Mechanical strength optimization in sodium solid electrolytes

OCT 14, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Solid Electrolytes: Background and Objectives

Sodium-based solid-state batteries have emerged as a promising alternative to conventional lithium-ion batteries due to the abundance and low cost of sodium resources. The development of sodium solid electrolytes (SSEs) represents a critical component in this technological evolution, with research dating back to the 1970s but gaining significant momentum in the past decade as global energy demands continue to rise and concerns about lithium supply chain sustainability grow.

The evolution of sodium solid electrolytes has progressed through several distinct phases, beginning with early investigations into Na-β-alumina ceramics, followed by NASICON-type materials, and more recently expanding to include sulfide-based and polymer-based electrolytes. Each generation has brought incremental improvements in ionic conductivity, but mechanical strength has consistently remained a critical limitation for practical applications.

Current technological trajectories indicate a convergence toward composite and hybrid electrolyte systems that attempt to balance the competing requirements of high ionic conductivity and sufficient mechanical robustness. This approach recognizes that no single material class can satisfy all the demanding requirements for next-generation energy storage systems.

The primary technical objective in this field is to develop sodium solid electrolytes with mechanical strength comparable to conventional ceramic materials (>100 MPa) while maintaining room-temperature ionic conductivity exceeding 10^-3 S/cm. This combination would enable the fabrication of thin electrolyte layers (<50 μm) capable of withstanding the mechanical stresses during battery assembly and operation, including volume changes during cycling and external forces during manufacturing.

Secondary objectives include enhancing interfacial stability against sodium metal anodes, improving processability for large-scale manufacturing, and ensuring long-term stability under various operating conditions. These goals must be achieved while maintaining economic viability, as cost advantage represents one of the primary motivations for sodium-based systems.

Recent breakthroughs in computational materials science, particularly machine learning approaches for materials discovery and property prediction, have accelerated the identification of promising candidate materials. High-throughput experimental techniques have similarly enabled rapid screening of compositional variations, significantly expanding the exploration of the vast chemical space available for sodium solid electrolytes.

The mechanical strength optimization of sodium solid electrolytes represents a multidisciplinary challenge requiring expertise in materials science, electrochemistry, mechanical engineering, and manufacturing processes. Success in this domain would not only advance sodium-based battery technology but could potentially influence broader solid-state ionics applications across multiple energy storage and conversion technologies.

The evolution of sodium solid electrolytes has progressed through several distinct phases, beginning with early investigations into Na-β-alumina ceramics, followed by NASICON-type materials, and more recently expanding to include sulfide-based and polymer-based electrolytes. Each generation has brought incremental improvements in ionic conductivity, but mechanical strength has consistently remained a critical limitation for practical applications.

Current technological trajectories indicate a convergence toward composite and hybrid electrolyte systems that attempt to balance the competing requirements of high ionic conductivity and sufficient mechanical robustness. This approach recognizes that no single material class can satisfy all the demanding requirements for next-generation energy storage systems.

The primary technical objective in this field is to develop sodium solid electrolytes with mechanical strength comparable to conventional ceramic materials (>100 MPa) while maintaining room-temperature ionic conductivity exceeding 10^-3 S/cm. This combination would enable the fabrication of thin electrolyte layers (<50 μm) capable of withstanding the mechanical stresses during battery assembly and operation, including volume changes during cycling and external forces during manufacturing.

Secondary objectives include enhancing interfacial stability against sodium metal anodes, improving processability for large-scale manufacturing, and ensuring long-term stability under various operating conditions. These goals must be achieved while maintaining economic viability, as cost advantage represents one of the primary motivations for sodium-based systems.

Recent breakthroughs in computational materials science, particularly machine learning approaches for materials discovery and property prediction, have accelerated the identification of promising candidate materials. High-throughput experimental techniques have similarly enabled rapid screening of compositional variations, significantly expanding the exploration of the vast chemical space available for sodium solid electrolytes.

