Design Challenges in Transient Electronics Circuits.

SEP 4, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Transient Electronics Background and Objectives

Transient electronics represents a revolutionary paradigm shift in electronic device design, focusing on systems that can physically disappear or transform in a controlled manner after serving their intended functions. This emerging field has evolved from traditional permanent electronics to address growing concerns about electronic waste, data security, and specialized applications requiring temporary functionality. The concept originated in the early 2000s, with significant acceleration in research and development occurring over the past decade as environmental sustainability gained prominence in technological innovation.

The evolution of transient electronics has been marked by progressive improvements in materials science, particularly the development of water-soluble polymers, bioresorbable semiconductors, and environmentally degradable conductors. These advancements have enabled the creation of electronic components that can dissolve in water, biofluids, or degrade under specific environmental conditions while maintaining reliable performance during their operational lifetime.

Current technological trajectories indicate a convergence of biodegradable materials with conventional electronic manufacturing techniques, aiming to bridge the gap between transient functionality and the performance standards established by permanent electronics. The field is witnessing increasing integration with Internet of Things (IoT) applications, medical implants, and environmental monitoring systems, suggesting a diversification of application domains beyond initial medical use cases.

The primary objectives of transient electronics research center on addressing several critical challenges. First, designing circuits that maintain stable electrical performance during their intended lifetime while ensuring complete and predictable dissolution afterward. Second, developing reliable triggering mechanisms that can initiate the transience process at precisely the right moment. Third, creating power sources compatible with transient systems that themselves can disappear without environmental harm.

Additionally, researchers aim to establish standardized testing protocols and performance metrics specific to transient electronics, as conventional reliability standards do not adequately capture the unique requirements of these systems. The field seeks to develop comprehensive lifecycle assessment methodologies that account for both the functional period and the dissolution phase of transient devices.

From a materials perspective, objectives include expanding the library of transient-compatible materials to enhance performance capabilities, extending operational lifetimes from days to months when required, and ensuring that dissolution byproducts remain environmentally benign. Parallel efforts focus on developing manufacturing techniques that can scale production while maintaining precise control over dissolution kinetics and functional properties.

The ultimate goal remains creating electronic systems that can perform complex functions reliably for a predetermined period before disappearing completely, leaving minimal or no trace in their environment, thereby revolutionizing applications in healthcare, environmental monitoring, and secure electronics.

The evolution of transient electronics has been marked by progressive improvements in materials science, particularly the development of water-soluble polymers, bioresorbable semiconductors, and environmentally degradable conductors. These advancements have enabled the creation of electronic components that can dissolve in water, biofluids, or degrade under specific environmental conditions while maintaining reliable performance during their operational lifetime.

Current technological trajectories indicate a convergence of biodegradable materials with conventional electronic manufacturing techniques, aiming to bridge the gap between transient functionality and the performance standards established by permanent electronics. The field is witnessing increasing integration with Internet of Things (IoT) applications, medical implants, and environmental monitoring systems, suggesting a diversification of application domains beyond initial medical use cases.

The primary objectives of transient electronics research center on addressing several critical challenges. First, designing circuits that maintain stable electrical performance during their intended lifetime while ensuring complete and predictable dissolution afterward. Second, developing reliable triggering mechanisms that can initiate the transience process at precisely the right moment. Third, creating power sources compatible with transient systems that themselves can disappear without environmental harm.

Additionally, researchers aim to establish standardized testing protocols and performance metrics specific to transient electronics, as conventional reliability standards do not adequately capture the unique requirements of these systems. The field seeks to develop comprehensive lifecycle assessment methodologies that account for both the functional period and the dissolution phase of transient devices.

From a materials perspective, objectives include expanding the library of transient-compatible materials to enhance performance capabilities, extending operational lifetimes from days to months when required, and ensuring that dissolution byproducts remain environmentally benign. Parallel efforts focus on developing manufacturing techniques that can scale production while maintaining precise control over dissolution kinetics and functional properties.

The ultimate goal remains creating electronic systems that can perform complex functions reliably for a predetermined period before disappearing completely, leaving minimal or no trace in their environment, thereby revolutionizing applications in healthcare, environmental monitoring, and secure electronics.

