Transient Electronics for Sustainable Consumer Electronics.

SEP 4, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Transient Electronics Background and Objectives

Transient electronics represents a revolutionary paradigm shift in the field of electronic devices, characterized by their ability to dissolve, disintegrate, or degrade in a controlled manner after serving their intended functions. This emerging technology has evolved from the convergence of materials science, electronics engineering, and environmental sustainability research over the past decade. The concept originated from biomedical applications where temporary implantable devices were designed to avoid secondary surgical removal procedures, but has since expanded to address the growing electronic waste crisis in consumer electronics.

The evolution of transient electronics has been marked by significant advancements in biodegradable materials, water-soluble conductors, and environmentally friendly semiconductors. Early developments focused primarily on medical applications, while recent research has pivoted toward consumer electronics applications where planned obsolescence and electronic waste present substantial environmental challenges. Current technological trajectories indicate a growing emphasis on developing transient components that can maintain performance comparable to conventional electronics while offering controlled degradability.

The primary objective of transient electronics in the consumer sector is to create functional electronic devices that deliver expected performance during their operational lifetime but can harmlessly decompose afterward, thereby minimizing electronic waste and reducing environmental impact. This approach aims to transform the linear "take-make-dispose" model of electronics consumption into a more sustainable circular economy framework where materials return safely to the environment or can be easily recovered for reuse.

Secondary objectives include developing manufacturing processes compatible with existing electronics production infrastructure, ensuring cost-effectiveness to enable market adoption, and establishing appropriate regulatory frameworks for this new class of electronics. The technology also seeks to address critical resource conservation challenges by reducing dependence on rare earth elements and precious metals that are currently essential to conventional electronics manufacturing.

The technical goals encompass creating transient electronic components with predictable and controllable degradation timelines, developing trigger mechanisms that can initiate decomposition on demand, and ensuring that degradation products are environmentally benign. Additionally, researchers aim to achieve comparable performance metrics to conventional electronics during the functional lifetime of these devices, as consumer acceptance will depend on maintaining expected functionality and reliability.

As electronic waste continues to be the fastest-growing waste stream globally, with an estimated 53.6 million metric tons generated in 2019 alone, transient electronics represents a promising technological solution to mitigate this environmental crisis while supporting the continued advancement of consumer electronics technologies in a more sustainable paradigm.

The evolution of transient electronics has been marked by significant advancements in biodegradable materials, water-soluble conductors, and environmentally friendly semiconductors. Early developments focused primarily on medical applications, while recent research has pivoted toward consumer electronics applications where planned obsolescence and electronic waste present substantial environmental challenges. Current technological trajectories indicate a growing emphasis on developing transient components that can maintain performance comparable to conventional electronics while offering controlled degradability.

The primary objective of transient electronics in the consumer sector is to create functional electronic devices that deliver expected performance during their operational lifetime but can harmlessly decompose afterward, thereby minimizing electronic waste and reducing environmental impact. This approach aims to transform the linear "take-make-dispose" model of electronics consumption into a more sustainable circular economy framework where materials return safely to the environment or can be easily recovered for reuse.

Secondary objectives include developing manufacturing processes compatible with existing electronics production infrastructure, ensuring cost-effectiveness to enable market adoption, and establishing appropriate regulatory frameworks for this new class of electronics. The technology also seeks to address critical resource conservation challenges by reducing dependence on rare earth elements and precious metals that are currently essential to conventional electronics manufacturing.

The technical goals encompass creating transient electronic components with predictable and controllable degradation timelines, developing trigger mechanisms that can initiate decomposition on demand, and ensuring that degradation products are environmentally benign. Additionally, researchers aim to achieve comparable performance metrics to conventional electronics during the functional lifetime of these devices, as consumer acceptance will depend on maintaining expected functionality and reliability.

As electronic waste continues to be the fastest-growing waste stream globally, with an estimated 53.6 million metric tons generated in 2019 alone, transient electronics represents a promising technological solution to mitigate this environmental crisis while supporting the continued advancement of consumer electronics technologies in a more sustainable paradigm.

