High-throughput screening of sodium superionic conductors

OCT 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Superionic Conductors Background and Objectives

Sodium-ion batteries (SIBs) have emerged as a promising alternative to lithium-ion batteries due to the abundance and low cost of sodium resources. The development of high-performance sodium superionic conductors (SSICs) is crucial for advancing solid-state sodium batteries, which offer enhanced safety and energy density compared to conventional liquid electrolyte systems. The evolution of SSICs has progressed from early phosphate-based materials to more complex structures incorporating various elements to optimize ionic conductivity.

The technological trajectory of SSICs has been marked by significant breakthroughs in material design and synthesis methods. Initial research focused on NASICON-type compounds, which demonstrated moderate ionic conductivity but suffered from stability issues. Subsequent advancements led to the exploration of β-alumina and β"-alumina structures, which exhibited improved conductivity but presented manufacturing challenges. Recent developments have centered on sulfide-based and polymer-based electrolytes, each offering distinct advantages in terms of conductivity, processability, and electrochemical stability.

Current research trends indicate a growing interest in composite and hybrid electrolyte systems that combine the benefits of different material classes. The integration of nanotechnology and advanced manufacturing techniques has further expanded the design space for SSICs, enabling precise control over microstructure and interfacial properties that significantly influence ionic transport mechanisms.

The primary technical objective in the high-throughput screening of SSICs is to systematically identify and optimize materials with superior sodium-ion conductivity (>10^-3 S/cm at room temperature), excellent electrochemical stability windows (>4V), and mechanical robustness for practical battery applications. Additionally, the screening process aims to establish clear structure-property relationships that can guide rational material design and accelerate discovery cycles.

Secondary objectives include developing computational models and algorithms capable of predicting ionic conductivity based on structural features, establishing standardized protocols for material synthesis and characterization to ensure reproducibility, and creating comprehensive databases of material properties to facilitate machine learning approaches for future material discovery.

The long-term vision encompasses the creation of a unified framework for SSIC development that integrates theoretical predictions, high-throughput experimental validation, and advanced characterization techniques. This framework would enable the rapid identification of promising candidate materials and significantly reduce the time from discovery to commercial implementation, ultimately accelerating the broader adoption of sodium-based energy storage technologies across various sectors including grid storage, electric vehicles, and portable electronics.

The technological trajectory of SSICs has been marked by significant breakthroughs in material design and synthesis methods. Initial research focused on NASICON-type compounds, which demonstrated moderate ionic conductivity but suffered from stability issues. Subsequent advancements led to the exploration of β-alumina and β"-alumina structures, which exhibited improved conductivity but presented manufacturing challenges. Recent developments have centered on sulfide-based and polymer-based electrolytes, each offering distinct advantages in terms of conductivity, processability, and electrochemical stability.

Current research trends indicate a growing interest in composite and hybrid electrolyte systems that combine the benefits of different material classes. The integration of nanotechnology and advanced manufacturing techniques has further expanded the design space for SSICs, enabling precise control over microstructure and interfacial properties that significantly influence ionic transport mechanisms.

The primary technical objective in the high-throughput screening of SSICs is to systematically identify and optimize materials with superior sodium-ion conductivity (>10^-3 S/cm at room temperature), excellent electrochemical stability windows (>4V), and mechanical robustness for practical battery applications. Additionally, the screening process aims to establish clear structure-property relationships that can guide rational material design and accelerate discovery cycles.

Secondary objectives include developing computational models and algorithms capable of predicting ionic conductivity based on structural features, establishing standardized protocols for material synthesis and characterization to ensure reproducibility, and creating comprehensive databases of material properties to facilitate machine learning approaches for future material discovery.

The long-term vision encompasses the creation of a unified framework for SSIC development that integrates theoretical predictions, high-throughput experimental validation, and advanced characterization techniques. This framework would enable the rapid identification of promising candidate materials and significantly reduce the time from discovery to commercial implementation, ultimately accelerating the broader adoption of sodium-based energy storage technologies across various sectors including grid storage, electric vehicles, and portable electronics.

Market Analysis for Sodium-based Energy Storage Solutions

The global market for sodium-based energy storage solutions is experiencing significant growth, driven by increasing demand for sustainable and cost-effective alternatives to lithium-ion batteries. The market value was estimated at $1.2 billion in 2022 and is projected to reach $4.5 billion by 2030, representing a compound annual growth rate of 18.2%. This growth trajectory is supported by the abundant availability of sodium resources, which are approximately 1,000 times more plentiful than lithium in the Earth's crust.

