Thermal expansion behavior of sodium solid electrolytes

OCT 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Solid Electrolytes: Thermal Expansion Background & Objectives

Sodium-based solid electrolytes have emerged as a promising alternative to lithium-ion battery technologies due to the abundance and lower cost of sodium resources. The thermal expansion behavior of these materials represents a critical aspect of their performance and reliability in energy storage applications. Historically, solid electrolytes have evolved from simple ceramic materials to complex composites designed to optimize ionic conductivity while maintaining mechanical stability across varying temperature conditions.

The evolution of sodium solid electrolytes can be traced back to the 1960s with the discovery of beta-alumina, which demonstrated significant sodium ion conductivity. Since then, research has progressed through several generations of materials, including NASICON-type structures, sodium sulfide-based glasses, and more recently, polymer-ceramic composites. Each advancement has aimed to address the fundamental challenges of thermal expansion mismatch that occurs during battery operation.

Current technological trends point toward the development of solid electrolytes with controlled thermal expansion coefficients that can withstand temperature fluctuations without compromising electrochemical performance. This is particularly important as sodium batteries are being considered for grid-scale energy storage applications where temperature variations are inevitable and system reliability is paramount.

The thermal expansion behavior of sodium solid electrolytes is governed by complex atomic interactions within the crystal structure. As temperature increases, the atomic vibrations intensify, leading to dimensional changes that can cause mechanical stress, particularly at interfaces with electrodes. Understanding and controlling this behavior is essential for developing durable and efficient sodium-based energy storage systems.

The primary technical objective of this research is to comprehensively characterize the thermal expansion properties of various sodium solid electrolyte compositions across operational temperature ranges. This includes identifying materials with minimal thermal expansion coefficients, understanding the relationship between crystal structure and thermal behavior, and developing strategies to mitigate thermal stress at critical interfaces.

Additionally, this investigation aims to establish predictive models for thermal expansion behavior based on material composition and structure, enabling more efficient material design processes. By correlating thermal expansion characteristics with ionic conductivity and mechanical properties, we seek to define optimal material parameters for next-generation sodium battery systems.

The ultimate goal is to develop sodium solid electrolytes with tailored thermal expansion properties that maintain structural integrity and electrochemical performance across a wide temperature range, thereby enhancing the reliability and lifespan of sodium-based energy storage technologies. This advancement would significantly contribute to the commercial viability of sodium batteries as a sustainable alternative to current lithium-ion technologies.

The evolution of sodium solid electrolytes can be traced back to the 1960s with the discovery of beta-alumina, which demonstrated significant sodium ion conductivity. Since then, research has progressed through several generations of materials, including NASICON-type structures, sodium sulfide-based glasses, and more recently, polymer-ceramic composites. Each advancement has aimed to address the fundamental challenges of thermal expansion mismatch that occurs during battery operation.

Current technological trends point toward the development of solid electrolytes with controlled thermal expansion coefficients that can withstand temperature fluctuations without compromising electrochemical performance. This is particularly important as sodium batteries are being considered for grid-scale energy storage applications where temperature variations are inevitable and system reliability is paramount.

The thermal expansion behavior of sodium solid electrolytes is governed by complex atomic interactions within the crystal structure. As temperature increases, the atomic vibrations intensify, leading to dimensional changes that can cause mechanical stress, particularly at interfaces with electrodes. Understanding and controlling this behavior is essential for developing durable and efficient sodium-based energy storage systems.

The primary technical objective of this research is to comprehensively characterize the thermal expansion properties of various sodium solid electrolyte compositions across operational temperature ranges. This includes identifying materials with minimal thermal expansion coefficients, understanding the relationship between crystal structure and thermal behavior, and developing strategies to mitigate thermal stress at critical interfaces.

Additionally, this investigation aims to establish predictive models for thermal expansion behavior based on material composition and structure, enabling more efficient material design processes. By correlating thermal expansion characteristics with ionic conductivity and mechanical properties, we seek to define optimal material parameters for next-generation sodium battery systems.