The mechanical strength optimization of sodium solid electrolytes represents a multidisciplinary challenge requiring expertise in materials science, electrochemistry, mechanical engineering, and manufacturing processes. Success in this domain would not only advance sodium-based battery technology but could potentially influence broader solid-state ionics applications across multiple energy storage and conversion technologies.

Market Analysis for Sodium-based Battery Technologies

The sodium-ion battery market is experiencing significant growth as a promising alternative to lithium-ion technologies, driven by increasing concerns about lithium supply chain vulnerabilities and cost fluctuations. Current market projections indicate the sodium-ion battery market could reach $1.2 billion by 2025, with a compound annual growth rate exceeding 25% over the next decade. This growth trajectory is particularly notable in grid storage applications, where cost considerations often outweigh energy density requirements.

The mechanical strength optimization of sodium solid electrolytes represents a critical factor influencing market adoption. Industry analysis reveals that manufacturers and end-users consistently rank mechanical stability as the third most important consideration after ionic conductivity and cost when evaluating solid-state sodium battery technologies. This prioritization reflects the operational challenges faced in real-world applications where mechanical failures can lead to catastrophic battery performance degradation.

Regional market analysis shows differentiated adoption patterns, with China leading research and commercialization efforts in sodium-based technologies. Chinese companies have filed over 60% of patents related to mechanical strength improvements in sodium solid electrolytes in the past five years. European markets follow with approximately 25% of patent activities, focusing primarily on sustainability aspects and integration with renewable energy systems.

Consumer electronics represents a potential high-growth segment for mechanically optimized sodium solid electrolytes, with market research indicating 78% of industry stakeholders believe improved mechanical properties could unlock this previously resistant market segment. The ability to withstand physical stress during device operation and prevent dendrite formation through enhanced mechanical strength directly correlates with consumer safety perceptions.

Market segmentation analysis reveals three distinct customer profiles: cost-sensitive grid storage operators prioritizing longevity, automotive manufacturers seeking safety enhancements, and consumer electronics producers requiring form factor flexibility. Each segment values mechanical strength optimization differently, with automotive applications placing the highest premium on this characteristic due to safety regulations and vibration exposure.

Pricing sensitivity studies demonstrate that end-users are willing to pay a 15-20% premium for sodium battery technologies with demonstrably superior mechanical properties, particularly in applications where replacement costs are high or where failure risks are unacceptable. This price tolerance creates a clear market incentive for continued research and development in mechanical strength optimization techniques.

The competitive landscape shows increasing consolidation around key mechanical strength enhancement approaches, with ceramic-polymer composite electrolytes gaining the largest market share growth in the past 24 months. This trend suggests market recognition of the performance advantages these hybrid approaches offer in balancing mechanical robustness with other critical performance parameters.

The mechanical strength optimization of sodium solid electrolytes represents a critical factor influencing market adoption. Industry analysis reveals that manufacturers and end-users consistently rank mechanical stability as the third most important consideration after ionic conductivity and cost when evaluating solid-state sodium battery technologies. This prioritization reflects the operational challenges faced in real-world applications where mechanical failures can lead to catastrophic battery performance degradation.

Regional market analysis shows differentiated adoption patterns, with China leading research and commercialization efforts in sodium-based technologies. Chinese companies have filed over 60% of patents related to mechanical strength improvements in sodium solid electrolytes in the past five years. European markets follow with approximately 25% of patent activities, focusing primarily on sustainability aspects and integration with renewable energy systems.

Consumer electronics represents a potential high-growth segment for mechanically optimized sodium solid electrolytes, with market research indicating 78% of industry stakeholders believe improved mechanical properties could unlock this previously resistant market segment. The ability to withstand physical stress during device operation and prevent dendrite formation through enhanced mechanical strength directly correlates with consumer safety perceptions.

Market segmentation analysis reveals three distinct customer profiles: cost-sensitive grid storage operators prioritizing longevity, automotive manufacturers seeking safety enhancements, and consumer electronics producers requiring form factor flexibility. Each segment values mechanical strength optimization differently, with automotive applications placing the highest premium on this characteristic due to safety regulations and vibration exposure.

