleum samples; sophisticated chemometric models integrating both techniques; comprehensive databases correlating spectroscopic and chromatographic features. Weaknesses: Highly specialized for petroleum industry applications; proprietary nature of some analytical protocols limits broader scientific validation.

Halliburton Energy Services, Inc.

Technical Solution: Halliburton has developed specialized analytical protocols for comparing FTIR and Py-GC techniques specifically optimized for petroleum industry applications. Their approach focuses on reservoir fluid characterization, drilling fluid analysis, and formation damage assessment. Halliburton's comparative methodology employs FTIR for rapid on-site screening of drilling fluids and contaminants, while utilizing Py-GC for detailed hydrocarbon typing and source rock characterization. Their proprietary software integrates data from both techniques to provide comprehensive fluid property predictions and contamination assessments. Halliburton has pioneered downhole FTIR tools that can be correlated with laboratory Py-GC results, creating a multi-scale analytical framework spanning from field to lab environments. Their research has established specific correlation parameters between FTIR functional group analysis and Py-GC biomarker identification for reservoir connectivity studies and fluid compatibility assessments.

Strengths: Industry-specific optimization for petroleum applications; seamless integration between field and laboratory analytical workflows; extensive experience with complex hydrocarbon mixtures. Weaknesses: Limited applicability outside petroleum industry contexts; proprietary nature of correlation algorithms restricts academic validation.

Key Innovations in Molecular Structure Analysis

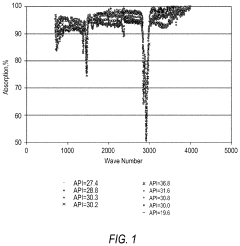

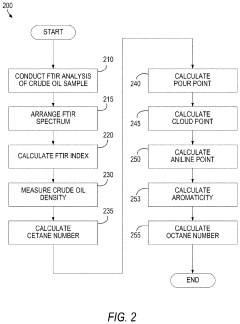

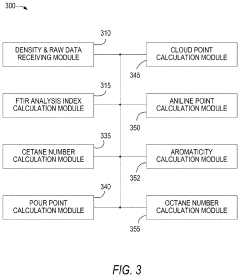

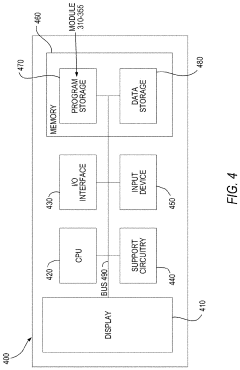

Characterization of crude oil and its fractions by fourier transform infrared (FTIR) spectroscopy analysis

PatentActiveUS20200264156A1

Innovation

- Employing Fourier Transform Infrared Spectroscopy (FTIR) analysis to directly assess the density and FTIR index of crude oil samples, allowing for the prediction of indicative properties without fractionation, using a system that includes an FTIR spectrophotometer and calculation modules to derive properties like cetane number, pour point, and aromaticity.

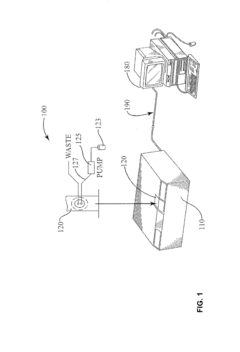

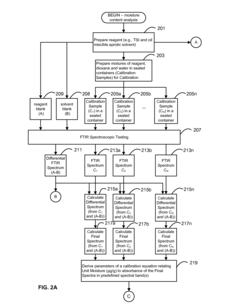

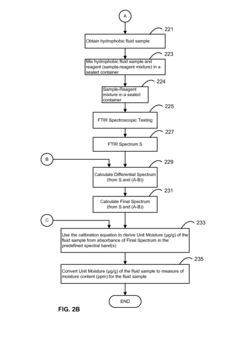

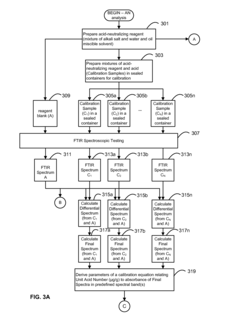

FTIR System and Method for Compositional Analysis of Matter

PatentInactiveUS20170059411A1

Innovation

- A system and method using FTIR spectroscopy that involves preparing reagents reacting with the sample to produce carbon dioxide gas, allowing for calibration equations to be derived from standard mixtures, enabling precise measurement of moisture, acidity, or basicity by analyzing absorbance in specific spectral bands, which can be applied to various hydrophobic fluids and solid matrices.