The industrial sector currently dominates the market share at 42%, followed by renewable energy integration at 28%, grid-scale storage at 18%, and emerging applications in electric vehicles and consumer electronics at 12%. Geographically, Asia-Pacific leads with 45% market share, with China being the primary contributor due to its aggressive renewable energy targets and substantial investments in energy storage technologies.

Key market drivers include the escalating costs of lithium carbonate, which has seen price increases of over 400% between 2020 and 2022, creating economic pressure to find alternatives. Additionally, government initiatives supporting renewable energy integration have allocated substantial funding for advanced energy storage research, with the European Union dedicating €3.2 billion specifically for next-generation battery technologies including sodium-ion systems.

Market challenges persist, primarily centered around technical limitations. Current sodium superionic conductors exhibit lower ionic conductivity compared to their lithium counterparts, with the best performing materials reaching 10-3 S/cm at room temperature versus 10-2 S/cm for leading lithium conductors. Cycle stability remains another concern, with most sodium-based systems achieving 2,000-3,000 cycles compared to 5,000+ for commercial lithium-ion batteries.

Consumer adoption faces barriers related to energy density limitations, with current sodium-ion batteries delivering 120-150 Wh/kg versus 250-300 Wh/kg for lithium-ion technologies. This performance gap has restricted market penetration in mobile applications and electric vehicles where weight and space considerations are critical.

Industry analysts forecast that breakthroughs in sodium superionic conductors could potentially reduce production costs by 30-40% compared to lithium-ion batteries, creating a compelling economic case for adoption in stationary storage applications. The market for grid-scale sodium-based storage solutions is expected to grow at 22% annually through 2030, outpacing the overall market growth rate.

The industrial sector currently dominates the market share at 42%, followed by renewable energy integration at 28%, grid-scale storage at 18%, and emerging applications in electric vehicles and consumer electronics at 12%. Geographically, Asia-Pacific leads with 45% market share, with China being the primary contributor due to its aggressive renewable energy targets and substantial investments in energy storage technologies.

Key market drivers include the escalating costs of lithium carbonate, which has seen price increases of over 400% between 2020 and 2022, creating economic pressure to find alternatives. Additionally, government initiatives supporting renewable energy integration have allocated substantial funding for advanced energy storage research, with the European Union dedicating €3.2 billion specifically for next-generation battery technologies including sodium-ion systems.

Market challenges persist, primarily centered around technical limitations. Current sodium superionic conductors exhibit lower ionic conductivity compared to their lithium counterparts, with the best performing materials reaching 10-3 S/cm at room temperature versus 10-2 S/cm for leading lithium conductors. Cycle stability remains another concern, with most sodium-based systems achieving 2,000-3,000 cycles compared to 5,000+ for commercial lithium-ion batteries.

Consumer adoption faces barriers related to energy density limitations, with current sodium-ion batteries delivering 120-150 Wh/kg versus 250-300 Wh/kg for lithium-ion technologies. This performance gap has restricted market penetration in mobile applications and electric vehicles where weight and space considerations are critical.

Industry analysts forecast that breakthroughs in sodium superionic conductors could potentially reduce production costs by 30-40% compared to lithium-ion batteries, creating a compelling economic case for adoption in stationary storage applications. The market for grid-scale sodium-based storage solutions is expected to grow at 22% annually through 2030, outpacing the overall market growth rate.

Current Challenges in High-throughput Screening Technologies

Despite significant advancements in high-throughput screening (HTS) technologies for sodium superionic conductors, several critical challenges continue to impede progress in this field. The primary obstacle remains the inherent trade-off between throughput and measurement accuracy. While conventional techniques can achieve high precision in conductivity measurements, they typically process only a limited number of samples per day, creating a bottleneck in the discovery pipeline.

Material synthesis represents another significant challenge, as preparing consistent sample libraries with precise compositional gradients requires sophisticated automation systems that many research institutions cannot readily access. The variability in synthesis conditions often leads to inconsistent results across different screening platforms, complicating data interpretation and validation efforts.