Market Applications and Demand Analysis

Transient electronics, designed to dissolve or degrade after a predetermined period, represent a rapidly expanding market driven by diverse applications across multiple sectors. The global market for transient electronics is projected to reach $4.5 billion by 2028, with a compound annual growth rate of approximately 21% from 2023 to 2028, reflecting the growing demand for environmentally friendly and temporary electronic solutions.

The healthcare sector demonstrates the strongest demand for transient electronics circuits, particularly for implantable medical devices that eliminate the need for secondary removal surgeries. Biodegradable sensors for post-operative monitoring, dissolvable drug delivery systems, and temporary diagnostic tools collectively account for nearly 38% of the current market applications. Patient monitoring systems using transient electronics are experiencing particularly robust growth due to their ability to provide continuous data while reducing infection risks associated with long-term device implantation.

Environmental monitoring represents another significant market segment, with demand for degradable sensors deployed in natural ecosystems, agricultural settings, and urban environments. These applications leverage the ability of transient electronics to collect critical environmental data without contributing to electronic waste or requiring resource-intensive retrieval operations. Market analysis indicates this segment is growing at 24% annually, faster than the overall market average.

Consumer electronics manufacturers are increasingly exploring transient technologies for temporary-use devices, particularly in the wearable technology sector. Disposable health monitors, temporary electronic tattoos, and short-term use consumer devices represent emerging applications with substantial growth potential. Market surveys indicate 67% of consumers express interest in electronics that leave minimal environmental footprint after their useful life.

Military and defense applications constitute a specialized but high-value market segment, with demand for secure electronics that can be remotely triggered to degrade, preventing sensitive technology from falling into unauthorized hands. This segment, while smaller in volume, commands premium pricing and significant research investment.

The market faces demand-side challenges including cost barriers, performance limitations compared to conventional electronics, and consumer education regarding proper disposal protocols. However, regulatory trends toward extended producer responsibility and electronic waste reduction are creating favorable market conditions for transient electronics adoption across all identified sectors.

Regional analysis reveals North America currently leads market demand with 42% share, followed by Europe at 31%, while Asia-Pacific represents the fastest-growing regional market with increasing adoption in both healthcare and consumer applications. This geographic distribution reflects varying regulatory environments and technological adoption rates across major markets.

The healthcare sector demonstrates the strongest demand for transient electronics circuits, particularly for implantable medical devices that eliminate the need for secondary removal surgeries. Biodegradable sensors for post-operative monitoring, dissolvable drug delivery systems, and temporary diagnostic tools collectively account for nearly 38% of the current market applications. Patient monitoring systems using transient electronics are experiencing particularly robust growth due to their ability to provide continuous data while reducing infection risks associated with long-term device implantation.

Environmental monitoring represents another significant market segment, with demand for degradable sensors deployed in natural ecosystems, agricultural settings, and urban environments. These applications leverage the ability of transient electronics to collect critical environmental data without contributing to electronic waste or requiring resource-intensive retrieval operations. Market analysis indicates this segment is growing at 24% annually, faster than the overall market average.

Consumer electronics manufacturers are increasingly exploring transient technologies for temporary-use devices, particularly in the wearable technology sector. Disposable health monitors, temporary electronic tattoos, and short-term use consumer devices represent emerging applications with substantial growth potential. Market surveys indicate 67% of consumers express interest in electronics that leave minimal environmental footprint after their useful life.

Military and defense applications constitute a specialized but high-value market segment, with demand for secure electronics that can be remotely triggered to degrade, preventing sensitive technology from falling into unauthorized hands. This segment, while smaller in volume, commands premium pricing and significant research investment.

The market faces demand-side challenges including cost barriers, performance limitations compared to conventional electronics, and consumer education regarding proper disposal protocols. However, regulatory trends toward extended producer responsibility and electronic waste reduction are creating favorable market conditions for transient electronics adoption across all identified sectors.

Regional analysis reveals North America currently leads market demand with 42% share, followed by Europe at 31%, while Asia-Pacific represents the fastest-growing regional market with increasing adoption in both healthcare and consumer applications. This geographic distribution reflects varying regulatory environments and technological adoption rates across major markets.

Current Technical Challenges and Limitations

Transient electronics circuits face significant technical challenges that currently limit their widespread application and commercialization. The fundamental challenge lies in achieving controlled degradation while maintaining reliable functionality during the intended operational lifetime. Material selection presents a critical limitation, as materials must simultaneously possess suitable electronic properties and predictable degradation characteristics. Current biodegradable conductors, semiconductors, and dielectrics often exhibit inferior performance compared to conventional electronics materials, resulting in compromised circuit efficiency and reliability.

