Defining Mechanical Mastery with Thermoelectric Construction Methods

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Construction Evolution and Objectives

Thermoelectric construction methods have evolved significantly over the past several decades, transforming from rudimentary applications to sophisticated systems that integrate mechanical and electrical principles. The journey began in the mid-20th century with the discovery of the Seebeck effect, which established the fundamental relationship between temperature differentials and electrical potential. This discovery laid the groundwork for early thermoelectric generators that, while inefficient, demonstrated the core principles that would later be refined.

The 1960s marked a pivotal shift with the introduction of semiconductor materials in thermoelectric construction, dramatically improving conversion efficiency. This period saw the development of bismuth telluride compounds that remain standard in many applications today. By the 1980s, thermoelectric construction had expanded beyond simple power generation to include cooling applications through the Peltier effect, opening new avenues for thermal management in electronics and specialized industrial processes.

Recent advancements have been driven by nanotechnology, allowing for unprecedented control over material properties at the molecular level. Quantum well structures, superlattices, and nanocomposites have emerged as promising approaches to overcome traditional efficiency limitations. These developments have pushed thermoelectric figure of merit (ZT) values from historically below 1.0 to exceeding 2.0 in laboratory settings, signaling a potential breakthrough for widespread commercial viability.

The primary objective of modern thermoelectric construction research is to achieve mechanical mastery through the seamless integration of thermal and electrical systems. This involves optimizing material selection, junction design, and manufacturing processes to maximize energy conversion efficiency while ensuring structural integrity and longevity. Specific goals include developing materials with ZT values consistently above 2.5 at commercially viable production scales, reducing manufacturing costs by at least 40% through innovative fabrication techniques, and extending operational lifespans to exceed 15 years under standard conditions.

Additional objectives focus on expanding application versatility through modular designs that can be adapted to various industrial and consumer contexts. This includes developing flexible thermoelectric materials capable of conforming to complex geometries, creating self-healing interfaces that maintain electrical contact despite thermal cycling, and implementing advanced control systems that dynamically optimize performance based on environmental conditions.

The ultimate aim is to position thermoelectric construction as a mainstream solution for energy recovery and thermal management across multiple sectors, from automotive and aerospace to residential and wearable technologies. This requires not only technical advancement but also standardization of design methodologies and testing protocols to ensure consistent performance and facilitate broader industry adoption.

The 1960s marked a pivotal shift with the introduction of semiconductor materials in thermoelectric construction, dramatically improving conversion efficiency. This period saw the development of bismuth telluride compounds that remain standard in many applications today. By the 1980s, thermoelectric construction had expanded beyond simple power generation to include cooling applications through the Peltier effect, opening new avenues for thermal management in electronics and specialized industrial processes.

Recent advancements have been driven by nanotechnology, allowing for unprecedented control over material properties at the molecular level. Quantum well structures, superlattices, and nanocomposites have emerged as promising approaches to overcome traditional efficiency limitations. These developments have pushed thermoelectric figure of merit (ZT) values from historically below 1.0 to exceeding 2.0 in laboratory settings, signaling a potential breakthrough for widespread commercial viability.

The primary objective of modern thermoelectric construction research is to achieve mechanical mastery through the seamless integration of thermal and electrical systems. This involves optimizing material selection, junction design, and manufacturing processes to maximize energy conversion efficiency while ensuring structural integrity and longevity. Specific goals include developing materials with ZT values consistently above 2.5 at commercially viable production scales, reducing manufacturing costs by at least 40% through innovative fabrication techniques, and extending operational lifespans to exceed 15 years under standard conditions.

Additional objectives focus on expanding application versatility through modular designs that can be adapted to various industrial and consumer contexts. This includes developing flexible thermoelectric materials capable of conforming to complex geometries, creating self-healing interfaces that maintain electrical contact despite thermal cycling, and implementing advanced control systems that dynamically optimize performance based on environmental conditions.

The ultimate aim is to position thermoelectric construction as a mainstream solution for energy recovery and thermal management across multiple sectors, from automotive and aerospace to residential and wearable technologies. This requires not only technical advancement but also standardization of design methodologies and testing protocols to ensure consistent performance and facilitate broader industry adoption.

