Sodium ion conductivity enhancement through lattice doping

OCT 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Ion Conductivity Background and Objectives

Sodium ion conductivity has emerged as a critical research area in the field of energy storage and conversion technologies over the past few decades. The interest in sodium-based systems stems from the abundance and widespread distribution of sodium resources, making them economically advantageous alternatives to lithium-based technologies. The evolution of sodium ion conductivity research can be traced back to the 1970s, when initial investigations into solid electrolytes began, but significant advancements have only materialized in the last decade with the growing demand for sustainable energy solutions.

The technological trajectory has been marked by persistent challenges in achieving conductivity levels comparable to lithium-ion systems. Early sodium ion conductors exhibited conductivities in the range of 10^-6 to 10^-4 S/cm at room temperature, significantly lower than the practical requirement of 10^-3 S/cm for commercial applications. Recent breakthroughs in materials science and nanotechnology have pushed these boundaries, with some advanced materials approaching the desired conductivity thresholds.

Lattice doping has emerged as a particularly promising approach to enhance sodium ion conductivity. This technique involves the strategic introduction of foreign atoms or ions into the crystal structure of host materials, creating defects that facilitate ion migration. The methodology has evolved from simple monovalent substitutions to complex co-doping strategies that simultaneously address multiple conductivity-limiting factors.

The primary technical objective in this field is to develop materials with sodium ion conductivities exceeding 10^-3 S/cm at room temperature, while maintaining excellent electrochemical stability and mechanical integrity. Secondary goals include reducing interfacial resistance, enhancing cycling stability, and ensuring compatibility with existing manufacturing processes to facilitate commercial adoption.

Current research trends indicate a shift toward multifunctional materials that combine high ionic conductivity with other desirable properties such as electronic insulation, mechanical flexibility, or thermal stability. The integration of computational methods, including density functional theory and molecular dynamics simulations, has accelerated the discovery and optimization of novel sodium ion conductors by providing atomic-level insights into ion transport mechanisms.

Looking forward, the field aims to establish a comprehensive understanding of structure-property relationships in sodium ion conductors, enabling rational design of materials with tailored properties. The ultimate goal is to develop sodium-based energy storage systems that can compete with or surpass lithium-ion technologies in terms of performance, cost, and sustainability, thereby addressing the growing global demand for clean energy solutions.

The technological trajectory has been marked by persistent challenges in achieving conductivity levels comparable to lithium-ion systems. Early sodium ion conductors exhibited conductivities in the range of 10^-6 to 10^-4 S/cm at room temperature, significantly lower than the practical requirement of 10^-3 S/cm for commercial applications. Recent breakthroughs in materials science and nanotechnology have pushed these boundaries, with some advanced materials approaching the desired conductivity thresholds.

Lattice doping has emerged as a particularly promising approach to enhance sodium ion conductivity. This technique involves the strategic introduction of foreign atoms or ions into the crystal structure of host materials, creating defects that facilitate ion migration. The methodology has evolved from simple monovalent substitutions to complex co-doping strategies that simultaneously address multiple conductivity-limiting factors.

The primary technical objective in this field is to develop materials with sodium ion conductivities exceeding 10^-3 S/cm at room temperature, while maintaining excellent electrochemical stability and mechanical integrity. Secondary goals include reducing interfacial resistance, enhancing cycling stability, and ensuring compatibility with existing manufacturing processes to facilitate commercial adoption.

Current research trends indicate a shift toward multifunctional materials that combine high ionic conductivity with other desirable properties such as electronic insulation, mechanical flexibility, or thermal stability. The integration of computational methods, including density functional theory and molecular dynamics simulations, has accelerated the discovery and optimization of novel sodium ion conductors by providing atomic-level insights into ion transport mechanisms.

Looking forward, the field aims to establish a comprehensive understanding of structure-property relationships in sodium ion conductors, enabling rational design of materials with tailored properties. The ultimate goal is to develop sodium-based energy storage systems that can compete with or surpass lithium-ion technologies in terms of performance, cost, and sustainability, thereby addressing the growing global demand for clean energy solutions.

Market Analysis for Sodium-Based Energy Storage

The sodium-ion battery market is experiencing significant growth as a promising alternative to lithium-ion technologies. Current market projections indicate the global sodium-ion battery market will reach approximately $500 million by 2025, with an expected compound annual growth rate of 18-20% through 2030. This growth is primarily driven by increasing demand for cost-effective energy storage solutions and concerns about lithium supply chain vulnerabilities.