Data management presents a formidable hurdle as HTS generates massive datasets that require advanced computational infrastructure for storage, processing, and analysis. The lack of standardized data formats and reporting protocols further exacerbates this issue, making cross-comparison between different research groups problematic and hindering collaborative efforts in the field.

The correlation between screening results and real-world performance constitutes a persistent challenge. Many HTS methodologies evaluate materials under idealized conditions that fail to account for practical operational environments, including temperature fluctuations, mechanical stress, and long-term cycling stability. This disconnect often leads to promising candidates failing during subsequent validation stages.

Computational screening approaches, while increasingly powerful, still struggle with accuracy in predicting ionic conductivity due to limitations in current theoretical models. The complex interplay between crystal structure, defect chemistry, and ion transport mechanisms remains difficult to capture in computational frameworks, necessitating experimental validation that slows the discovery process.

Cost considerations present another barrier, as establishing and maintaining HTS facilities requires substantial financial investment in specialized equipment, software systems, and trained personnel. This economic constraint limits widespread adoption of comprehensive screening approaches, particularly in smaller research institutions or developing regions.

Interdisciplinary expertise requirements further complicate HTS implementation, as effective screening programs demand collaboration between materials scientists, electrochemists, data scientists, and engineers. The shortage of professionals with cross-disciplinary training creates operational challenges in managing integrated screening workflows.

Validation protocols represent a final critical challenge, as the scientific community has yet to establish consensus on standardized methods for confirming HTS results. This lack of uniformity creates uncertainty in material performance metrics and impedes the transition from laboratory discovery to commercial application.

Material synthesis represents another significant challenge, as preparing consistent sample libraries with precise compositional gradients requires sophisticated automation systems that many research institutions cannot readily access. The variability in synthesis conditions often leads to inconsistent results across different screening platforms, complicating data interpretation and validation efforts.

Data management presents a formidable hurdle as HTS generates massive datasets that require advanced computational infrastructure for storage, processing, and analysis. The lack of standardized data formats and reporting protocols further exacerbates this issue, making cross-comparison between different research groups problematic and hindering collaborative efforts in the field.

The correlation between screening results and real-world performance constitutes a persistent challenge. Many HTS methodologies evaluate materials under idealized conditions that fail to account for practical operational environments, including temperature fluctuations, mechanical stress, and long-term cycling stability. This disconnect often leads to promising candidates failing during subsequent validation stages.

Computational screening approaches, while increasingly powerful, still struggle with accuracy in predicting ionic conductivity due to limitations in current theoretical models. The complex interplay between crystal structure, defect chemistry, and ion transport mechanisms remains difficult to capture in computational frameworks, necessitating experimental validation that slows the discovery process.

Cost considerations present another barrier, as establishing and maintaining HTS facilities requires substantial financial investment in specialized equipment, software systems, and trained personnel. This economic constraint limits widespread adoption of comprehensive screening approaches, particularly in smaller research institutions or developing regions.

Interdisciplinary expertise requirements further complicate HTS implementation, as effective screening programs demand collaboration between materials scientists, electrochemists, data scientists, and engineers. The shortage of professionals with cross-disciplinary training creates operational challenges in managing integrated screening workflows.

Validation protocols represent a final critical challenge, as the scientific community has yet to establish consensus on standardized methods for confirming HTS results. This lack of uniformity creates uncertainty in material performance metrics and impedes the transition from laboratory discovery to commercial application.

State-of-the-art High-throughput Screening Approaches

01 NASICON-type sodium superionic conductors

NASICON (Sodium Super Ionic Conductor) materials are a class of ceramic compounds with high sodium ion conductivity. These materials typically have a three-dimensional framework structure that allows for fast sodium ion transport. They exhibit high ionic conductivity at room temperature, making them suitable for solid-state sodium batteries and other electrochemical devices. The composition can be modified by substituting different elements to enhance the ionic conductivity and stability.- NASICON-type sodium superionic conductors: NASICON (Sodium Super Ionic Conductor) materials are a class of ceramic compounds with high sodium ion conductivity. These materials typically have a three-dimensional framework structure that allows for fast sodium ion transport. They exhibit superior ionic conductivity at room temperature, making them suitable for solid-state sodium batteries and other electrochemical devices. The composition often includes sodium, zirconium, silicon, and phosphorus in various ratios to optimize conductivity properties.

