Sodium superionic conductors for room-temperature operation

OCT 14, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Superionic Conductors Background and Objectives

Sodium-ion batteries (SIBs) have emerged as a promising alternative to lithium-ion batteries due to the abundance and low cost of sodium resources. The global lithium supply constraints and increasing demand for energy storage solutions have accelerated research into sodium-based technologies over the past decade. Historically, sodium superionic conductors have been studied since the 1970s, but recent advancements in materials science and electrochemistry have revitalized interest in these materials for practical applications.

The evolution of sodium superionic conductors has progressed from early Na-β-alumina systems to more complex structures including NASICON-type materials, sodium thiophosphates, and polymer-based electrolytes. Each generation has addressed specific limitations of its predecessors, gradually improving ionic conductivity, electrochemical stability, and mechanical properties. The current technological trajectory points toward hybrid and composite systems that combine the advantages of different material classes.

The primary objective of research on room-temperature sodium superionic conductors is to develop solid electrolytes with ionic conductivities exceeding 10^-3 S/cm at ambient temperatures, while maintaining excellent electrochemical stability windows (>4V) and favorable mechanical properties. These materials must enable the construction of all-solid-state sodium batteries that can compete with conventional lithium-ion technologies in terms of energy density, power capability, and cycle life.

Secondary objectives include enhancing the interfacial stability between the electrolyte and electrodes, reducing manufacturing complexity, and ensuring long-term reliability under various operating conditions. The development of scalable and cost-effective production methods represents another critical goal, as commercial viability ultimately depends on economic feasibility.

Recent breakthroughs in computational materials science have accelerated the discovery process through high-throughput screening and machine learning approaches. These tools have identified promising structural motifs and compositional spaces that facilitate rapid sodium-ion transport. Experimental validation of these computational predictions has yielded several candidate materials with unprecedented room-temperature performance.

The technical challenges that remain include addressing the mechanical instability during sodium plating/stripping processes, mitigating dendrite formation, and developing compatible electrode materials that can fully utilize the advantages of solid electrolytes. Solving these interconnected issues requires a multidisciplinary approach combining fundamental materials science with practical engineering considerations.

As global energy demands continue to rise and sustainability concerns intensify, the successful development of room-temperature sodium superionic conductors could revolutionize grid-scale energy storage, electric transportation, and portable electronics by providing a more sustainable and economically viable alternative to current technologies.

The evolution of sodium superionic conductors has progressed from early Na-β-alumina systems to more complex structures including NASICON-type materials, sodium thiophosphates, and polymer-based electrolytes. Each generation has addressed specific limitations of its predecessors, gradually improving ionic conductivity, electrochemical stability, and mechanical properties. The current technological trajectory points toward hybrid and composite systems that combine the advantages of different material classes.

The primary objective of research on room-temperature sodium superionic conductors is to develop solid electrolytes with ionic conductivities exceeding 10^-3 S/cm at ambient temperatures, while maintaining excellent electrochemical stability windows (>4V) and favorable mechanical properties. These materials must enable the construction of all-solid-state sodium batteries that can compete with conventional lithium-ion technologies in terms of energy density, power capability, and cycle life.

Secondary objectives include enhancing the interfacial stability between the electrolyte and electrodes, reducing manufacturing complexity, and ensuring long-term reliability under various operating conditions. The development of scalable and cost-effective production methods represents another critical goal, as commercial viability ultimately depends on economic feasibility.

Recent breakthroughs in computational materials science have accelerated the discovery process through high-throughput screening and machine learning approaches. These tools have identified promising structural motifs and compositional spaces that facilitate rapid sodium-ion transport. Experimental validation of these computational predictions has yielded several candidate materials with unprecedented room-temperature performance.

The technical challenges that remain include addressing the mechanical instability during sodium plating/stripping processes, mitigating dendrite formation, and developing compatible electrode materials that can fully utilize the advantages of solid electrolytes. Solving these interconnected issues requires a multidisciplinary approach combining fundamental materials science with practical engineering considerations.

As global energy demands continue to rise and sustainability concerns intensify, the successful development of room-temperature sodium superionic conductors could revolutionize grid-scale energy storage, electric transportation, and portable electronics by providing a more sustainable and economically viable alternative to current technologies.