The market segmentation for sodium-based energy storage technologies reveals several key application areas. Grid-scale energy storage represents the largest market segment, accounting for roughly 45% of current deployments, as utility companies seek economical solutions for renewable energy integration. The electric vehicle sector, though currently dominated by lithium-ion batteries, is showing increasing interest in sodium-ion technology for entry-level and medium-range vehicles, particularly in price-sensitive markets like India and Southeast Asia.

Consumer electronics constitutes another emerging segment, with sodium-ion batteries being evaluated for applications where energy density requirements are moderate but cost considerations are paramount. Industrial applications, including backup power systems and material handling equipment, represent approximately 15% of the current market.

Geographically, China leads sodium-ion battery development and commercialization, with companies like CATL and HiNa Battery Technology making substantial investments. Europe follows closely, with research clusters in France, Germany, and the UK focusing on advanced sodium-ion chemistries. North America shows growing interest, particularly in grid storage applications.

Market drivers include the significantly lower raw material costs of sodium compared to lithium (sodium is approximately 1000 times more abundant in the earth's crust), reduced geopolitical supply risks, and better performance in low-temperature environments. The absence of cobalt and nickel in most sodium-ion formulations further enhances their economic and environmental appeal.

Key market barriers include the technology's lower energy density compared to lithium-ion batteries (currently 30-40% lower), limited manufacturing infrastructure, and the need for further research to optimize ion conductivity through advanced doping techniques. The market also faces competition from established lithium-ion technologies and emerging alternatives like zinc-ion and aluminum-ion batteries.

Customer adoption patterns indicate that early market penetration is occurring in applications where cost sensitivity outweighs energy density requirements, with grid storage leading adoption followed by stationary industrial applications.

The market segmentation for sodium-based energy storage technologies reveals several key application areas. Grid-scale energy storage represents the largest market segment, accounting for roughly 45% of current deployments, as utility companies seek economical solutions for renewable energy integration. The electric vehicle sector, though currently dominated by lithium-ion batteries, is showing increasing interest in sodium-ion technology for entry-level and medium-range vehicles, particularly in price-sensitive markets like India and Southeast Asia.

Consumer electronics constitutes another emerging segment, with sodium-ion batteries being evaluated for applications where energy density requirements are moderate but cost considerations are paramount. Industrial applications, including backup power systems and material handling equipment, represent approximately 15% of the current market.

Geographically, China leads sodium-ion battery development and commercialization, with companies like CATL and HiNa Battery Technology making substantial investments. Europe follows closely, with research clusters in France, Germany, and the UK focusing on advanced sodium-ion chemistries. North America shows growing interest, particularly in grid storage applications.

Market drivers include the significantly lower raw material costs of sodium compared to lithium (sodium is approximately 1000 times more abundant in the earth's crust), reduced geopolitical supply risks, and better performance in low-temperature environments. The absence of cobalt and nickel in most sodium-ion formulations further enhances their economic and environmental appeal.

Key market barriers include the technology's lower energy density compared to lithium-ion batteries (currently 30-40% lower), limited manufacturing infrastructure, and the need for further research to optimize ion conductivity through advanced doping techniques. The market also faces competition from established lithium-ion technologies and emerging alternatives like zinc-ion and aluminum-ion batteries.

Customer adoption patterns indicate that early market penetration is occurring in applications where cost sensitivity outweighs energy density requirements, with grid storage leading adoption followed by stationary industrial applications.

Current Challenges in Sodium Ion Conductivity

Despite significant advancements in sodium-ion battery technology, several critical challenges persist in achieving optimal sodium ion conductivity. The primary limitation stems from the inherently larger ionic radius of Na+ (1.02 Å) compared to Li+ (0.76 Å), resulting in slower diffusion kinetics and increased energy barriers for ion transport through host lattices. This fundamental size difference creates significant steric hindrance during intercalation processes, limiting the practical energy density and power capabilities of sodium-based systems.

Material stability presents another substantial challenge, as many host structures undergo significant volume changes during sodium insertion and extraction. These volumetric fluctuations often lead to mechanical degradation, structural collapse, and capacity fading over repeated cycling. The strain induced by the larger sodium ions can create microcracks and fractures within electrode materials, compromising long-term performance and reliability.