Market Analysis for Sustainable Consumer Electronics

The sustainable consumer electronics market is experiencing unprecedented growth, driven by increasing environmental awareness and regulatory pressures. Current market valuations indicate the global sustainable electronics sector reached approximately $160 billion in 2022, with projections suggesting a compound annual growth rate of 11.2% through 2030. This growth significantly outpaces the traditional consumer electronics market, which maintains a more modest 5.3% CAGR.

Consumer demand patterns reveal a notable shift in purchasing behavior, with 73% of consumers across major markets expressing willingness to pay premium prices for electronics with proven sustainability credentials. This represents a 24% increase from similar surveys conducted five years ago, indicating rapidly evolving consumer priorities.

Transient electronics—devices designed to harmlessly dissolve after their useful life—address a critical market need as electronic waste continues to be the fastest-growing waste stream globally. With over 50 million metric tons of e-waste generated annually and less than 20% properly recycled, the market opportunity for degradable electronics solutions is substantial.

Regional analysis shows varying adoption rates, with European markets leading in sustainable electronics demand due to stringent regulatory frameworks like the European Green Deal and Extended Producer Responsibility legislation. North American markets follow closely, driven primarily by consumer preference rather than regulation, while Asia-Pacific regions represent the fastest-growing market segment with 14.7% year-over-year growth.

Key market segments demonstrating particular promise for transient electronics include wearable health monitors, temporary consumer devices, and packaging electronics. The wearable health segment alone is projected to reach $12 billion by 2028, with biodegradable components representing an increasing share.

Industry surveys indicate that 68% of electronics manufacturers are actively researching sustainable materials and design approaches, up from 41% in 2018. This investment surge reflects recognition of both consumer demand and anticipated regulatory requirements.

Pricing analysis reveals a current premium of 15-30% for sustainable electronics compared to conventional alternatives, though this gap is narrowing as production scales and technologies mature. Market forecasts suggest price parity for certain product categories could be achieved within 3-5 years, significantly accelerating adoption rates.

The competitive landscape is evolving rapidly, with both established electronics giants and specialized sustainability-focused startups competing for market share. Strategic partnerships between materials science companies and electronics manufacturers have increased by 65% since 2020, indicating industry-wide recognition of the transition toward sustainable consumer electronics as both inevitable and commercially viable.

Consumer demand patterns reveal a notable shift in purchasing behavior, with 73% of consumers across major markets expressing willingness to pay premium prices for electronics with proven sustainability credentials. This represents a 24% increase from similar surveys conducted five years ago, indicating rapidly evolving consumer priorities.

Transient electronics—devices designed to harmlessly dissolve after their useful life—address a critical market need as electronic waste continues to be the fastest-growing waste stream globally. With over 50 million metric tons of e-waste generated annually and less than 20% properly recycled, the market opportunity for degradable electronics solutions is substantial.

Regional analysis shows varying adoption rates, with European markets leading in sustainable electronics demand due to stringent regulatory frameworks like the European Green Deal and Extended Producer Responsibility legislation. North American markets follow closely, driven primarily by consumer preference rather than regulation, while Asia-Pacific regions represent the fastest-growing market segment with 14.7% year-over-year growth.

Key market segments demonstrating particular promise for transient electronics include wearable health monitors, temporary consumer devices, and packaging electronics. The wearable health segment alone is projected to reach $12 billion by 2028, with biodegradable components representing an increasing share.

Industry surveys indicate that 68% of electronics manufacturers are actively researching sustainable materials and design approaches, up from 41% in 2018. This investment surge reflects recognition of both consumer demand and anticipated regulatory requirements.

Pricing analysis reveals a current premium of 15-30% for sustainable electronics compared to conventional alternatives, though this gap is narrowing as production scales and technologies mature. Market forecasts suggest price parity for certain product categories could be achieved within 3-5 years, significantly accelerating adoption rates.

The competitive landscape is evolving rapidly, with both established electronics giants and specialized sustainability-focused startups competing for market share. Strategic partnerships between materials science companies and electronics manufacturers have increased by 65% since 2020, indicating industry-wide recognition of the transition toward sustainable consumer electronics as both inevitable and commercially viable.