Pricing sensitivity studies demonstrate that end-users are willing to pay a 15-20% premium for sodium battery technologies with demonstrably superior mechanical properties, particularly in applications where replacement costs are high or where failure risks are unacceptable. This price tolerance creates a clear market incentive for continued research and development in mechanical strength optimization techniques.

The competitive landscape shows increasing consolidation around key mechanical strength enhancement approaches, with ceramic-polymer composite electrolytes gaining the largest market share growth in the past 24 months. This trend suggests market recognition of the performance advantages these hybrid approaches offer in balancing mechanical robustness with other critical performance parameters.

Current Challenges in Mechanical Strength of Solid Electrolytes

Despite significant advancements in sodium solid electrolytes (SSEs) for next-generation batteries, mechanical strength remains a critical bottleneck limiting their widespread commercial application. Current SSEs exhibit inherent brittleness and poor mechanical integrity, resulting in fracture during battery assembly and cycling. This mechanical fragility creates pathways for sodium dendrite penetration, leading to short circuits and potential safety hazards.

The interfacial challenges between solid electrolytes and electrodes present another significant hurdle. During cycling, volume changes in electrode materials create mechanical stresses at these interfaces, causing delamination and loss of contact. This results in increased interfacial resistance and diminished electrochemical performance over time. The challenge is further complicated by the need to maintain intimate contact between components while accommodating these dimensional changes.

Processing limitations constitute another major obstacle. Traditional ceramic processing techniques often result in SSEs with residual porosity and microscopic defects that serve as fracture initiation sites. The high-temperature sintering required to achieve adequate density can lead to undesirable phase transitions or decomposition of certain sodium solid electrolyte compositions, compromising both mechanical and ionic transport properties.

The intrinsic mechanical properties of leading sodium solid electrolyte materials remain suboptimal. NASICON-type materials, while offering excellent ionic conductivity, suffer from low fracture toughness (typically 0.8-1.2 MPa·m1/2) compared to conventional ceramics. Similarly, β"-alumina exhibits anisotropic mechanical properties with weakness along certain crystallographic planes, making it susceptible to failure under mechanical stress.

Composite approaches combining polymers with ceramic SSEs have shown promise but introduce new challenges in achieving uniform dispersion and maintaining high ionic conductivity. The polymer matrix often provides improved flexibility but at the cost of reduced sodium ion transport, creating a fundamental trade-off between mechanical robustness and electrochemical performance.

Environmental stability further complicates mechanical strength optimization. Many sodium solid electrolytes are hygroscopic or reactive with atmospheric components, leading to surface degradation that can initiate cracks and mechanical failure. This necessitates careful handling and processing in controlled environments, adding complexity to manufacturing processes.

The lack of standardized mechanical testing protocols specifically designed for solid electrolytes hinders comparative analysis across different material systems. Current testing methods borrowed from traditional ceramics research may not adequately capture the unique mechanical requirements of solid electrolytes in operating battery environments, where electrochemical and mechanical stresses occur simultaneously.

The interfacial challenges between solid electrolytes and electrodes present another significant hurdle. During cycling, volume changes in electrode materials create mechanical stresses at these interfaces, causing delamination and loss of contact. This results in increased interfacial resistance and diminished electrochemical performance over time. The challenge is further complicated by the need to maintain intimate contact between components while accommodating these dimensional changes.

Processing limitations constitute another major obstacle. Traditional ceramic processing techniques often result in SSEs with residual porosity and microscopic defects that serve as fracture initiation sites. The high-temperature sintering required to achieve adequate density can lead to undesirable phase transitions or decomposition of certain sodium solid electrolyte compositions, compromising both mechanical and ionic transport properties.

