Development of Biodegradable Transient Electronics Components.

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Biodegradable Electronics Background and Objectives

Biodegradable transient electronics represent a revolutionary paradigm shift in the electronics industry, moving away from conventional persistent electronic components toward environmentally benign alternatives that can harmlessly decompose after fulfilling their intended functions. The concept emerged in the early 2000s, driven by growing environmental concerns regarding electronic waste and the increasing demand for temporary implantable medical devices. The evolution of this technology has accelerated significantly over the past decade, with major breakthroughs in materials science, fabrication techniques, and system integration.

The development trajectory of biodegradable electronics has been characterized by progressive improvements in material selection, from simple water-soluble polymers to sophisticated biocompatible composites. Early research focused primarily on basic circuit elements, while recent advancements have enabled the creation of complex functional systems including sensors, actuators, and energy harvesting components that can operate reliably before degrading in controlled timeframes.

Current technological trends point toward the integration of multiple biodegradable components into cohesive systems capable of performing sophisticated functions in medical, environmental monitoring, and consumer electronics applications. The convergence of biodegradable materials with flexible electronics design principles has further expanded the potential application landscape, enabling conformable devices that can adapt to various deployment scenarios.

The primary objective of biodegradable transient electronics development is to create fully functional electronic components and systems that maintain operational stability during their useful lifetime while ensuring complete degradation into environmentally benign substances afterward. This involves achieving precise control over degradation kinetics to match application requirements, whether rapid dissolution within hours or gradual decomposition over months.

Secondary objectives include minimizing the ecological footprint of electronic devices throughout their lifecycle, reducing the accumulation of electronic waste, and enabling novel applications in fields where temporary electronic functionality is advantageous. In medical applications specifically, the goal is to develop implantable devices that eliminate the need for secondary removal surgeries, thereby reducing patient risk and healthcare costs.

Technical objectives encompass the development of biodegradable substrates, conductors, semiconductors, and encapsulation materials with tunable degradation profiles and sufficient performance metrics. This includes achieving adequate electrical conductivity, mechanical flexibility, and thermal stability while maintaining biocompatibility for medical applications. The ultimate aim is to establish a comprehensive material and design framework that enables the systematic development of transient electronic systems tailored to specific application requirements and environmental conditions.

The development trajectory of biodegradable electronics has been characterized by progressive improvements in material selection, from simple water-soluble polymers to sophisticated biocompatible composites. Early research focused primarily on basic circuit elements, while recent advancements have enabled the creation of complex functional systems including sensors, actuators, and energy harvesting components that can operate reliably before degrading in controlled timeframes.

Current technological trends point toward the integration of multiple biodegradable components into cohesive systems capable of performing sophisticated functions in medical, environmental monitoring, and consumer electronics applications. The convergence of biodegradable materials with flexible electronics design principles has further expanded the potential application landscape, enabling conformable devices that can adapt to various deployment scenarios.

The primary objective of biodegradable transient electronics development is to create fully functional electronic components and systems that maintain operational stability during their useful lifetime while ensuring complete degradation into environmentally benign substances afterward. This involves achieving precise control over degradation kinetics to match application requirements, whether rapid dissolution within hours or gradual decomposition over months.

Secondary objectives include minimizing the ecological footprint of electronic devices throughout their lifecycle, reducing the accumulation of electronic waste, and enabling novel applications in fields where temporary electronic functionality is advantageous. In medical applications specifically, the goal is to develop implantable devices that eliminate the need for secondary removal surgeries, thereby reducing patient risk and healthcare costs.

Technical objectives encompass the development of biodegradable substrates, conductors, semiconductors, and encapsulation materials with tunable degradation profiles and sufficient performance metrics. This includes achieving adequate electrical conductivity, mechanical flexibility, and thermal stability while maintaining biocompatibility for medical applications. The ultimate aim is to establish a comprehensive material and design framework that enables the systematic development of transient electronic systems tailored to specific application requirements and environmental conditions.

Market Analysis for Transient Electronics

The transient electronics market is experiencing significant growth, driven by increasing environmental concerns and the need for sustainable electronic solutions. The global market for biodegradable electronics was valued at approximately $3.2 billion in 2022 and is projected to reach $7.8 billion by 2028, representing a compound annual growth rate of 16.1%. This rapid expansion reflects the growing recognition of the environmental impact of electronic waste and the potential benefits of transient electronic components.

Healthcare applications currently dominate the market landscape, accounting for nearly 45% of the total market share. Implantable medical devices that can dissolve after serving their purpose eliminate the need for secondary surgeries and reduce patient discomfort. The medical segment is expected to maintain its leading position due to increasing investments in healthcare infrastructure and rising demand for minimally invasive procedures.

Consumer electronics represents the second-largest application segment, with biodegradable sensors, displays, and packaging solutions gaining traction. Environmental monitoring applications are emerging as a fast-growing segment, with a projected CAGR of 19.3% through 2028, driven by increasing regulatory pressure for sustainable environmental practices and real-time monitoring solutions.

Regionally, North America leads the market with approximately 38% share, followed by Europe at 29% and Asia-Pacific at 24%. However, the Asia-Pacific region is expected to witness the fastest growth rate due to increasing electronic manufacturing activities, government initiatives promoting sustainable technologies, and rising environmental awareness among consumers.