Market Analysis for Room-Temperature Sodium Battery Technologies

The global market for sodium-based battery technologies is experiencing significant growth, driven by increasing demand for sustainable and cost-effective energy storage solutions. Unlike lithium-ion batteries that dominate the current market, sodium-based batteries offer compelling economic advantages due to sodium's abundance in the earth's crust, costing approximately $150 per ton compared to lithium at $15,000 per ton. This substantial cost differential positions sodium batteries as an attractive alternative, particularly for large-scale stationary storage applications where cost sensitivity outweighs energy density considerations.

Market projections indicate that the sodium battery market could reach $500 million by 2025, with a compound annual growth rate of 23% between 2021-2028. This growth trajectory is supported by increasing investments in renewable energy infrastructure, which requires efficient and economical energy storage systems to manage intermittency issues. Grid-scale storage represents the largest market segment, accounting for approximately 45% of potential sodium battery applications.

The industrial sector presents another significant market opportunity, particularly for backup power systems and uninterruptible power supplies where the lower cost of sodium batteries offers competitive advantages. Consumer electronics manufacturers are also exploring sodium battery technologies for low-cost devices where weight and size constraints are less critical.

Geographically, Asia-Pacific leads market development, with China, Japan, and South Korea investing heavily in sodium battery research and manufacturing capabilities. Europe follows closely, driven by stringent environmental regulations and renewable energy targets. North America shows growing interest, particularly in grid-scale applications and electric vehicle segments seeking cost-effective alternatives to lithium-ion technologies.

Market barriers include technical challenges related to sodium superionic conductors' stability and performance at room temperature, competition from established lithium-ion technologies, and limited manufacturing infrastructure. However, recent breakthroughs in room-temperature sodium superionic conductors have significantly improved the commercial viability of these technologies.

Customer adoption patterns indicate growing acceptance among utility companies and renewable energy developers seeking cost-effective storage solutions. Early commercial deployments have demonstrated promising performance metrics, with lifecycle costs approximately 30% lower than comparable lithium-ion systems for stationary applications.

The market outlook remains positive, with sodium battery technologies positioned to capture significant market share in specific applications where their cost advantages outweigh energy density limitations. As research advances in sodium superionic conductors continue to improve performance at room temperature, market penetration is expected to accelerate across multiple sectors.

Market projections indicate that the sodium battery market could reach $500 million by 2025, with a compound annual growth rate of 23% between 2021-2028. This growth trajectory is supported by increasing investments in renewable energy infrastructure, which requires efficient and economical energy storage systems to manage intermittency issues. Grid-scale storage represents the largest market segment, accounting for approximately 45% of potential sodium battery applications.

The industrial sector presents another significant market opportunity, particularly for backup power systems and uninterruptible power supplies where the lower cost of sodium batteries offers competitive advantages. Consumer electronics manufacturers are also exploring sodium battery technologies for low-cost devices where weight and size constraints are less critical.

Geographically, Asia-Pacific leads market development, with China, Japan, and South Korea investing heavily in sodium battery research and manufacturing capabilities. Europe follows closely, driven by stringent environmental regulations and renewable energy targets. North America shows growing interest, particularly in grid-scale applications and electric vehicle segments seeking cost-effective alternatives to lithium-ion technologies.

Market barriers include technical challenges related to sodium superionic conductors' stability and performance at room temperature, competition from established lithium-ion technologies, and limited manufacturing infrastructure. However, recent breakthroughs in room-temperature sodium superionic conductors have significantly improved the commercial viability of these technologies.

Customer adoption patterns indicate growing acceptance among utility companies and renewable energy developers seeking cost-effective storage solutions. Early commercial deployments have demonstrated promising performance metrics, with lifecycle costs approximately 30% lower than comparable lithium-ion systems for stationary applications.

The market outlook remains positive, with sodium battery technologies positioned to capture significant market share in specific applications where their cost advantages outweigh energy density limitations. As research advances in sodium superionic conductors continue to improve performance at room temperature, market penetration is expected to accelerate across multiple sectors.