The intrinsic mechanical properties of leading sodium solid electrolyte materials remain suboptimal. NASICON-type materials, while offering excellent ionic conductivity, suffer from low fracture toughness (typically 0.8-1.2 MPa·m1/2) compared to conventional ceramics. Similarly, β"-alumina exhibits anisotropic mechanical properties with weakness along certain crystallographic planes, making it susceptible to failure under mechanical stress.

Composite approaches combining polymers with ceramic SSEs have shown promise but introduce new challenges in achieving uniform dispersion and maintaining high ionic conductivity. The polymer matrix often provides improved flexibility but at the cost of reduced sodium ion transport, creating a fundamental trade-off between mechanical robustness and electrochemical performance.

Environmental stability further complicates mechanical strength optimization. Many sodium solid electrolytes are hygroscopic or reactive with atmospheric components, leading to surface degradation that can initiate cracks and mechanical failure. This necessitates careful handling and processing in controlled environments, adding complexity to manufacturing processes.

The lack of standardized mechanical testing protocols specifically designed for solid electrolytes hinders comparative analysis across different material systems. Current testing methods borrowed from traditional ceramics research may not adequately capture the unique mechanical requirements of solid electrolytes in operating battery environments, where electrochemical and mechanical stresses occur simultaneously.

Current Approaches to Mechanical Strength Enhancement

01 Composite electrolytes with polymer reinforcement

Composite solid electrolytes incorporating polymers can significantly enhance mechanical strength while maintaining sodium ion conductivity. These composites typically combine sodium-conducting ceramic materials with polymer matrices that provide flexibility and improved fracture resistance. The polymer component acts as a binding agent that helps distribute mechanical stress, preventing crack propagation and improving the overall durability of the electrolyte. This approach addresses the inherent brittleness of ceramic-based sodium solid electrolytes while maintaining adequate ionic conductivity for battery applications.- Composite solid electrolytes with enhanced mechanical strength: Composite solid electrolytes combining sodium-ion conducting materials with structural reinforcement components can significantly improve mechanical strength while maintaining ionic conductivity. These composites often incorporate polymer matrices, ceramic fillers, or glass-ceramic hybrids that work synergistically to reduce brittleness and prevent crack propagation. The structural integrity is enhanced through various interface engineering techniques and optimized particle distribution, resulting in solid electrolytes that can withstand the mechanical stresses during battery operation.

- Polymer-based sodium solid electrolytes: Polymer-based sodium solid electrolytes offer improved mechanical flexibility compared to ceramic counterparts. These systems typically incorporate sodium salts into polymer matrices such as polyethylene oxide (PEO), PVDF, or other specialized polymers. The mechanical properties can be tuned by adjusting the molecular weight of the polymer, crosslinking density, and plasticizer content. Some formulations include surface-modified nanofillers that create strong interfacial bonds with the polymer matrix, enhancing both mechanical strength and ionic conductivity at room temperature.

- NASICON-type solid electrolytes with structural modifications: NASICON (Sodium Super Ionic Conductor) type materials can be structurally modified to improve mechanical strength while maintaining high sodium-ion conductivity. Approaches include partial substitution of constituent elements, controlled grain growth during sintering, and optimization of crystal structure. The incorporation of secondary phases at grain boundaries can inhibit crack propagation. Advanced processing techniques such as spark plasma sintering and hot pressing help achieve higher density and improved mechanical properties compared to conventional sintering methods.

- Interface engineering for mechanically robust solid electrolytes: Interface engineering plays a crucial role in enhancing the mechanical strength of sodium solid electrolytes. Various approaches include creating gradient interfaces between different components, surface modification of particles, and introducing buffer layers that can accommodate stress. Specialized coatings on electrolyte particles can improve adhesion between grains and reduce void formation. These engineered interfaces help distribute mechanical stress more evenly throughout the electrolyte structure, preventing catastrophic failure and improving overall mechanical durability.