Fabrication processes represent another major hurdle in transient electronics development. Traditional manufacturing techniques are optimized for permanent devices and often prove incompatible with transient materials. The integration of dissimilar materials with varying degradation rates requires novel fabrication approaches that can ensure uniform dissolution without premature failure points. Additionally, achieving precise control over degradation timing remains difficult, as environmental factors such as temperature, humidity, and pH can significantly alter dissolution rates.

Power management presents unique challenges in transient systems. Conventional batteries contain toxic materials incompatible with biodegradable applications, while existing transient power sources typically offer limited capacity and unstable output. This power constraint severely restricts the complexity and functionality of transient circuits, particularly for applications requiring extended operation periods or higher power consumption.

Encapsulation technologies represent a critical bottleneck in transient electronics development. Current encapsulation materials struggle to provide adequate protection during the operational period while still enabling controlled degradation afterward. The interface between encapsulation layers and electronic components often creates weak points vulnerable to premature environmental infiltration, leading to unpredictable device failure.

Reliability and performance consistency remain significant concerns across the transient electronics landscape. Environmental variations can cause substantial deviations in circuit performance and degradation rates, making it difficult to guarantee consistent functionality across different deployment scenarios. The lack of standardized testing protocols for transient electronics further complicates quality assurance and performance validation.

From a design perspective, transient circuits face unique constraints not present in conventional electronics. Circuit designers must account for changing electrical properties as materials begin to degrade, requiring novel compensation mechanisms and fault-tolerant architectures. The limited selection of available transient components restricts design flexibility, often necessitating compromises in circuit complexity and functionality.

Scaling transient electronics from laboratory prototypes to commercial production introduces additional challenges related to manufacturing consistency, cost-effectiveness, and quality control. Current production methods remain largely experimental and difficult to scale, resulting in high costs and limited accessibility for potential applications.

Fabrication processes represent another major hurdle in transient electronics development. Traditional manufacturing techniques are optimized for permanent devices and often prove incompatible with transient materials. The integration of dissimilar materials with varying degradation rates requires novel fabrication approaches that can ensure uniform dissolution without premature failure points. Additionally, achieving precise control over degradation timing remains difficult, as environmental factors such as temperature, humidity, and pH can significantly alter dissolution rates.

Power management presents unique challenges in transient systems. Conventional batteries contain toxic materials incompatible with biodegradable applications, while existing transient power sources typically offer limited capacity and unstable output. This power constraint severely restricts the complexity and functionality of transient circuits, particularly for applications requiring extended operation periods or higher power consumption.

Encapsulation technologies represent a critical bottleneck in transient electronics development. Current encapsulation materials struggle to provide adequate protection during the operational period while still enabling controlled degradation afterward. The interface between encapsulation layers and electronic components often creates weak points vulnerable to premature environmental infiltration, leading to unpredictable device failure.

Reliability and performance consistency remain significant concerns across the transient electronics landscape. Environmental variations can cause substantial deviations in circuit performance and degradation rates, making it difficult to guarantee consistent functionality across different deployment scenarios. The lack of standardized testing protocols for transient electronics further complicates quality assurance and performance validation.

From a design perspective, transient circuits face unique constraints not present in conventional electronics. Circuit designers must account for changing electrical properties as materials begin to degrade, requiring novel compensation mechanisms and fault-tolerant architectures. The limited selection of available transient components restricts design flexibility, often necessitating compromises in circuit complexity and functionality.

Scaling transient electronics from laboratory prototypes to commercial production introduces additional challenges related to manufacturing consistency, cost-effectiveness, and quality control. Current production methods remain largely experimental and difficult to scale, resulting in high costs and limited accessibility for potential applications.

Current Circuit Design Approaches

01 Biodegradable and Dissolvable Circuit Materials

Transient electronics face challenges in material selection that can degrade safely after use. These circuits require biodegradable substrates, water-soluble conductors, and environmentally friendly semiconductors that maintain functionality during operation but can decompose under specific environmental conditions. The design must balance performance requirements with controlled degradation mechanisms while ensuring biocompatibility for medical applications.- Biodegradable and Dissolvable Circuit Materials: Transient electronics face challenges in material selection that can degrade or dissolve in controlled environments while maintaining functionality during their operational lifetime. These circuits require specialized biodegradable substrates, water-soluble conductors, and environmentally responsive components that can break down after use. The design must balance performance requirements with degradation timelines, ensuring circuits function properly before dissolving or decomposing.