Current Status and Technical Barriers in Sodium Superionic Conductors

Sodium superionic conductors have garnered significant attention in recent years due to their potential applications in solid-state sodium batteries, which offer a promising alternative to lithium-ion technology. Currently, the field has achieved notable progress with several materials demonstrating sodium ionic conductivity exceeding 10^-3 S/cm at room temperature, a threshold considered viable for practical applications. Among these, NASICON-type materials (Na₃Zr₂Si₂PO₁₂), β-alumina (Na₁₊ₓAl₁₁O₁₇), and sodium thiophosphates (Na₃PS₄) have emerged as leading candidates.

Despite these advancements, significant technical barriers persist in the development of sodium superionic conductors for room-temperature operation. The primary challenge remains achieving consistently high ionic conductivity (>10^-3 S/cm) at ambient temperatures while maintaining mechanical stability. Many promising materials exhibit excellent conductivity only at elevated temperatures, limiting their practical utility in consumer applications.

Interface stability represents another critical obstacle. When in contact with sodium metal anodes, many solid electrolytes form resistive interphases that impede ion transport and increase cell impedance over time. This degradation mechanism is particularly pronounced in sulfide-based conductors, which despite their high conductivity, often suffer from poor electrochemical stability windows.

Manufacturing scalability presents additional challenges. Current synthesis methods for high-performance sodium conductors often require complex processing conditions, including high-temperature sintering or controlled atmosphere environments. These requirements significantly increase production costs and hinder commercial viability. Furthermore, many synthesis routes involve toxic precursors or generate hazardous byproducts, raising environmental and safety concerns.

Mechanical properties of sodium superionic conductors also require substantial improvement. Many materials with excellent ionic conductivity suffer from poor mechanical strength or are prone to fracture during cycling. This fragility compromises the long-term durability of solid-state sodium batteries, particularly under conditions involving volume changes in electrode materials.

The development of sodium superionic conductors is further complicated by fundamental knowledge gaps in ion transport mechanisms. While computational studies have provided valuable insights, the complex relationship between crystal structure, defect chemistry, and ion mobility remains incompletely understood. This limited mechanistic understanding hampers rational design approaches for new materials with optimized properties.

Standardization of testing protocols represents an additional barrier to progress. Variations in measurement techniques and conditions across research groups make direct comparisons between different materials challenging, slowing the identification of truly promising candidates for further development.

Despite these advancements, significant technical barriers persist in the development of sodium superionic conductors for room-temperature operation. The primary challenge remains achieving consistently high ionic conductivity (>10^-3 S/cm) at ambient temperatures while maintaining mechanical stability. Many promising materials exhibit excellent conductivity only at elevated temperatures, limiting their practical utility in consumer applications.

Interface stability represents another critical obstacle. When in contact with sodium metal anodes, many solid electrolytes form resistive interphases that impede ion transport and increase cell impedance over time. This degradation mechanism is particularly pronounced in sulfide-based conductors, which despite their high conductivity, often suffer from poor electrochemical stability windows.

Manufacturing scalability presents additional challenges. Current synthesis methods for high-performance sodium conductors often require complex processing conditions, including high-temperature sintering or controlled atmosphere environments. These requirements significantly increase production costs and hinder commercial viability. Furthermore, many synthesis routes involve toxic precursors or generate hazardous byproducts, raising environmental and safety concerns.

Mechanical properties of sodium superionic conductors also require substantial improvement. Many materials with excellent ionic conductivity suffer from poor mechanical strength or are prone to fracture during cycling. This fragility compromises the long-term durability of solid-state sodium batteries, particularly under conditions involving volume changes in electrode materials.

The development of sodium superionic conductors is further complicated by fundamental knowledge gaps in ion transport mechanisms. While computational studies have provided valuable insights, the complex relationship between crystal structure, defect chemistry, and ion mobility remains incompletely understood. This limited mechanistic understanding hampers rational design approaches for new materials with optimized properties.

Standardization of testing protocols represents an additional barrier to progress. Variations in measurement techniques and conditions across research groups make direct comparisons between different materials challenging, slowing the identification of truly promising candidates for further development.

