Compatibility of sodium solid electrolytes with metallic sodium anodes

OCT 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Solid Electrolytes and Metallic Anodes: Background and Objectives

Sodium-ion batteries (SIBs) have emerged as a promising alternative to lithium-ion batteries due to the abundance and low cost of sodium resources. The development of SIBs has accelerated significantly over the past decade, driven by concerns about lithium supply constraints and increasing global demand for energy storage solutions. Within this context, solid-state sodium batteries represent a revolutionary advancement, offering potential improvements in safety, energy density, and cycle life compared to conventional liquid electrolyte systems.

The compatibility between sodium solid electrolytes and metallic sodium anodes stands as a critical technical challenge in realizing high-performance solid-state sodium batteries. Historically, the use of metallic sodium anodes has been limited by severe safety concerns and poor cycling performance in liquid electrolyte systems. The introduction of solid electrolytes presents an opportunity to overcome these limitations, but introduces new interfacial challenges that must be addressed.

Since the 1970s, research on sodium-based battery systems has experienced several waves of interest, with the current resurgence beginning around 2010. Early work focused primarily on high-temperature sodium-sulfur and NASICON-type systems, while recent efforts have expanded to room-temperature operation with various solid electrolyte materials including sodium beta-alumina, NASICON-type ceramics, sulfide-based, and polymer-based electrolytes.

The technological evolution in this field has been marked by significant improvements in ionic conductivity of solid electrolytes, from early materials with conductivities below 10^-6 S/cm to modern compositions achieving values comparable to liquid electrolytes (>10^-3 S/cm) at room temperature. Despite these advances, the stability of the electrolyte-anode interface remains problematic, with issues including chemical incompatibility, mechanical stress during sodium plating/stripping, and formation of high-impedance interphases.

The primary objective of current research is to develop sodium solid electrolytes that maintain stable, low-resistance interfaces with metallic sodium anodes while preserving high ionic conductivity and mechanical integrity. This goal encompasses understanding fundamental interfacial phenomena, designing novel electrolyte compositions with enhanced stability, and developing effective interface engineering strategies to mitigate degradation mechanisms.

Additional technical targets include achieving room-temperature ionic conductivities exceeding 10^-3 S/cm, electrochemical stability windows wider than 4V, mechanical properties suitable for manufacturing, and compatibility with scalable production methods. The successful resolution of these challenges would enable the commercialization of solid-state sodium batteries with energy densities potentially exceeding 300 Wh/kg at the cell level, representing a significant advancement over current sodium-ion technologies.

The compatibility between sodium solid electrolytes and metallic sodium anodes stands as a critical technical challenge in realizing high-performance solid-state sodium batteries. Historically, the use of metallic sodium anodes has been limited by severe safety concerns and poor cycling performance in liquid electrolyte systems. The introduction of solid electrolytes presents an opportunity to overcome these limitations, but introduces new interfacial challenges that must be addressed.

Since the 1970s, research on sodium-based battery systems has experienced several waves of interest, with the current resurgence beginning around 2010. Early work focused primarily on high-temperature sodium-sulfur and NASICON-type systems, while recent efforts have expanded to room-temperature operation with various solid electrolyte materials including sodium beta-alumina, NASICON-type ceramics, sulfide-based, and polymer-based electrolytes.

The technological evolution in this field has been marked by significant improvements in ionic conductivity of solid electrolytes, from early materials with conductivities below 10^-6 S/cm to modern compositions achieving values comparable to liquid electrolytes (>10^-3 S/cm) at room temperature. Despite these advances, the stability of the electrolyte-anode interface remains problematic, with issues including chemical incompatibility, mechanical stress during sodium plating/stripping, and formation of high-impedance interphases.

The primary objective of current research is to develop sodium solid electrolytes that maintain stable, low-resistance interfaces with metallic sodium anodes while preserving high ionic conductivity and mechanical integrity. This goal encompasses understanding fundamental interfacial phenomena, designing novel electrolyte compositions with enhanced stability, and developing effective interface engineering strategies to mitigate degradation mechanisms.