Interface phenomena further complicate sodium ion conductivity enhancement. The formation of solid-electrolyte interphases (SEI) at electrode surfaces often exhibits higher resistance to sodium ion transport compared to lithium-based systems. These interfacial layers can be thicker and less conductive, creating additional barriers to efficient ion movement. Moreover, the composition and stability of these interfaces remain poorly understood, hampering targeted optimization efforts.

Computational modeling of sodium ion transport mechanisms presents unique difficulties due to the complex interactions between sodium ions and host lattices. Current simulation approaches often struggle to accurately predict conductivity enhancements from specific doping strategies, limiting the efficiency of rational design approaches. The multiscale nature of ion transport phenomena requires sophisticated modeling techniques that can bridge atomic-level interactions with macroscopic performance metrics.

Manufacturing scalability of high-conductivity sodium materials represents a significant industrial challenge. Many promising laboratory-scale materials with enhanced conductivity through lattice doping utilize expensive or rare dopants, complex synthesis procedures, or require precisely controlled processing conditions that are difficult to maintain in large-scale production environments.

Environmental factors such as temperature and humidity significantly impact sodium ion conductivity in practical applications. Many doped materials exhibit conductivity that varies dramatically across operating conditions, limiting their practical utility in real-world scenarios where consistent performance across diverse environments is essential.

Material stability presents another substantial challenge, as many host structures undergo significant volume changes during sodium insertion and extraction. These volumetric fluctuations often lead to mechanical degradation, structural collapse, and capacity fading over repeated cycling. The strain induced by the larger sodium ions can create microcracks and fractures within electrode materials, compromising long-term performance and reliability.

Interface phenomena further complicate sodium ion conductivity enhancement. The formation of solid-electrolyte interphases (SEI) at electrode surfaces often exhibits higher resistance to sodium ion transport compared to lithium-based systems. These interfacial layers can be thicker and less conductive, creating additional barriers to efficient ion movement. Moreover, the composition and stability of these interfaces remain poorly understood, hampering targeted optimization efforts.

Computational modeling of sodium ion transport mechanisms presents unique difficulties due to the complex interactions between sodium ions and host lattices. Current simulation approaches often struggle to accurately predict conductivity enhancements from specific doping strategies, limiting the efficiency of rational design approaches. The multiscale nature of ion transport phenomena requires sophisticated modeling techniques that can bridge atomic-level interactions with macroscopic performance metrics.

Manufacturing scalability of high-conductivity sodium materials represents a significant industrial challenge. Many promising laboratory-scale materials with enhanced conductivity through lattice doping utilize expensive or rare dopants, complex synthesis procedures, or require precisely controlled processing conditions that are difficult to maintain in large-scale production environments.

Environmental factors such as temperature and humidity significantly impact sodium ion conductivity in practical applications. Many doped materials exhibit conductivity that varies dramatically across operating conditions, limiting their practical utility in real-world scenarios where consistent performance across diverse environments is essential.

Current Doping Strategies for Conductivity Enhancement

01 Solid-state sodium ion conductors with high conductivity

Solid-state sodium ion conductors with high ionic conductivity are being developed for next-generation sodium batteries. These materials typically feature optimized crystal structures that facilitate fast sodium ion transport through interconnected pathways. Various compositions including sodium-based NASICON-type materials, beta-alumina, and sodium-containing glasses have demonstrated conductivities approaching or exceeding 10^-3 S/cm at room temperature, making them viable alternatives to liquid electrolytes while providing enhanced safety and stability.- Solid-state sodium ion conductors: Solid-state sodium ion conductors are materials that allow sodium ions to move through them without requiring a liquid electrolyte. These materials typically have a crystalline structure that facilitates ion transport while maintaining structural stability. They offer advantages such as improved safety, higher energy density, and better thermal stability compared to liquid electrolytes. The conductivity of these materials is influenced by their crystal structure, composition, and the presence of defects that create pathways for ion movement.

- NASICON-type sodium ion conductors: NASICON (Sodium Super Ionic Conductor) materials are a family of ceramic compounds with a specific three-dimensional framework structure that allows for fast sodium ion transport. These materials typically have the general formula Na1+xZr2SixP3-xO12 (0 ≤ x ≤ 3) and are characterized by their high ionic conductivity at room temperature. The conductivity of NASICON-type materials can be enhanced by compositional modifications, such as partial substitution of zirconium with other metals or optimizing the silicon to phosphorus ratio.