State-of-the-Art Room-Temperature Sodium Conductor Solutions

01 Sodium-based solid electrolyte materials for batteries

Sodium-based solid electrolyte materials with high ionic conductivity are being developed for use in sodium-ion batteries. These materials offer advantages such as improved safety, higher energy density, and longer cycle life compared to conventional liquid electrolytes. The solid electrolytes facilitate the movement of sodium ions between electrodes while preventing short circuits and dendrite formation. Various compositions and structures are being explored to optimize ionic conductivity at room temperature.- NASICON-type sodium superionic conductors: NASICON (Sodium Super Ionic Conductor) materials are a class of ceramic compounds with high sodium ion conductivity. These materials typically have a three-dimensional framework structure that allows for fast sodium ion transport. NASICON-type materials often contain phosphate groups and can be modified with various dopants to enhance their ionic conductivity. They are promising candidates for solid-state electrolytes in sodium-ion batteries due to their high ionic conductivity and good chemical stability.

- Beta-alumina sodium ion conductors: Beta-alumina is a well-established sodium ion conductor with a layered crystal structure that facilitates fast sodium ion transport. It consists of alternating dense blocks and conduction planes where sodium ions can move rapidly. Beta-alumina materials have been extensively studied for applications in sodium batteries and other electrochemical devices. Their ionic conductivity can be enhanced through compositional modifications and processing techniques to optimize the microstructure and reduce grain boundary resistance.

- Polymer-based sodium ion conductors: Polymer-based sodium ion conductors combine organic polymer matrices with sodium salts to create flexible electrolyte materials. These systems typically incorporate polyethylene oxide (PEO) or other polymer hosts that can coordinate with sodium ions and facilitate their transport. The addition of plasticizers, ceramic fillers, or ionic liquids can enhance the ionic conductivity of these polymer electrolytes. These materials offer advantages in terms of processability, flexibility, and interfacial compatibility with electrodes.

- Glass and glass-ceramic sodium ion conductors: Glass and glass-ceramic materials can exhibit high sodium ion conductivity through optimized compositions and microstructures. These materials typically contain network formers like silica or borate, along with sodium oxide and other modifiers that create pathways for sodium ion transport. The controlled crystallization of sodium-conducting phases within a glassy matrix can lead to enhanced ionic conductivity. These materials offer advantages in terms of isotropic conductivity and the ability to form dense, pinhole-free electrolytes.

- Novel sodium superionic conductor materials and fabrication methods: Recent advances in sodium superionic conductors include the development of new material compositions and innovative fabrication techniques to enhance ionic conductivity. These approaches include the synthesis of nanostructured materials, composite electrolytes combining different conductor types, and surface modification strategies to improve interfacial properties. Advanced characterization techniques are employed to understand ion transport mechanisms and optimize material performance. These novel materials aim to achieve room-temperature ionic conductivities comparable to liquid electrolytes while maintaining good mechanical properties and electrochemical stability.

02 NASICON-type sodium superionic conductors

NASICON (Sodium Super Ionic CONductor) materials represent a significant class of sodium ion conductors with three-dimensional frameworks that facilitate fast ion transport. These materials typically have the general formula Na1+xZr2SixP3-xO12 and feature interconnected channels that allow for high sodium ion mobility. Research focuses on optimizing composition through elemental substitution and structural modifications to enhance ionic conductivity while maintaining mechanical and chemical stability for applications in energy storage and conversion devices.Expand Specific Solutions03 Beta-alumina sodium ion conductors

Beta-alumina is a well-established sodium superionic conductor with a layered crystal structure that provides two-dimensional pathways for sodium ion migration. The material consists of dense blocks of aluminum oxide separated by conduction planes containing mobile sodium ions. Various doping strategies and processing techniques are employed to enhance the ionic conductivity and mechanical properties of beta-alumina. These materials are particularly important for high-temperature sodium batteries and other electrochemical applications requiring efficient sodium ion transport.Expand Specific Solutions04 Polymer-based sodium ion conductors

Polymer-based sodium ion conductors combine organic polymer matrices with sodium salts to create flexible electrolyte systems with appreciable ionic conductivity. These materials offer advantages such as ease of processing, good interfacial contact with electrodes, and mechanical flexibility. Research focuses on developing polymer composites with enhanced sodium ion transport properties through the incorporation of plasticizers, ceramic fillers, or ionic liquids. Applications include flexible sodium batteries, sensors, and other electrochemical devices requiring soft electrolyte materials.Expand Specific Solutions05 Manufacturing and characterization methods for sodium superionic conductors