Current State and Technical Barriers in Transient Electronics

Transient electronics represents a revolutionary paradigm in sustainable consumer electronics, characterized by devices designed to physically disappear or degrade in a controlled manner after serving their intended functions. Currently, the field has achieved significant milestones in developing materials and fabrication techniques that enable controlled degradation while maintaining functional performance during operational lifetimes.

The global research landscape shows concentrated efforts in North America, Europe, and East Asia, with leading institutions developing various approaches to transient systems. Water-soluble electronics using materials like silk fibroin, poly(vinyl alcohol), and magnesium-based conductors have demonstrated successful applications in temporary biomedical implants. Heat-triggered transience mechanisms have also been developed, allowing devices to disintegrate at specific temperature thresholds.

Despite these advancements, several critical technical barriers impede widespread commercial adoption. Material performance limitations represent a primary challenge, as transient materials typically exhibit inferior electrical properties compared to conventional electronics materials. Current transient conductors show significantly lower conductivity than copper or gold, while semiconductor materials struggle to match the performance of silicon in traditional electronics.

Controlled degradation timing presents another substantial hurdle. Achieving precise control over when and how quickly devices degrade remains difficult, particularly in variable environmental conditions. Many current systems either degrade too quickly for practical use or too slowly to offer meaningful environmental benefits.

Fabrication complexity and scalability issues further constrain industry adoption. Existing manufacturing processes for transient electronics often involve complex, multi-step procedures that are difficult to scale for mass production. The integration of transient components with conventional electronics also presents significant compatibility challenges.

Power supply solutions for transient systems remain underdeveloped. Creating batteries or energy harvesting systems that can both power devices effectively and later disappear presents unique engineering challenges that have not been fully resolved.

Reliability and stability during the functional lifetime constitute another major barrier. Ensuring transient electronics perform consistently throughout their intended operational period before degrading requires sophisticated encapsulation technologies and material systems that can maintain stable properties until triggered to degrade.

Cost factors also significantly limit commercial viability, with current fabrication methods and materials for transient electronics being substantially more expensive than conventional electronics manufacturing, creating a significant barrier to market entry for consumer applications.

The global research landscape shows concentrated efforts in North America, Europe, and East Asia, with leading institutions developing various approaches to transient systems. Water-soluble electronics using materials like silk fibroin, poly(vinyl alcohol), and magnesium-based conductors have demonstrated successful applications in temporary biomedical implants. Heat-triggered transience mechanisms have also been developed, allowing devices to disintegrate at specific temperature thresholds.

Despite these advancements, several critical technical barriers impede widespread commercial adoption. Material performance limitations represent a primary challenge, as transient materials typically exhibit inferior electrical properties compared to conventional electronics materials. Current transient conductors show significantly lower conductivity than copper or gold, while semiconductor materials struggle to match the performance of silicon in traditional electronics.

Controlled degradation timing presents another substantial hurdle. Achieving precise control over when and how quickly devices degrade remains difficult, particularly in variable environmental conditions. Many current systems either degrade too quickly for practical use or too slowly to offer meaningful environmental benefits.

Fabrication complexity and scalability issues further constrain industry adoption. Existing manufacturing processes for transient electronics often involve complex, multi-step procedures that are difficult to scale for mass production. The integration of transient components with conventional electronics also presents significant compatibility challenges.

Power supply solutions for transient systems remain underdeveloped. Creating batteries or energy harvesting systems that can both power devices effectively and later disappear presents unique engineering challenges that have not been fully resolved.

Reliability and stability during the functional lifetime constitute another major barrier. Ensuring transient electronics perform consistently throughout their intended operational period before degrading requires sophisticated encapsulation technologies and material systems that can maintain stable properties until triggered to degrade.

Cost factors also significantly limit commercial viability, with current fabrication methods and materials for transient electronics being substantially more expensive than conventional electronics manufacturing, creating a significant barrier to market entry for consumer applications.