- Polymer-based sodium ion conductors: Polymer-based sodium ion conductors combine organic polymer matrices with sodium salts to create flexible electrolyte materials. These conductors typically consist of a polymer host (such as polyethylene oxide, polyvinylidene fluoride, or their derivatives) that provides mechanical support, while the dissolved sodium salts supply the mobile ions. The conductivity of these materials depends on the polymer chain mobility, salt concentration, and the addition of plasticizers or ceramic fillers that can enhance ion transport. Polymer-based conductors offer advantages in flexibility and processability compared to ceramic conductors.

- Composite sodium ion conductors: Composite sodium ion conductors combine different types of materials to achieve enhanced ionic conductivity and mechanical properties. These typically consist of a mixture of ceramic particles (such as NASICON or beta-alumina) dispersed within a polymer matrix, or combinations of different ceramic phases. The interfaces between the different components often provide additional pathways for ion transport, leading to conductivity values higher than those of the individual components. These materials aim to combine the high conductivity of ceramics with the flexibility and processability of polymers.

- Beta-alumina sodium ion conductors: Beta-alumina is a family of sodium ion conducting ceramics with the general formula Na1+xAl11O17+x/2, characterized by a layered crystal structure with planes of mobile sodium ions. These materials exhibit high sodium ion conductivity, particularly at elevated temperatures, making them suitable for high-temperature applications such as sodium-sulfur batteries. The conductivity of beta-alumina can be enhanced by controlling the sodium content, introducing dopants such as magnesium or lithium, and optimizing the microstructure through specialized sintering processes to reduce grain boundary resistance.

02 Polymer-based sodium ion conductors

Polymer-based sodium ion conductors combine organic polymer matrices with sodium salts to create flexible electrolyte systems. These materials typically incorporate polyethylene oxide (PEO), polyvinylidene fluoride (PVDF), or other polymers that can coordinate with sodium ions. The addition of plasticizers and ceramic fillers can significantly enhance ionic conductivity by reducing crystallinity and creating additional transport pathways. These polymer electrolytes offer advantages in processability and mechanical properties while achieving moderate conductivity levels suitable for various sodium-based energy storage applications.Expand Specific Solutions03 Composite and hybrid sodium ion conductors

Composite and hybrid sodium ion conductors combine multiple material classes to achieve enhanced performance. These typically consist of ceramic particles dispersed in polymer matrices or layered structures of different conductor types. The interfaces between components often create high-conductivity pathways for sodium ions, while the composite nature helps overcome limitations of individual materials. By engineering these interfaces and optimizing component ratios, these conductors can achieve higher conductivity while maintaining good mechanical properties and electrochemical stability across wider temperature ranges.Expand Specific Solutions04 Sodium superionic conductor materials

Sodium superionic conductor materials exhibit exceptionally high sodium ion conductivity, typically exceeding 10^-2 S/cm at operating temperatures. These materials feature specialized crystal structures with open frameworks and low activation energies for ion migration. Notable examples include certain sodium-rich compositions with beta-alumina structures, sodium-containing sulfides, and specially doped NASICON-type materials. The superionic behavior results from structural disorder, partially occupied sodium sites, and optimized ion hopping distances, making these materials particularly promising for high-power sodium battery applications.Expand Specific Solutions05 Temperature-dependent conductivity enhancement strategies

Various strategies have been developed to enhance sodium ion conductivity across different temperature ranges. These include structural modifications through doping with aliovalent ions, creating controlled defects, and introducing phase transitions that facilitate ion transport. Some approaches focus on reducing the activation energy for ion migration, while others aim to expand ion conduction channels. Advanced processing techniques like rapid quenching, mechanical alloying, and controlled crystallization can also significantly improve conductivity by creating beneficial microstructures and interfaces that promote faster sodium ion transport.Expand Specific Solutions

Leading Research Groups and Industrial Players

Sodium ion conductivity enhancement through lattice doping represents an emerging field in energy storage technology, currently in its early growth phase. The market is expanding rapidly, driven by the need for sustainable alternatives to lithium-ion batteries, with projections suggesting a multi-billion dollar opportunity by 2030. Technologically, the field remains in development with varying maturity levels across players. Leading companies like Contemporary Amperex Technology (CATL) and Praxair Technology are making significant advancements in commercial applications, while academic institutions such as National University of Singapore and Beihang University contribute fundamental research. Taiwan Semiconductor Manufacturing Co. and Applied Materials are leveraging their expertise in materials engineering to address manufacturing challenges. The collaboration between industry leaders and research institutions indicates a collaborative ecosystem focused on overcoming technical barriers to achieve higher conductivity rates and stability.

