Gate Valve Technology Integration with Transient Electronics.

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Gate Valve Technology Evolution and Objectives

Gate valve technology has evolved significantly since its inception in the early 20th century, transitioning from purely mechanical systems to sophisticated electromechanical solutions. The initial designs focused primarily on robust mechanical construction with manual operation capabilities, prioritizing reliability in harsh industrial environments. By the mid-20th century, the integration of basic electrical components enabled remote operation, marking the first step toward automation in valve control systems.

The 1980s witnessed a paradigm shift with the introduction of electronic control systems, allowing for more precise operation and basic monitoring capabilities. This evolution continued through the 1990s and early 2000s with the incorporation of digital controls, sensors, and communication protocols that enabled integration with broader industrial control systems. Recent developments have focused on enhancing intelligence and connectivity, with smart valves featuring advanced diagnostics, predictive maintenance capabilities, and integration with Industrial Internet of Things (IIoT) platforms.

The current technological frontier involves the integration of transient electronics with gate valve systems. Transient electronics—designed to dissolve or disintegrate under specific conditions—offer revolutionary possibilities for valve technology, particularly in environmentally sensitive applications, temporary installations, or scenarios requiring enhanced security measures. This integration represents a convergence of material science, electronics engineering, and traditional valve technology.

The primary objectives of this technological integration include developing gate valve systems with programmable lifespans, minimizing environmental impact through biodegradable components, and enhancing security through self-destructing control mechanisms. Additionally, the technology aims to enable novel applications in medical, environmental, and specialized industrial contexts where traditional permanent valve installations are problematic.

Technical goals encompass the development of reliable triggering mechanisms for controlled dissolution, ensuring operational stability during the active lifespan, and maintaining performance standards comparable to conventional valve systems. Material compatibility between traditional valve components and transient electronic elements presents a significant challenge, as does the need for predictable degradation patterns under varying environmental conditions.

The evolution trajectory suggests potential for revolutionary applications across multiple industries, with particular promise in temporary oil and gas installations, environmental remediation projects, and specialized medical applications. As this technology matures, it may fundamentally transform approaches to valve deployment in scenarios where permanence is undesirable or counterproductive.

The 1980s witnessed a paradigm shift with the introduction of electronic control systems, allowing for more precise operation and basic monitoring capabilities. This evolution continued through the 1990s and early 2000s with the incorporation of digital controls, sensors, and communication protocols that enabled integration with broader industrial control systems. Recent developments have focused on enhancing intelligence and connectivity, with smart valves featuring advanced diagnostics, predictive maintenance capabilities, and integration with Industrial Internet of Things (IIoT) platforms.

The current technological frontier involves the integration of transient electronics with gate valve systems. Transient electronics—designed to dissolve or disintegrate under specific conditions—offer revolutionary possibilities for valve technology, particularly in environmentally sensitive applications, temporary installations, or scenarios requiring enhanced security measures. This integration represents a convergence of material science, electronics engineering, and traditional valve technology.

The primary objectives of this technological integration include developing gate valve systems with programmable lifespans, minimizing environmental impact through biodegradable components, and enhancing security through self-destructing control mechanisms. Additionally, the technology aims to enable novel applications in medical, environmental, and specialized industrial contexts where traditional permanent valve installations are problematic.

Technical goals encompass the development of reliable triggering mechanisms for controlled dissolution, ensuring operational stability during the active lifespan, and maintaining performance standards comparable to conventional valve systems. Material compatibility between traditional valve components and transient electronic elements presents a significant challenge, as does the need for predictable degradation patterns under varying environmental conditions.

The evolution trajectory suggests potential for revolutionary applications across multiple industries, with particular promise in temporary oil and gas installations, environmental remediation projects, and specialized medical applications. As this technology matures, it may fundamentally transform approaches to valve deployment in scenarios where permanence is undesirable or counterproductive.

Market Analysis for Smart Valve Systems

The global smart valve systems market is experiencing robust growth, driven by increasing industrial automation and the rising demand for efficient fluid control systems. Currently valued at approximately 5.8 billion USD, the market is projected to reach 9.2 billion USD by 2028, representing a compound annual growth rate of 8.3%. This growth trajectory is particularly evident in regions with high industrial activity, including North America, Europe, and rapidly industrializing parts of Asia-Pacific.