- Beta-alumina sodium ion conductors: Beta-alumina is a well-established sodium ion conductor with a layered crystal structure that facilitates fast sodium ion transport. These materials consist of alternating dense blocks and conduction planes where sodium ions can move rapidly. The ionic conductivity can be enhanced by doping with various elements or by controlling the microstructure through specific synthesis methods. Beta-alumina sodium ion conductors are widely used in sodium-sulfur batteries and other high-temperature electrochemical systems.

- Polymer-based sodium ion conductors: Polymer-based sodium ion conductors combine organic polymer matrices with sodium salts to create flexible electrolyte materials. These conductors often incorporate polyethylene oxide (PEO) or other polymer hosts that can coordinate with sodium ions to facilitate their transport. The addition of plasticizers, ceramic fillers, or ionic liquids can significantly enhance the ionic conductivity at room temperature. These materials offer advantages in terms of processability, flexibility, and interfacial compatibility with electrodes.

- Glass and glass-ceramic sodium ion conductors: Glass and glass-ceramic materials can exhibit high sodium ion conductivity through their disordered or partially ordered structures. These materials typically contain sodium oxide combined with network formers like silica, borate, or phosphate. The ionic conductivity can be enhanced by controlling the composition, thermal treatment, and crystallization process. Glass-ceramic sodium ion conductors often provide a good balance between mechanical stability and ionic transport properties, making them suitable for various electrochemical applications.

- Novel sodium superionic conductor compositions and fabrication methods: Recent advances in sodium superionic conductors focus on developing novel compositions and fabrication methods to achieve higher ionic conductivity. These approaches include the synthesis of composite materials combining different types of conductors, nanostructuring to increase the active surface area, and interface engineering to reduce resistance at grain boundaries. Advanced fabrication techniques such as sol-gel processing, solid-state reactions, and various thin-film deposition methods are employed to optimize the microstructure and enhance the overall performance of sodium ion conductors.

02 Beta-alumina sodium ion conductors

Beta-alumina is a well-established sodium ion conductor with a layered crystal structure that facilitates fast sodium ion transport. These materials have been extensively studied for applications in sodium batteries and other electrochemical systems. The conductivity of beta-alumina can be enhanced by doping with various elements and controlling the microstructure. These materials typically operate at elevated temperatures where they exhibit superior ionic conductivity.Expand Specific Solutions03 Polymer-based sodium ion conductors

Polymer-based sodium ion conductors combine organic polymers with sodium salts to create flexible electrolyte materials. These conductors offer advantages such as ease of processing, flexibility, and good interfacial contact with electrodes. The ionic conductivity can be improved by incorporating various additives, plasticizers, or by creating composite structures with ceramic fillers. These materials are particularly promising for flexible and wearable energy storage devices.Expand Specific Solutions04 Glass and glass-ceramic sodium ion conductors

Glass and glass-ceramic materials can serve as effective sodium ion conductors with tunable properties. These materials typically contain sodium oxide along with other components that form an amorphous or partially crystallized structure. The ionic conductivity can be enhanced by controlling the composition, crystallization process, and microstructure. Glass-ceramics often offer a good balance between mechanical stability and ionic conductivity, making them suitable for various electrochemical applications.Expand Specific Solutions05 Composite and interface-engineered sodium ion conductors

Composite sodium ion conductors combine different materials to achieve enhanced properties beyond those of single-phase conductors. These may include polymer-ceramic composites, multi-phase ceramics, or materials with engineered interfaces. By controlling the interfaces between different components, the ionic conductivity can be significantly improved. Additionally, surface modifications and interface engineering techniques can reduce interfacial resistance and enhance the overall performance of sodium ion conducting systems.Expand Specific Solutions

Leading Research Groups and Industrial Players

High-throughput screening of sodium superionic conductors is currently in an emerging growth phase, with the market expanding rapidly due to increasing demand for advanced battery technologies. The global market size for solid-state electrolytes is projected to reach significant scale as electric vehicle adoption accelerates. Academic institutions like The Regents of the University of California, Central South University, and Yale University are leading fundamental research, while commercial players such as Toyota Motor Corp., LG Chem Ltd., and Wildcat Discovery Technologies are advancing practical applications. The technology is approaching commercial viability, with companies like Toyota and LG Chem making substantial investments in solid-state battery development. Research collaborations between academia and industry are accelerating material discovery through AI-driven screening methodologies.