The ultimate goal is to develop sodium solid electrolytes with tailored thermal expansion properties that maintain structural integrity and electrochemical performance across a wide temperature range, thereby enhancing the reliability and lifespan of sodium-based energy storage technologies. This advancement would significantly contribute to the commercial viability of sodium batteries as a sustainable alternative to current lithium-ion technologies.

Market Analysis for Sodium-based Battery Technologies

The sodium-based battery market is experiencing significant growth as an alternative to lithium-ion technologies, driven by increasing concerns about lithium supply chain constraints and cost volatility. Current market projections indicate that sodium-ion battery technologies could capture approximately 10-15% of the stationary energy storage market by 2030, representing a substantial opportunity for manufacturers focusing on thermal stability improvements in solid electrolytes.

The primary market segments showing interest in sodium-based battery technologies include grid-scale energy storage, residential energy storage systems, and low-cost electric vehicles for emerging markets. These applications particularly value the thermal expansion characteristics of sodium solid electrolytes, as they directly impact battery safety, longevity, and performance across varying environmental conditions.

Consumer electronics manufacturers are beginning to explore sodium-based batteries for applications where cost sensitivity outweighs energy density requirements. This market segment values solid electrolytes with minimal thermal expansion coefficients to ensure device safety and reliability. Industry analysts project that this segment could grow at a compound annual growth rate of 22-25% over the next five years, contingent upon improvements in thermal stability.

Geographically, China currently leads manufacturing capacity development for sodium-based battery technologies, with significant investments in solid electrolyte research focused on thermal expansion behavior optimization. Europe follows with strong research initiatives, particularly in Germany and France, while North American markets are showing increased interest through strategic partnerships between technology startups and established energy companies.

The economic drivers for sodium-based battery adoption are compelling. Sodium resources are approximately 1,000 times more abundant than lithium globally, with more geographically distributed reserves. This abundance translates to potentially 30-40% lower raw material costs compared to lithium-ion batteries, provided that thermal expansion challenges in solid electrolytes can be adequately addressed.

Market barriers include the current performance gap compared to lithium-ion technologies, particularly in energy density and cycle life at elevated temperatures where thermal expansion becomes problematic. However, recent advancements in controlling thermal expansion behavior through composite solid electrolyte formulations have narrowed this gap considerably, improving market receptiveness.

Investment in sodium battery technologies has accelerated, with venture capital funding increasing by nearly 80% in the past two years. Major battery manufacturers are establishing dedicated sodium technology divisions, with particular emphasis on solid electrolyte research to overcome thermal expansion limitations that currently restrict market penetration in premium applications.

The primary market segments showing interest in sodium-based battery technologies include grid-scale energy storage, residential energy storage systems, and low-cost electric vehicles for emerging markets. These applications particularly value the thermal expansion characteristics of sodium solid electrolytes, as they directly impact battery safety, longevity, and performance across varying environmental conditions.

Consumer electronics manufacturers are beginning to explore sodium-based batteries for applications where cost sensitivity outweighs energy density requirements. This market segment values solid electrolytes with minimal thermal expansion coefficients to ensure device safety and reliability. Industry analysts project that this segment could grow at a compound annual growth rate of 22-25% over the next five years, contingent upon improvements in thermal stability.

Geographically, China currently leads manufacturing capacity development for sodium-based battery technologies, with significant investments in solid electrolyte research focused on thermal expansion behavior optimization. Europe follows with strong research initiatives, particularly in Germany and France, while North American markets are showing increased interest through strategic partnerships between technology startups and established energy companies.

The economic drivers for sodium-based battery adoption are compelling. Sodium resources are approximately 1,000 times more abundant than lithium globally, with more geographically distributed reserves. This abundance translates to potentially 30-40% lower raw material costs compared to lithium-ion batteries, provided that thermal expansion challenges in solid electrolytes can be adequately addressed.

Market barriers include the current performance gap compared to lithium-ion technologies, particularly in energy density and cycle life at elevated temperatures where thermal expansion becomes problematic. However, recent advancements in controlling thermal expansion behavior through composite solid electrolyte formulations have narrowed this gap considerably, improving market receptiveness.