Additional technical targets include achieving room-temperature ionic conductivities exceeding 10^-3 S/cm, electrochemical stability windows wider than 4V, mechanical properties suitable for manufacturing, and compatibility with scalable production methods. The successful resolution of these challenges would enable the commercialization of solid-state sodium batteries with energy densities potentially exceeding 300 Wh/kg at the cell level, representing a significant advancement over current sodium-ion technologies.

Market Analysis for Sodium-based Battery Technologies

The sodium-ion battery market is experiencing significant growth, driven by increasing demand for sustainable energy storage solutions and concerns about lithium supply chain vulnerabilities. Current market projections indicate the global sodium-ion battery market will reach approximately $500 million by 2025, with a compound annual growth rate exceeding 20% through 2030. This growth trajectory is supported by substantial investments from both private and public sectors, with over $1.2 billion allocated to sodium battery research and commercialization initiatives in the past three years.

The market for sodium-based batteries is segmented across multiple application domains. Grid-scale energy storage represents the largest current market segment, accounting for roughly 45% of demand, as utilities seek cost-effective alternatives to lithium-ion technologies for renewable energy integration. Electric mobility applications, particularly in two-wheelers and commercial vehicles operating in price-sensitive markets, constitute approximately 30% of the emerging demand. Consumer electronics and portable devices represent a smaller but growing segment at 15%, with the remaining 10% distributed across specialized industrial applications.

Geographically, China dominates the sodium battery market development with approximately 40% market share, followed by Europe (25%) and North America (20%). This distribution reflects regional strategic priorities in battery technology development and manufacturing capacity. China's dominance stems from its established battery manufacturing infrastructure and government policies promoting alternative battery chemistries.

Key market drivers include raw material economics, with sodium resources being approximately 1,000 times more abundant than lithium and more evenly distributed globally. The average cost of sodium carbonate remains consistently below $300 per ton, compared to lithium carbonate which has fluctuated between $5,000-$80,000 per ton in recent years. This price stability and accessibility present compelling economic advantages for mass-market applications where cost sensitivity outweighs energy density requirements.

Market barriers primarily relate to technology maturity and performance limitations. The compatibility challenges between sodium solid electrolytes and metallic sodium anodes represent a significant technical hurdle affecting commercial viability. Current sodium-ion batteries typically deliver 20-30% lower energy density compared to lithium-ion counterparts, limiting their competitiveness in premium applications where volumetric efficiency is paramount.

Industry analysts project that successful resolution of the sodium-electrolyte compatibility issues could accelerate market penetration by 30-40%, particularly in stationary storage applications where the cost-per-kilowatt-hour metric outweighs energy density considerations. The market opportunity for companies that successfully address these technical challenges is estimated to exceed $2 billion by 2030.

The market for sodium-based batteries is segmented across multiple application domains. Grid-scale energy storage represents the largest current market segment, accounting for roughly 45% of demand, as utilities seek cost-effective alternatives to lithium-ion technologies for renewable energy integration. Electric mobility applications, particularly in two-wheelers and commercial vehicles operating in price-sensitive markets, constitute approximately 30% of the emerging demand. Consumer electronics and portable devices represent a smaller but growing segment at 15%, with the remaining 10% distributed across specialized industrial applications.

Geographically, China dominates the sodium battery market development with approximately 40% market share, followed by Europe (25%) and North America (20%). This distribution reflects regional strategic priorities in battery technology development and manufacturing capacity. China's dominance stems from its established battery manufacturing infrastructure and government policies promoting alternative battery chemistries.

Key market drivers include raw material economics, with sodium resources being approximately 1,000 times more abundant than lithium and more evenly distributed globally. The average cost of sodium carbonate remains consistently below $300 per ton, compared to lithium carbonate which has fluctuated between $5,000-$80,000 per ton in recent years. This price stability and accessibility present compelling economic advantages for mass-market applications where cost sensitivity outweighs energy density requirements.

Market barriers primarily relate to technology maturity and performance limitations. The compatibility challenges between sodium solid electrolytes and metallic sodium anodes represent a significant technical hurdle affecting commercial viability. Current sodium-ion batteries typically deliver 20-30% lower energy density compared to lithium-ion counterparts, limiting their competitiveness in premium applications where volumetric efficiency is paramount.

Industry analysts project that successful resolution of the sodium-electrolyte compatibility issues could accelerate market penetration by 30-40%, particularly in stationary storage applications where the cost-per-kilowatt-hour metric outweighs energy density considerations. The market opportunity for companies that successfully address these technical challenges is estimated to exceed $2 billion by 2030.