Key market drivers include stringent environmental regulations regarding electronic waste management, growing consumer preference for sustainable products, and technological advancements enabling cost-effective production of biodegradable electronic components. The implementation of extended producer responsibility policies in several countries is further accelerating market growth by placing the responsibility for end-of-life product management on manufacturers.

Despite promising growth prospects, the market faces several challenges. High production costs compared to conventional electronics, limited functionality and performance of biodegradable components, and technical challenges related to controlled degradation rates remain significant barriers to widespread adoption. Additionally, the lack of standardized testing protocols and certification processes for biodegradable electronics creates uncertainty among potential adopters.

Market segmentation analysis reveals that silicon-based transient electronics currently dominate with 42% market share, followed by organic materials at 31% and metal-based solutions at 18%. However, organic materials are expected to witness the highest growth rate due to their superior biodegradability characteristics and improving performance metrics.

Healthcare applications currently dominate the market landscape, accounting for nearly 45% of the total market share. Implantable medical devices that can dissolve after serving their purpose eliminate the need for secondary surgeries and reduce patient discomfort. The medical segment is expected to maintain its leading position due to increasing investments in healthcare infrastructure and rising demand for minimally invasive procedures.

Consumer electronics represents the second-largest application segment, with biodegradable sensors, displays, and packaging solutions gaining traction. Environmental monitoring applications are emerging as a fast-growing segment, with a projected CAGR of 19.3% through 2028, driven by increasing regulatory pressure for sustainable environmental practices and real-time monitoring solutions.

Regionally, North America leads the market with approximately 38% share, followed by Europe at 29% and Asia-Pacific at 24%. However, the Asia-Pacific region is expected to witness the fastest growth rate due to increasing electronic manufacturing activities, government initiatives promoting sustainable technologies, and rising environmental awareness among consumers.

Key market drivers include stringent environmental regulations regarding electronic waste management, growing consumer preference for sustainable products, and technological advancements enabling cost-effective production of biodegradable electronic components. The implementation of extended producer responsibility policies in several countries is further accelerating market growth by placing the responsibility for end-of-life product management on manufacturers.

Despite promising growth prospects, the market faces several challenges. High production costs compared to conventional electronics, limited functionality and performance of biodegradable components, and technical challenges related to controlled degradation rates remain significant barriers to widespread adoption. Additionally, the lack of standardized testing protocols and certification processes for biodegradable electronics creates uncertainty among potential adopters.

Market segmentation analysis reveals that silicon-based transient electronics currently dominate with 42% market share, followed by organic materials at 31% and metal-based solutions at 18%. However, organic materials are expected to witness the highest growth rate due to their superior biodegradability characteristics and improving performance metrics.

Technical Challenges in Biodegradable Components

The development of biodegradable transient electronics faces several significant technical challenges that currently limit widespread implementation. Material selection represents one of the most critical barriers, as components must simultaneously meet contradictory requirements: sufficient stability during operational lifetime while ensuring complete degradation afterward. Conventional biodegradable polymers like polylactic acid (PLA) and polyglycolic acid (PGA) often lack the necessary electrical properties, while conductive materials that degrade safely remain limited.

Controlled degradation timing presents another substantial hurdle. Creating electronics that maintain functionality for precisely defined periods before degrading requires sophisticated material engineering. Environmental factors such as temperature, humidity, and pH significantly impact degradation rates, making consistent performance difficult to achieve across varied deployment conditions. Current solutions lack robust mechanisms to trigger degradation at predetermined timepoints.