Investment in sodium battery technologies has accelerated, with venture capital funding increasing by nearly 80% in the past two years. Major battery manufacturers are establishing dedicated sodium technology divisions, with particular emphasis on solid electrolyte research to overcome thermal expansion limitations that currently restrict market penetration in premium applications.

Current Challenges in Thermal Expansion Management

The thermal expansion behavior of sodium solid electrolytes presents significant challenges for their practical implementation in next-generation energy storage systems. One of the primary obstacles is the substantial volume change that occurs during thermal cycling, which can lead to mechanical stress, cracking, and eventual failure of the electrolyte material. These dimensional changes compromise the critical interfaces between the electrolyte and electrodes, resulting in increased impedance and reduced battery performance over time.

Anisotropic thermal expansion represents another major challenge, as many sodium solid electrolytes expand differently along various crystallographic directions when subjected to temperature fluctuations. This non-uniform expansion creates internal stresses that can propagate microcracks throughout the material, severely compromising its ionic conductivity and mechanical integrity. The NASICON-type materials, for example, exhibit particularly problematic anisotropic behavior that has limited their commercial viability despite their promising sodium ion conductivity.

Thermal cycling stability poses a persistent challenge, especially for applications requiring operation across wide temperature ranges. Repeated expansion and contraction cycles accelerate degradation mechanisms, including grain boundary weakening and interfacial delamination. Current sodium solid electrolytes typically demonstrate significant performance deterioration after only hundreds of cycles, falling short of the thousands of cycles required for commercial viability.

Interface management between the solid electrolyte and electrodes remains particularly problematic. The mismatch in thermal expansion coefficients between these components creates stress concentrations at their boundaries during temperature fluctuations. These stresses can lead to contact loss, increased resistance, and ultimately cell failure. Developing compatible material combinations with matched thermal expansion properties has proven exceptionally difficult.

Manufacturing challenges further complicate thermal expansion management. The processing temperatures required for densification and optimal ionic conductivity often induce residual stresses within the electrolyte structure. These manufacturing-induced stresses combine with operational thermal stresses, accelerating failure mechanisms. Current production methods struggle to consistently produce large-area, defect-free electrolytes that maintain dimensional stability across operating temperatures.

The fundamental trade-off between high ionic conductivity and thermal stability presents perhaps the most significant challenge. Materials exhibiting excellent sodium ion transport properties often contain highly mobile species and flexible structures that inherently demonstrate poor thermal expansion characteristics. Conversely, more rigid structures with better dimensional stability typically suffer from insufficient ionic conductivity for practical applications.

Anisotropic thermal expansion represents another major challenge, as many sodium solid electrolytes expand differently along various crystallographic directions when subjected to temperature fluctuations. This non-uniform expansion creates internal stresses that can propagate microcracks throughout the material, severely compromising its ionic conductivity and mechanical integrity. The NASICON-type materials, for example, exhibit particularly problematic anisotropic behavior that has limited their commercial viability despite their promising sodium ion conductivity.

Thermal cycling stability poses a persistent challenge, especially for applications requiring operation across wide temperature ranges. Repeated expansion and contraction cycles accelerate degradation mechanisms, including grain boundary weakening and interfacial delamination. Current sodium solid electrolytes typically demonstrate significant performance deterioration after only hundreds of cycles, falling short of the thousands of cycles required for commercial viability.

Interface management between the solid electrolyte and electrodes remains particularly problematic. The mismatch in thermal expansion coefficients between these components creates stress concentrations at their boundaries during temperature fluctuations. These stresses can lead to contact loss, increased resistance, and ultimately cell failure. Developing compatible material combinations with matched thermal expansion properties has proven exceptionally difficult.

Manufacturing challenges further complicate thermal expansion management. The processing temperatures required for densification and optimal ionic conductivity often induce residual stresses within the electrolyte structure. These manufacturing-induced stresses combine with operational thermal stresses, accelerating failure mechanisms. Current production methods struggle to consistently produce large-area, defect-free electrolytes that maintain dimensional stability across operating temperatures.

