Comparison of Vacuum Forming vs. Traditional Casting Methods

JUL 30, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Manufacturing Evolution

The evolution of manufacturing processes has been a continuous journey of innovation and improvement, with vacuum forming and traditional casting methods representing significant milestones in this progression. The transition from traditional casting to vacuum forming exemplifies the industry's pursuit of more efficient, cost-effective, and versatile production techniques.

Traditional casting methods, such as sand casting and investment casting, have been utilized for centuries. These processes involve pouring molten material into a mold and allowing it to solidify, forming the desired shape. While effective for producing complex shapes and working with a wide range of materials, traditional casting often requires significant time, labor, and material resources.

The advent of vacuum forming in the mid-20th century marked a significant leap forward in manufacturing technology. This process involves heating a sheet of thermoplastic material and using vacuum pressure to conform it to a mold's shape. Vacuum forming offered several advantages over traditional casting, including faster production times, lower tooling costs, and the ability to produce large, thin-walled parts with intricate details.

As manufacturing demands evolved, vacuum forming found widespread adoption in industries such as packaging, automotive, and consumer goods. Its ability to produce lightweight, durable parts with consistent quality made it particularly attractive for mass production scenarios. The process also allowed for greater design flexibility and reduced material waste compared to traditional casting methods.

The shift towards vacuum forming reflects broader trends in manufacturing evolution, including the drive for process automation, material efficiency, and reduced production cycles. This transition has been further accelerated by advancements in materials science, with the development of high-performance thermoplastics expanding the range of applications for vacuum-formed products.

However, it's important to note that the evolution from traditional casting to vacuum forming has not been a complete replacement. Rather, it represents a diversification of manufacturing techniques, with each method finding its niche based on specific product requirements, production volumes, and material properties. Traditional casting methods remain irreplaceable for certain applications, particularly in industries requiring high-strength metal components or extremely complex geometries.

The ongoing evolution of manufacturing continues to push the boundaries of both vacuum forming and traditional casting. Innovations such as computer-controlled mold design, advanced material formulations, and hybrid manufacturing processes are further refining these techniques, blurring the lines between different production methods and opening new possibilities for product design and manufacturing efficiency.

Traditional casting methods, such as sand casting and investment casting, have been utilized for centuries. These processes involve pouring molten material into a mold and allowing it to solidify, forming the desired shape. While effective for producing complex shapes and working with a wide range of materials, traditional casting often requires significant time, labor, and material resources.

The advent of vacuum forming in the mid-20th century marked a significant leap forward in manufacturing technology. This process involves heating a sheet of thermoplastic material and using vacuum pressure to conform it to a mold's shape. Vacuum forming offered several advantages over traditional casting, including faster production times, lower tooling costs, and the ability to produce large, thin-walled parts with intricate details.

As manufacturing demands evolved, vacuum forming found widespread adoption in industries such as packaging, automotive, and consumer goods. Its ability to produce lightweight, durable parts with consistent quality made it particularly attractive for mass production scenarios. The process also allowed for greater design flexibility and reduced material waste compared to traditional casting methods.

The shift towards vacuum forming reflects broader trends in manufacturing evolution, including the drive for process automation, material efficiency, and reduced production cycles. This transition has been further accelerated by advancements in materials science, with the development of high-performance thermoplastics expanding the range of applications for vacuum-formed products.

However, it's important to note that the evolution from traditional casting to vacuum forming has not been a complete replacement. Rather, it represents a diversification of manufacturing techniques, with each method finding its niche based on specific product requirements, production volumes, and material properties. Traditional casting methods remain irreplaceable for certain applications, particularly in industries requiring high-strength metal components or extremely complex geometries.

The ongoing evolution of manufacturing continues to push the boundaries of both vacuum forming and traditional casting. Innovations such as computer-controlled mold design, advanced material formulations, and hybrid manufacturing processes are further refining these techniques, blurring the lines between different production methods and opening new possibilities for product design and manufacturing efficiency.