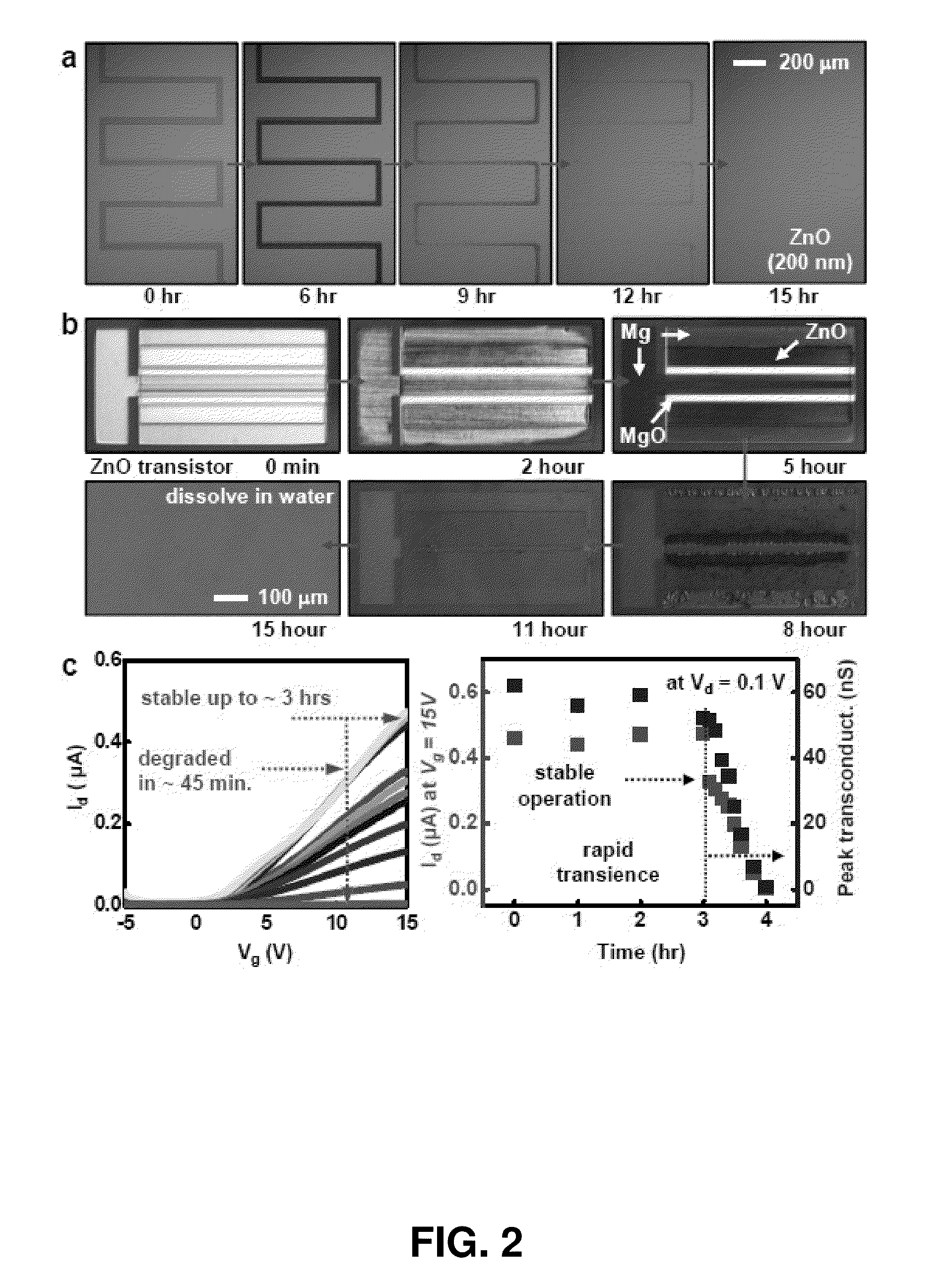

Electrical performance constraints pose additional challenges. Biodegradable conductors typically exhibit lower conductivity than conventional metals, resulting in higher resistance and power consumption. This limitation restricts application in high-performance or energy-intensive devices. Similarly, biodegradable semiconductors currently demonstrate inferior carrier mobility and switching speeds compared to silicon-based counterparts.

Manufacturing compatibility represents a significant technical obstacle. Many biodegradable materials cannot withstand standard electronics manufacturing processes, including high-temperature soldering, vacuum deposition, or harsh chemical treatments. This incompatibility necessitates the development of entirely new fabrication techniques, increasing production complexity and costs.

Encapsulation and packaging solutions present unique difficulties. While the active components must degrade, they require protection during their operational lifetime. Developing encapsulants that shield electronics from environmental factors while remaining biodegradable themselves requires careful material selection and design. Current biodegradable encapsulants often suffer from moisture permeability issues that compromise device reliability.

Biocompatibility concerns further complicate development, particularly for implantable applications. Degradation byproducts must be non-toxic and safely metabolized or excreted by the body. Some biodegradable materials produce acidic byproducts during degradation that can cause local inflammation or tissue damage, limiting their suitability for medical applications.

Testing and standardization remain underdeveloped areas. The field lacks established protocols for evaluating degradation rates, environmental impact, and performance reliability. This absence of standardized testing methodologies makes it difficult to compare different solutions and establish regulatory frameworks, further slowing commercial adoption and technological advancement.

Controlled degradation timing presents another substantial hurdle. Creating electronics that maintain functionality for precisely defined periods before degrading requires sophisticated material engineering. Environmental factors such as temperature, humidity, and pH significantly impact degradation rates, making consistent performance difficult to achieve across varied deployment conditions. Current solutions lack robust mechanisms to trigger degradation at predetermined timepoints.

Electrical performance constraints pose additional challenges. Biodegradable conductors typically exhibit lower conductivity than conventional metals, resulting in higher resistance and power consumption. This limitation restricts application in high-performance or energy-intensive devices. Similarly, biodegradable semiconductors currently demonstrate inferior carrier mobility and switching speeds compared to silicon-based counterparts.

Manufacturing compatibility represents a significant technical obstacle. Many biodegradable materials cannot withstand standard electronics manufacturing processes, including high-temperature soldering, vacuum deposition, or harsh chemical treatments. This incompatibility necessitates the development of entirely new fabrication techniques, increasing production complexity and costs.

Encapsulation and packaging solutions present unique difficulties. While the active components must degrade, they require protection during their operational lifetime. Developing encapsulants that shield electronics from environmental factors while remaining biodegradable themselves requires careful material selection and design. Current biodegradable encapsulants often suffer from moisture permeability issues that compromise device reliability.