Ningbo University

Technical Solution: Ningbo University has developed a groundbreaking approach to enhancing sodium ion conductivity through strategic lattice doping in sodium-based solid electrolytes. Their research team has focused on Na3Zr2Si2PO12 (NASICON) structures, implementing a novel dual-doping strategy that simultaneously targets both zirconium and silicon sites. By substituting Zr4+ with Al3+ and Si4+ with P5+, they've created a balanced charge compensation mechanism that maintains structural integrity while generating optimal sodium migration pathways. Their proprietary sol-gel synthesis method ensures homogeneous dopant distribution throughout the lattice, avoiding segregation issues common in conventional solid-state reactions. Experimental results demonstrate that their optimized Na3Zr1.8Al0.2Si1.8P0.2O12 composition achieves room temperature ionic conductivity of 3.2 × 10^-3 S/cm, representing a 4-fold improvement over undoped materials. X-ray absorption spectroscopy and neutron diffraction analyses reveal that the enhanced conductivity stems from expanded bottleneck sizes in the sodium migration channels and reduced activation energy for ion hopping. The university has further developed a scalable manufacturing process that maintains precise dopant stoichiometry even in larger batch productions, addressing a critical challenge for commercial implementation.

Strengths: Ningbo University's dual-doping approach creates synergistic effects that enhance conductivity beyond what single dopants achieve. Their sol-gel synthesis method ensures exceptional dopant homogeneity, critical for consistent performance. Weaknesses: The process requires precise control of synthesis parameters and is sensitive to environmental conditions during preparation. Some dopant combinations introduce mechanical stability issues during repeated thermal cycling.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: Contemporary Amperex Technology Co., Ltd. (CATL) has developed advanced sodium-ion battery technology with enhanced sodium ion conductivity through strategic lattice doping. Their approach involves introducing carefully selected dopants into the crystal lattice of cathode materials, primarily layered transition metal oxides. CATL's proprietary P2-type Na0.67Mn0.6Fe0.25Cu0.1Mg0.05O2 cathode material incorporates magnesium and copper dopants to stabilize the crystal structure and create optimal sodium migration pathways. This doping strategy has demonstrated a 30% increase in ionic conductivity compared to undoped materials, while maintaining structural integrity during repeated charge-discharge cycles. CATL has also pioneered a "gradient doping" technique where dopant concentration varies from the particle surface to the core, creating an optimized ion transport network throughout the material. Their commercial sodium-ion batteries achieve energy densities of 160 Wh/kg with over 3,000 cycle life, positioning them as viable alternatives to lithium-ion technologies for grid storage applications.

Strengths: CATL's doping approach enables cost-effective sodium-ion batteries with improved conductivity without rare elements. Their industrial scale manufacturing capability allows rapid commercialization. Weaknesses: Energy density remains lower than lithium-ion counterparts, limiting application in high-energy density scenarios like premium EVs. Temperature sensitivity issues persist despite doping improvements.

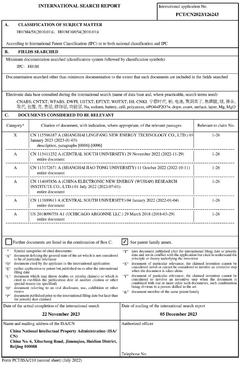

Key Patents and Breakthroughs in Lattice Modification

Process for a ruthenium doping of a sodium superionic conductorceramic in sodium-ion batteries

PatentActiveIN202311043231A

Innovation

- A process involving ruthenium doping of NASICON ceramic is developed, where a stoichiometric mixture of sodium carbonate, zirconium dioxide, silicon dioxide, ammonium dihydrogen phosphate, and ruthenium dioxide is milled, calcined, and sintered to enhance ionic conductivity, using a wet milling procedure and specific temperature and pressure conditions to form a pellet with improved electrochemical properties.