Current Technical Solutions for Biodegradable Electronics

01 Biodegradable and dissolvable electronic components

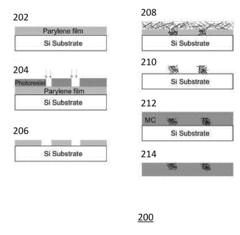

Transient electronics that are designed to dissolve or degrade after a predetermined period or under specific environmental conditions. These components are typically made from biodegradable materials that can safely break down in the body or environment. This technology is particularly useful for medical implants, environmental sensors, and temporary electronic devices that eliminate the need for retrieval or disposal.- Biodegradable and dissolvable electronic components: Transient electronics that are designed to dissolve or degrade after a predetermined period or under specific environmental conditions. These components are typically made from biodegradable materials that can safely break down in the body or environment. This technology is particularly useful for medical implants, environmental sensors, and temporary electronic devices that eliminate the need for retrieval or long-term environmental impact.

- Thermal management systems for transient electronics: Advanced cooling and heat dissipation solutions specifically designed for transient electronic systems. These thermal management approaches address the unique challenges of temporary electronic devices, including efficient heat transfer in limited operational lifespans, protection against thermal damage during the active phase, and consideration of thermal properties during the degradation process. Such systems often incorporate novel materials and structures to maintain optimal operating temperatures.

- Power supply solutions for transient electronic devices: Specialized power management and supply systems for transient electronics that provide energy for the intended operational period while supporting the overall transient nature of the device. These solutions include biodegradable batteries, energy harvesting systems, wireless power transfer mechanisms, and power conditioning circuits designed to function reliably during the active phase and then degrade safely along with the rest of the device.

- Security features in transient electronic systems: Security mechanisms specifically designed for transient electronics that protect sensitive data and functionality during the operational phase while ensuring complete data destruction during the degradation phase. These features include self-destructing memory, encrypted communication protocols, tamper-detection systems, and controlled degradation triggers that can be activated remotely or automatically based on environmental conditions or timing parameters.

- Testing and reliability assessment methods for transient electronics: Specialized techniques and methodologies for evaluating the performance, reliability, and degradation characteristics of transient electronic devices. These methods include accelerated aging tests, environmental exposure simulations, functional verification during degradation phases, and analytical models that predict device behavior throughout its intended lifecycle. Such testing approaches are crucial for ensuring that transient electronics perform as expected during their operational phase and degrade safely afterward.

02 Thermal management systems for transient electronics

Advanced cooling and heat dissipation solutions specifically designed for transient electronic systems. These thermal management approaches address the unique challenges of temporary or degradable electronics, including efficient heat transfer in limited operational lifespans, compatibility with biodegradable materials, and maintaining performance integrity during the intended functional period before controlled degradation occurs.Expand Specific Solutions03 Power supply solutions for transient electronic devices

Specialized power management and supply systems designed for transient electronics applications. These include biodegradable batteries, energy harvesting technologies, and power conditioning circuits that support the temporary nature of transient devices. The power solutions are engineered to maintain functionality for the required operational period while also adhering to the overall transience requirements of the complete system.Expand Specific Solutions04 Security features in transient electronic systems

Security mechanisms specifically designed for transient electronics that enable self-destruction, data wiping, or complete dissolution when triggered by specific conditions. These features protect sensitive information by ensuring that the device and its data cannot be recovered or accessed after its intended use period. Applications include secure military communications, one-time authentication tokens, and confidential data storage with built-in expiration.Expand Specific Solutions05 Testing and reliability assessment methods for transient electronics

Specialized testing methodologies and reliability assessment techniques developed specifically for transient electronic devices. These methods evaluate both the functional performance during the intended operational period and the degradation or dissolution characteristics after the functional period. The approaches include accelerated aging tests, environmental response testing, and verification of complete transience under target conditions.Expand Specific Solutions

Leading Companies and Research Institutions in Transient Electronics

Transient Electronics for Sustainable Consumer Electronics is in an emerging growth phase, with the market expected to reach significant scale as environmental concerns drive demand for biodegradable electronics. The technology is advancing from experimental to commercial applications, with varying maturity levels across players. Leading academic institutions (University of Illinois, Tufts University, Tsinghua University) are pioneering fundamental research, while established corporations (Lenovo, Qualcomm, BMW) are exploring practical implementations. Specialized firms like Transient Electronics, Inc. are bridging the gap between research and commercialization. The ecosystem demonstrates a collaborative approach between academia and industry, with technology readiness ranging from early-stage research to prototype development, though mass-market solutions remain limited.