Biocompatibility concerns further complicate development, particularly for implantable applications. Degradation byproducts must be non-toxic and safely metabolized or excreted by the body. Some biodegradable materials produce acidic byproducts during degradation that can cause local inflammation or tissue damage, limiting their suitability for medical applications.

Testing and standardization remain underdeveloped areas. The field lacks established protocols for evaluating degradation rates, environmental impact, and performance reliability. This absence of standardized testing methodologies makes it difficult to compare different solutions and establish regulatory frameworks, further slowing commercial adoption and technological advancement.

Current Biodegradable Material Solutions

01 Biodegradable substrate materials for transient electronics

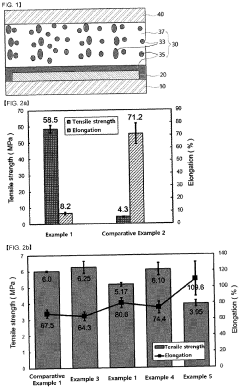

Various biodegradable substrate materials can be used as the foundation for transient electronic components. These include natural polymers like cellulose, silk, and chitin derivatives, as well as synthetic biodegradable polymers such as polylactic acid (PLA) and polyglycolic acid (PGA). These materials provide mechanical support for electronic components while being able to decompose naturally in the environment or within biological systems after their functional lifetime, reducing electronic waste.- Biodegradable substrate materials for transient electronics: Various biodegradable substrate materials can be used as the foundation for transient electronic components. These materials include natural polymers like cellulose, silk, and starch derivatives, as well as synthetic biodegradable polymers such as polylactic acid (PLA) and polyglycolic acid (PGA). These substrates provide mechanical support for electronic components while being able to degrade in specific environments, contributing to the overall biodegradability of the electronic device.