Market Analysis for Thermoelectric Building Applications

The global thermoelectric building materials market is experiencing significant growth, projected to reach $3.5 billion by 2028 with a compound annual growth rate of 8.7% from 2023. This expansion is primarily driven by increasing energy efficiency regulations, rising energy costs, and growing awareness of sustainable building practices across residential, commercial, and industrial sectors.

North America currently leads the market with approximately 35% share, followed closely by Europe at 30% and Asia-Pacific at 25%. The remaining 10% is distributed across other regions. The European market shows particularly strong growth potential due to stringent energy efficiency directives and substantial government incentives for green building technologies.

Demand segmentation reveals that commercial buildings represent the largest application sector (45%), followed by residential (30%) and industrial facilities (25%). Within these segments, wall and roof applications dominate, accounting for over 60% of thermoelectric implementations, while floor systems and specialized applications make up the remainder.

Consumer behavior analysis indicates increasing willingness to invest in higher upfront costs for thermoelectric building solutions when clear long-term energy savings can be demonstrated. The average return on investment period has decreased from 8-10 years to 5-7 years over the past decade, significantly improving market attractiveness.

Key market drivers include tightening building codes and energy efficiency standards worldwide, with over 40 countries having implemented specific regulations promoting thermoelectric technologies in construction. Additionally, rising energy prices have accelerated adoption rates, with regions experiencing energy price increases of 15% or more showing twice the implementation rate of thermoelectric solutions.

Market barriers remain significant despite growth trends. High initial installation costs continue to deter approximately 40% of potential adopters. Technical integration challenges with existing building systems and limited awareness among architects and builders also restrict market penetration, particularly in developing regions.

Future market projections indicate accelerating adoption as manufacturing scales increase and installation expertise becomes more widespread. The retrofit market segment is expected to grow at 12% annually, outpacing new construction applications. Smart building integration represents the fastest-growing application niche, with thermoelectric systems increasingly incorporated into comprehensive building management systems that optimize energy usage through artificial intelligence and predictive analytics.

North America currently leads the market with approximately 35% share, followed closely by Europe at 30% and Asia-Pacific at 25%. The remaining 10% is distributed across other regions. The European market shows particularly strong growth potential due to stringent energy efficiency directives and substantial government incentives for green building technologies.

Demand segmentation reveals that commercial buildings represent the largest application sector (45%), followed by residential (30%) and industrial facilities (25%). Within these segments, wall and roof applications dominate, accounting for over 60% of thermoelectric implementations, while floor systems and specialized applications make up the remainder.

Consumer behavior analysis indicates increasing willingness to invest in higher upfront costs for thermoelectric building solutions when clear long-term energy savings can be demonstrated. The average return on investment period has decreased from 8-10 years to 5-7 years over the past decade, significantly improving market attractiveness.

Key market drivers include tightening building codes and energy efficiency standards worldwide, with over 40 countries having implemented specific regulations promoting thermoelectric technologies in construction. Additionally, rising energy prices have accelerated adoption rates, with regions experiencing energy price increases of 15% or more showing twice the implementation rate of thermoelectric solutions.

Market barriers remain significant despite growth trends. High initial installation costs continue to deter approximately 40% of potential adopters. Technical integration challenges with existing building systems and limited awareness among architects and builders also restrict market penetration, particularly in developing regions.

Future market projections indicate accelerating adoption as manufacturing scales increase and installation expertise becomes more widespread. The retrofit market segment is expected to grow at 12% annually, outpacing new construction applications. Smart building integration represents the fastest-growing application niche, with thermoelectric systems increasingly incorporated into comprehensive building management systems that optimize energy usage through artificial intelligence and predictive analytics.

Current Challenges in Thermoelectric Mechanical Systems

Despite significant advancements in thermoelectric technology, the mechanical integration of thermoelectric systems faces several persistent challenges that impede widespread commercial adoption. Material compatibility issues represent a primary obstacle, as the junction between thermoelectric materials and mechanical components often creates thermal expansion mismatches. These disparities lead to mechanical stress during thermal cycling, resulting in premature system failure and reduced operational lifespan.