Market Demand Analysis

The market demand for vacuum forming and traditional casting methods continues to evolve, driven by various industries' needs for efficient and cost-effective manufacturing processes. Vacuum forming has gained significant traction in recent years due to its versatility, speed, and ability to produce complex shapes with relatively low tooling costs. This method has found widespread application in packaging, automotive, aerospace, and consumer goods industries.

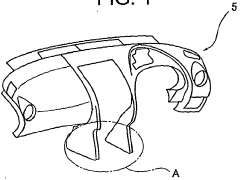

The packaging sector, in particular, has shown a strong preference for vacuum-formed products, especially in food packaging and retail displays. The ability to create lightweight, durable, and visually appealing containers has led to increased adoption in this sector. Additionally, the automotive industry has embraced vacuum forming for interior components, such as dashboards and door panels, due to its ability to produce large, lightweight parts with consistent quality.

Traditional casting methods, including die casting and investment casting, maintain a strong market presence in industries requiring high-strength, precision metal components. The aerospace and defense sectors continue to rely heavily on these methods for producing critical parts that demand exceptional mechanical properties and tight tolerances. The automotive industry also utilizes traditional casting for engine components and structural elements that require superior strength and durability.

The medical device industry has shown growing interest in both vacuum forming and traditional casting methods. Vacuum forming is increasingly used for producing disposable medical trays and packaging, while traditional casting remains crucial for manufacturing implants and surgical instruments that require biocompatible metals and precise geometries.

Market trends indicate a shift towards more sustainable manufacturing processes, which has influenced the demand for both vacuum forming and traditional casting. Vacuum forming has an advantage in this area due to its ability to use recycled plastics and produce lightweight parts that contribute to fuel efficiency in transportation applications. However, traditional casting methods are also adapting by incorporating more recycled materials and optimizing processes to reduce energy consumption.

The global market for plastic thermoforming, which includes vacuum forming, has been expanding steadily. This growth is attributed to the increasing demand for packaged food products, healthcare supplies, and consumer electronics. On the other hand, the metal casting market, while mature, continues to grow moderately, driven by the need for complex metal components in various industries.

As industries increasingly focus on customization and rapid prototyping, vacuum forming has gained an edge due to its lower tooling costs and faster turnaround times for small to medium production runs. This has made it particularly attractive for startups and companies looking to test new product designs quickly. Traditional casting, however, remains the preferred choice for high-volume production of metal parts where the initial tooling costs can be amortized over large production runs.

The packaging sector, in particular, has shown a strong preference for vacuum-formed products, especially in food packaging and retail displays. The ability to create lightweight, durable, and visually appealing containers has led to increased adoption in this sector. Additionally, the automotive industry has embraced vacuum forming for interior components, such as dashboards and door panels, due to its ability to produce large, lightweight parts with consistent quality.

Traditional casting methods, including die casting and investment casting, maintain a strong market presence in industries requiring high-strength, precision metal components. The aerospace and defense sectors continue to rely heavily on these methods for producing critical parts that demand exceptional mechanical properties and tight tolerances. The automotive industry also utilizes traditional casting for engine components and structural elements that require superior strength and durability.

The medical device industry has shown growing interest in both vacuum forming and traditional casting methods. Vacuum forming is increasingly used for producing disposable medical trays and packaging, while traditional casting remains crucial for manufacturing implants and surgical instruments that require biocompatible metals and precise geometries.

Market trends indicate a shift towards more sustainable manufacturing processes, which has influenced the demand for both vacuum forming and traditional casting. Vacuum forming has an advantage in this area due to its ability to use recycled plastics and produce lightweight parts that contribute to fuel efficiency in transportation applications. However, traditional casting methods are also adapting by incorporating more recycled materials and optimizing processes to reduce energy consumption.

The global market for plastic thermoforming, which includes vacuum forming, has been expanding steadily. This growth is attributed to the increasing demand for packaged food products, healthcare supplies, and consumer electronics. On the other hand, the metal casting market, while mature, continues to grow moderately, driven by the need for complex metal components in various industries.