Advanced manufacturing and characterization techniques are essential for developing high-performance sodium superionic conductors. These include specialized synthesis methods such as solid-state reaction, sol-gel processing, and mechanochemical approaches to control microstructure and phase purity. Analytical techniques like impedance spectroscopy, X-ray diffraction, and electron microscopy are employed to evaluate ionic conductivity, structural properties, and transport mechanisms. Computational modeling helps predict and optimize material compositions for enhanced sodium ion mobility and stability under operating conditions.Expand Specific Solutions

Leading Research Groups and Industrial Stakeholders

The sodium superionic conductor market for room-temperature applications is in an early growth phase, with increasing research momentum driven by demand for safer, more efficient energy storage solutions. The global market is projected to expand significantly as these materials become critical for next-generation solid-state batteries. Technologically, the field shows promising developments but remains in transition from research to commercialization. Leading players include established industrial giants like Robert Bosch, Honda Motor, Hitachi, and BASF, alongside specialized entities such as Svolt Energy and JSR Corp. Academic institutions including the University of Rochester, Virginia Commonwealth University, and the Indian Institute of Science are contributing fundamental research advancements. The ecosystem demonstrates a balanced mix of commercial and research entities working to overcome conductivity and stability challenges for practical room-temperature applications.

Sumitomo Electric Industries Ltd.

Technical Solution: Sumitomo Electric has developed an innovative sodium superionic conductor technology based on β″-alumina structures with enhanced room-temperature performance. Their approach involves precise control of the crystal structure through advanced ceramic processing techniques and careful composition optimization. The company has achieved sodium ionic conductivity exceeding 2 mS/cm at room temperature through microstructural engineering that creates optimized ion transport pathways[1]. Their proprietary manufacturing process includes a specialized sintering protocol that minimizes grain boundary resistance while maintaining mechanical integrity. Sumitomo's conductors feature a unique surface treatment that improves compatibility with electrode materials and enhances long-term stability. The company has demonstrated these materials in sodium battery prototypes achieving energy densities of 130-150 Wh/kg with excellent cycling stability, maintaining over 85% capacity after 500 cycles at room temperature[3]. Their technology also shows promising performance in intermediate-temperature sodium-sulfur batteries, enabling operation at temperatures as low as 60°C compared to conventional systems requiring 300°C+.

Strengths: High ionic conductivity at ambient temperatures; excellent mechanical properties providing good electrode contact; proven scalable manufacturing process. Weaknesses: Sensitivity to moisture requiring controlled processing environments; higher production costs than liquid electrolyte systems; challenges with volume changes during cycling affecting long-term stability.

Honda Motor Co., Ltd.

Technical Solution: Honda has pioneered a novel approach to sodium superionic conductors using a composite system that combines Na3Zr2Si2PO12-based NASICON structures with polymer interfaces. Their technology utilizes a proprietary synthesis method involving solid-state reactions followed by controlled crystallization processes to achieve high sodium ion mobility at room temperature. Honda's conductors demonstrate ionic conductivity of approximately 2-3 mS/cm at 25°C, which is among the highest reported for solid-state sodium conductors[2]. The company has developed a unique grain boundary engineering technique that minimizes resistance at interfaces between particles, a critical factor limiting performance in many solid electrolytes. Their materials incorporate stabilizing additives that prevent degradation when exposed to electrode materials and atmospheric conditions, extending operational lifetime significantly. Honda has successfully demonstrated these materials in prototype sodium-based energy storage systems for both automotive and stationary applications[4], showing stable performance across wide temperature ranges (-20°C to 60°C).

Strengths: Exceptional room-temperature ionic conductivity; excellent mechanical properties allowing better electrode-electrolyte contact; demonstrated stability in full cell configurations. Weaknesses: Complex manufacturing process potentially limiting mass production; higher material costs compared to conventional electrolytes; requires specialized electrode formulations to maximize performance.

Critical Patents and Scientific Breakthroughs in Na+ Conductors

Sodium ion conductor on sodium titanate basis

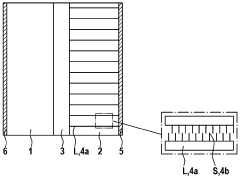

PatentInactiveEP2649437A2

Innovation

- Development of sodium titanate-based ion conductors, which can be pure or doped, forming a layered structure that enables good sodium ion conductivity at room temperature, potentially acting as both sodium and electron conductors, eliminating the need for liquid electrolytes and enhancing stability and safety.