The Regents of the University of California

Technical Solution: The University of California has developed a sophisticated high-throughput screening platform for sodium superionic conductors that combines computational materials science with automated experimental validation. Their approach begins with density functional theory calculations to identify promising structural motifs and compositions, followed by machine learning models trained on existing conductivity data to prioritize candidates. The experimental workflow incorporates robotic synthesis systems capable of preparing compositional gradients across substrate plates, enabling evaluation of hundreds of compositions simultaneously. UC researchers have implemented parallel impedance spectroscopy measurement stations with temperature control from -20°C to 100°C to rapidly assess ionic conductivity. Their platform includes automated structural characterization using synchrotron X-ray diffraction at Lawrence Berkeley National Laboratory facilities. The UC system has successfully identified several novel sodium-containing garnets and NASICON variants with ionic conductivities exceeding 1.5 mS/cm at room temperature through this integrated approach.

Strengths: UC's academic research environment fosters exploration of novel structural families without commercial constraints. Their access to national laboratory facilities provides advanced characterization capabilities. The open publication of results accelerates broader field advancement. Weaknesses: Academic funding cycles may limit long-term continuity of screening efforts. The focus on fundamental understanding sometimes comes at the expense of practical considerations like material processability and scalability.

Toyota Motor Corp.

Technical Solution: Toyota has developed an advanced high-throughput screening platform specifically for sodium superionic conductors that combines computational and experimental approaches. Their system utilizes first-principles calculations and machine learning algorithms to predict promising sodium-ion conducting materials before synthesis. The experimental workflow incorporates automated synthesis robots capable of preparing hundreds of samples daily with precise compositional control. Toyota's screening platform employs impedance spectroscopy arrays that can simultaneously measure ionic conductivity of multiple samples across various temperatures. Their system integrates X-ray diffraction for structural characterization and nuclear magnetic resonance for sodium ion dynamics analysis. Toyota has successfully identified several novel Na3Zr2Si2PO12 (NASICON) structural variants with conductivities exceeding 1 mS/cm at room temperature through this approach.

Strengths: Toyota's integrated computational-experimental approach significantly accelerates discovery timeline. Their automated synthesis capabilities ensure high reproducibility and compositional precision. The company's established battery research infrastructure provides advantages in scaling promising materials. Weaknesses: The approach may prioritize automotive applications over other potential uses for sodium superionic conductors. The proprietary nature of their screening platform limits broader scientific collaboration.

Key Technical Innovations in Superionic Conductor Discovery

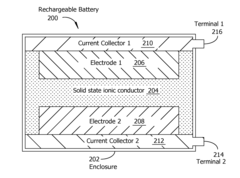

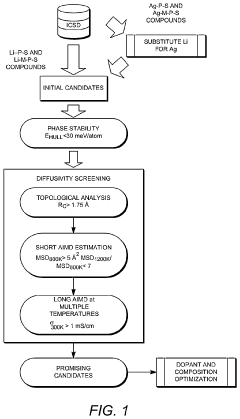

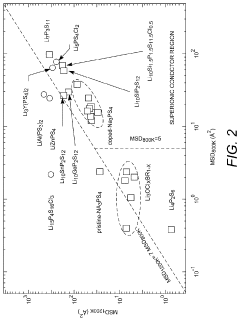

Screening solid state ionic conductors for high ionic conductivity

PatentActiveUS20150204809A1

Innovation

- A method using a Skellam distribution to estimate diffusivity from atomic displacement calculations, allowing for rapid screening of inorganic materials by simulating their crystal structures at short simulation times and comparing the results to a threshold value, thereby identifying preferred conductive materials.