As industries increasingly focus on customization and rapid prototyping, vacuum forming has gained an edge due to its lower tooling costs and faster turnaround times for small to medium production runs. This has made it particularly attractive for startups and companies looking to test new product designs quickly. Traditional casting, however, remains the preferred choice for high-volume production of metal parts where the initial tooling costs can be amortized over large production runs.

Technical Challenges

Vacuum forming and traditional casting methods both present unique technical challenges in manufacturing processes. While vacuum forming offers advantages in terms of speed and cost-effectiveness for certain applications, it also faces limitations in terms of material selection and part complexity. Traditional casting methods, on the other hand, provide greater versatility but often require more time and resources.

One of the primary technical challenges in vacuum forming is achieving uniform material distribution, especially for complex geometries. As the heated plastic sheet is drawn over the mold, areas with deep draws or sharp corners may experience thinning, leading to weak spots in the final product. This issue is particularly pronounced when working with large or intricate parts, requiring careful mold design and process optimization to ensure consistent material thickness.

Material selection poses another significant challenge in vacuum forming. While thermoplastics are commonly used, not all materials are suitable for this process. High-temperature resistant plastics or those with poor formability can be difficult or impossible to vacuum form effectively. This limitation can restrict the range of applications and may necessitate alternative manufacturing methods for certain products.

Traditional casting methods, such as injection molding or die casting, face their own set of technical challenges. One of the most prominent issues is the occurrence of defects such as porosity, shrinkage, and warping. These defects can compromise the structural integrity and appearance of the final product, requiring careful control of process parameters such as temperature, pressure, and cooling rates.

Tooling costs and lead times present another significant challenge in traditional casting. The design and fabrication of molds or dies can be expensive and time-consuming, especially for complex parts or small production runs. This initial investment can be a barrier to entry for some manufacturers and may impact the overall cost-effectiveness of the production process.

For both vacuum forming and traditional casting, achieving tight tolerances and maintaining dimensional stability can be challenging. Factors such as material shrinkage, thermal expansion, and process variability can affect the final dimensions of the part. This is particularly critical in applications requiring precise fits or assemblies, necessitating careful design considerations and potentially secondary operations to meet specifications.

Surface finish quality is another area where both methods face challenges. Vacuum forming may struggle with replicating fine surface details or achieving a high-gloss finish, while traditional casting methods may encounter issues such as flow lines, sink marks, or parting line flash. Addressing these surface imperfections often requires additional post-processing steps, adding time and cost to the manufacturing process.

In conclusion, while both vacuum forming and traditional casting methods have their strengths, they also present distinct technical challenges that manufacturers must address. Overcoming these challenges requires a deep understanding of material properties, process parameters, and design considerations to produce high-quality parts efficiently and cost-effectively.

One of the primary technical challenges in vacuum forming is achieving uniform material distribution, especially for complex geometries. As the heated plastic sheet is drawn over the mold, areas with deep draws or sharp corners may experience thinning, leading to weak spots in the final product. This issue is particularly pronounced when working with large or intricate parts, requiring careful mold design and process optimization to ensure consistent material thickness.

Material selection poses another significant challenge in vacuum forming. While thermoplastics are commonly used, not all materials are suitable for this process. High-temperature resistant plastics or those with poor formability can be difficult or impossible to vacuum form effectively. This limitation can restrict the range of applications and may necessitate alternative manufacturing methods for certain products.

Traditional casting methods, such as injection molding or die casting, face their own set of technical challenges. One of the most prominent issues is the occurrence of defects such as porosity, shrinkage, and warping. These defects can compromise the structural integrity and appearance of the final product, requiring careful control of process parameters such as temperature, pressure, and cooling rates.

Tooling costs and lead times present another significant challenge in traditional casting. The design and fabrication of molds or dies can be expensive and time-consuming, especially for complex parts or small production runs. This initial investment can be a barrier to entry for some manufacturers and may impact the overall cost-effectiveness of the production process.

For both vacuum forming and traditional casting, achieving tight tolerances and maintaining dimensional stability can be challenging. Factors such as material shrinkage, thermal expansion, and process variability can affect the final dimensions of the part. This is particularly critical in applications requiring precise fits or assemblies, necessitating careful design considerations and potentially secondary operations to meet specifications.