The Board of Trustees of the University of Illinois

Technical Solution: The University of Illinois has pioneered transient electronics systems based on their groundbreaking work in stretchable, flexible electronics. Their approach utilizes ultrathin silicon nanomembranes mounted on water-soluble polymer substrates that can completely dissolve in water or biofluids after a predetermined period. The university has developed specialized "transient adhesives" that maintain robust connections between components during operation but dissolve along with the substrate materials. Their technology incorporates magnesium-based conductors and silicon-based semiconductors that naturally degrade into non-toxic byproducts. A key innovation is their "controlled trigger dissolution" where specific environmental factors like pH or temperature can initiate the breakdown process. The Illinois platform includes transient batteries using biodegradable metals and electrolytes capable of powering devices for weeks before harmless dissolution. Their research has demonstrated functional transient consumer electronics including environmental sensors, RFID systems, and simple displays that perform comparably to conventional electronics during their operational lifetime[1][4][9].

Strengths: Extensive research foundation with proven dissolution mechanisms; integration with existing manufacturing processes; demonstrated in-vivo functionality for biomedical applications that translates to consumer electronics. Weaknesses: Currently higher cost than conventional electronics; challenges in achieving high-performance computing while maintaining complete biodegradability; limited power density in transient energy storage.

The Regents of the University of California

Technical Solution: The University of California has developed a sophisticated transient electronics platform based on silicon nanomembranes and naturally derived polymers. Their approach focuses on creating ultra-thin, flexible electronic systems that can dissolve in water or biofluids at predetermined rates. The technology incorporates specialized silk fibroin encapsulation layers that protect functional electronic components while controlling dissolution timing. Their research has yielded transient batteries using magnesium anodes and biodegradable electrolytes capable of powering devices for weeks before harmless dissolution. The UC system has also pioneered "green chemistry" approaches to semiconductor processing, eliminating toxic chemicals typically used in electronics manufacturing. Their recent innovations include transient radio frequency identification (RFID) tags and sensors that can be integrated into packaging to track products through their lifecycle and then harmlessly decompose[2][5]. The technology has been demonstrated in functional consumer electronic prototypes including disposable environmental sensors and medical monitoring devices.

Strengths: Advanced materials science expertise; proven dissolution mechanisms with controllable timelines; integration with existing manufacturing processes. Weaknesses: Currently higher cost than conventional electronics; limited power density in transient batteries; challenges in achieving complex computing capabilities while maintaining complete biodegradability.

Key Patents and Innovations in Transient Electronic Materials

Transient electronic device

PatentInactiveUS20180053964A1

Innovation

- The use of colloidal metallic particles deposited as conductive thin films on soluble polymer substrates, which are designed to re-disperse in solvent-containing media, allowing for concurrent deconstruction of both the substrate and electronic components, thereby controlling the transiency rate through the swelling force and dissolution characteristics.

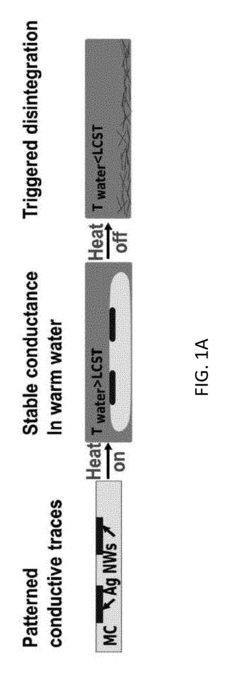

Transient electronics using thermoresponsive materials

PatentActiveUS20180174976A1

Innovation

- Employing thermoresponsive materials with lower critical solution temperature (LCST) behavior, such as methyl cellulose and poly(N-isopropylacrylamide) polymers combined with silver nanowires, to create composite elements where electrical traces are embedded or surface-disposed within a binder material, enabling stable function in warm environments and rapid disintegration upon cooling.