- Power Supply and Energy Harvesting Limitations: Designing power sources for transient electronics presents significant challenges as conventional batteries are often incompatible with biodegradable requirements. Engineers must develop novel energy harvesting techniques, ultra-low-power circuit designs, and temporary storage solutions that can power the device during its functional lifetime while still meeting transience requirements. These power systems must be miniaturized, efficient, and capable of degrading along with the rest of the circuit.

- Environmental Triggers and Controlled Dissolution: Creating reliable trigger mechanisms that initiate the dissolution or degradation process at the appropriate time is a major design challenge. These triggers may respond to specific environmental conditions such as moisture, temperature, pH levels, or external signals. Engineers must ensure precise control over the dissolution timing and rate, preventing premature degradation while guaranteeing complete breakdown when required.

- Reliability and Performance Consistency: Maintaining consistent performance throughout the operational lifetime of transient electronics is challenging due to the inherent instability of degradable materials. Circuit designs must account for potential parameter drift, environmental sensitivity, and gradual material changes that occur even before the triggered dissolution. This requires robust error correction, redundancy mechanisms, and adaptive circuit designs that can compensate for changing material properties.

- Integration and Packaging Challenges: Integrating transient components with different dissolution rates and properties presents significant packaging challenges. The interface between transient and non-transient parts must be carefully designed to maintain functionality while ensuring complete dissolution when required. Packaging must protect sensitive components during operation while not impeding the dissolution process, often requiring novel encapsulation techniques and hermetic sealing methods that themselves can degrade in controlled ways.

02 Power Supply and Energy Harvesting Solutions

Designing reliable power sources for transient electronics presents significant challenges. These circuits often require specialized energy harvesting mechanisms or biodegradable batteries that can power the device for its intended lifespan but decompose afterward. Engineers must develop ultra-low-power circuit designs that can operate with minimal energy while maintaining necessary functionality, as conventional power solutions are typically not compatible with transient applications.Expand Specific Solutions03 Controlled Degradation Timing Mechanisms

A critical challenge in transient electronics is designing circuits with precisely controlled lifespans. This requires developing trigger mechanisms that initiate dissolution at specific times or under particular environmental conditions. Circuit designers must incorporate timing elements that maintain stability during operation but enable rapid degradation when triggered, which demands innovative approaches to circuit architecture and material interfaces.Expand Specific Solutions04 Integration and Packaging Challenges

Transient electronics face unique packaging and integration challenges as all components must maintain functionality while being compatible with degradation mechanisms. Designers must develop novel interconnection techniques between dissimilar materials that can maintain electrical performance during operation but allow for complete system dissolution. The packaging must protect sensitive components from premature degradation while not impeding the intended dissolution process when activated.Expand Specific Solutions05 Testing and Reliability Verification

Verifying the reliability and performance of transient electronics presents unique testing challenges. Conventional testing methodologies must be adapted to evaluate both operational performance and controlled degradation characteristics. Engineers need to develop specialized test protocols that can predict dissolution behavior under various environmental conditions while ensuring circuit functionality during the intended operational period. This requires innovative approaches to accelerated testing and reliability modeling specific to transient systems.Expand Specific Solutions

Leading Companies and Research Institutions

The transient electronics circuits market is in an early growth phase, characterized by increasing research activity but limited commercial deployment. The global market size is estimated to reach $1.5 billion by 2026, with a CAGR of approximately 25%. Regarding technological maturity, academic institutions like Tsinghua University, University of Electronic Science & Technology of China, and Peking University are leading fundamental research, while companies demonstrate varying levels of development. Huawei and Toshiba have made significant advances in transient circuit design, with MXTronics and Himax Technologies focusing on specialized applications. Smaller players like DSIM Technology and uPI Semiconductor are developing niche solutions, indicating an ecosystem still evolving from research to commercial viability.

Huawei Technologies Co., Ltd.