Surface finish quality is another area where both methods face challenges. Vacuum forming may struggle with replicating fine surface details or achieving a high-gloss finish, while traditional casting methods may encounter issues such as flow lines, sink marks, or parting line flash. Addressing these surface imperfections often requires additional post-processing steps, adding time and cost to the manufacturing process.

In conclusion, while both vacuum forming and traditional casting methods have their strengths, they also present distinct technical challenges that manufacturers must address. Overcoming these challenges requires a deep understanding of material properties, process parameters, and design considerations to produce high-quality parts efficiently and cost-effectively.

Current Solutions

01 Vacuum forming techniques

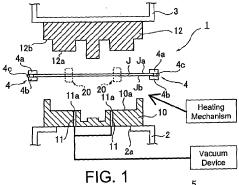

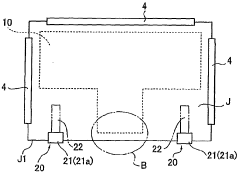

Vacuum forming is a process where a heated plastic sheet is drawn onto a mold by vacuum suction. This method is often used for creating thin-walled plastic parts with complex shapes. It offers advantages such as quick production times and lower tooling costs compared to traditional casting methods.- Vacuum forming process improvements: Advancements in vacuum forming techniques include optimized heating methods, improved mold designs, and enhanced material handling systems. These improvements lead to better product quality, increased efficiency, and reduced production costs in the vacuum forming process.

- Traditional casting methods enhancements: Innovations in traditional casting methods focus on improving mold materials, refining pouring techniques, and developing advanced cooling systems. These enhancements result in better cast product quality, reduced defects, and increased production efficiency.

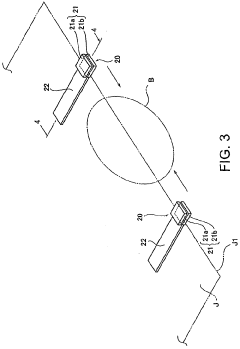

- Hybrid forming techniques: Combining vacuum forming and traditional casting methods creates hybrid techniques that leverage the advantages of both processes. These hybrid approaches offer improved versatility, enhanced product characteristics, and the ability to produce complex shapes more efficiently.

- Material innovations for forming processes: Development of new materials and composites specifically designed for vacuum forming and casting processes. These materials offer improved properties such as better flow characteristics, enhanced surface finish, and increased durability of the final products.

- Automation and control systems: Integration of advanced automation and control systems in both vacuum forming and traditional casting processes. These systems improve precision, repeatability, and overall process control, leading to higher quality products and increased production efficiency.

02 Traditional casting methods

Traditional casting methods involve pouring molten material into a mold and allowing it to solidify. These methods include sand casting, investment casting, and die casting. They are suitable for producing metal parts with complex geometries and are widely used in various industries.Expand Specific Solutions03 Comparison of vacuum forming and traditional casting

Vacuum forming and traditional casting methods have distinct advantages and limitations. Vacuum forming is generally faster and more cost-effective for producing large quantities of thin plastic parts, while traditional casting is better suited for creating metal components with high strength and complex internal structures.Expand Specific Solutions04 Innovations in vacuum forming

Recent innovations in vacuum forming include improved temperature control systems, advanced mold designs, and the use of composite materials. These advancements have expanded the range of products that can be manufactured using vacuum forming and improved the overall quality and consistency of the finished parts.Expand Specific Solutions05 Hybrid manufacturing processes

Hybrid manufacturing processes combine elements of vacuum forming and traditional casting methods to leverage the advantages of both techniques. These processes may involve using vacuum-assisted casting or integrating 3D printing with vacuum forming to create complex, multi-material parts with improved efficiency and reduced waste.Expand Specific Solutions

Industry Leaders

The competition landscape for vacuum forming versus traditional casting methods is evolving rapidly, with the market in a growth phase. The global market size for these technologies is expanding, driven by increasing demand in automotive, aerospace, and consumer goods industries. Technologically, vacuum forming is gaining traction due to its cost-effectiveness and efficiency for producing large, thin-walled parts. However, traditional casting methods remain dominant for complex, high-strength components. Companies like Toyota Motor Corp., Hyundai Motor Co., and Kia Corp. are at the forefront of adopting and refining these technologies in the automotive sector, while academic institutions such as Tsinghua University and Nanjing University of Aeronautics & Astronautics are contributing to research and development in this field.