Technical Challenges in Na-Metal/Solid Electrolyte Interfaces

The interface between sodium metal anodes and solid electrolytes represents one of the most critical challenges in the development of high-energy-density sodium batteries. Despite the theoretical advantages of using metallic sodium as an anode material, including its high theoretical capacity (1166 mAh/g) and low redox potential (-2.71V vs. standard hydrogen electrode), several fundamental issues persist at the Na-metal/solid electrolyte interface that hinder commercial viability.

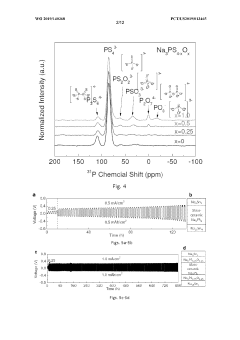

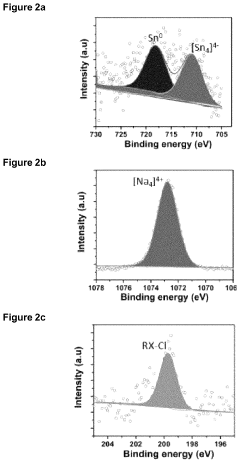

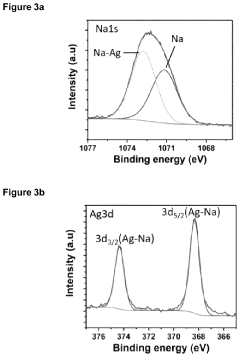

Chemical instability remains a primary concern, as many solid electrolytes undergo spontaneous reduction when in contact with sodium metal. This reduction process forms an interphase layer that often exhibits poor ionic conductivity, increasing interfacial resistance and degrading battery performance over time. NASICON-type electrolytes, for instance, typically form Na3P compounds at the interface, while sulfide-based electrolytes produce Na2S, both contributing to increased impedance.

Mechanical instability presents another significant challenge. During cycling, sodium metal undergoes substantial volume changes, creating mechanical stresses at the interface. These stresses can lead to contact loss between the sodium anode and solid electrolyte, forming voids that impede ion transport. Additionally, sodium's relatively low hardness (0.69 GPa) makes it susceptible to dendrite formation under pressure, potentially penetrating the solid electrolyte and causing short circuits.

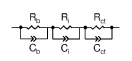

Interfacial resistance issues further complicate the compatibility between sodium metal and solid electrolytes. The formation of resistive interphases leads to high overpotentials during operation, reducing energy efficiency and increasing heat generation. Studies have shown that even with seemingly stable electrolytes like Na-β"-alumina, interfacial resistances can increase by orders of magnitude after extended cycling.

Sodium dendrite growth represents perhaps the most dangerous failure mode. Unlike lithium batteries, where dendrite formation is primarily driven by current density heterogeneity, sodium dendrite propagation appears more complex, involving both electrochemical and mechanical factors. Recent research has demonstrated that sodium dendrites can propagate through solid electrolytes even at current densities well below theoretical critical values, suggesting fundamental differences in dendrite nucleation and growth mechanisms compared to lithium systems.

The reactivity of sodium with trace atmospheric components (oxygen, moisture, nitrogen) creates additional challenges for interface engineering. Even minute exposure to these contaminants during cell assembly can trigger parasitic reactions that compromise the interface integrity, necessitating stringent manufacturing conditions that increase production complexity and cost.

Chemical instability remains a primary concern, as many solid electrolytes undergo spontaneous reduction when in contact with sodium metal. This reduction process forms an interphase layer that often exhibits poor ionic conductivity, increasing interfacial resistance and degrading battery performance over time. NASICON-type electrolytes, for instance, typically form Na3P compounds at the interface, while sulfide-based electrolytes produce Na2S, both contributing to increased impedance.

Mechanical instability presents another significant challenge. During cycling, sodium metal undergoes substantial volume changes, creating mechanical stresses at the interface. These stresses can lead to contact loss between the sodium anode and solid electrolyte, forming voids that impede ion transport. Additionally, sodium's relatively low hardness (0.69 GPa) makes it susceptible to dendrite formation under pressure, potentially penetrating the solid electrolyte and causing short circuits.