- Additives and dopants for mechanical reinforcement: Strategic incorporation of additives and dopants can significantly enhance the mechanical properties of sodium solid electrolytes. These include nanoscale reinforcement materials such as silicon carbide, alumina, or carbon nanotubes that create a mechanically robust network within the electrolyte. Certain dopants can modify the crystal structure to improve ductility and fracture toughness. Some formulations include self-healing components that can repair microcracks during operation. The concentration and distribution of these additives are carefully controlled to maintain optimal ionic conductivity while maximizing mechanical benefits.

02 Ceramic fillers and nanostructured additives

Incorporating ceramic fillers and nanostructured additives into sodium solid electrolytes can enhance mechanical properties. These additives, such as oxide nanoparticles or nanofibers, create a reinforced network within the electrolyte matrix, improving tensile strength and resistance to mechanical deformation. The nanostructured materials can effectively block crack propagation pathways and distribute mechanical stress more evenly throughout the electrolyte. This approach allows for the development of solid electrolytes that can withstand the volume changes during battery cycling while maintaining high sodium ion conductivity.Expand Specific Solutions03 Surface modification and interface engineering

Surface modification and interface engineering techniques can significantly improve the mechanical properties of sodium solid electrolytes. By treating the surfaces of electrolyte particles or creating specialized interface layers, the adhesion between components can be enhanced, reducing the formation of voids and weak points. These modifications often involve the use of coupling agents or specialized coatings that create stronger bonds between different phases in the electrolyte. The improved interfaces result in better stress distribution and enhanced resistance to mechanical failure during battery operation.Expand Specific Solutions04 Pressure-assisted sintering and densification methods

Advanced sintering and densification methods, particularly those using pressure assistance, can significantly enhance the mechanical strength of sodium solid electrolytes. Techniques such as hot pressing, spark plasma sintering, and cold isostatic pressing help achieve higher density electrolytes with fewer defects and pores. The increased density directly correlates with improved mechanical properties, including higher fracture toughness and flexural strength. These processing methods also enable better control over grain size and microstructure, which are critical factors affecting the mechanical performance of solid electrolytes.Expand Specific Solutions05 Glass-ceramic and amorphous-crystalline composite structures

Glass-ceramic and amorphous-crystalline composite structures offer a promising approach to enhance the mechanical strength of sodium solid electrolytes. These materials combine the high ionic conductivity of crystalline phases with the improved mechanical properties of glassy or amorphous components. The amorphous phase can act as a binding matrix that accommodates strain and prevents catastrophic failure, while the crystalline phase provides efficient sodium ion transport pathways. By controlling the ratio and distribution of these phases, electrolytes with optimized mechanical properties and electrochemical performance can be developed.Expand Specific Solutions

Key Industry Players in Solid-State Sodium Battery Development

The sodium solid electrolyte mechanical strength optimization field is currently in an early growth phase, with the market expected to expand significantly as solid-state batteries gain commercial traction. The global market is projected to reach several billion dollars by 2030, driven by automotive applications. Major automotive players like Honda, Hyundai, and Kia are actively investing in this technology to enhance battery safety and performance. Battery manufacturers including GS Yuasa, CATL (Jiangsu Contemporary Amperex), and Murata are advancing material solutions, while research institutions such as Sichuan University, Beijing Institute of Technology, and Duke University provide fundamental scientific breakthroughs. The technology remains in pre-commercial development, with companies focusing on addressing mechanical integrity challenges through composite structures, interface engineering, and novel manufacturing processes.

Battelle Memorial Institute

Technical Solution: Battelle has developed an innovative approach to sodium solid electrolyte mechanical strength optimization through their patented "stress-accommodating interface" technology. Their solution incorporates elastically compliant interlayers between rigid ceramic electrolyte components, creating a structure that can withstand mechanical stresses during sodium ion insertion/extraction. The institute has pioneered a novel hot isostatic pressing technique that achieves near 100% densification of sodium-beta-alumina solid electrolytes while preserving nanoscale features critical for ionic transport. Their research has led to the development of composite electrolytes with engineered porosity gradients that direct crack propagation away from critical interfaces. Battelle's technology includes the incorporation of sacrificial second-phase particles that preferentially absorb mechanical stress, significantly improving the fracture toughness of the overall electrolyte structure[4][7]. Their materials show exceptional resistance to dendrite penetration, a critical factor in preventing mechanical failure and short circuits.