Foseco International Ltd.

Technical Solution: Foseco specializes in foundry technologies and has developed innovative solutions for traditional casting methods. Their FEEDEX K sleeves for steel casting utilize exothermic and insulating materials to optimize the feeding process, reducing defects and improving yield [4]. For aluminum casting, Foseco's DYCOTE mold coatings enhance surface finish and reduce gas-related defects [5]. The company has also introduced the FDU Mark 6 degassing unit, which removes hydrogen from molten aluminum more efficiently than traditional methods, resulting in higher quality castings with reduced porosity [6].

Strengths: Improved casting quality, reduced defects, and increased efficiency in traditional casting processes. Weaknesses: Requires specialized equipment and materials, potentially higher initial costs compared to basic casting methods.

Bühler AG

Technical Solution: Bühler has developed advanced die-casting solutions that bridge the gap between traditional casting and more modern forming techniques. Their Carat series of die-casting machines utilize a two-platen design and advanced control systems to produce high-quality, complex parts with improved efficiency [7]. Bühler's DigiCast process combines traditional die-casting with digital monitoring and control, allowing for real-time adjustments and predictive maintenance [8]. The company has also introduced eco-friendly solutions, such as the Ecoline Pro, which reduces energy consumption in the die-casting process by up to 40% compared to conventional systems [9].

Strengths: High precision, improved efficiency, and integration of digital technologies in traditional casting. Weaknesses: High initial investment costs and potential complexity in implementation and operation.

Key Innovations

Vacuum forming apparatus and vacuum forming method

PatentInactiveGB2451735B

Innovation

- A vacuum forming apparatus with supplemental holding devices that allow for controlled sagging by clamping and supporting specific areas of the resin sheet, preventing excessive stretching and wrinkles by distributing load support along side portions.

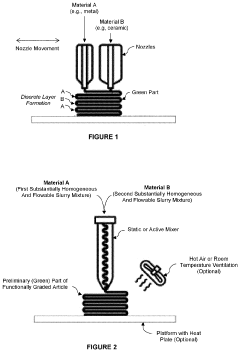

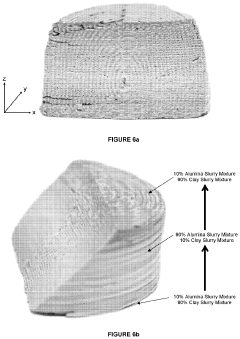

Slurry feedstock for extrusion-based 3D printing of functionally graded articles and casting metal/ceramic article under low pressure at room temperature, methods, and system therefor

PatentPendingUS20240190040A1

Innovation

- A slurry feedstock comprising a metal, ceramic, or their combinations, mixed with an organic polymer binder and additives, is used for extrusion-based 3D printing and casting, allowing for the creation of FGMs with varying composition and structure across multiple directions at room temperature and low pressure.

Cost-Benefit Analysis

A comprehensive cost-benefit analysis of vacuum forming versus traditional casting methods reveals significant differences in various aspects of production. Initial investment costs for vacuum forming equipment are generally lower than those required for traditional casting setups. Vacuum forming machines are typically less expensive and require less complex infrastructure, making them more accessible for small to medium-sized enterprises.

Operational costs also tend to favor vacuum forming. The process consumes less energy compared to traditional casting methods, which often involve high-temperature melting and prolonged heating cycles. Additionally, vacuum forming produces less waste material, reducing raw material costs and minimizing environmental impact. Labor costs are generally lower for vacuum forming due to its simpler operation and shorter production cycles.