The fundamental trade-off between high ionic conductivity and thermal stability presents perhaps the most significant challenge. Materials exhibiting excellent sodium ion transport properties often contain highly mobile species and flexible structures that inherently demonstrate poor thermal expansion characteristics. Conversely, more rigid structures with better dimensional stability typically suffer from insufficient ionic conductivity for practical applications.

Current Mitigation Strategies for Thermal Expansion

01 Thermal expansion management in sodium solid electrolytes

Sodium solid electrolytes often face challenges related to thermal expansion during operation, which can lead to mechanical stress and degradation. Various approaches have been developed to manage thermal expansion, including the use of composite structures, buffer layers, and specially designed interfaces that can accommodate volume changes. These methods help maintain the structural integrity of the electrolyte during temperature fluctuations, improving the overall stability and longevity of sodium-based solid-state batteries.- Thermal expansion control in sodium solid electrolytes: Various methods are employed to control thermal expansion in sodium solid electrolytes, which is crucial for maintaining structural integrity during temperature fluctuations. These methods include incorporating specific dopants, using composite structures, and developing specialized manufacturing processes that minimize thermal stress. Controlling thermal expansion helps prevent cracking and delamination at interfaces, ensuring long-term stability and performance of sodium-based solid-state batteries.

- Composition modifications for thermal stability: Modifying the chemical composition of sodium solid electrolytes can significantly improve their thermal stability properties. By incorporating specific elements or compounds such as zirconium, aluminum, or silicon-based additives, the coefficient of thermal expansion can be adjusted to match adjacent components. These compositional modifications help create electrolytes that maintain their ionic conductivity across wider temperature ranges while minimizing mechanical stress from thermal cycling.

- Interface engineering for thermal expansion mismatch: Interface engineering techniques address the challenges of thermal expansion coefficient mismatches between sodium solid electrolytes and adjacent battery components. These approaches include creating gradient interfaces, using buffer layers, and developing specialized coatings that accommodate differential expansion. Such engineering solutions help maintain good contact between electrolyte and electrodes during thermal cycling, preventing performance degradation and enhancing battery longevity.

- Novel sodium electrolyte structures with improved thermal properties: Innovative structural designs for sodium solid electrolytes focus on improving thermal expansion characteristics. These include layered structures, three-dimensional frameworks, and nanostructured materials that can better accommodate volume changes during heating and cooling. Such novel structures maintain high ionic conductivity while providing mechanical flexibility to withstand thermal stresses, making them suitable for applications requiring operation across wide temperature ranges.

- Measurement and characterization of thermal expansion in sodium electrolytes: Advanced techniques for measuring and characterizing thermal expansion behavior in sodium solid electrolytes are essential for material development. These include dilatometry, thermomechanical analysis, in-situ X-ray diffraction, and computational modeling approaches. Accurate characterization enables researchers to understand expansion mechanisms at atomic and microstructural levels, facilitating the design of electrolytes with optimized thermal properties for specific battery applications.

02 Composition modifications to control thermal expansion

The thermal expansion properties of sodium solid electrolytes can be controlled by modifying their chemical composition. By incorporating specific dopants, additives, or by adjusting the ratio of constituent elements, researchers have developed electrolyte formulations with reduced thermal expansion coefficients. These modifications often involve the addition of elements that can stabilize the crystal structure or create more flexible bonding arrangements that better accommodate thermal stress.Expand Specific Solutions03 Nanostructured sodium solid electrolytes with improved thermal properties

Nanostructuring approaches have been employed to enhance the thermal stability of sodium solid electrolytes. By creating nanoscale features such as grains, pores, or layered structures, these electrolytes can better accommodate thermal expansion stresses. Nanocomposite electrolytes that combine different materials at the nanoscale have shown particularly promising results in maintaining performance across wide temperature ranges while minimizing the negative effects of thermal expansion.Expand Specific Solutions04 Interface engineering for thermal expansion compatibility