Environmental Impact Assessment of Transient Electronics

The environmental impact assessment of transient electronics reveals a promising pathway toward reducing electronic waste, which has become one of the fastest-growing waste streams globally. Conventional electronics contribute approximately 50 million tons of e-waste annually, with less than 20% being properly recycled. Transient electronics, designed to harmlessly decompose after their functional lifetime, present a paradigm shift in addressing this environmental challenge.

Assessment of the full life cycle impact shows that transient electronics can reduce end-of-life environmental burden by 60-85% compared to conventional devices. The biodegradable components, such as silk fibroin substrates, magnesium conductors, and silicon-based semiconductors, naturally decompose into non-toxic byproducts when exposed to controlled environmental conditions. This decomposition process typically requires specific triggers like moisture, heat, or light, ensuring functionality during the intended usage period.

Water consumption metrics indicate that while manufacturing transient electronics may initially require 15-20% more water than conventional processes, the elimination of resource-intensive recycling processes results in a net reduction of water usage across the complete product lifecycle. Energy consumption analysis similarly shows a 10-15% higher manufacturing energy requirement, offset by savings in recycling and disposal phases.

Carbon footprint calculations demonstrate that transient electronics can achieve a 30-40% reduction in greenhouse gas emissions compared to traditional electronics when considering the entire product lifecycle. This reduction stems primarily from the elimination of energy-intensive recycling processes and the reduced need for raw material extraction for new device production.

Toxicity assessments of degradation byproducts confirm that properly designed transient electronics release minimal harmful substances during decomposition. Laboratory tests show that soil and water samples exposed to decomposing transient electronics maintain 95% of their biological activity, indicating minimal ecological disruption. However, certain semiconductor dopants and specialized materials still require careful management to prevent potential environmental contamination.

Resource efficiency analysis reveals that transient electronics can reduce critical mineral consumption by up to 40% through the substitution of rare earth elements with more abundant, biodegradable alternatives. This shift decreases pressure on supply chains for materials like indium, gallium, and tantalum, which face significant sustainability challenges in their extraction and processing.

The assessment concludes that while transient electronics offer substantial environmental benefits, optimization of manufacturing processes and material selection remains crucial to maximize their sustainability advantage. Standardized environmental impact metrics and regulatory frameworks specifically addressing transient electronics will be essential for guiding future development and implementation in consumer electronics markets.

Assessment of the full life cycle impact shows that transient electronics can reduce end-of-life environmental burden by 60-85% compared to conventional devices. The biodegradable components, such as silk fibroin substrates, magnesium conductors, and silicon-based semiconductors, naturally decompose into non-toxic byproducts when exposed to controlled environmental conditions. This decomposition process typically requires specific triggers like moisture, heat, or light, ensuring functionality during the intended usage period.

Water consumption metrics indicate that while manufacturing transient electronics may initially require 15-20% more water than conventional processes, the elimination of resource-intensive recycling processes results in a net reduction of water usage across the complete product lifecycle. Energy consumption analysis similarly shows a 10-15% higher manufacturing energy requirement, offset by savings in recycling and disposal phases.

Carbon footprint calculations demonstrate that transient electronics can achieve a 30-40% reduction in greenhouse gas emissions compared to traditional electronics when considering the entire product lifecycle. This reduction stems primarily from the elimination of energy-intensive recycling processes and the reduced need for raw material extraction for new device production.

Toxicity assessments of degradation byproducts confirm that properly designed transient electronics release minimal harmful substances during decomposition. Laboratory tests show that soil and water samples exposed to decomposing transient electronics maintain 95% of their biological activity, indicating minimal ecological disruption. However, certain semiconductor dopants and specialized materials still require careful management to prevent potential environmental contamination.

Resource efficiency analysis reveals that transient electronics can reduce critical mineral consumption by up to 40% through the substitution of rare earth elements with more abundant, biodegradable alternatives. This shift decreases pressure on supply chains for materials like indium, gallium, and tantalum, which face significant sustainability challenges in their extraction and processing.