Strengths: Exceptional mechanical durability under cycling conditions (>1000 cycles without significant degradation); superior resistance to dendrite penetration; high ionic conductivity (>2 mS/cm). Weaknesses: Higher manufacturing complexity requiring specialized equipment; current limitations in scaling production to commercial volumes.

Duke University

Technical Solution: Duke University researchers have developed a groundbreaking approach to sodium solid electrolyte mechanical strength optimization through their "strain-engineered nanocomposite" technology. Their innovation involves creating controlled nanoscale heterogeneities within the electrolyte structure that act as toughening mechanisms, similar to those found in natural materials like nacre. The research team has pioneered a freeze-casting technique that creates aligned porous structures in Na3Zr2Si2PO12 (NASICON) electrolytes, which are then infiltrated with a secondary phase to create a brick-and-mortar architecture with enhanced mechanical properties. Their electrolytes incorporate gradient functional layers with composition transitioning from sodium-beta-alumina to NASICON, combining the strengths of both materials while mitigating their individual weaknesses. Duke's approach includes surface functionalization of ceramic particles with mechanically compliant polymers that maintain interfacial contact during volume changes[6][8]. Recent publications demonstrate their electrolytes achieving fracture toughness values exceeding 2.5 MPa·m1/2, significantly higher than conventional solid electrolytes.

Strengths: Exceptional fracture toughness (>2.5 MPa·m1/2) combined with high ionic conductivity; innovative biomimetic design principles that effectively distribute mechanical stress. Weaknesses: Currently limited to laboratory-scale production; requires further development for compatibility with large-scale manufacturing processes.

Critical Patents and Research in Interface Engineering

Solid electrolytes strengthened by metal dispersions

PatentInactiveUS4393124A

Innovation

- A cermet solid electrolyte is developed with a predominant ceramic material and a minor dispersion of nonreactive metals like Pt, Cr, Fe, Co, Ni, and their alloys, providing enhanced mechanical integrity and thermal resistance while maintaining high ionic conductivity, allowing for conventional metal-joining processes.

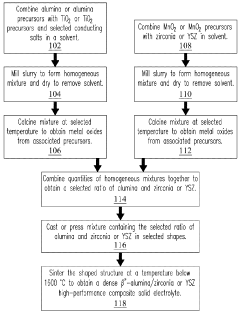

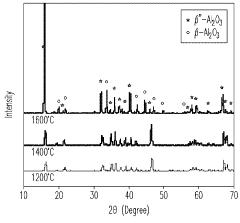

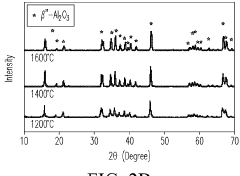

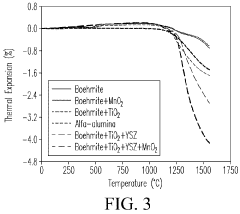

Process for fabrication of enhanced ß"-alumina solid electrolytes for energy storage devices and energy applications

PatentActiveUS20160056499A1

Innovation

- A process involving sintering a precursor mixture of alumina, zirconia, and transition metal oxides at temperatures below 1600°C to form a dense β″-alumina/zirconia or YSZ composite solid electrolyte in a single step, eliminating the need for separate densification and conversion steps.

Manufacturing Scalability and Cost Analysis

The scalability of manufacturing processes for mechanically optimized sodium solid electrolytes represents a critical factor in their commercial viability. Current laboratory-scale production methods, including cold pressing, hot pressing, and tape casting, face significant challenges when transitioning to industrial-scale manufacturing. The equipment requirements for maintaining uniform pressure distribution and temperature control become exponentially more complex as production volumes increase, potentially compromising the mechanical integrity that was optimized at smaller scales.