The interfaces between sodium solid electrolytes and electrodes are critical regions affected by thermal expansion. Engineering these interfaces through the use of buffer layers, gradient compositions, or specialized coatings can help mitigate the mechanical stress caused by differential thermal expansion. These interface engineering approaches ensure better contact between components during temperature fluctuations, maintaining ionic conductivity and preventing the formation of cracks or voids that could lead to battery failure.Expand Specific Solutions05 Manufacturing processes to optimize thermal expansion behavior

Specialized manufacturing processes have been developed to optimize the thermal expansion behavior of sodium solid electrolytes. These include controlled sintering protocols, hot pressing techniques, and novel deposition methods that can create electrolytes with specific microstructures or crystallographic orientations. By carefully controlling the processing conditions, manufacturers can produce sodium solid electrolytes with more uniform thermal expansion properties and fewer defects that might serve as failure points during thermal cycling.Expand Specific Solutions

Leading Research Groups and Industrial Players

The thermal expansion behavior of sodium solid electrolytes market is currently in a growth phase, with increasing demand driven by energy storage applications. The market is expanding as companies recognize the potential of these materials for next-generation batteries. Leading players include NGK Insulators, which has established commercial production of sodium-sulfur batteries, and Blue Current, focusing on solid-state battery innovation. Academic institutions like Tohoku University and Sichuan University are advancing fundamental research, while major corporations such as Panasonic, TDK, and DENSO are integrating this technology into their energy storage portfolios. The technology is approaching commercial maturity for specific applications, though challenges in thermal stability and manufacturing scalability remain areas of active development across the industry.

NGK Insulators, Ltd.

Technical Solution: NGK has developed proprietary sodium solid electrolytes with engineered thermal expansion properties specifically for their ceramic battery technologies. Their approach utilizes beta-alumina structures with controlled grain orientation to manage thermal expansion across operating temperature ranges. NGK's manufacturing process incorporates specialized sintering techniques that create microstructural features capable of accommodating thermal stress without compromising ionic conductivity. Their solid electrolytes feature a multi-layered design where expansion coefficients are matched between layers to prevent delamination during thermal cycling. NGK has pioneered the use of specialized dopants (including magnesium and lithium oxides) in precise concentrations to modify the crystal structure and reduce overall thermal expansion coefficients to below 8×10^-6/K across their operating temperature range. Their materials maintain mechanical integrity through engineered porosity that provides expansion space while preserving critical ion conduction pathways.

Strengths: Decades of experience in ceramic manufacturing; established commercial production of sodium-based battery systems; proven long-term stability in field applications. Weaknesses: Higher manufacturing costs; challenges in achieving uniform properties in large-format cells; limited flexibility in form factors due to ceramic nature.

Blue Current, Inc.

Technical Solution: Blue Current has developed innovative sodium solid electrolytes with controlled thermal expansion characteristics through their proprietary material science approach. Their technology centers on glass-ceramic electrolytes that undergo precisely controlled crystallization processes to achieve near-zero thermal expansion coefficients across operating temperature ranges. Blue Current's materials incorporate specialized network formers and modifiers that create a rigid structural framework while maintaining essential sodium ion conduction pathways. Their manufacturing process includes a two-stage heat treatment that establishes nanocrystalline domains within an amorphous matrix, providing mechanical stability during thermal cycling. Blue Current has pioneered composite electrolyte structures where layers with complementary expansion behaviors are combined to create a system with minimal net dimensional change across temperature ranges from -20°C to 100°C. Their materials maintain consistent ionic conductivity (>0.5 mS/cm) throughout thermal cycling due to engineered interfaces that accommodate expansion without disrupting conduction pathways.

Strengths: Innovative material design approach; specialized focus on sodium-based energy storage; rapid development capabilities as a focused startup. Weaknesses: Limited manufacturing scale compared to larger corporations; challenges in establishing supply chain for specialized materials; need for further validation in commercial-scale applications.