Interfacial resistance issues further complicate the compatibility between sodium metal and solid electrolytes. The formation of resistive interphases leads to high overpotentials during operation, reducing energy efficiency and increasing heat generation. Studies have shown that even with seemingly stable electrolytes like Na-β"-alumina, interfacial resistances can increase by orders of magnitude after extended cycling.

Sodium dendrite growth represents perhaps the most dangerous failure mode. Unlike lithium batteries, where dendrite formation is primarily driven by current density heterogeneity, sodium dendrite propagation appears more complex, involving both electrochemical and mechanical factors. Recent research has demonstrated that sodium dendrites can propagate through solid electrolytes even at current densities well below theoretical critical values, suggesting fundamental differences in dendrite nucleation and growth mechanisms compared to lithium systems.

The reactivity of sodium with trace atmospheric components (oxygen, moisture, nitrogen) creates additional challenges for interface engineering. Even minute exposure to these contaminants during cell assembly can trigger parasitic reactions that compromise the interface integrity, necessitating stringent manufacturing conditions that increase production complexity and cost.

Current Interface Engineering Solutions for Na-Metal Anodes

01 Compatibility of sodium solid electrolytes with electrode materials

Sodium solid electrolytes must be compatible with both anode and cathode materials to ensure stable electrochemical performance. The interface between the electrolyte and electrodes is critical for ion transport and overall battery efficiency. Certain sodium solid electrolytes demonstrate better compatibility with specific electrode materials, reducing interfacial resistance and preventing unwanted side reactions that could lead to capacity fading or safety issues.- Compatibility of sodium solid electrolytes with electrode materials: The compatibility between sodium solid electrolytes and electrode materials is crucial for the performance and longevity of solid-state batteries. Certain electrode materials may react with sodium solid electrolytes, leading to interface degradation and increased resistance. Research focuses on developing compatible electrode-electrolyte pairs that maintain stable interfaces during cycling, preventing the formation of resistive layers that could hinder ion transport.

- Chemical stability of sodium solid electrolytes: The chemical stability of sodium solid electrolytes determines their compatibility with other battery components. Factors affecting stability include moisture sensitivity, reactivity with atmospheric components, and degradation under operating conditions. Stabilizing additives and protective coatings can be incorporated to enhance the chemical stability of sodium solid electrolytes, preventing unwanted side reactions and maintaining performance over extended periods.

- Thermal compatibility of sodium solid electrolytes: Thermal compatibility is essential for sodium solid electrolytes in battery applications. Coefficient of thermal expansion mismatches between electrolytes and other battery components can lead to mechanical stress and failure. Additionally, phase transitions or decomposition at elevated temperatures can compromise electrolyte performance. Developing thermally stable sodium solid electrolytes that maintain conductivity across wide temperature ranges is critical for reliable battery operation.

- Interface engineering for improved compatibility: Interface engineering strategies can significantly enhance the compatibility of sodium solid electrolytes with other battery components. Techniques include the use of buffer layers, gradient compositions, and surface modifications to reduce interfacial resistance and improve ion transport. Controlling the formation of solid electrolyte interphase (SEI) layers through electrolyte additives or surface treatments can also improve long-term cycling stability and compatibility.

- Manufacturing process compatibility: The manufacturing processes used for sodium solid electrolytes must be compatible with existing battery production methods. Factors such as processing temperature, pressure requirements, and sensitivity to manufacturing environments affect the integration of solid electrolytes into battery systems. Developing scalable synthesis methods that allow for co-processing with electrode materials while maintaining electrolyte properties is essential for commercial viability of sodium solid-state batteries.