Thermal interface management presents another significant challenge. The creation of efficient thermal pathways between thermoelectric modules and heat sources/sinks remains problematic, with contact resistance accounting for substantial performance losses. Current interface materials often degrade over time, particularly in high-temperature applications, compromising the system's overall efficiency and reliability.

Manufacturing scalability continues to constrain industry growth, as precision assembly requirements for thermoelectric modules demand specialized equipment and expertise. The miniaturization trend in modern applications further complicates this challenge, requiring ever more precise mechanical tolerances while maintaining thermal performance. Traditional manufacturing methods struggle to cost-effectively produce thermoelectric systems at scales necessary for mass-market adoption.

Durability under thermal cycling represents a persistent reliability concern. Thermoelectric systems typically operate under conditions of frequent temperature fluctuations, creating mechanical fatigue at material interfaces. Current mechanical designs often fail to adequately address the cumulative effects of thermal expansion and contraction, leading to connection degradation and performance decline over time.

Heat dissipation efficiency remains suboptimal in many thermoelectric applications. The mechanical design of heat sinks and cooling systems frequently becomes a limiting factor in overall system performance. Conventional approaches to heat management often prove inadequate for the unique thermal profiles of thermoelectric devices, particularly in confined spaces or weight-sensitive applications.

Integration complexity with existing mechanical systems presents significant implementation barriers. Engineers face difficulties incorporating thermoelectric modules into established mechanical frameworks without compromising either system's functionality. The interdisciplinary nature of thermoelectric integration requires expertise across thermal, electrical, and mechanical domains—a combination not commonly found in traditional engineering teams.

Cost-performance optimization continues to challenge designers, as the mechanical components of thermoelectric systems often represent a substantial portion of total system cost. Finding the optimal balance between mechanical robustness, thermal efficiency, and manufacturing economics remains elusive for many applications, particularly in price-sensitive consumer markets.

Thermal interface management presents another significant challenge. The creation of efficient thermal pathways between thermoelectric modules and heat sources/sinks remains problematic, with contact resistance accounting for substantial performance losses. Current interface materials often degrade over time, particularly in high-temperature applications, compromising the system's overall efficiency and reliability.

Manufacturing scalability continues to constrain industry growth, as precision assembly requirements for thermoelectric modules demand specialized equipment and expertise. The miniaturization trend in modern applications further complicates this challenge, requiring ever more precise mechanical tolerances while maintaining thermal performance. Traditional manufacturing methods struggle to cost-effectively produce thermoelectric systems at scales necessary for mass-market adoption.

Durability under thermal cycling represents a persistent reliability concern. Thermoelectric systems typically operate under conditions of frequent temperature fluctuations, creating mechanical fatigue at material interfaces. Current mechanical designs often fail to adequately address the cumulative effects of thermal expansion and contraction, leading to connection degradation and performance decline over time.

Heat dissipation efficiency remains suboptimal in many thermoelectric applications. The mechanical design of heat sinks and cooling systems frequently becomes a limiting factor in overall system performance. Conventional approaches to heat management often prove inadequate for the unique thermal profiles of thermoelectric devices, particularly in confined spaces or weight-sensitive applications.

Integration complexity with existing mechanical systems presents significant implementation barriers. Engineers face difficulties incorporating thermoelectric modules into established mechanical frameworks without compromising either system's functionality. The interdisciplinary nature of thermoelectric integration requires expertise across thermal, electrical, and mechanical domains—a combination not commonly found in traditional engineering teams.

Cost-performance optimization continues to challenge designers, as the mechanical components of thermoelectric systems often represent a substantial portion of total system cost. Finding the optimal balance between mechanical robustness, thermal efficiency, and manufacturing economics remains elusive for many applications, particularly in price-sensitive consumer markets.