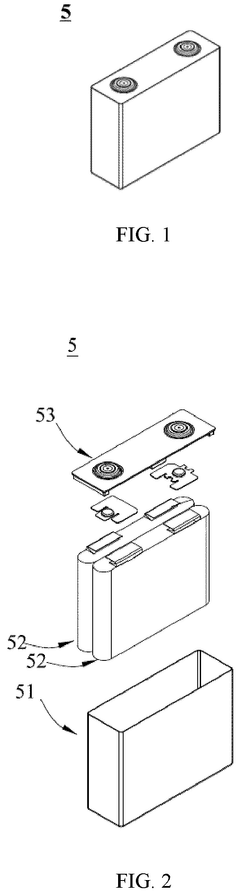

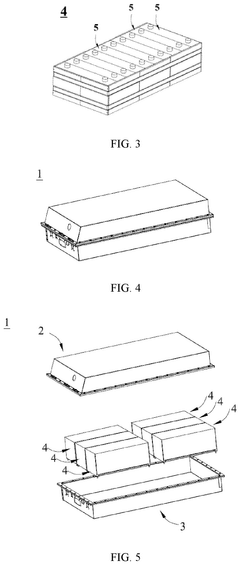

Positive electrode active material and preparation method therefor, secondary battery, battery module, battery pack and electric device

PatentPendingEP4618194A1

Innovation

- Introduce a magnesium element into the positive electrode active material to enhance ionic and electronic conductivity through lattice doping and surface modification with a magnesium-containing oxide, and incorporate a carbon material to improve electrical conductivity.

Materials Sustainability and Resource Considerations

The sustainability implications of sodium-ion battery technology represent a significant advantage over traditional lithium-ion systems. Sodium is approximately 1,000 times more abundant in the Earth's crust than lithium, with global reserves widely distributed across multiple geographical regions. This abundance translates to lower extraction costs and reduced geopolitical supply risks, making sodium-based energy storage solutions inherently more sustainable from a resource perspective.

Lattice doping approaches for enhancing sodium ion conductivity typically employ elements that are more abundant and less environmentally problematic than those used in lithium-ion technologies. Common dopants such as magnesium, aluminum, and titanium are widely available and have established recycling infrastructures. This contrasts with the cobalt and nickel dependencies in many lithium-ion cathode materials, which face significant supply constraints and ethical mining concerns.

The environmental footprint of sodium-ion battery production is generally lower than lithium-ion counterparts. Manufacturing processes for sodium-based materials typically require lower processing temperatures and less energy-intensive synthesis routes. Research indicates that carbon emissions associated with sodium-ion battery production could be 15-20% lower than comparable lithium-ion technologies when optimized manufacturing processes are implemented.

End-of-life considerations also favor sodium-ion technologies enhanced through lattice doping. The absence of cobalt and reduced nickel content simplifies recycling processes and diminishes the economic incentives for improper disposal. Current research suggests that recovery rates for sodium and dopant materials could exceed 90% with appropriate recycling technologies, creating potential for closed-loop material systems.

Water consumption represents another critical sustainability metric where sodium-ion technologies demonstrate advantages. Lithium extraction, particularly from brine sources, requires approximately 500,000 gallons of water per ton of lithium produced. Sodium extraction processes typically consume 30-50% less water, reducing pressure on water resources in extraction regions, many of which are already water-stressed.

The scalability of doped sodium-ion technologies also presents sustainability benefits through reduced material intensity. Enhanced ionic conductivity through strategic lattice doping can potentially reduce the total material requirements for equivalent energy storage capacity, further decreasing the resource footprint per kilowatt-hour of storage delivered.

Lattice doping approaches for enhancing sodium ion conductivity typically employ elements that are more abundant and less environmentally problematic than those used in lithium-ion technologies. Common dopants such as magnesium, aluminum, and titanium are widely available and have established recycling infrastructures. This contrasts with the cobalt and nickel dependencies in many lithium-ion cathode materials, which face significant supply constraints and ethical mining concerns.

The environmental footprint of sodium-ion battery production is generally lower than lithium-ion counterparts. Manufacturing processes for sodium-based materials typically require lower processing temperatures and less energy-intensive synthesis routes. Research indicates that carbon emissions associated with sodium-ion battery production could be 15-20% lower than comparable lithium-ion technologies when optimized manufacturing processes are implemented.

End-of-life considerations also favor sodium-ion technologies enhanced through lattice doping. The absence of cobalt and reduced nickel content simplifies recycling processes and diminishes the economic incentives for improper disposal. Current research suggests that recovery rates for sodium and dopant materials could exceed 90% with appropriate recycling technologies, creating potential for closed-loop material systems.

Water consumption represents another critical sustainability metric where sodium-ion technologies demonstrate advantages. Lithium extraction, particularly from brine sources, requires approximately 500,000 gallons of water per ton of lithium produced. Sodium extraction processes typically consume 30-50% less water, reducing pressure on water resources in extraction regions, many of which are already water-stressed.