Sample Preparation Optimization Strategies

Sample preparation represents a critical determinant in the analytical performance of both FTIR and Pyrolysis-Gas Chromatography techniques. Optimizing these preparatory steps can significantly enhance sensitivity, reproducibility, and accuracy of results while minimizing potential interferences and contamination.

For FTIR analysis, several preparation strategies have demonstrated superior outcomes. The KBr pellet method remains widely utilized, with optimization focusing on consistent sample-to-KBr ratios (typically 1:100 to 1:200) and uniform grinding to prevent scattering effects. Vacuum drying of KBr powder prior to pellet formation effectively reduces moisture interference, particularly important for hygroscopic samples. Attenuated Total Reflection (ATR) accessories have revolutionized sample preparation by enabling direct analysis with minimal processing, though surface contact optimization remains essential for quantitative work.

Pyrolysis-GC sample preparation presents distinct challenges requiring specialized approaches. Precise temperature control during pyrolysis significantly impacts reproducibility, with step-wise temperature programs often yielding more comprehensive chemical profiles than single-temperature methods. Sample encapsulation in quartz tubes or specialized cups prevents contamination and ensures complete pyrolysis. For complex matrices, pre-extraction steps using appropriate solvents can remove potential interferents, though care must be taken to avoid removing compounds of interest.

Cryogenic grinding has emerged as a valuable preparation technique for both methodologies, particularly for polymeric or fibrous samples. By maintaining samples below their glass transition temperature during grinding, structural integrity is preserved while achieving the necessary particle size reduction. This approach has shown particular promise for heterogeneous materials where conventional grinding may cause localized heating and chemical alterations.

Derivatization strategies can significantly enhance analytical capabilities, especially for Pyrolysis-GC. Tetramethylammonium hydroxide (TMAH) thermochemolysis has proven effective for analyzing fatty acids and phenolic compounds, while silylation agents improve chromatographic behavior of polar compounds. For FTIR, chemical derivatization can shift absorption bands to less congested spectral regions, improving specificity in complex mixtures.

Microsampling techniques represent the frontier of sample preparation optimization, with laser microdissection enabling targeted analysis of specific regions within heterogeneous samples. This approach has particular value in cultural heritage applications and forensic analysis where sample conservation is paramount and spatial resolution provides critical contextual information.

For FTIR analysis, several preparation strategies have demonstrated superior outcomes. The KBr pellet method remains widely utilized, with optimization focusing on consistent sample-to-KBr ratios (typically 1:100 to 1:200) and uniform grinding to prevent scattering effects. Vacuum drying of KBr powder prior to pellet formation effectively reduces moisture interference, particularly important for hygroscopic samples. Attenuated Total Reflection (ATR) accessories have revolutionized sample preparation by enabling direct analysis with minimal processing, though surface contact optimization remains essential for quantitative work.

Pyrolysis-GC sample preparation presents distinct challenges requiring specialized approaches. Precise temperature control during pyrolysis significantly impacts reproducibility, with step-wise temperature programs often yielding more comprehensive chemical profiles than single-temperature methods. Sample encapsulation in quartz tubes or specialized cups prevents contamination and ensures complete pyrolysis. For complex matrices, pre-extraction steps using appropriate solvents can remove potential interferents, though care must be taken to avoid removing compounds of interest.

Cryogenic grinding has emerged as a valuable preparation technique for both methodologies, particularly for polymeric or fibrous samples. By maintaining samples below their glass transition temperature during grinding, structural integrity is preserved while achieving the necessary particle size reduction. This approach has shown particular promise for heterogeneous materials where conventional grinding may cause localized heating and chemical alterations.

Derivatization strategies can significantly enhance analytical capabilities, especially for Pyrolysis-GC. Tetramethylammonium hydroxide (TMAH) thermochemolysis has proven effective for analyzing fatty acids and phenolic compounds, while silylation agents improve chromatographic behavior of polar compounds. For FTIR, chemical derivatization can shift absorption bands to less congested spectral regions, improving specificity in complex mixtures.