Mainstream Mechanical-Thermoelectric Integration Solutions

01 Thermoelectric module assembly techniques

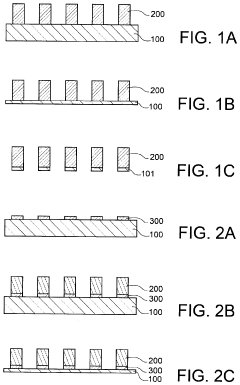

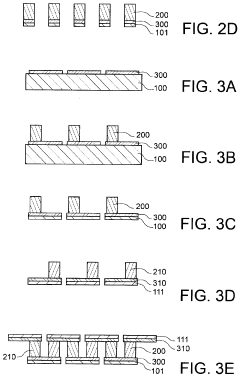

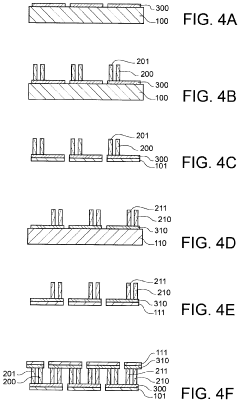

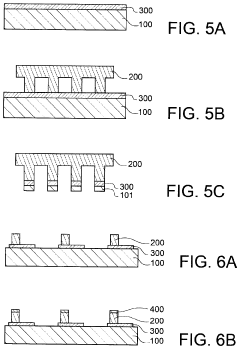

Advanced assembly methods for thermoelectric modules that focus on mechanical integrity and electrical connectivity. These techniques include specialized bonding processes, precision alignment of thermoelectric elements, and integration methods that enhance thermal transfer efficiency while maintaining structural stability under thermal cycling conditions. The assembly approaches often incorporate automated positioning systems to ensure consistent placement of thermoelectric components.- Thermoelectric module assembly techniques: Advanced assembly methods for thermoelectric modules that focus on mechanical integrity and electrical connectivity. These techniques include specialized bonding processes, precision alignment of thermoelectric elements, and integration methods that ensure optimal thermal contact between components. The assembly approaches are designed to maximize energy conversion efficiency while maintaining structural durability under thermal cycling conditions.

- Thermal interface optimization for thermoelectric devices: Methods for optimizing the thermal interfaces between thermoelectric materials and heat exchangers to maximize heat transfer efficiency. These approaches include surface preparation techniques, application of thermal interface materials, and mechanical designs that minimize thermal resistance. The optimization techniques focus on maintaining consistent thermal contact under varying operating conditions while accommodating thermal expansion differences between materials.

- Educational systems for thermoelectric construction: Educational tools and methodologies designed to teach thermoelectric principles and construction techniques. These systems include hands-on learning modules, interactive demonstrations, and structured curricula that build mechanical skills related to thermoelectric device assembly. The educational approaches emphasize practical understanding of thermoelectric phenomena through direct manipulation and construction of functional devices.

- Manufacturing processes for thermoelectric components: Specialized manufacturing processes for producing thermoelectric components with high precision and consistency. These processes include advanced material deposition techniques, microfabrication methods, and quality control procedures specific to thermoelectric materials. The manufacturing approaches focus on achieving uniform electrical and thermal properties while maintaining mechanical integrity throughout the production process.

- Mechanical integration of thermoelectric systems: Methods for mechanically integrating thermoelectric devices into larger systems while maintaining optimal performance. These integration techniques address challenges such as vibration isolation, thermal expansion management, and structural support that preserves electrical connections. The approaches focus on creating robust mechanical interfaces that protect thermoelectric components while allowing them to operate at maximum efficiency in various application environments.

02 Thermal interface optimization for thermoelectric devices

Methods for optimizing the thermal interfaces between thermoelectric materials and heat exchangers to maximize energy conversion efficiency. These approaches include surface preparation techniques, application of specialized thermal interface materials, and mechanical designs that minimize thermal resistance while accommodating thermal expansion. The optimization techniques focus on maintaining consistent contact pressure across the thermoelectric junction to ensure uniform heat transfer.Expand Specific Solutions03 Educational systems for thermoelectric construction

Educational tools and methodologies designed to teach thermoelectric principles and construction techniques. These systems include hands-on learning modules, interactive simulations, and structured curriculum materials that demonstrate the mechanical aspects of thermoelectric device assembly. The educational approaches emphasize practical skills development while conveying theoretical understanding of thermoelectric phenomena.Expand Specific Solutions04 Advanced manufacturing processes for thermoelectric systems