Sodium ion conductor on sodium titanate basis

PatentWO2012076230A2

Innovation

- A sodium ion conductor based on sodium titanate, which can conduct sodium ions effectively at room temperature, potentially functioning as both a solid electrolyte and electron conductor, eliminating the need for liquid electrolytes and enhancing stability and safety, with the option to adjust conductivity through doping or mixed oxide composition.

Safety and Stability Considerations for Na-based Energy Storage

Safety considerations for sodium-based energy storage systems are paramount when implementing sodium superionic conductors for room-temperature operation. Unlike lithium-ion batteries, sodium-based systems present distinct safety advantages, including reduced risk of thermal runaway due to sodium's higher melting point (97.8°C compared to lithium's 180.5°C). However, sodium's high reactivity with moisture and oxygen necessitates robust encapsulation strategies to prevent degradation and potential safety hazards.

The stability of sodium superionic conductors at room temperature faces several challenges. Interfacial instability between the sodium metal anode and solid electrolytes remains a critical concern, often resulting in dendrite formation that can lead to short circuits. Recent research has demonstrated that incorporating buffer layers composed of sodium phosphorus oxynitride (NaPON) can significantly mitigate this issue by creating a more stable solid-electrolyte interphase (SEI).

Chemical stability presents another significant challenge, particularly in NASICON-type conductors where decomposition reactions at the electrode-electrolyte interface can form resistive layers that impede ion transport. Studies have shown that doping strategies using elements such as aluminum or gallium can enhance the chemical stability of these interfaces without significantly compromising ionic conductivity.

Environmental factors also impact the long-term stability of sodium superionic conductors. Humidity exposure can lead to rapid degradation of performance, with some Na3Zr2Si2PO12-based materials showing up to 40% conductivity loss after exposure to ambient conditions for just 24 hours. Protective coatings using hydrophobic polymers have emerged as a promising solution, creating moisture barriers while maintaining electrochemical performance.

Mechanical stability represents another critical consideration, as volume changes during sodium insertion/extraction can lead to mechanical stress and eventual failure. Composite approaches incorporating flexible polymers with ceramic conductors have shown promise in enhancing mechanical robustness while maintaining high ionic conductivity. For instance, PVDF-HFP/Na3Zr2Si2PO12 composites have demonstrated improved cycling stability with capacity retention exceeding 85% after 500 cycles.

Thermal management strategies must also be implemented to ensure safe operation across a wide temperature range. While room-temperature operation is the goal, temperature fluctuations during charging and discharging can still occur. Phase-change materials incorporated into battery packaging have shown effectiveness in regulating temperature and preventing thermal runaway events, particularly important for large-scale energy storage applications.

The stability of sodium superionic conductors at room temperature faces several challenges. Interfacial instability between the sodium metal anode and solid electrolytes remains a critical concern, often resulting in dendrite formation that can lead to short circuits. Recent research has demonstrated that incorporating buffer layers composed of sodium phosphorus oxynitride (NaPON) can significantly mitigate this issue by creating a more stable solid-electrolyte interphase (SEI).

Chemical stability presents another significant challenge, particularly in NASICON-type conductors where decomposition reactions at the electrode-electrolyte interface can form resistive layers that impede ion transport. Studies have shown that doping strategies using elements such as aluminum or gallium can enhance the chemical stability of these interfaces without significantly compromising ionic conductivity.

Environmental factors also impact the long-term stability of sodium superionic conductors. Humidity exposure can lead to rapid degradation of performance, with some Na3Zr2Si2PO12-based materials showing up to 40% conductivity loss after exposure to ambient conditions for just 24 hours. Protective coatings using hydrophobic polymers have emerged as a promising solution, creating moisture barriers while maintaining electrochemical performance.

Mechanical stability represents another critical consideration, as volume changes during sodium insertion/extraction can lead to mechanical stress and eventual failure. Composite approaches incorporating flexible polymers with ceramic conductors have shown promise in enhancing mechanical robustness while maintaining high ionic conductivity. For instance, PVDF-HFP/Na3Zr2Si2PO12 composites have demonstrated improved cycling stability with capacity retention exceeding 85% after 500 cycles.