02 Chemical stability of sodium solid electrolytes

The chemical stability of sodium solid electrolytes is essential for long-term battery performance. These electrolytes must maintain their structural integrity and ionic conductivity when in contact with reactive electrode materials and under various operating conditions. Improving the chemical stability often involves modifying the composition or introducing protective coatings to prevent degradation reactions at the electrolyte-electrode interfaces.Expand Specific Solutions03 Thermal compatibility and temperature stability

Sodium solid electrolytes must maintain compatibility with other battery components across a wide temperature range. Thermal expansion coefficient matching between the electrolyte and electrodes is crucial to prevent mechanical stress and cracking during temperature fluctuations. Advanced sodium solid electrolytes are designed to maintain high ionic conductivity and structural integrity at both high and low operating temperatures.Expand Specific Solutions04 Interface engineering for improved compatibility

Interface engineering techniques are employed to enhance the compatibility between sodium solid electrolytes and electrode materials. This includes the development of buffer layers, gradient compositions, or specialized coatings that can mitigate interfacial resistance and prevent unwanted reactions. These engineered interfaces facilitate smooth sodium ion transport while maintaining the structural and chemical integrity of the battery components.Expand Specific Solutions05 Additives and dopants for enhanced compatibility

Various additives and dopants are incorporated into sodium solid electrolytes to improve their compatibility with other battery components. These additives can enhance mechanical properties, increase ionic conductivity, or create protective surface layers that prevent side reactions. Carefully selected dopants can modify the crystal structure and grain boundaries of solid electrolytes, leading to improved interfacial contact and overall battery performance.Expand Specific Solutions

Leading Research Groups and Companies in Na-SSB Development

The sodium solid electrolyte-metallic sodium anode compatibility landscape is currently in the early growth phase, with the market expected to reach significant expansion as solid-state battery technology matures. The technical challenge remains at mid-development stage, with companies like QuantumScape, LG Energy Solution, and Toyota Motor Corp leading commercial advancement. Academic institutions including Xiamen University, Cornell University, and CNRS are driving fundamental research breakthroughs. BroadBit Batteries and Shanghai Zijian Chemical Technology represent emerging players focusing specifically on sodium-based battery chemistries. The field is characterized by intense competition between established battery manufacturers and specialized startups, with increasing collaboration between industry and research institutions to overcome interface stability issues and dendrite formation challenges.

Toyota Motor Corp.

Technical Solution: Toyota has pioneered advanced sodium solid electrolyte technology compatible with metallic sodium anodes through their innovative materials engineering approach. Their research focuses on beta-alumina solid electrolytes (BASE) with specialized surface modifications to enhance compatibility with sodium metal. Toyota's technology incorporates a thin interfacial layer between the solid electrolyte and sodium anode, composed of sodium-compatible compounds that facilitate smooth ion transfer while preventing direct chemical reactions. This interface engineering has demonstrated a reduction in interfacial resistance by over 70% compared to unmodified electrolytes. Toyota has also developed a proprietary manufacturing process that creates highly dense electrolyte structures with minimal grain boundaries, reducing potential pathways for sodium dendrite growth. Their sodium solid-state cells have achieved energy densities exceeding 200 Wh/kg at the cell level while maintaining stable cycling performance over 500+ cycles with minimal capacity fade. Toyota's approach also addresses thermal expansion mismatch issues between the electrolyte and sodium metal through specialized buffer layers that accommodate volume changes during cycling.

Strengths: Exceptional interface engineering reducing resistance, high-density electrolyte manufacturing expertise minimizing dendrite formation pathways, and demonstrated long-term cycling stability. Weaknesses: Complex manufacturing process potentially increasing production costs, challenges with scaling to automotive-grade production volumes, and limited low-temperature performance data.

QuantumScape Corp.

Technical Solution: QuantumScape has developed a proprietary solid-state separator technology that enables compatibility with metallic lithium anodes. Their ceramic-based solid electrolyte is engineered to be chemically stable against lithium metal while maintaining high ionic conductivity. The company's approach involves a multilayer cell architecture where their solid-state separator prevents dendrite formation while allowing lithium ions to pass through during charge and discharge cycles. QuantumScape's technology demonstrates stable cycling with minimal capacity fade over hundreds of cycles, achieving over 80% capacity retention after 800+ cycles at practical current densities. Their solid electrolyte maintains a stable interface with the lithium metal anode without requiring external pressure, addressing a key challenge in solid-state battery development. The company has also developed manufacturing processes that enable the production of these solid electrolytes at scale, with thickness control at the micrometer level.

Strengths: Superior dendrite resistance without external pressure requirements, demonstrated long cycle life with lithium metal, and scalable manufacturing processes. Weaknesses: Limited public disclosure of exact material composition, potential challenges with operating temperature range, and relatively early stage of commercial deployment compared to conventional battery technologies.