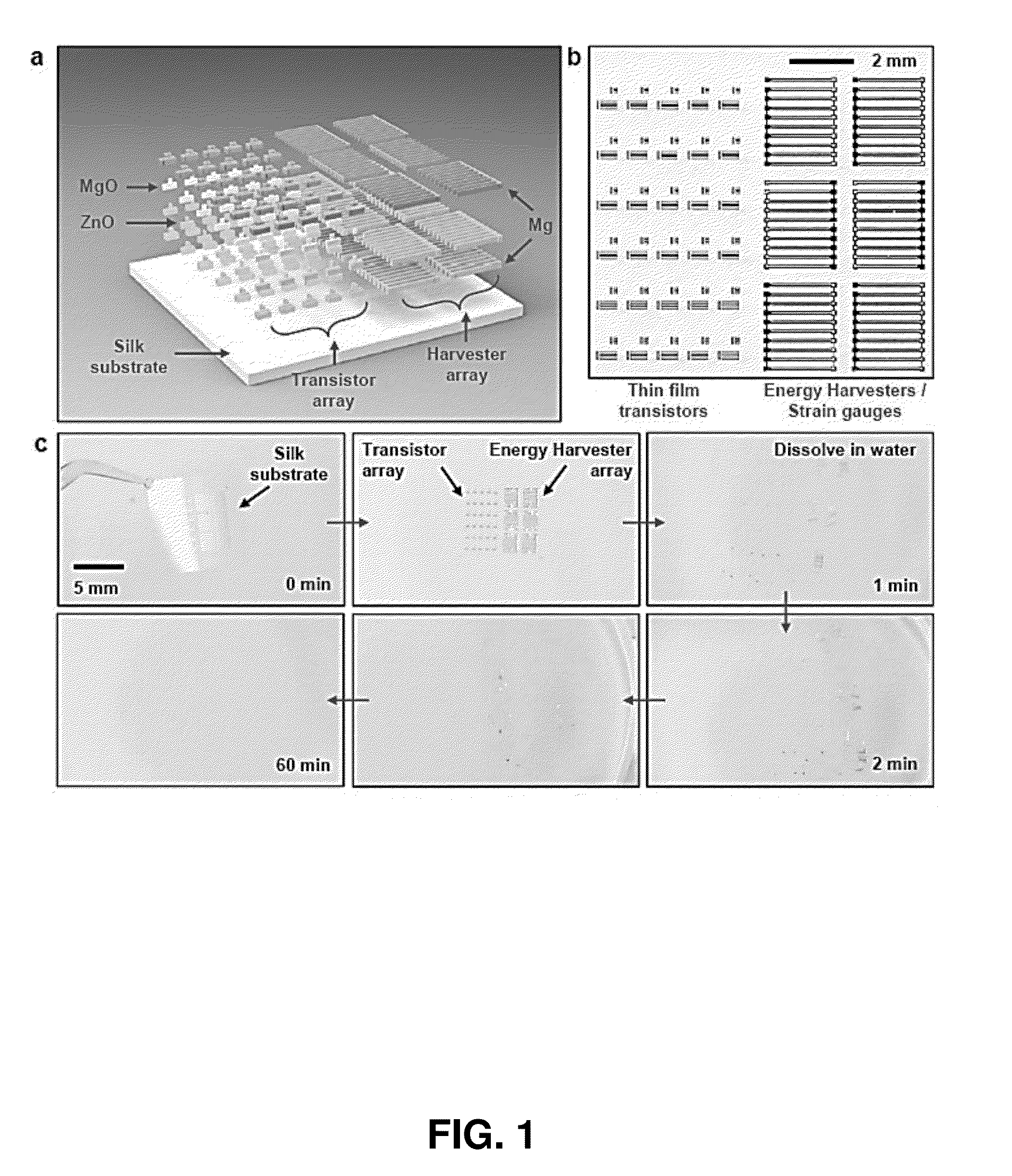

- Water-soluble electronic components: Water-soluble materials can be incorporated into electronic components to enable their dissolution in aqueous environments. These materials include water-soluble conductors like magnesium, zinc, and iron, as well as water-soluble dielectrics and semiconductors. When exposed to moisture or water, these components dissolve at controlled rates, allowing for the complete disintegration of the electronic device after its functional lifetime, reducing electronic waste and environmental impact.

- Enzymatically degradable electronic materials: Electronic components can be designed to degrade through enzymatic processes. These materials are formulated to be susceptible to specific enzymes found in natural environments or the human body. The enzymatic degradation can be tailored to occur at predetermined rates by controlling the material composition and structure. This approach is particularly useful for biomedical applications where electronics need to function for a specific period before safely degrading within the body.

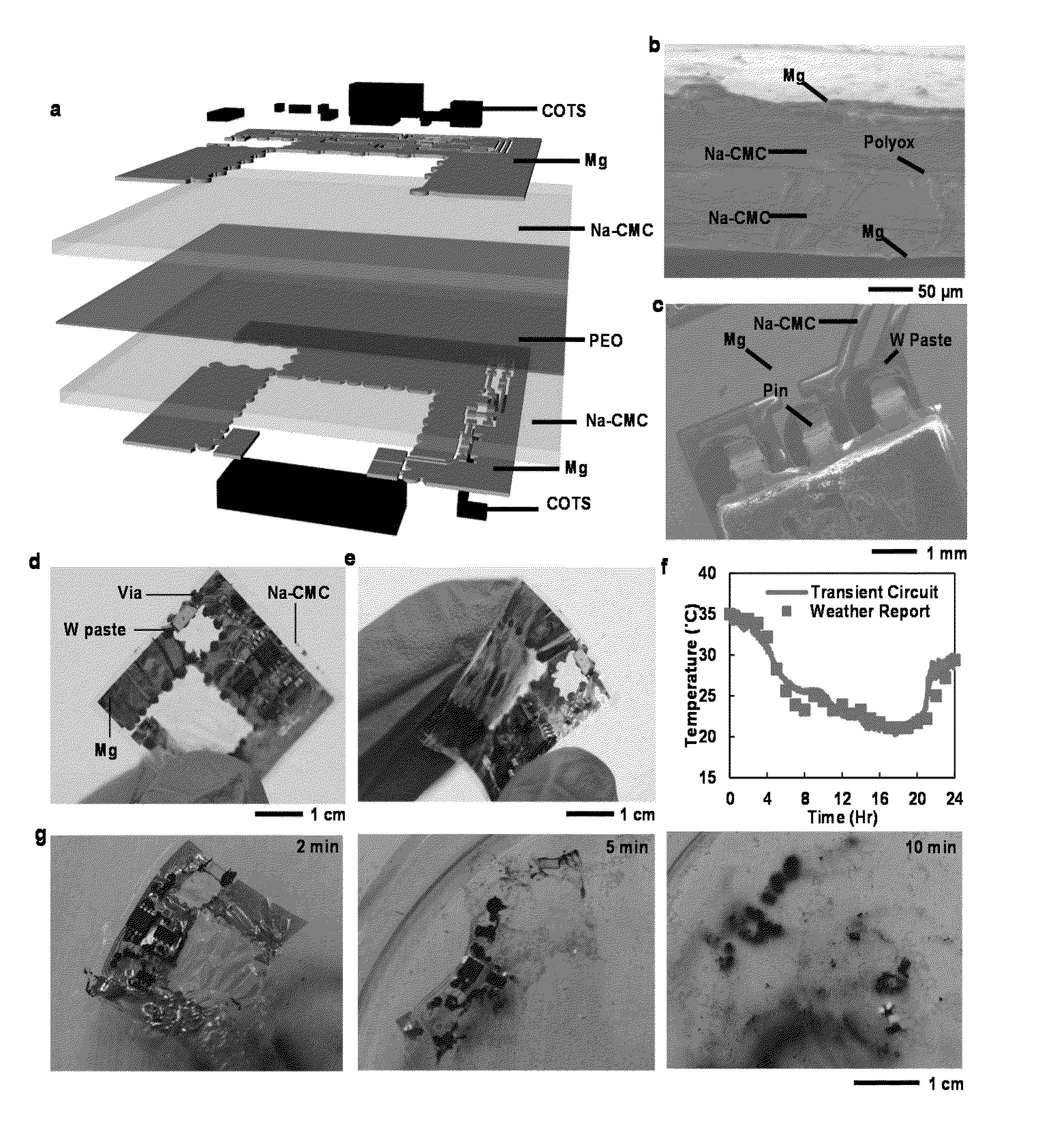

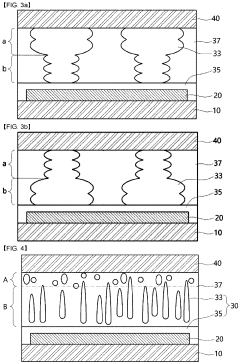

- Encapsulation systems for controlled degradation: Specialized encapsulation systems can be used to control the degradation rate of transient electronic components. These systems typically involve biodegradable polymers or composites that protect the electronic components from environmental factors until degradation is desired. By engineering the encapsulation material's properties, such as thickness, porosity, and chemical composition, the lifetime of the electronic device can be precisely controlled before biodegradation begins.