Thermal management strategies must also be implemented to ensure safe operation across a wide temperature range. While room-temperature operation is the goal, temperature fluctuations during charging and discharging can still occur. Phase-change materials incorporated into battery packaging have shown effectiveness in regulating temperature and preventing thermal runaway events, particularly important for large-scale energy storage applications.

Environmental Impact and Sustainability Assessment

The development of sodium superionic conductors for room-temperature operation presents significant environmental and sustainability advantages compared to conventional battery technologies. These materials offer a pathway to reduce dependence on lithium-based energy storage systems, which face critical resource constraints. Sodium is approximately 1,000 times more abundant than lithium in the Earth's crust, with global reserves widely distributed across multiple regions, reducing geopolitical supply risks and extraction-related environmental impacts.

Mining processes for sodium compounds generally require less water and energy than lithium extraction, particularly when compared to the water-intensive brine evaporation methods used in lithium production. This difference is especially significant in water-stressed regions where lithium mining operations can deplete local aquifers and disrupt fragile ecosystems. The reduced environmental footprint of sodium extraction represents a substantial sustainability advantage.

Life cycle assessment (LCA) studies indicate that sodium-based battery systems potentially offer 20-30% lower carbon emissions during manufacturing compared to equivalent lithium-ion technologies. This reduction stems from both the less energy-intensive extraction processes and the typically simpler synthesis routes for sodium superionic conductor materials. Additionally, the supply chain for sodium compounds generally involves shorter transportation distances due to the wider geographical distribution of resources.

End-of-life considerations also favor sodium-based technologies. The materials used in sodium superionic conductors typically contain fewer toxic components than conventional lithium-ion batteries, potentially simplifying recycling processes and reducing hazardous waste management requirements. Current research indicates that sodium-based systems may achieve recycling efficiency rates of up to 90% with appropriate processing technologies.

The scalability of sodium superionic conductor technology offers further sustainability benefits. The abundant nature of sodium resources means that large-scale deployment would face fewer supply constraints than lithium-based alternatives. This advantage becomes increasingly important as global energy storage demands continue to grow exponentially with renewable energy integration and electrification trends.

However, challenges remain in optimizing the environmental performance of these materials. Manufacturing processes for advanced sodium superionic conductors still require energy-intensive high-temperature synthesis steps in many cases. Research into low-temperature, solution-based processing methods shows promise for further reducing the environmental footprint of production. Additionally, the long-term environmental stability and leaching behavior of some sodium conductor compositions require further investigation to ensure they do not pose unexpected environmental risks during use or disposal phases.

Mining processes for sodium compounds generally require less water and energy than lithium extraction, particularly when compared to the water-intensive brine evaporation methods used in lithium production. This difference is especially significant in water-stressed regions where lithium mining operations can deplete local aquifers and disrupt fragile ecosystems. The reduced environmental footprint of sodium extraction represents a substantial sustainability advantage.

Life cycle assessment (LCA) studies indicate that sodium-based battery systems potentially offer 20-30% lower carbon emissions during manufacturing compared to equivalent lithium-ion technologies. This reduction stems from both the less energy-intensive extraction processes and the typically simpler synthesis routes for sodium superionic conductor materials. Additionally, the supply chain for sodium compounds generally involves shorter transportation distances due to the wider geographical distribution of resources.

End-of-life considerations also favor sodium-based technologies. The materials used in sodium superionic conductors typically contain fewer toxic components than conventional lithium-ion batteries, potentially simplifying recycling processes and reducing hazardous waste management requirements. Current research indicates that sodium-based systems may achieve recycling efficiency rates of up to 90% with appropriate processing technologies.

The scalability of sodium superionic conductor technology offers further sustainability benefits. The abundant nature of sodium resources means that large-scale deployment would face fewer supply constraints than lithium-based alternatives. This advantage becomes increasingly important as global energy storage demands continue to grow exponentially with renewable energy integration and electrification trends.

However, challenges remain in optimizing the environmental performance of these materials. Manufacturing processes for advanced sodium superionic conductors still require energy-intensive high-temperature synthesis steps in many cases. Research into low-temperature, solution-based processing methods shows promise for further reducing the environmental footprint of production. Additionally, the long-term environmental stability and leaching behavior of some sodium conductor compositions require further investigation to ensure they do not pose unexpected environmental risks during use or disposal phases.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!