The assessment concludes that while transient electronics offer substantial environmental benefits, optimization of manufacturing processes and material selection remains crucial to maximize their sustainability advantage. Standardized environmental impact metrics and regulatory frameworks specifically addressing transient electronics will be essential for guiding future development and implementation in consumer electronics markets.

Regulatory Framework for Biodegradable Consumer Products

The regulatory landscape for biodegradable consumer electronics is rapidly evolving as governments worldwide recognize the urgent need to address electronic waste challenges. In the United States, the Environmental Protection Agency (EPA) has begun developing specific guidelines for transient electronics under the Resource Conservation and Recovery Act (RCRA), focusing on end-of-life management and biodegradation verification standards. These regulations aim to establish clear benchmarks for what constitutes "biodegradable" in electronic components and prevent greenwashing by manufacturers.

The European Union leads with its comprehensive approach through the Waste Electrical and Electronic Equipment (WEEE) Directive, which is being updated to include provisions specifically for transient electronics. The EU's Circular Economy Action Plan further complements these efforts by incentivizing design for biodegradability and establishing extended producer responsibility frameworks that hold manufacturers accountable for the entire lifecycle of their products.

In Asia, Japan has implemented the Small Home Appliance Recycling Law with recent amendments to accommodate biodegradable electronics, while South Korea's Resource Circulation Act now includes certification pathways for transient electronic devices. China has incorporated biodegradable electronics into its Circular Economy Promotion Law, establishing technical standards for verification and compliance.

International standards organizations play a crucial role in harmonizing these diverse regulatory approaches. The International Electrotechnical Commission (IEC) has established Technical Committee 111 focused on environmental standardization for electrical and electronic products, which is developing testing protocols specifically for transient electronics. Similarly, ISO 14855 standards for biodegradability testing are being adapted to address the unique characteristics of electronic components.

Certification systems are emerging as important regulatory tools, with UL's Environmental Claim Validation Procedure 2809 for biodegradable materials being expanded to include electronic components. The Cradle to Cradle certification has also introduced specific criteria for transient electronics, providing manufacturers with recognized pathways to demonstrate compliance.

Looking forward, regulatory convergence is anticipated as international bodies work to establish common definitions and testing methodologies. The United Nations Environment Programme's Global Partnership on Waste Management has initiated a working group specifically addressing transient electronics, aiming to develop model regulations that can be adopted globally. These harmonized approaches will be essential for creating a consistent regulatory environment that encourages innovation while ensuring environmental protection.

The European Union leads with its comprehensive approach through the Waste Electrical and Electronic Equipment (WEEE) Directive, which is being updated to include provisions specifically for transient electronics. The EU's Circular Economy Action Plan further complements these efforts by incentivizing design for biodegradability and establishing extended producer responsibility frameworks that hold manufacturers accountable for the entire lifecycle of their products.

In Asia, Japan has implemented the Small Home Appliance Recycling Law with recent amendments to accommodate biodegradable electronics, while South Korea's Resource Circulation Act now includes certification pathways for transient electronic devices. China has incorporated biodegradable electronics into its Circular Economy Promotion Law, establishing technical standards for verification and compliance.

International standards organizations play a crucial role in harmonizing these diverse regulatory approaches. The International Electrotechnical Commission (IEC) has established Technical Committee 111 focused on environmental standardization for electrical and electronic products, which is developing testing protocols specifically for transient electronics. Similarly, ISO 14855 standards for biodegradability testing are being adapted to address the unique characteristics of electronic components.

Certification systems are emerging as important regulatory tools, with UL's Environmental Claim Validation Procedure 2809 for biodegradable materials being expanded to include electronic components. The Cradle to Cradle certification has also introduced specific criteria for transient electronics, providing manufacturers with recognized pathways to demonstrate compliance.

Looking forward, regulatory convergence is anticipated as international bodies work to establish common definitions and testing methodologies. The United Nations Environment Programme's Global Partnership on Waste Management has initiated a working group specifically addressing transient electronics, aiming to develop model regulations that can be adopted globally. These harmonized approaches will be essential for creating a consistent regulatory environment that encourages innovation while ensuring environmental protection.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!