Technical Solution: Huawei has developed a comprehensive approach to transient electronics focusing on security-critical applications. Their technology incorporates self-destructing circuits that can be triggered remotely or automatically based on specific environmental conditions. Huawei's transient electronics platform utilizes metastable materials that undergo rapid structural changes when exposed to specific triggers such as heat, electrical signals, or chemical agents. Their circuits feature specialized fuse-like structures embedded throughout critical components that, when activated, create open circuits rendering the device inoperable. Additionally, Huawei has pioneered the use of phase-change materials in memory components that can be rapidly transformed from crystalline to amorphous states, effectively erasing stored data. Their research also extends to encapsulation technologies that maintain device integrity during normal operation but facilitate rapid dissolution when triggered.

Strengths: Strong integration with existing secure communication infrastructure; advanced remote triggering mechanisms; robust protection against reverse engineering attempts. Weaknesses: Higher manufacturing costs compared to conventional electronics; potential for accidental triggering in harsh environments; trade-off between transience speed and operational reliability during normal use.

The University of Hong Kong

Technical Solution: The University of Hong Kong has developed significant innovations in transient electronics focusing on biomedical applications. Their approach centers on silicon nanomembrane-based electronics that can dissolve safely in bodily fluids after completing their therapeutic or diagnostic functions. They've pioneered ultra-thin flexible circuit designs (less than 100 nm thickness) that conform to biological tissues while maintaining electronic functionality. Their technology incorporates specialized biocompatible conductors using magnesium, zinc, and iron alloys with controlled corrosion rates in physiological environments. HKU researchers have developed novel encapsulation strategies using silk fibroin and poly(lactic-co-glycolic acid) that provide temporary protection while enabling programmed dissolution. Their recent advancements include transient sensors for post-surgical monitoring that eliminate the need for secondary removal procedures, and therapeutic devices that deliver electrical stimulation before harmlessly dissolving in the body.

Strengths: Excellent biocompatibility profile; advanced integration with biological systems; precise control over dissolution timeframes in physiological environments. Weaknesses: Limited power capacity due to size constraints; challenges in wireless communication through biological tissues; trade-offs between mechanical flexibility and electronic performance.

Key Patents and Technical Innovations

Circuit structure with gate configuration

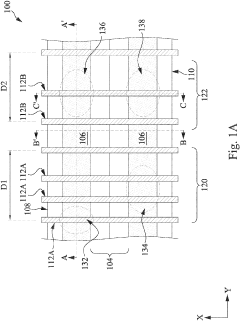

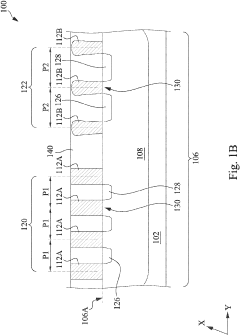

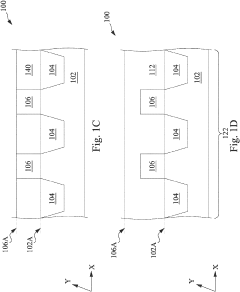

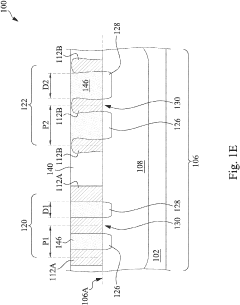

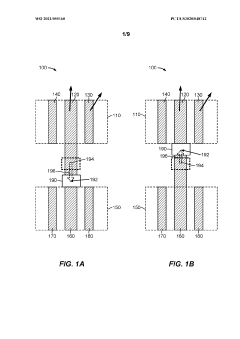

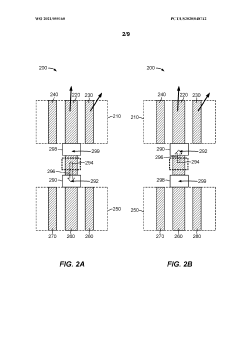

PatentActiveUS20230207650A1

Innovation

- A semiconductor circuit structure with field-effect transistors featuring gates configured with multiple pitches tailored to different functional blocks, such as logic and high-frequency devices, along with the use of dummy gates to adjust pattern density and enhance fabrication, allowing for optimized performance and reliability.

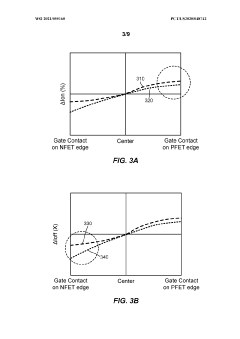

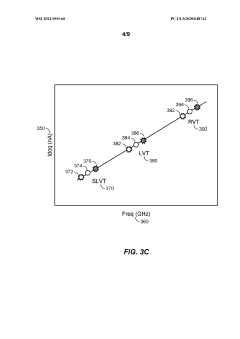

Offset gate contact

PatentWO2021055160A1

Innovation

- The placement of a gate contact is offset from the center point between transistors, allowing for independent modulation of threshold voltage without altering the Front End of Line (FEOL) process, thereby reducing leakage current in low power applications and increasing on current for high speed applications.