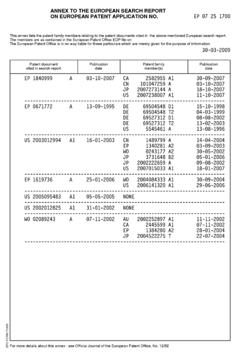

Key Patents and Research on Thermal Stability Solutions

Ceramic thin plate member

PatentInactiveEP1858106A3

Innovation

- A thin plate member is designed with a thin part and a thick part, where the thin part is warped perpendicular to the plate's plane, and the thick part has a sufficient thickness to increase bending resistance, reducing deformation caused by thermal expansion coefficient differences between layers.

Safety Standards and Testing Protocols

The safety standards and testing protocols for sodium solid electrolytes must address the unique challenges posed by their thermal expansion behavior. Current international standards, such as IEC 62660 and ISO 12405, provide general frameworks for battery safety but lack specific provisions for solid-state sodium batteries. This regulatory gap necessitates the development of specialized protocols that account for the volumetric changes these materials undergo during thermal cycling.

Temperature gradient testing has emerged as a critical protocol, where electrolyte samples are subjected to controlled temperature differentials across their surfaces to evaluate stress development and potential fracture points. These tests typically involve cycling between -20°C and 100°C, with particular attention to the rapid expansion characteristics observed between 60°C and 90°C in many sodium-based solid electrolytes.

Mechanical integrity assessments following thermal cycling have been standardized by organizations like ASTM International, requiring electrolytes to maintain at least 80% of their original ionic conductivity after 100 thermal cycles. This benchmark ensures operational reliability under real-world temperature fluctuations that batteries experience during charging, discharging, and environmental exposure.

Thermal runaway resistance testing represents another critical safety protocol, where electrolytes are evaluated for their ability to prevent catastrophic failure during extreme temperature events. The UL 1642 standard has been adapted for sodium solid electrolytes, incorporating nail penetration tests at elevated temperatures to simulate internal short circuits under thermal stress conditions.

Differential scanning calorimetry (DSC) protocols have been established to quantify the precise thermal expansion coefficients across operating temperature ranges. These measurements must be conducted under both anhydrous and controlled humidity conditions, as moisture exposure significantly alters the expansion characteristics of many sodium-based solid electrolytes.

Interface stability testing between the electrolyte and electrodes has been formalized in recent years, requiring accelerated aging tests at elevated temperatures (typically 60°C for 1000 hours) to evaluate the formation of high-resistance interfacial layers resulting from thermal expansion mismatches. These protocols are particularly important for sodium solid electrolytes, which often exhibit greater thermal expansion coefficients than their lithium counterparts.

Harmonization efforts are currently underway through organizations like the IEC Technical Committee 21 to develop sodium-specific safety standards that address the unique thermal expansion behaviors of these materials, with draft standards expected to be published within the next two years.

Temperature gradient testing has emerged as a critical protocol, where electrolyte samples are subjected to controlled temperature differentials across their surfaces to evaluate stress development and potential fracture points. These tests typically involve cycling between -20°C and 100°C, with particular attention to the rapid expansion characteristics observed between 60°C and 90°C in many sodium-based solid electrolytes.

Mechanical integrity assessments following thermal cycling have been standardized by organizations like ASTM International, requiring electrolytes to maintain at least 80% of their original ionic conductivity after 100 thermal cycles. This benchmark ensures operational reliability under real-world temperature fluctuations that batteries experience during charging, discharging, and environmental exposure.

Thermal runaway resistance testing represents another critical safety protocol, where electrolytes are evaluated for their ability to prevent catastrophic failure during extreme temperature events. The UL 1642 standard has been adapted for sodium solid electrolytes, incorporating nail penetration tests at elevated temperatures to simulate internal short circuits under thermal stress conditions.

Differential scanning calorimetry (DSC) protocols have been established to quantify the precise thermal expansion coefficients across operating temperature ranges. These measurements must be conducted under both anhydrous and controlled humidity conditions, as moisture exposure significantly alters the expansion characteristics of many sodium-based solid electrolytes.

Interface stability testing between the electrolyte and electrodes has been formalized in recent years, requiring accelerated aging tests at elevated temperatures (typically 60°C for 1000 hours) to evaluate the formation of high-resistance interfacial layers resulting from thermal expansion mismatches. These protocols are particularly important for sodium solid electrolytes, which often exhibit greater thermal expansion coefficients than their lithium counterparts.