However, traditional casting methods often have an advantage in terms of production volume and scalability. For large-scale production runs, the per-unit cost of traditional casting can be lower due to economies of scale. Casting also allows for the production of more complex geometries and thicker parts, which may be challenging or impossible with vacuum forming.

Material versatility is another factor to consider. While vacuum forming is limited to thermoplastics, traditional casting can work with a wider range of materials, including metals, ceramics, and thermoset plastics. This versatility can be crucial for certain industries and applications, potentially justifying the higher costs associated with traditional casting methods.

Tooling costs vary between the two methods. Vacuum forming typically requires less expensive molds, which can be produced more quickly and at a lower cost. This makes vacuum forming more suitable for prototyping and small production runs. In contrast, traditional casting often requires more durable and expensive molds, which can be a significant upfront investment but may prove more cost-effective for high-volume production over time.

Product quality and finish should also be factored into the cost-benefit analysis. Traditional casting methods often produce parts with better surface finish and dimensional accuracy, which may reduce post-processing costs. Vacuum forming, while capable of producing high-quality parts, may require additional finishing steps for certain applications, potentially offsetting some of its cost advantages.

In conclusion, the cost-benefit analysis between vacuum forming and traditional casting methods depends heavily on specific production requirements, volume, and application. Vacuum forming generally offers lower initial and operational costs, making it attractive for smaller-scale production and rapid prototyping. Traditional casting, while often more expensive, provides advantages in material versatility, part complexity, and high-volume production efficiency. Companies must carefully weigh these factors against their specific needs and long-term production goals to determine the most cost-effective solution.

Operational costs also tend to favor vacuum forming. The process consumes less energy compared to traditional casting methods, which often involve high-temperature melting and prolonged heating cycles. Additionally, vacuum forming produces less waste material, reducing raw material costs and minimizing environmental impact. Labor costs are generally lower for vacuum forming due to its simpler operation and shorter production cycles.

However, traditional casting methods often have an advantage in terms of production volume and scalability. For large-scale production runs, the per-unit cost of traditional casting can be lower due to economies of scale. Casting also allows for the production of more complex geometries and thicker parts, which may be challenging or impossible with vacuum forming.

Material versatility is another factor to consider. While vacuum forming is limited to thermoplastics, traditional casting can work with a wider range of materials, including metals, ceramics, and thermoset plastics. This versatility can be crucial for certain industries and applications, potentially justifying the higher costs associated with traditional casting methods.

Tooling costs vary between the two methods. Vacuum forming typically requires less expensive molds, which can be produced more quickly and at a lower cost. This makes vacuum forming more suitable for prototyping and small production runs. In contrast, traditional casting often requires more durable and expensive molds, which can be a significant upfront investment but may prove more cost-effective for high-volume production over time.

Product quality and finish should also be factored into the cost-benefit analysis. Traditional casting methods often produce parts with better surface finish and dimensional accuracy, which may reduce post-processing costs. Vacuum forming, while capable of producing high-quality parts, may require additional finishing steps for certain applications, potentially offsetting some of its cost advantages.

In conclusion, the cost-benefit analysis between vacuum forming and traditional casting methods depends heavily on specific production requirements, volume, and application. Vacuum forming generally offers lower initial and operational costs, making it attractive for smaller-scale production and rapid prototyping. Traditional casting, while often more expensive, provides advantages in material versatility, part complexity, and high-volume production efficiency. Companies must carefully weigh these factors against their specific needs and long-term production goals to determine the most cost-effective solution.

Environmental Impact

The environmental impact of manufacturing processes has become increasingly important in recent years, and the comparison between vacuum forming and traditional casting methods reveals significant differences in their ecological footprints. Vacuum forming, a process that uses heat and pressure to shape thermoplastic sheets, generally has a lower environmental impact compared to traditional casting methods.

One of the primary advantages of vacuum forming is its energy efficiency. The process requires less energy input compared to traditional casting, which often involves melting and pouring molten materials. This reduced energy consumption translates to lower greenhouse gas emissions and a smaller carbon footprint. Additionally, vacuum forming typically produces less waste material, as the plastic sheets can be precisely cut to size before forming, minimizing excess material.