Innovative manufacturing techniques specifically developed for thermoelectric device production, including precision machining, micro-fabrication, and advanced joining methods. These processes focus on achieving tight tolerances, consistent material properties, and reliable electrical connections while maintaining cost-effectiveness in production. The manufacturing approaches often incorporate quality control systems to ensure performance consistency across produced devices.Expand Specific Solutions05 Integration of thermoelectric elements in structural components

Methods for embedding thermoelectric devices within structural elements to create multifunctional components that provide both mechanical support and energy harvesting capabilities. These integration techniques address challenges of thermal management, electrical isolation, and mechanical stress distribution while maintaining the structural integrity of the host component. The approaches often utilize advanced materials and design strategies to protect thermoelectric elements from environmental factors.Expand Specific Solutions

Industry Leaders in Thermoelectric Construction

The thermoelectric construction methods market is currently in a growth phase, characterized by increasing adoption across automotive, industrial, and energy sectors. The global market size is expanding steadily, driven by rising demand for waste heat recovery solutions and energy efficiency improvements. Technologically, the field shows varying maturity levels, with established players like Toyota Motor Corp., DENSO Corp., and Panasonic Holdings leading commercial applications, while research institutions such as CEA, KIST, and Fraunhofer-Gesellschaft drive innovation. Companies like Samsung Electro-Mechanics, Robert Bosch, and LG Chem are advancing material science aspects, while specialized firms like Romny Scientific and GMZ Energy focus on niche applications. The competitive landscape features collaboration between industrial manufacturers and research organizations to overcome efficiency and cost barriers.

Commissariat à l´énergie atomique et aux énergies Alternatives

Technical Solution: CEA has developed advanced thermoelectric construction methods focusing on nanostructured materials and thin-film deposition techniques. Their approach combines silicon-germanium alloys with nano-inclusions to create high-efficiency thermoelectric modules. CEA's construction methodology involves precision multi-layer deposition processes that create optimized interfaces between thermoelectric materials, reducing thermal conductivity while maintaining electrical conductivity. Their manufacturing protocol incorporates specialized annealing treatments that enhance the Seebeck coefficient of the materials. CEA has also pioneered flexible thermoelectric generators using organic/inorganic hybrid materials that can be integrated into curved surfaces and textiles for wearable energy harvesting applications.

Strengths: Superior material integration capabilities, advanced thin-film fabrication expertise, and strong fundamental research foundation. Weaknesses: Higher production costs compared to conventional methods and challenges in scaling to mass production.

DENSO Corp.

Technical Solution: DENSO has developed sophisticated thermoelectric construction methods focused on automotive applications. Their approach integrates thermoelectric modules directly into vehicle exhaust systems using specialized high-temperature materials and proprietary joining techniques that withstand thermal cycling and vibration. DENSO's construction methodology incorporates segmented thermoelectric legs with compositionally graded materials to optimize performance across temperature gradients. Their manufacturing process includes precision automated assembly systems that ensure consistent module quality and performance. DENSO has pioneered the use of skutterudite-based materials in commercial applications, achieving power densities of up to 2.5 W/cm² in their latest generation modules. Their thermoelectric systems are designed to recover waste heat from vehicle exhaust, potentially improving fuel efficiency by 2-5% in conventional vehicles.

Strengths: Exceptional reliability in harsh automotive environments and highly automated manufacturing capabilities. Weaknesses: Higher system complexity and integration challenges compared to simpler thermoelectric applications.

Key Patents and Innovations in Thermoelectric Construction

method for MANUFACTURING THERMOELECTRIC CONSTRUCTION ELEMENT AND THERMOELECTRIC CONSTRUCTION ELEMENT

PatentActiveRU2014154137A

Innovation

- Innovative manufacturing process involving coating fibers with thermoelectric material and twisting them into a ring structure, followed by pressing to create a thermoelectric structural element.

- The annular design of the thermoelectric structural element with coated fibers extending in the peripheral direction for at least 120° angular range, creating a continuous thermoelectric path.

- The ability to divide the thermoelectric structural element along the axial direction into multiple smaller elements with corresponding reduced extension, enabling scalable manufacturing.