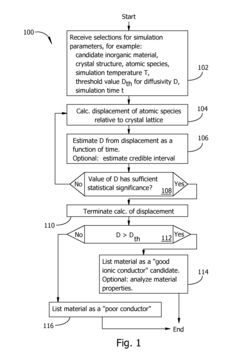

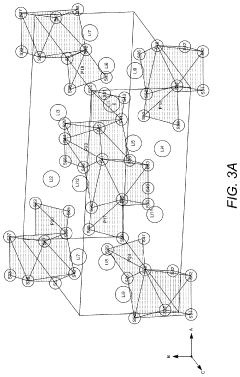

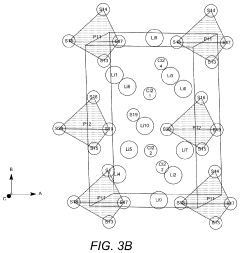

Lithium and sodium superionic conductors

PatentActiveUS11769908B2

Innovation

- The development of new earth-abundant lithium superionic conductors, Li3Y(PS4)2 and Li5PS4Cl2, derived from a high-throughput first principles screening approach, which predicts materials with enhanced Li+ conductivity and stability, and the application of aliovalent doping strategies to further enhance conductivity.

Materials Database Integration and Machine Learning Applications

The integration of comprehensive materials databases with advanced machine learning techniques has revolutionized the high-throughput screening of sodium superionic conductors. Materials databases such as the Materials Project, NOMAD, and AFLOW have become essential repositories containing vast amounts of structural, electronic, and ionic transport properties of potential sodium-ion conductors. These databases now incorporate experimental data alongside computational predictions, creating rich ecosystems for materials discovery.

Machine learning algorithms have demonstrated remarkable efficiency in navigating these extensive databases to identify promising sodium superionic conductor candidates. Supervised learning approaches, particularly gradient boosting and neural networks, have shown success in predicting ionic conductivity based on structural descriptors and elemental properties. These models can rapidly screen thousands of materials, reducing the computational expense associated with density functional theory calculations.

Feature engineering plays a crucial role in developing effective machine learning models for sodium conductor screening. Researchers have identified key descriptors including bond valence sums, ionic radii ratios, electronegativity differences, and structural void spaces as critical parameters that correlate with superionic behavior. Advanced representation techniques such as crystal graph convolutional neural networks have further improved prediction accuracy by capturing complex structural relationships.

Transfer learning approaches have emerged as particularly valuable in the sodium superionic conductor domain. Models initially trained on lithium conductor data can be fine-tuned with limited sodium conductor data, leveraging similarities in ion transport mechanisms while accounting for the larger ionic radius and different coordination preferences of sodium ions.

Active learning frameworks represent the cutting edge of database-ML integration, intelligently selecting which materials to investigate next based on model uncertainty and predicted performance. This approach optimizes computational and experimental resources by focusing on the most informative candidates, accelerating the discovery timeline for novel sodium superionic materials.

Data standardization and interoperability between different materials databases remain significant challenges. Efforts like the OPTIMADE API are working to create unified interfaces that allow seamless querying across multiple databases, enhancing the breadth of materials that can be screened simultaneously through machine learning pipelines.

The combination of high-throughput computational screening with targeted experimental validation has created a powerful feedback loop, continuously improving both database quality and machine learning model accuracy. This synergistic approach has already identified several promising sodium superionic conductor candidates that traditional methods might have overlooked.

Machine learning algorithms have demonstrated remarkable efficiency in navigating these extensive databases to identify promising sodium superionic conductor candidates. Supervised learning approaches, particularly gradient boosting and neural networks, have shown success in predicting ionic conductivity based on structural descriptors and elemental properties. These models can rapidly screen thousands of materials, reducing the computational expense associated with density functional theory calculations.

Feature engineering plays a crucial role in developing effective machine learning models for sodium conductor screening. Researchers have identified key descriptors including bond valence sums, ionic radii ratios, electronegativity differences, and structural void spaces as critical parameters that correlate with superionic behavior. Advanced representation techniques such as crystal graph convolutional neural networks have further improved prediction accuracy by capturing complex structural relationships.

Transfer learning approaches have emerged as particularly valuable in the sodium superionic conductor domain. Models initially trained on lithium conductor data can be fine-tuned with limited sodium conductor data, leveraging similarities in ion transport mechanisms while accounting for the larger ionic radius and different coordination preferences of sodium ions.

Active learning frameworks represent the cutting edge of database-ML integration, intelligently selecting which materials to investigate next based on model uncertainty and predicted performance. This approach optimizes computational and experimental resources by focusing on the most informative candidates, accelerating the discovery timeline for novel sodium superionic materials.

Data standardization and interoperability between different materials databases remain significant challenges. Efforts like the OPTIMADE API are working to create unified interfaces that allow seamless querying across multiple databases, enhancing the breadth of materials that can be screened simultaneously through machine learning pipelines.