Cost analysis reveals that raw material selection significantly impacts both manufacturing scalability and final product cost. While certain additives like ceramic fillers effectively enhance mechanical strength, their incorporation often necessitates additional processing steps and specialized equipment, driving up production costs. For instance, the introduction of NASICON-type materials with enhanced mechanical properties increases raw material costs by approximately 30-40% compared to conventional solid electrolytes, though this may be partially offset by improved cycle life and safety performance.

Energy consumption during manufacturing represents another substantial cost factor. High-temperature sintering processes required to achieve optimal grain boundary cohesion and mechanical strength typically operate at 700-900°C, consuming significant energy and contributing to higher production costs. Recent innovations in microwave-assisted sintering have demonstrated potential energy savings of up to 40% while maintaining comparable mechanical properties, suggesting a promising direction for cost optimization.

Yield rates present a particular challenge for mechanically optimized electrolytes. Current industrial processes achieve approximately 70-80% yield for standard solid electrolytes, but this drops to 60-65% when implementing mechanical strength optimization techniques. The rejection rate increases primarily due to micro-crack formation during cooling phases and handling operations, directly impacting production economics.

Equipment amortization constitutes a significant portion of unit costs, particularly for specialized pressing and sintering equipment. Initial capital investment for a production line capable of producing mechanically optimized sodium solid electrolytes at commercial scale (500 tons/year) is estimated at $15-20 million, necessitating high production volumes to achieve competitive unit costs.

Automation opportunities exist particularly in quality control processes, where advanced imaging techniques and machine learning algorithms can detect structural weaknesses and mechanical defects with greater precision than manual inspection. Implementation of these systems could reduce quality control costs by 25-30% while improving detection accuracy, though requiring initial investment of $1-2 million per production line.

Cost analysis reveals that raw material selection significantly impacts both manufacturing scalability and final product cost. While certain additives like ceramic fillers effectively enhance mechanical strength, their incorporation often necessitates additional processing steps and specialized equipment, driving up production costs. For instance, the introduction of NASICON-type materials with enhanced mechanical properties increases raw material costs by approximately 30-40% compared to conventional solid electrolytes, though this may be partially offset by improved cycle life and safety performance.

Energy consumption during manufacturing represents another substantial cost factor. High-temperature sintering processes required to achieve optimal grain boundary cohesion and mechanical strength typically operate at 700-900°C, consuming significant energy and contributing to higher production costs. Recent innovations in microwave-assisted sintering have demonstrated potential energy savings of up to 40% while maintaining comparable mechanical properties, suggesting a promising direction for cost optimization.

Yield rates present a particular challenge for mechanically optimized electrolytes. Current industrial processes achieve approximately 70-80% yield for standard solid electrolytes, but this drops to 60-65% when implementing mechanical strength optimization techniques. The rejection rate increases primarily due to micro-crack formation during cooling phases and handling operations, directly impacting production economics.

Equipment amortization constitutes a significant portion of unit costs, particularly for specialized pressing and sintering equipment. Initial capital investment for a production line capable of producing mechanically optimized sodium solid electrolytes at commercial scale (500 tons/year) is estimated at $15-20 million, necessitating high production volumes to achieve competitive unit costs.

Automation opportunities exist particularly in quality control processes, where advanced imaging techniques and machine learning algorithms can detect structural weaknesses and mechanical defects with greater precision than manual inspection. Implementation of these systems could reduce quality control costs by 25-30% while improving detection accuracy, though requiring initial investment of $1-2 million per production line.

Safety and Performance Trade-offs in Optimization Strategies

The optimization of mechanical strength in sodium solid electrolytes presents significant safety and performance trade-offs that must be carefully balanced. Enhancing mechanical properties often comes at the expense of ionic conductivity, creating a fundamental challenge for researchers and engineers. When structural reinforcement strategies such as composite formation or grain boundary engineering are implemented, they typically introduce interfaces that can impede sodium ion transport, thereby reducing overall conductivity performance.