- Integration of biodegradable conductive materials: Biodegradable conductive materials are essential components in transient electronics. These include conductive polymers, carbon-based materials modified for biodegradability, and metal alloys designed to safely corrode and degrade. These materials provide the necessary electrical conductivity for device function while maintaining the ability to break down into environmentally benign byproducts after use. The integration of these materials with biodegradable substrates creates fully transient electronic systems.

02 Dissolvable conductive materials and circuits

Transient electronics utilize conductive materials that can dissolve or degrade under specific environmental conditions. These include water-soluble metals like magnesium, zinc, and iron, as well as conductive polymers with degradable properties. These materials can form functional circuits and interconnects that maintain electrical performance during the device's operational period but break down afterward. The dissolution rate can be controlled through material composition and protective layers, allowing for programmable lifetimes of electronic components.Expand Specific Solutions03 Environmentally triggered degradation mechanisms

Transient electronic components can be designed to degrade in response to specific environmental triggers. These mechanisms include hydrolysis (reaction with water), enzymatic degradation, pH-sensitive dissolution, or thermal decomposition. By engineering components to respond to these triggers, electronics can be designed to break down under predetermined conditions, such as when exposed to soil microorganisms, composting environments, or physiological fluids in the body. This controlled degradation enables applications in environmental monitoring and medical implants.Expand Specific Solutions04 Semiconductor and dielectric materials with transient properties

Biodegradable semiconductors and dielectric materials are essential components of transient electronics. These include silicon nanomembranes, zinc oxide, organic semiconductors, and biodegradable metal oxides that can function as active electronic components while maintaining the ability to degrade. Dielectric materials such as silk fibroin, biodegradable polymers, and certain metal oxides provide insulation and capacitive properties. These materials enable the creation of transistors, sensors, and other active components that can decompose after their useful lifetime.Expand Specific Solutions05 Encapsulation strategies for controlled lifetime

Protective encapsulation layers play a crucial role in controlling the lifetime and degradation rate of transient electronics. These encapsulants can be engineered with varying thicknesses and compositions to protect the functional components during operation while allowing controlled degradation afterward. Materials used include biodegradable polymers, silk, and water-soluble compounds that provide temporary protection from environmental factors. By designing the encapsulation strategy, the operational lifetime of transient electronics can be precisely tuned from minutes to months, depending on the application requirements.Expand Specific Solutions

Leading Organizations in Biodegradable Electronics

Biodegradable transient electronics is currently in an early growth phase, with the market expected to expand significantly as environmental concerns drive demand for sustainable electronic solutions. The global market size is estimated to reach $1.5 billion by 2027, growing at a CAGR of approximately 25%. From a technological maturity perspective, academic institutions are leading research efforts, with the University of Illinois, Northwestern University, and Tsinghua University pioneering fundamental breakthroughs in dissolvable substrates and biocompatible materials. Commercial players like Surmodics, FUJIFILM, and Delta Electronics are beginning to translate these innovations into practical applications, though most remain in pre-commercial development stages. The field is characterized by strong university-industry collaborations, with companies like Transient Electronics and ANPOL emerging as specialized startups focused exclusively on biodegradable electronic components for medical and environmental monitoring applications.

The Board of Trustees of the University of Illinois

Technical Solution: The University of Illinois has pioneered transient electronics through their development of silicon-based biodegradable components that can dissolve in water or bodily fluids after a predetermined period. Their approach utilizes ultrathin silicon nanomembranes (Si NMs) as semiconductors, magnesium (Mg) for conductors, and silk fibroin or poly(lactic-co-glycolic acid) (PLGA) as substrate materials. These components are designed to dissolve into non-toxic byproducts when exposed to aqueous environments. The university has demonstrated functional transient electronic systems including transistors, diodes, wireless power coils, temperature and strain sensors, and even simple integrated circuits that can operate normally before dissolving completely within controlled timeframes ranging from days to weeks[1][3]. Their recent innovations include bioresorbable pressure sensors for intracranial monitoring and transient radio frequency electronics for wireless communication applications.

Strengths: Leading expertise in silicon-based transient electronics with proven functionality in biomedical applications; established methods for controlling dissolution rates; strong integration capabilities for complex systems. Weaknesses: Silicon processing requires sophisticated cleanroom facilities; dissolution rates can be affected by environmental variables; challenges in achieving longer operational lifetimes before dissolution begins.