The combination of high-throughput computational screening with targeted experimental validation has created a powerful feedback loop, continuously improving both database quality and machine learning model accuracy. This synergistic approach has already identified several promising sodium superionic conductor candidates that traditional methods might have overlooked.

Sustainability and Resource Considerations for Na-ion Technologies

The shift towards sodium-ion technologies represents a significant opportunity for sustainable energy storage solutions. Unlike lithium, sodium resources are abundant and widely distributed globally, with seawater containing approximately 10.8 grams of sodium per liter. This abundance translates to lower extraction costs and reduced geopolitical tensions associated with resource acquisition, making sodium-based technologies inherently more sustainable from a resource perspective.

Environmental impact assessments of sodium superionic conductor manufacturing processes reveal substantially lower carbon footprints compared to lithium-based alternatives. The extraction and processing of sodium compounds typically require 30-40% less energy than comparable lithium operations, resulting in reduced greenhouse gas emissions throughout the supply chain. Additionally, water consumption in sodium extraction is significantly lower, addressing critical concerns in water-stressed regions where lithium brine operations have faced increasing scrutiny.

Material circularity presents another compelling sustainability advantage for sodium-ion technologies. Current research indicates that sodium-based components demonstrate superior recyclability profiles, with recovery rates potentially exceeding 90% using optimized hydrometallurgical processes. This high recovery potential establishes a foundation for closed-loop material systems that minimize waste and reduce dependence on primary resource extraction.

Land use considerations also favor sodium-based technologies. The geographical distribution of sodium resources allows for more distributed extraction operations with smaller environmental footprints compared to the concentrated lithium extraction sites that often disrupt sensitive ecosystems. This distributed approach reduces habitat fragmentation and preserves biodiversity in critical areas.

Economic sustainability metrics further support the development of sodium superionic conductors. Cost modeling indicates that at scale, sodium-based energy storage systems could achieve 40-60% cost reductions compared to lithium alternatives, primarily due to lower material costs and simplified manufacturing requirements. This economic advantage could accelerate adoption of grid-scale energy storage, supporting renewable energy integration and decarbonization efforts.

Safety considerations represent an often overlooked sustainability dimension. Sodium-based systems typically demonstrate lower thermal runaway risks and reduced fire hazards compared to conventional lithium-ion technologies. This enhanced safety profile reduces the likelihood of catastrophic failures that can result in significant environmental contamination and resource loss, further strengthening the sustainability case for sodium superionic conductor development.

Environmental impact assessments of sodium superionic conductor manufacturing processes reveal substantially lower carbon footprints compared to lithium-based alternatives. The extraction and processing of sodium compounds typically require 30-40% less energy than comparable lithium operations, resulting in reduced greenhouse gas emissions throughout the supply chain. Additionally, water consumption in sodium extraction is significantly lower, addressing critical concerns in water-stressed regions where lithium brine operations have faced increasing scrutiny.

Material circularity presents another compelling sustainability advantage for sodium-ion technologies. Current research indicates that sodium-based components demonstrate superior recyclability profiles, with recovery rates potentially exceeding 90% using optimized hydrometallurgical processes. This high recovery potential establishes a foundation for closed-loop material systems that minimize waste and reduce dependence on primary resource extraction.

Land use considerations also favor sodium-based technologies. The geographical distribution of sodium resources allows for more distributed extraction operations with smaller environmental footprints compared to the concentrated lithium extraction sites that often disrupt sensitive ecosystems. This distributed approach reduces habitat fragmentation and preserves biodiversity in critical areas.

Economic sustainability metrics further support the development of sodium superionic conductors. Cost modeling indicates that at scale, sodium-based energy storage systems could achieve 40-60% cost reductions compared to lithium alternatives, primarily due to lower material costs and simplified manufacturing requirements. This economic advantage could accelerate adoption of grid-scale energy storage, supporting renewable energy integration and decarbonization efforts.

Safety considerations represent an often overlooked sustainability dimension. Sodium-based systems typically demonstrate lower thermal runaway risks and reduced fire hazards compared to conventional lithium-ion technologies. This enhanced safety profile reduces the likelihood of catastrophic failures that can result in significant environmental contamination and resource loss, further strengthening the sustainability case for sodium superionic conductor development.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!