Materials Science Considerations

Materials science forms the foundation of transient electronics development, presenting unique challenges that require innovative approaches. The selection of materials for transient electronic circuits demands careful consideration of both functional performance during operation and controlled degradation mechanisms after use. Silicon-based materials remain prominent due to their established semiconductor properties, but their natural degradation rates are typically slow. Research has focused on ultra-thin silicon membranes (< 100 nm) that can dissolve in physiological environments within days to weeks, striking a balance between operational stability and transience.

Biodegradable polymers such as polylactic acid (PLA), polyglycolic acid (PGA), and silk fibroin serve as substrates and encapsulation materials, offering tunable degradation rates through molecular weight and crystallinity adjustments. However, these materials often exhibit inferior electrical and mechanical properties compared to conventional electronics materials, creating a fundamental performance-transience tradeoff that designers must navigate.

Conductive materials present another critical challenge, as traditional metals like gold and copper offer excellent conductivity but poor degradability. Alternative approaches include water-soluble metals (magnesium, zinc, iron), conductive polymers (PEDOT:PSS), and composite materials that combine degradability with acceptable electrical performance. The interface between different material layers introduces additional complexity, as degradation rates must be synchronized to prevent premature device failure or incomplete dissolution.

Environmental responsiveness of materials represents both a challenge and opportunity in transient electronics design. Materials that respond to specific triggers—such as pH changes, enzymatic activity, or temperature shifts—enable precise control over device lifetime. However, ensuring consistent degradation behavior across varying environmental conditions remains difficult, particularly for applications with unpredictable exposure scenarios.

Manufacturing compatibility presents another significant hurdle, as many promising transient materials are incompatible with standard microelectronics fabrication processes. Techniques like low-temperature deposition, solution processing, and transfer printing have been developed to address these limitations, but often result in reduced device performance or increased production costs. The development of materials that can withstand conventional fabrication processes while maintaining transient properties represents an ongoing research priority.

Stability during the intended operational lifetime versus complete degradation afterward creates a fundamental materials science paradox that defines the field. Advances in interface engineering, composite materials, and environmentally responsive chemistries continue to push the boundaries of what's possible, gradually narrowing the performance gap between transient and conventional electronic systems.

Biodegradable polymers such as polylactic acid (PLA), polyglycolic acid (PGA), and silk fibroin serve as substrates and encapsulation materials, offering tunable degradation rates through molecular weight and crystallinity adjustments. However, these materials often exhibit inferior electrical and mechanical properties compared to conventional electronics materials, creating a fundamental performance-transience tradeoff that designers must navigate.

Conductive materials present another critical challenge, as traditional metals like gold and copper offer excellent conductivity but poor degradability. Alternative approaches include water-soluble metals (magnesium, zinc, iron), conductive polymers (PEDOT:PSS), and composite materials that combine degradability with acceptable electrical performance. The interface between different material layers introduces additional complexity, as degradation rates must be synchronized to prevent premature device failure or incomplete dissolution.

Environmental responsiveness of materials represents both a challenge and opportunity in transient electronics design. Materials that respond to specific triggers—such as pH changes, enzymatic activity, or temperature shifts—enable precise control over device lifetime. However, ensuring consistent degradation behavior across varying environmental conditions remains difficult, particularly for applications with unpredictable exposure scenarios.

Manufacturing compatibility presents another significant hurdle, as many promising transient materials are incompatible with standard microelectronics fabrication processes. Techniques like low-temperature deposition, solution processing, and transfer printing have been developed to address these limitations, but often result in reduced device performance or increased production costs. The development of materials that can withstand conventional fabrication processes while maintaining transient properties represents an ongoing research priority.

Stability during the intended operational lifetime versus complete degradation afterward creates a fundamental materials science paradox that defines the field. Advances in interface engineering, composite materials, and environmentally responsive chemistries continue to push the boundaries of what's possible, gradually narrowing the performance gap between transient and conventional electronic systems.