Microsampling techniques represent the frontier of sample preparation optimization, with laser microdissection enabling targeted analysis of specific regions within heterogeneous samples. This approach has particular value in cultural heritage applications and forensic analysis where sample conservation is paramount and spatial resolution provides critical contextual information.

Environmental Impact and Sustainability Considerations

The environmental impact of analytical techniques is becoming increasingly important in scientific research and industrial applications. When comparing FTIR (Fourier Transform Infrared Spectroscopy) and Pyrolysis-Gas Chromatography techniques, their environmental footprints differ significantly across multiple dimensions.

FTIR spectroscopy generally demonstrates superior environmental credentials due to its non-destructive nature and minimal sample preparation requirements. The technique typically requires small sample quantities and generates minimal waste, with most samples remaining intact after analysis. Additionally, modern FTIR instruments are energy-efficient, with relatively low power consumption during operation compared to many other analytical technologies.

In contrast, Pyrolysis-Gas Chromatography involves thermal decomposition processes that consume considerable energy. The technique requires heating samples to high temperatures (typically 500-1000°C), resulting in significant energy expenditure. Furthermore, the carrier gases used in gas chromatography—often helium or hydrogen—present sustainability concerns, with helium being a finite natural resource facing global supply challenges.

Waste generation represents another critical environmental consideration. FTIR produces minimal chemical waste, with most analyses requiring no solvents or reagents. Conversely, Pyrolysis-GC often necessitates sample preparation involving organic solvents and generates post-analysis waste that may contain hazardous decomposition products requiring specialized disposal procedures.

The lifecycle assessment of both technologies reveals that FTIR instruments generally have longer operational lifespans with fewer consumable parts, reducing electronic waste generation. Modern FTIR systems also incorporate energy-saving features such as standby modes and efficient optical designs that minimize environmental impact during routine laboratory operations.

Regulatory compliance considerations are increasingly influencing analytical technique selection. Many organizations are adopting green chemistry principles that favor techniques with reduced environmental footprints. FTIR aligns well with these principles through its non-destructive methodology and minimal waste generation, potentially offering advantages in regulatory reporting and sustainability metrics.

Future developments in both technologies are focusing on enhancing environmental performance. Innovations in FTIR include more energy-efficient components and miniaturized systems, while Pyrolysis-GC research explores alternative carrier gases and more efficient heating technologies to reduce resource consumption. These advancements may eventually narrow the sustainability gap between these analytical approaches.

FTIR spectroscopy generally demonstrates superior environmental credentials due to its non-destructive nature and minimal sample preparation requirements. The technique typically requires small sample quantities and generates minimal waste, with most samples remaining intact after analysis. Additionally, modern FTIR instruments are energy-efficient, with relatively low power consumption during operation compared to many other analytical technologies.

In contrast, Pyrolysis-Gas Chromatography involves thermal decomposition processes that consume considerable energy. The technique requires heating samples to high temperatures (typically 500-1000°C), resulting in significant energy expenditure. Furthermore, the carrier gases used in gas chromatography—often helium or hydrogen—present sustainability concerns, with helium being a finite natural resource facing global supply challenges.

Waste generation represents another critical environmental consideration. FTIR produces minimal chemical waste, with most analyses requiring no solvents or reagents. Conversely, Pyrolysis-GC often necessitates sample preparation involving organic solvents and generates post-analysis waste that may contain hazardous decomposition products requiring specialized disposal procedures.

The lifecycle assessment of both technologies reveals that FTIR instruments generally have longer operational lifespans with fewer consumable parts, reducing electronic waste generation. Modern FTIR systems also incorporate energy-saving features such as standby modes and efficient optical designs that minimize environmental impact during routine laboratory operations.

Regulatory compliance considerations are increasingly influencing analytical technique selection. Many organizations are adopting green chemistry principles that favor techniques with reduced environmental footprints. FTIR aligns well with these principles through its non-destructive methodology and minimal waste generation, potentially offering advantages in regulatory reporting and sustainability metrics.

Future developments in both technologies are focusing on enhancing environmental performance. Innovations in FTIR include more energy-efficient components and miniaturized systems, while Pyrolysis-GC research explores alternative carrier gases and more efficient heating technologies to reduce resource consumption. These advancements may eventually narrow the sustainability gap between these analytical approaches.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!