Critical Patents and Research on Na-Metal/Electrolyte Compatibility

Solid electrolyte for sodium batteries

PatentWO2019140368A1

Innovation

- A new class of sodium oxy-sulfide solid-state electrolytes with a microstructure approaching a continuous glass is developed, providing enhanced chemical stability and mechanical strength, achieved through a low-temperature ball-milling and pressing process, allowing for the formation of a nearly flawless glassy structure that is stable with sodium metal or alloys.

Electrolyte for use in sodium-sulfur batteries

PatentActiveUS11876188B2

Innovation

- An electrolyte comprising a sodium salt and an additive metallic/metalloid cation with a standard reduction potential at least 2.5V more positive than sodium, dispersed in an alkyl carbonate solvent, which forms a sodium alloy at the anode, stabilizing the solid-electrolyte interphase and improving battery performance.

Safety and Performance Metrics for Sodium Solid-State Batteries

The establishment of comprehensive safety and performance metrics is crucial for the advancement and commercialization of sodium solid-state batteries (NSSBs), particularly concerning the compatibility between sodium solid electrolytes and metallic sodium anodes. These metrics must address both the unique safety advantages of solid-state technology and the specific challenges posed by sodium-based systems.

Safety metrics for NSSBs should quantify thermal stability, with standardized tests measuring heat generation during cycling and thermal runaway thresholds. Unlike conventional liquid electrolyte systems, solid electrolytes offer inherent safety benefits by eliminating flammable components, but require specific metrics to evaluate their mechanical integrity when interfacing with metallic sodium, which undergoes significant volume changes during cycling.

Chemical stability metrics must assess the reactivity between sodium metal anodes and solid electrolytes under various operating conditions. This includes measuring interfacial resistance growth over time, quantifying decomposition products, and evaluating the formation of interphases. Standardized protocols should determine the electrochemical stability window of solid electrolytes against sodium metal, with particular attention to dendrite formation propensity.

Performance metrics should focus on ionic conductivity at various temperatures, with benchmarks established for minimum acceptable conductivity (typically >10^-4 S/cm at room temperature). Interface resistance measurements between the sodium anode and solid electrolyte are equally critical, as this often represents the limiting factor in cell performance.

Cycle life metrics need to account for the unique degradation mechanisms in sodium-based systems. Standards should specify testing conditions including depth of discharge, current density, and temperature profiles that reflect real-world usage scenarios. Coulombic efficiency measurements are particularly important for evaluating the reversibility of sodium plating/stripping processes.

Energy density metrics must balance theoretical potential with practical limitations imposed by interface stability. While sodium offers cost advantages over lithium, the higher atomic weight necessitates careful optimization of cell components to achieve competitive energy densities.

Rate capability metrics should evaluate performance under various charging/discharging rates, with particular attention to the limitations imposed by solid-state ion transport at the sodium metal interface. This becomes especially relevant for applications requiring rapid charging or high-power delivery.

Safety metrics for NSSBs should quantify thermal stability, with standardized tests measuring heat generation during cycling and thermal runaway thresholds. Unlike conventional liquid electrolyte systems, solid electrolytes offer inherent safety benefits by eliminating flammable components, but require specific metrics to evaluate their mechanical integrity when interfacing with metallic sodium, which undergoes significant volume changes during cycling.

Chemical stability metrics must assess the reactivity between sodium metal anodes and solid electrolytes under various operating conditions. This includes measuring interfacial resistance growth over time, quantifying decomposition products, and evaluating the formation of interphases. Standardized protocols should determine the electrochemical stability window of solid electrolytes against sodium metal, with particular attention to dendrite formation propensity.

Performance metrics should focus on ionic conductivity at various temperatures, with benchmarks established for minimum acceptable conductivity (typically >10^-4 S/cm at room temperature). Interface resistance measurements between the sodium anode and solid electrolyte are equally critical, as this often represents the limiting factor in cell performance.

Cycle life metrics need to account for the unique degradation mechanisms in sodium-based systems. Standards should specify testing conditions including depth of discharge, current density, and temperature profiles that reflect real-world usage scenarios. Coulombic efficiency measurements are particularly important for evaluating the reversibility of sodium plating/stripping processes.