Environmental Impact Assessment

Transient electronics represent a paradigm shift in electronic waste management, offering biodegradable alternatives to conventional persistent circuits. The environmental impact assessment of these systems reveals both significant benefits and challenges that must be addressed as this technology advances toward widespread implementation.

The primary environmental advantage of transient electronics lies in their ability to decompose naturally after their functional lifetime, potentially eliminating millions of tons of electronic waste annually. Conventional electronics contribute approximately 50 million metric tons of e-waste globally each year, with less than 20% being properly recycled. Transient circuits could dramatically reduce this environmental burden by dissolving into non-toxic components when exposed to specific environmental triggers such as moisture, heat, or light.

Material selection plays a critical role in determining the environmental footprint of transient electronics. Silicon-based substrates, while effective for circuit functionality, may not degrade as efficiently as organic alternatives. Recent research indicates that circuits utilizing silk fibroin, cellulose derivatives, and other biopolymers demonstrate superior environmental compatibility, breaking down into harmless byproducts within weeks rather than centuries required for conventional electronic components.

However, the environmental assessment must also consider the manufacturing processes involved in transient electronics production. Current fabrication methods often require specialized solvents and energy-intensive processes that may offset some of the end-of-life environmental benefits. Life cycle analyses indicate that the production phase of transient electronics currently generates 30-40% more greenhouse gas emissions compared to conventional electronics manufacturing, primarily due to the specialized nature of biodegradable material processing.

Water systems face particular vulnerability to electronic waste contamination. Transient electronics designed to dissolve in aqueous environments must be carefully engineered to ensure their degradation products do not introduce new contaminants. Studies monitoring dissolution byproducts have identified potential concerns with certain metal ions that, while present in small quantities, could accumulate in aquatic ecosystems if deployment scales significantly.

The time-dependent nature of environmental impact presents another consideration. Controlled degradation timing remains challenging, with environmental factors like temperature fluctuations and humidity levels significantly affecting dissolution rates. This variability could lead to premature failure in some applications or extended persistence in others, potentially undermining the intended environmental benefits.

Regulatory frameworks for assessing and certifying the environmental impact of transient electronics remain underdeveloped. Standardized testing protocols that accurately predict real-world degradation behavior across diverse environmental conditions are essential for meaningful environmental impact assessment and responsible deployment of this promising technology.

The primary environmental advantage of transient electronics lies in their ability to decompose naturally after their functional lifetime, potentially eliminating millions of tons of electronic waste annually. Conventional electronics contribute approximately 50 million metric tons of e-waste globally each year, with less than 20% being properly recycled. Transient circuits could dramatically reduce this environmental burden by dissolving into non-toxic components when exposed to specific environmental triggers such as moisture, heat, or light.

Material selection plays a critical role in determining the environmental footprint of transient electronics. Silicon-based substrates, while effective for circuit functionality, may not degrade as efficiently as organic alternatives. Recent research indicates that circuits utilizing silk fibroin, cellulose derivatives, and other biopolymers demonstrate superior environmental compatibility, breaking down into harmless byproducts within weeks rather than centuries required for conventional electronic components.

However, the environmental assessment must also consider the manufacturing processes involved in transient electronics production. Current fabrication methods often require specialized solvents and energy-intensive processes that may offset some of the end-of-life environmental benefits. Life cycle analyses indicate that the production phase of transient electronics currently generates 30-40% more greenhouse gas emissions compared to conventional electronics manufacturing, primarily due to the specialized nature of biodegradable material processing.

Water systems face particular vulnerability to electronic waste contamination. Transient electronics designed to dissolve in aqueous environments must be carefully engineered to ensure their degradation products do not introduce new contaminants. Studies monitoring dissolution byproducts have identified potential concerns with certain metal ions that, while present in small quantities, could accumulate in aquatic ecosystems if deployment scales significantly.

The time-dependent nature of environmental impact presents another consideration. Controlled degradation timing remains challenging, with environmental factors like temperature fluctuations and humidity levels significantly affecting dissolution rates. This variability could lead to premature failure in some applications or extended persistence in others, potentially undermining the intended environmental benefits.

Regulatory frameworks for assessing and certifying the environmental impact of transient electronics remain underdeveloped. Standardized testing protocols that accurately predict real-world degradation behavior across diverse environmental conditions are essential for meaningful environmental impact assessment and responsible deployment of this promising technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!