Method for manufacturing a thermoelectric structure

PatentPendingUS20240130236A1

Innovation

- A method involving additive manufacturing to create thermoelectric structures by depositing thermoelectric elements on a substrate, followed by thinning and cutting to form a film, with metallization integrated during the process, using techniques like laser powder bed fusion or selective laser sintering, allowing for reduced steps, lower costs, and improved mechanical and electrical conduction properties.

Energy Efficiency Standards and Regulations

The regulatory landscape for thermoelectric construction methods has evolved significantly over the past decade, with energy efficiency standards becoming increasingly stringent worldwide. In the United States, the Department of Energy (DOE) has established comprehensive guidelines through the Building Energy Codes Program, which specifically addresses thermoelectric systems in commercial and residential buildings. These regulations mandate minimum efficiency ratings for thermoelectric heating and cooling applications, with performance metrics typically measured in Coefficient of Performance (COP) and Energy Efficiency Ratio (EER).

The European Union has implemented even more rigorous standards through the Energy Performance of Buildings Directive (EPBD), which was updated in 2021 to include specific provisions for innovative thermoelectric construction techniques. These regulations require all new buildings to be nearly zero-energy by 2030, with thermoelectric systems playing a crucial role in meeting these ambitious targets. The directive also establishes a framework for calculating the energy performance of buildings that incorporate thermoelectric elements.

In Asia, countries like Japan and South Korea have pioneered performance-based regulatory approaches. Japan's Top Runner Program sets efficiency standards based on the most efficient products in the market, creating a continuous improvement cycle for thermoelectric technologies. This regulatory model has proven particularly effective in driving innovation in the thermoelectric construction sector.

International standards organizations have also contributed significantly to the regulatory framework. The International Organization for Standardization (ISO) has developed ISO 23993:2018, which specifically addresses thermal insulation products for building equipment and industrial installations, including thermoelectric applications. Similarly, ASTM International has established testing protocols (ASTM E2186) for evaluating the performance of thermoelectric materials in construction environments.

Compliance verification mechanisms have become increasingly sophisticated, with many jurisdictions implementing digital monitoring systems to track real-time energy performance of buildings utilizing thermoelectric construction methods. These systems enable regulators to assess compliance continuously rather than relying solely on pre-construction modeling or post-construction testing.

Looking forward, regulatory trends indicate a shift toward outcome-based compliance paths that focus on actual building performance rather than prescriptive requirements. This approach allows greater flexibility in implementing innovative thermoelectric solutions while ensuring that energy efficiency goals are met. Additionally, several jurisdictions are developing incentive programs specifically targeting advanced thermoelectric construction methods, offering tax credits, expedited permitting, or density bonuses for projects that exceed minimum standards.

The European Union has implemented even more rigorous standards through the Energy Performance of Buildings Directive (EPBD), which was updated in 2021 to include specific provisions for innovative thermoelectric construction techniques. These regulations require all new buildings to be nearly zero-energy by 2030, with thermoelectric systems playing a crucial role in meeting these ambitious targets. The directive also establishes a framework for calculating the energy performance of buildings that incorporate thermoelectric elements.

In Asia, countries like Japan and South Korea have pioneered performance-based regulatory approaches. Japan's Top Runner Program sets efficiency standards based on the most efficient products in the market, creating a continuous improvement cycle for thermoelectric technologies. This regulatory model has proven particularly effective in driving innovation in the thermoelectric construction sector.

International standards organizations have also contributed significantly to the regulatory framework. The International Organization for Standardization (ISO) has developed ISO 23993:2018, which specifically addresses thermal insulation products for building equipment and industrial installations, including thermoelectric applications. Similarly, ASTM International has established testing protocols (ASTM E2186) for evaluating the performance of thermoelectric materials in construction environments.

Compliance verification mechanisms have become increasingly sophisticated, with many jurisdictions implementing digital monitoring systems to track real-time energy performance of buildings utilizing thermoelectric construction methods. These systems enable regulators to assess compliance continuously rather than relying solely on pre-construction modeling or post-construction testing.

Looking forward, regulatory trends indicate a shift toward outcome-based compliance paths that focus on actual building performance rather than prescriptive requirements. This approach allows greater flexibility in implementing innovative thermoelectric solutions while ensuring that energy efficiency goals are met. Additionally, several jurisdictions are developing incentive programs specifically targeting advanced thermoelectric construction methods, offering tax credits, expedited permitting, or density bonuses for projects that exceed minimum standards.