Energy density metrics must balance theoretical potential with practical limitations imposed by interface stability. While sodium offers cost advantages over lithium, the higher atomic weight necessitates careful optimization of cell components to achieve competitive energy densities.

Rate capability metrics should evaluate performance under various charging/discharging rates, with particular attention to the limitations imposed by solid-state ion transport at the sodium metal interface. This becomes especially relevant for applications requiring rapid charging or high-power delivery.

Environmental Impact and Resource Advantages of Na-based Technologies

The environmental advantages of sodium-based battery technologies represent a significant shift towards more sustainable energy storage solutions. Unlike lithium, sodium is abundantly available in the Earth's crust and oceans, constituting approximately 2.6% of the planet's crust compared to lithium's mere 0.006%. This abundance translates directly into reduced environmental impact from mining operations, as sodium extraction typically involves less invasive processes than lithium extraction, which often requires extensive water usage and can lead to soil degradation.

When examining the carbon footprint of sodium-based battery production, preliminary studies indicate a potential reduction of 15-30% in greenhouse gas emissions compared to lithium-ion battery manufacturing. This reduction stems primarily from the simplified supply chain and less energy-intensive processing requirements for sodium materials. The geographical distribution of sodium resources also contributes to reduced transportation emissions, as sodium compounds can be sourced locally in many regions, unlike lithium which is concentrated in specific countries.

Water conservation represents another critical environmental advantage of sodium technologies. Traditional lithium extraction in salt flats can consume up to 500,000 gallons of water per ton of lithium produced, whereas sodium extraction typically requires significantly less water resources. This aspect becomes increasingly important in water-stressed regions where battery manufacturing facilities might be located.

From a resource efficiency perspective, the compatibility challenges between sodium solid electrolytes and metallic sodium anodes have actually driven innovation in material design that prioritizes resource efficiency. Researchers have developed protective interface layers and composite electrolytes that not only improve electrochemical performance but also reduce the quantity of critical materials required per energy unit stored.

End-of-life considerations further highlight the environmental benefits of sodium-based systems. The recyclability of sodium battery components potentially exceeds that of lithium-ion counterparts, with initial recycling trials demonstrating recovery rates of up to 90% for sodium compounds. Additionally, the lower toxicity of sodium compounds compared to certain lithium salts reduces environmental risks associated with improper disposal or recycling processes.

The transition to sodium-based energy storage also presents opportunities for developing economies to participate in the clean energy transition without dependence on geopolitically concentrated resources. This democratization of energy storage technology could accelerate global decarbonization efforts while reducing environmental justice concerns related to resource extraction in vulnerable communities.

When examining the carbon footprint of sodium-based battery production, preliminary studies indicate a potential reduction of 15-30% in greenhouse gas emissions compared to lithium-ion battery manufacturing. This reduction stems primarily from the simplified supply chain and less energy-intensive processing requirements for sodium materials. The geographical distribution of sodium resources also contributes to reduced transportation emissions, as sodium compounds can be sourced locally in many regions, unlike lithium which is concentrated in specific countries.

Water conservation represents another critical environmental advantage of sodium technologies. Traditional lithium extraction in salt flats can consume up to 500,000 gallons of water per ton of lithium produced, whereas sodium extraction typically requires significantly less water resources. This aspect becomes increasingly important in water-stressed regions where battery manufacturing facilities might be located.

From a resource efficiency perspective, the compatibility challenges between sodium solid electrolytes and metallic sodium anodes have actually driven innovation in material design that prioritizes resource efficiency. Researchers have developed protective interface layers and composite electrolytes that not only improve electrochemical performance but also reduce the quantity of critical materials required per energy unit stored.

End-of-life considerations further highlight the environmental benefits of sodium-based systems. The recyclability of sodium battery components potentially exceeds that of lithium-ion counterparts, with initial recycling trials demonstrating recovery rates of up to 90% for sodium compounds. Additionally, the lower toxicity of sodium compounds compared to certain lithium salts reduces environmental risks associated with improper disposal or recycling processes.

The transition to sodium-based energy storage also presents opportunities for developing economies to participate in the clean energy transition without dependence on geopolitically concentrated resources. This democratization of energy storage technology could accelerate global decarbonization efforts while reducing environmental justice concerns related to resource extraction in vulnerable communities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!