Tufts University

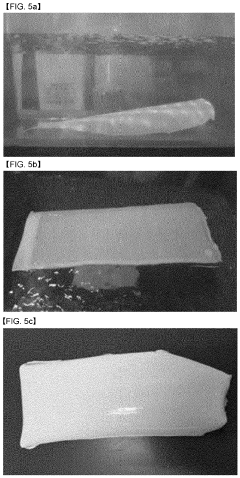

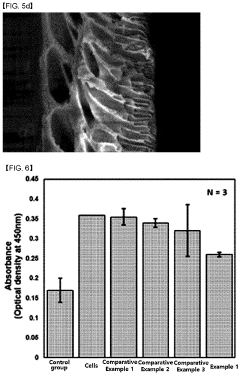

Technical Solution: Tufts University has pioneered the use of silk fibroin as a foundational material for biodegradable electronics. Their approach leverages silk's unique properties—biocompatibility, programmable degradation rates, and excellent mechanical characteristics—to create substrates, encapsulation layers, and even functional components for transient electronic systems. Researchers at Tufts have developed methods to precisely control silk crystallinity, which directly determines how quickly the material will biodegrade in various environments. Their technology platform includes silk-based dielectrics, transistor components, and optical elements that can be integrated with biodegradable metals like magnesium to form complete transient circuits[6]. A significant innovation is their development of "electroceuticals"—biodegradable electronic implants that can deliver electrical stimulation to promote tissue healing before harmlessly dissolving. These devices have been demonstrated in animal models for applications including wound healing acceleration, bone regeneration, and infection control[9]. Recent advances include silk-based biodegradable batteries and energy harvesting components that can power transient electronic systems without leaving persistent waste.

Strengths: World-leading expertise in silk-based materials for electronics; excellent biocompatibility profile for medical applications; highly tunable degradation rates through material processing. Weaknesses: Limited to applications where silk's mechanical and electrical properties are sufficient; challenges in creating high-performance electronic components solely from biodegradable materials; potential variability in natural silk sources.

Key Patents in Transient Electronic Components

Biodegradable materials for multilayer transient printed circuit boards

PatentActiveUS20160050750A1

Innovation

- Development of transient electronic devices that incorporate degradable materials and substrates, allowing for controlled transformation upon internal or external stimuli, such as silicon-based technology that can dissolve or degrade in a programmed manner, enabling applications like bio-resorbable medical implants or eco-resorbable environmental monitors.

Composite for controlling degradation of transient electronics

PatentPendingEP4316538A1

Innovation

- A composite with a support and a porous polymer layer containing biocompatible oil is used to control the degradation of transient electronics, allowing for controlled release and biodegradation, ensuring flexibility and biocompatibility to prevent organ damage and immune responses.

Environmental Impact Assessment

The environmental impact of biodegradable transient electronics represents a critical dimension in evaluating their sustainability credentials. Conventional electronic waste contributes significantly to global pollution, with approximately 50 million tons generated annually and only 20% properly recycled. Biodegradable transient electronics offer a promising alternative by decomposing naturally after their functional lifetime, substantially reducing e-waste accumulation in landfills.

Life cycle assessment (LCA) studies indicate that biodegradable electronic components can reduce environmental footprint by 40-60% compared to traditional electronics when considering extraction, manufacturing, use, and disposal phases. The primary environmental benefits derive from elimination of end-of-life processing requirements and reduced toxic material leaching into ecosystems. Materials such as silk fibroin, cellulose derivatives, and magnesium-based conductors demonstrate complete degradation within 3-6 months under controlled conditions, leaving minimal residual impact.

Water consumption represents another significant environmental factor. Manufacturing conventional silicon-based electronics requires approximately 2,000 liters of water per square inch of silicon wafer. Preliminary studies suggest biodegradable alternatives may reduce water requirements by 30-45% through simplified processing techniques and alternative substrate materials. However, certain biodegradable polymers still require substantial water inputs during synthesis and processing.

Energy efficiency considerations reveal mixed results. While biodegradable components typically require less energy during manufacturing, their operational efficiency often lags behind conventional electronics. Current biodegradable transistors and circuits demonstrate 15-25% lower energy efficiency during operation, potentially offsetting some manufacturing-phase environmental benefits if devices require frequent replacement.

Carbon footprint analysis shows promising results, with biodegradable electronic components potentially reducing greenhouse gas emissions by 35-50% across their lifecycle. This reduction stems primarily from simplified manufacturing processes and elimination of energy-intensive recycling or disposal methods required for conventional electronics.

Ecosystem impact studies indicate minimal toxicity from degradation byproducts when properly engineered. Laboratory and field tests demonstrate that silk, cellulose, and magnesium-based components break down into naturally occurring compounds with negligible ecological disruption. However, certain conductive polymers and specialized dopants require further investigation to ensure complete biodegradation without harmful intermediate compounds.

Regulatory frameworks are evolving to address this emerging technology. The European Union's Waste Electrical and Electronic Equipment (WEEE) Directive and similar regulations worldwide are beginning to incorporate provisions for biodegradable electronics, potentially offering regulatory incentives for their development and adoption.