The scalability of doped sodium-ion technologies also presents sustainability benefits through reduced material intensity. Enhanced ionic conductivity through strategic lattice doping can potentially reduce the total material requirements for equivalent energy storage capacity, further decreasing the resource footprint per kilowatt-hour of storage delivered.

Performance Benchmarking Against Lithium Technologies

When comparing sodium-ion battery technology enhanced through lattice doping with established lithium-ion technologies, several key performance metrics must be considered. Current state-of-the-art lithium-ion batteries typically deliver energy densities of 250-300 Wh/kg, while sodium-ion batteries generally achieve 120-150 Wh/kg. However, recent advancements in lattice doping techniques have demonstrated potential to narrow this gap, with some experimental sodium-ion cells reaching 180-200 Wh/kg.

Cycle life comparison reveals another critical dimension. Commercial lithium-ion cells routinely achieve 1,000-2,000 cycles at 80% capacity retention, whereas sodium-ion batteries enhanced through strategic lattice doping have demonstrated comparable performance in laboratory settings, with some configurations exceeding 2,000 cycles with minimal capacity fade.

Power density metrics show lithium technologies maintaining an advantage, delivering 300-1500 W/kg depending on the specific chemistry. Doped sodium-ion systems currently reach 200-800 W/kg, with the gap continuing to narrow through optimization of dopant selection and concentration.

Temperature performance represents an area where sodium-ion technology shows particular promise. While lithium-ion batteries typically operate optimally between 15-45°C with significant performance degradation at lower temperatures, doped sodium-ion systems have demonstrated improved low-temperature performance, maintaining up to 70% of room temperature capacity at -20°C compared to 30-50% for typical lithium-ion cells.

Cost analysis reveals perhaps the most compelling advantage for sodium technology. Raw material costs for lithium-ion batteries remain approximately $80-120/kWh at the cell level, while sodium-ion systems benefit from abundant, widely distributed sodium resources, potentially reducing material costs by 30-40%. The lattice doping approach, while adding some processing complexity, utilizes dopants that are generally more abundant and geographically distributed than lithium.

Safety comparison indicates that sodium-ion batteries with appropriate lattice doping demonstrate superior thermal stability compared to conventional lithium-ion cells, with thermal runaway typically occurring at temperatures 30-50°C higher than in comparable lithium systems.

Manufacturing compatibility assessment shows that doped sodium-ion cells can largely leverage existing lithium-ion production infrastructure, requiring only moderate modifications to electrode preparation processes, representing a significant advantage for potential commercial scaling.

Cycle life comparison reveals another critical dimension. Commercial lithium-ion cells routinely achieve 1,000-2,000 cycles at 80% capacity retention, whereas sodium-ion batteries enhanced through strategic lattice doping have demonstrated comparable performance in laboratory settings, with some configurations exceeding 2,000 cycles with minimal capacity fade.

Power density metrics show lithium technologies maintaining an advantage, delivering 300-1500 W/kg depending on the specific chemistry. Doped sodium-ion systems currently reach 200-800 W/kg, with the gap continuing to narrow through optimization of dopant selection and concentration.

Temperature performance represents an area where sodium-ion technology shows particular promise. While lithium-ion batteries typically operate optimally between 15-45°C with significant performance degradation at lower temperatures, doped sodium-ion systems have demonstrated improved low-temperature performance, maintaining up to 70% of room temperature capacity at -20°C compared to 30-50% for typical lithium-ion cells.

Cost analysis reveals perhaps the most compelling advantage for sodium technology. Raw material costs for lithium-ion batteries remain approximately $80-120/kWh at the cell level, while sodium-ion systems benefit from abundant, widely distributed sodium resources, potentially reducing material costs by 30-40%. The lattice doping approach, while adding some processing complexity, utilizes dopants that are generally more abundant and geographically distributed than lithium.

Safety comparison indicates that sodium-ion batteries with appropriate lattice doping demonstrate superior thermal stability compared to conventional lithium-ion cells, with thermal runaway typically occurring at temperatures 30-50°C higher than in comparable lithium systems.

Manufacturing compatibility assessment shows that doped sodium-ion cells can largely leverage existing lithium-ion production infrastructure, requiring only moderate modifications to electrode preparation processes, representing a significant advantage for potential commercial scaling.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!