The materials used in vacuum forming also contribute to its environmental benefits. Many thermoplastics used in this process are recyclable, allowing for a more circular economy approach. In contrast, traditional casting methods often use materials that are more difficult to recycle or reuse, leading to increased waste and resource depletion.

Water usage is another area where vacuum forming demonstrates environmental advantages. Unlike many traditional casting processes that may require significant amounts of water for cooling or cleaning, vacuum forming is generally a dry process, reducing water consumption and potential water pollution risks.

However, it is important to note that the environmental impact of both processes can vary depending on the specific materials and equipment used. For instance, some traditional casting methods have made significant advancements in recycling and energy efficiency, narrowing the gap with vacuum forming in certain applications.

The lifecycle of products manufactured using these methods also plays a role in their overall environmental impact. Vacuum-formed products are often lighter and more durable than their cast counterparts, potentially leading to reduced transportation emissions and longer product lifespans. This can offset some of the environmental costs associated with the initial production process.

In terms of air quality, vacuum forming generally produces fewer volatile organic compound (VOC) emissions compared to many traditional casting methods, particularly those involving chemical binders or solvents. This results in a healthier work environment and reduced atmospheric pollution.

While vacuum forming presents several environmental advantages, it is not without its challenges. The reliance on plastic materials raises concerns about long-term environmental persistence and potential microplastic pollution. Efforts to develop and utilize more biodegradable or bio-based plastics in vacuum forming are ongoing to address these issues.

In conclusion, when comparing the environmental impact of vacuum forming to traditional casting methods, vacuum forming generally emerges as the more environmentally friendly option. Its energy efficiency, reduced waste, and lower emissions contribute to a smaller ecological footprint. However, continuous improvement in both processes is essential to further minimize their environmental impact and meet increasingly stringent sustainability standards.

One of the primary advantages of vacuum forming is its energy efficiency. The process requires less energy input compared to traditional casting, which often involves melting and pouring molten materials. This reduced energy consumption translates to lower greenhouse gas emissions and a smaller carbon footprint. Additionally, vacuum forming typically produces less waste material, as the plastic sheets can be precisely cut to size before forming, minimizing excess material.

The materials used in vacuum forming also contribute to its environmental benefits. Many thermoplastics used in this process are recyclable, allowing for a more circular economy approach. In contrast, traditional casting methods often use materials that are more difficult to recycle or reuse, leading to increased waste and resource depletion.

Water usage is another area where vacuum forming demonstrates environmental advantages. Unlike many traditional casting processes that may require significant amounts of water for cooling or cleaning, vacuum forming is generally a dry process, reducing water consumption and potential water pollution risks.

However, it is important to note that the environmental impact of both processes can vary depending on the specific materials and equipment used. For instance, some traditional casting methods have made significant advancements in recycling and energy efficiency, narrowing the gap with vacuum forming in certain applications.

The lifecycle of products manufactured using these methods also plays a role in their overall environmental impact. Vacuum-formed products are often lighter and more durable than their cast counterparts, potentially leading to reduced transportation emissions and longer product lifespans. This can offset some of the environmental costs associated with the initial production process.

In terms of air quality, vacuum forming generally produces fewer volatile organic compound (VOC) emissions compared to many traditional casting methods, particularly those involving chemical binders or solvents. This results in a healthier work environment and reduced atmospheric pollution.

While vacuum forming presents several environmental advantages, it is not without its challenges. The reliance on plastic materials raises concerns about long-term environmental persistence and potential microplastic pollution. Efforts to develop and utilize more biodegradable or bio-based plastics in vacuum forming are ongoing to address these issues.

In conclusion, when comparing the environmental impact of vacuum forming to traditional casting methods, vacuum forming generally emerges as the more environmentally friendly option. Its energy efficiency, reduced waste, and lower emissions contribute to a smaller ecological footprint. However, continuous improvement in both processes is essential to further minimize their environmental impact and meet increasingly stringent sustainability standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!