Life cycle assessment (LCA) studies indicate that biodegradable electronic components can reduce environmental footprint by 40-60% compared to traditional electronics when considering extraction, manufacturing, use, and disposal phases. The primary environmental benefits derive from elimination of end-of-life processing requirements and reduced toxic material leaching into ecosystems. Materials such as silk fibroin, cellulose derivatives, and magnesium-based conductors demonstrate complete degradation within 3-6 months under controlled conditions, leaving minimal residual impact.

Water consumption represents another significant environmental factor. Manufacturing conventional silicon-based electronics requires approximately 2,000 liters of water per square inch of silicon wafer. Preliminary studies suggest biodegradable alternatives may reduce water requirements by 30-45% through simplified processing techniques and alternative substrate materials. However, certain biodegradable polymers still require substantial water inputs during synthesis and processing.

Energy efficiency considerations reveal mixed results. While biodegradable components typically require less energy during manufacturing, their operational efficiency often lags behind conventional electronics. Current biodegradable transistors and circuits demonstrate 15-25% lower energy efficiency during operation, potentially offsetting some manufacturing-phase environmental benefits if devices require frequent replacement.

Carbon footprint analysis shows promising results, with biodegradable electronic components potentially reducing greenhouse gas emissions by 35-50% across their lifecycle. This reduction stems primarily from simplified manufacturing processes and elimination of energy-intensive recycling or disposal methods required for conventional electronics.

Ecosystem impact studies indicate minimal toxicity from degradation byproducts when properly engineered. Laboratory and field tests demonstrate that silk, cellulose, and magnesium-based components break down into naturally occurring compounds with negligible ecological disruption. However, certain conductive polymers and specialized dopants require further investigation to ensure complete biodegradation without harmful intermediate compounds.

Regulatory frameworks are evolving to address this emerging technology. The European Union's Waste Electrical and Electronic Equipment (WEEE) Directive and similar regulations worldwide are beginning to incorporate provisions for biodegradable electronics, potentially offering regulatory incentives for their development and adoption.

Medical Applications and Safety Standards

Biodegradable transient electronics represent a revolutionary approach in medical device development, offering temporary functionality followed by complete dissolution within the body. These devices must adhere to stringent medical safety standards while delivering reliable performance during their operational lifetime. The FDA and international regulatory bodies have established specific guidelines for implantable medical devices, with additional considerations emerging for transient electronics that address their unique degradation characteristics.

Current medical applications of biodegradable electronics include temporary implantable sensors for post-surgical monitoring, drug delivery systems with programmable release mechanisms, and neural interfaces for temporary therapeutic interventions. These applications demonstrate significant advantages over traditional permanent implants by eliminating secondary removal surgeries and reducing long-term foreign body responses. Clinical trials have shown promising results in wound healing monitoring and infection detection using transient sensor arrays that dissolve after the critical healing period.

Safety standards for these devices focus on biocompatibility of both the initial components and their degradation byproducts. ISO 10993 series provides the framework for biological evaluation, while specialized testing protocols are being developed specifically for transient electronics. Material selection must balance functional requirements with degradation timelines and metabolic pathways. Silicon, magnesium, zinc, and various biodegradable polymers have demonstrated acceptable safety profiles when properly engineered.

Risk assessment for transient electronics requires consideration of failure modes unique to degradable systems, including premature dissolution, unexpected degradation byproducts, and inconsistent performance during the functional lifetime. Manufacturers must implement robust quality control measures to ensure predictable degradation kinetics and consistent performance until planned dissolution. Sterilization methods must also be carefully selected to avoid compromising the degradable components.

Patient monitoring protocols for recipients of transient electronic implants typically include regular assessment of degradation progress through imaging techniques and blood tests for degradation markers. The medical community has established consensus guidelines recommending comprehensive pre-market testing that simulates physiological conditions and accelerated aging to validate both performance and safety throughout the device lifecycle.

Current medical applications of biodegradable electronics include temporary implantable sensors for post-surgical monitoring, drug delivery systems with programmable release mechanisms, and neural interfaces for temporary therapeutic interventions. These applications demonstrate significant advantages over traditional permanent implants by eliminating secondary removal surgeries and reducing long-term foreign body responses. Clinical trials have shown promising results in wound healing monitoring and infection detection using transient sensor arrays that dissolve after the critical healing period.

Safety standards for these devices focus on biocompatibility of both the initial components and their degradation byproducts. ISO 10993 series provides the framework for biological evaluation, while specialized testing protocols are being developed specifically for transient electronics. Material selection must balance functional requirements with degradation timelines and metabolic pathways. Silicon, magnesium, zinc, and various biodegradable polymers have demonstrated acceptable safety profiles when properly engineered.

Risk assessment for transient electronics requires consideration of failure modes unique to degradable systems, including premature dissolution, unexpected degradation byproducts, and inconsistent performance during the functional lifetime. Manufacturers must implement robust quality control measures to ensure predictable degradation kinetics and consistent performance until planned dissolution. Sterilization methods must also be carefully selected to avoid compromising the degradable components.

Patient monitoring protocols for recipients of transient electronic implants typically include regular assessment of degradation progress through imaging techniques and blood tests for degradation markers. The medical community has established consensus guidelines recommending comprehensive pre-market testing that simulates physiological conditions and accelerated aging to validate both performance and safety throughout the device lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!