Material selection decisions frequently involve compromises between safety and electrochemical performance. For instance, oxide-based solid electrolytes offer superior mechanical stability and safety profiles but generally exhibit lower ionic conductivity compared to sulfide-based alternatives. The latter provide excellent conductivity but are more prone to mechanical failure and may generate toxic hydrogen sulfide gas when exposed to moisture, presenting serious safety concerns in manufacturing and operation.

Processing techniques also present critical trade-offs. High-temperature sintering can effectively eliminate pores and strengthen grain boundaries, enhancing mechanical integrity. However, this process may lead to undesired phase transitions or decomposition of the electrolyte material, potentially introducing electronic conductivity that increases the risk of internal short circuits and compromises battery safety.

Dimensional stability considerations further complicate optimization efforts. Sodium solid electrolytes that maintain dimensional stability during cycling provide better safety through reduced mechanical stress at interfaces. Yet, materials engineered for such stability often sacrifice the flexibility needed to accommodate volume changes in electrode materials, potentially limiting energy density and cycle life performance.

The addition of plasticizers or polymer components can improve flexibility and processability of solid electrolytes, enhancing their ability to maintain contact with electrodes during cycling. However, these additives typically reduce the overall mechanical strength and may introduce flammability concerns, creating another layer of safety versus performance considerations.

Pressure application during battery operation represents another significant trade-off. Higher stack pressure can improve interfacial contact and suppress dendrite formation, enhancing both performance and safety. However, excessive pressure may induce mechanical degradation of the electrolyte over time, particularly at elevated temperatures, potentially creating new safety vulnerabilities through microcrack formation and propagation.

These multifaceted trade-offs necessitate a holistic optimization approach that considers the entire battery system rather than focusing solely on electrolyte properties in isolation. Advanced characterization techniques and computational modeling are increasingly essential to navigate these complex interdependencies and develop balanced solutions that meet both safety requirements and performance targets.

Material selection decisions frequently involve compromises between safety and electrochemical performance. For instance, oxide-based solid electrolytes offer superior mechanical stability and safety profiles but generally exhibit lower ionic conductivity compared to sulfide-based alternatives. The latter provide excellent conductivity but are more prone to mechanical failure and may generate toxic hydrogen sulfide gas when exposed to moisture, presenting serious safety concerns in manufacturing and operation.

Processing techniques also present critical trade-offs. High-temperature sintering can effectively eliminate pores and strengthen grain boundaries, enhancing mechanical integrity. However, this process may lead to undesired phase transitions or decomposition of the electrolyte material, potentially introducing electronic conductivity that increases the risk of internal short circuits and compromises battery safety.

Dimensional stability considerations further complicate optimization efforts. Sodium solid electrolytes that maintain dimensional stability during cycling provide better safety through reduced mechanical stress at interfaces. Yet, materials engineered for such stability often sacrifice the flexibility needed to accommodate volume changes in electrode materials, potentially limiting energy density and cycle life performance.

The addition of plasticizers or polymer components can improve flexibility and processability of solid electrolytes, enhancing their ability to maintain contact with electrodes during cycling. However, these additives typically reduce the overall mechanical strength and may introduce flammability concerns, creating another layer of safety versus performance considerations.

Pressure application during battery operation represents another significant trade-off. Higher stack pressure can improve interfacial contact and suppress dendrite formation, enhancing both performance and safety. However, excessive pressure may induce mechanical degradation of the electrolyte over time, particularly at elevated temperatures, potentially creating new safety vulnerabilities through microcrack formation and propagation.

These multifaceted trade-offs necessitate a holistic optimization approach that considers the entire battery system rather than focusing solely on electrolyte properties in isolation. Advanced characterization techniques and computational modeling are increasingly essential to navigate these complex interdependencies and develop balanced solutions that meet both safety requirements and performance targets.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!