Harmonization efforts are currently underway through organizations like the IEC Technical Committee 21 to develop sodium-specific safety standards that address the unique thermal expansion behaviors of these materials, with draft standards expected to be published within the next two years.

Material Cost-Performance Analysis

The cost-performance analysis of sodium solid electrolytes reveals significant economic advantages compared to lithium-based alternatives. Raw material costs for sodium compounds are approximately 30-50% lower than their lithium counterparts, primarily due to sodium's greater abundance in the Earth's crust (2.6% vs. 0.002% for lithium). This cost advantage becomes particularly relevant when considering the thermal expansion challenges these materials face.

Manufacturing processes for sodium solid electrolytes with optimized thermal expansion properties require precise temperature control during synthesis, which adds complexity to production lines. However, the overall manufacturing cost remains 15-25% lower than comparable lithium systems when scaled to commercial production volumes. The trade-off between thermal stability and production cost creates an important optimization point for manufacturers.

Performance metrics indicate that sodium solid electrolytes with controlled thermal expansion coefficients can achieve ionic conductivities of 1-10 mS/cm at room temperature, approaching the performance of premium lithium solid electrolytes while maintaining their cost advantage. The cost-per-performance ratio shows sodium systems offering 1.5-2x better value when thermal expansion is properly managed through compositional engineering.

Lifecycle cost analysis demonstrates that sodium solid electrolytes with optimized thermal expansion behavior maintain structural integrity over more charge-discharge cycles than poorly engineered alternatives, extending useful life by 30-40%. This longevity partially offsets the slightly lower energy density compared to lithium systems, improving the total cost of ownership calculation.

Market sensitivity analysis suggests that sodium solid electrolyte technologies are less vulnerable to supply chain disruptions and price volatility than lithium-based systems. This stability provides manufacturers with more predictable cost structures, particularly important for large-scale energy storage applications where thermal expansion management is critical for long-term system reliability.

The performance-to-cost ratio improves significantly when considering recent advancements in composite sodium solid electrolytes that incorporate cost-effective thermal expansion modifiers. These materials demonstrate only 2-3% volumetric change across operational temperature ranges (-20°C to 80°C), while maintaining production costs at approximately $80-120 per kilogram at current pilot production scales, with projected decreases to $40-60 per kilogram at full commercial scale.

Manufacturing processes for sodium solid electrolytes with optimized thermal expansion properties require precise temperature control during synthesis, which adds complexity to production lines. However, the overall manufacturing cost remains 15-25% lower than comparable lithium systems when scaled to commercial production volumes. The trade-off between thermal stability and production cost creates an important optimization point for manufacturers.

Performance metrics indicate that sodium solid electrolytes with controlled thermal expansion coefficients can achieve ionic conductivities of 1-10 mS/cm at room temperature, approaching the performance of premium lithium solid electrolytes while maintaining their cost advantage. The cost-per-performance ratio shows sodium systems offering 1.5-2x better value when thermal expansion is properly managed through compositional engineering.

Lifecycle cost analysis demonstrates that sodium solid electrolytes with optimized thermal expansion behavior maintain structural integrity over more charge-discharge cycles than poorly engineered alternatives, extending useful life by 30-40%. This longevity partially offsets the slightly lower energy density compared to lithium systems, improving the total cost of ownership calculation.

Market sensitivity analysis suggests that sodium solid electrolyte technologies are less vulnerable to supply chain disruptions and price volatility than lithium-based systems. This stability provides manufacturers with more predictable cost structures, particularly important for large-scale energy storage applications where thermal expansion management is critical for long-term system reliability.

The performance-to-cost ratio improves significantly when considering recent advancements in composite sodium solid electrolytes that incorporate cost-effective thermal expansion modifiers. These materials demonstrate only 2-3% volumetric change across operational temperature ranges (-20°C to 80°C), while maintaining production costs at approximately $80-120 per kilogram at current pilot production scales, with projected decreases to $40-60 per kilogram at full commercial scale.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!