Material Science Advancements for Thermoelectric Applications

Recent advancements in material science have revolutionized the field of thermoelectric applications, creating unprecedented opportunities for mechanical mastery in construction methods. The development of novel semiconductor materials with enhanced Seebeck coefficients has significantly improved energy conversion efficiency, a critical factor in thermoelectric performance. These materials exhibit superior electron transport properties while simultaneously reducing thermal conductivity, addressing the fundamental challenge of thermoelectric design.

Nanostructured materials represent a particularly promising frontier, with quantum confinement effects enabling manipulation of electron and phonon transport at the nanoscale. Research indicates that nanocomposites incorporating bismuth telluride, lead telluride, and silicon-germanium alloys demonstrate significantly higher figures of merit (ZT values) compared to their bulk counterparts, with some laboratory prototypes achieving ZT values exceeding 2.0 at operational temperatures.

Flexible thermoelectric materials have emerged as another transformative development, enabling conformal integration into complex mechanical systems. Polymer-based thermoelectric composites, while exhibiting lower ZT values than inorganic counterparts, offer unprecedented mechanical flexibility and processing advantages. These materials can be solution-processed, printed, or extruded, opening new avenues for large-area manufacturing and integration into non-planar surfaces.

Interface engineering has become a critical focus area, with researchers developing specialized techniques to minimize contact resistance between thermoelectric modules and heat sources/sinks. Advanced metallization processes, diffusion barrier layers, and gradient interface structures have demonstrated substantial improvements in device performance and long-term reliability under thermal cycling conditions.

Environmental considerations have driven research toward lead-free and rare-earth-free thermoelectric materials. Compounds based on abundant elements such as magnesium silicide, tetrahedrites, and half-Heusler alloys show promising thermoelectric properties while addressing sustainability concerns. These materials enable construction methods that align with increasingly stringent environmental regulations.

Additive manufacturing techniques have transformed fabrication capabilities for thermoelectric devices, allowing precise control over material composition and geometric complexity. Selective laser sintering and direct ink writing processes enable the creation of thermoelectric structures with optimized thermal and electrical pathways, previously impossible with conventional manufacturing methods. These techniques facilitate the integration of thermoelectric functionality directly into structural components, blurring the distinction between thermal management systems and mechanical structures.

Nanostructured materials represent a particularly promising frontier, with quantum confinement effects enabling manipulation of electron and phonon transport at the nanoscale. Research indicates that nanocomposites incorporating bismuth telluride, lead telluride, and silicon-germanium alloys demonstrate significantly higher figures of merit (ZT values) compared to their bulk counterparts, with some laboratory prototypes achieving ZT values exceeding 2.0 at operational temperatures.

Flexible thermoelectric materials have emerged as another transformative development, enabling conformal integration into complex mechanical systems. Polymer-based thermoelectric composites, while exhibiting lower ZT values than inorganic counterparts, offer unprecedented mechanical flexibility and processing advantages. These materials can be solution-processed, printed, or extruded, opening new avenues for large-area manufacturing and integration into non-planar surfaces.

Interface engineering has become a critical focus area, with researchers developing specialized techniques to minimize contact resistance between thermoelectric modules and heat sources/sinks. Advanced metallization processes, diffusion barrier layers, and gradient interface structures have demonstrated substantial improvements in device performance and long-term reliability under thermal cycling conditions.

Environmental considerations have driven research toward lead-free and rare-earth-free thermoelectric materials. Compounds based on abundant elements such as magnesium silicide, tetrahedrites, and half-Heusler alloys show promising thermoelectric properties while addressing sustainability concerns. These materials enable construction methods that align with increasingly stringent environmental regulations.

Additive manufacturing techniques have transformed fabrication capabilities for thermoelectric devices, allowing precise control over material composition and geometric complexity. Selective laser sintering and direct ink writing processes enable the creation of thermoelectric structures with optimized thermal and electrical pathways, previously impossible with conventional manufacturing methods. These techniques facilitate the integration of thermoelectric functionality directly into structural components, blurring the distinction between thermal management systems and mechanical structures.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!