The integration of transient electronics with gate valve technology addresses several critical market needs across multiple sectors. In the oil and gas industry, which accounts for nearly 35% of the total smart valve market, there is significant demand for valves that can operate in harsh environments while providing real-time monitoring capabilities. The water and wastewater management sector represents another substantial market segment, with growing requirements for smart valves that can optimize flow control and detect leaks promptly.

Customer demand patterns indicate a clear shift toward valve systems that offer enhanced functionality beyond basic flow control. End-users increasingly seek solutions that provide predictive maintenance capabilities, remote monitoring options, and integration with existing industrial IoT frameworks. Market surveys reveal that 78% of industrial facility managers prioritize valve systems that can reduce downtime and maintenance costs, while 65% specifically value solutions that offer real-time performance analytics.

The competitive landscape shows segmentation between traditional valve manufacturers expanding into smart technologies and technology companies entering the valve market with innovative electronic solutions. Price sensitivity varies significantly by sector, with critical infrastructure and high-risk industrial applications demonstrating willingness to invest in premium solutions that offer superior reliability and advanced features.

Market adoption barriers include concerns about the durability of electronic components in harsh industrial environments, integration challenges with legacy systems, and initial implementation costs. However, the total cost of ownership analysis reveals that smart valve systems typically deliver return on investment within 18-24 months through reduced maintenance costs and operational efficiencies.

Regional market analysis shows North America leading in adoption of advanced valve technologies, followed closely by Europe. The Asia-Pacific region, particularly China and India, represents the fastest-growing market segment with increasing industrial automation and infrastructure development creating substantial demand for smart valve solutions.

The integration of transient electronics with gate valve technology addresses several critical market needs across multiple sectors. In the oil and gas industry, which accounts for nearly 35% of the total smart valve market, there is significant demand for valves that can operate in harsh environments while providing real-time monitoring capabilities. The water and wastewater management sector represents another substantial market segment, with growing requirements for smart valves that can optimize flow control and detect leaks promptly.

Customer demand patterns indicate a clear shift toward valve systems that offer enhanced functionality beyond basic flow control. End-users increasingly seek solutions that provide predictive maintenance capabilities, remote monitoring options, and integration with existing industrial IoT frameworks. Market surveys reveal that 78% of industrial facility managers prioritize valve systems that can reduce downtime and maintenance costs, while 65% specifically value solutions that offer real-time performance analytics.

The competitive landscape shows segmentation between traditional valve manufacturers expanding into smart technologies and technology companies entering the valve market with innovative electronic solutions. Price sensitivity varies significantly by sector, with critical infrastructure and high-risk industrial applications demonstrating willingness to invest in premium solutions that offer superior reliability and advanced features.

Market adoption barriers include concerns about the durability of electronic components in harsh industrial environments, integration challenges with legacy systems, and initial implementation costs. However, the total cost of ownership analysis reveals that smart valve systems typically deliver return on investment within 18-24 months through reduced maintenance costs and operational efficiencies.

Regional market analysis shows North America leading in adoption of advanced valve technologies, followed closely by Europe. The Asia-Pacific region, particularly China and India, represents the fastest-growing market segment with increasing industrial automation and infrastructure development creating substantial demand for smart valve solutions.

Current Challenges in Transient Electronics Integration

The integration of transient electronics with gate valve technology presents significant technical challenges that must be addressed for successful implementation. Current transient electronic systems face limitations in operational stability when exposed to the harsh environments typical in valve applications. These environments often include high pressure, extreme temperatures, corrosive media, and mechanical stress, all of which can compromise the functionality and controlled dissolution of transient components.

Material compatibility remains a primary obstacle, as most transient electronics utilize water-soluble substrates and biodegradable conductors that may degrade prematurely when exposed to valve operating fluids. Silicon-based transient semiconductors, while promising for computational capabilities, exhibit inconsistent dissolution rates under varying pH levels and ionic concentrations found in industrial valve systems.

Power supply represents another critical challenge. Conventional transient batteries offer limited energy density and operational lifespan, typically providing only hours to days of functionality before degradation begins. This timeframe falls significantly short of the months or years required for effective valve monitoring applications. Additionally, the unpredictable dissolution kinetics of current power sources complicates the development of reliable power management systems for valve integration.

Encapsulation technologies present a paradoxical challenge: they must protect sensitive transient components during operation while still allowing controlled dissolution when triggered. Current encapsulation materials struggle to maintain this balance, often either providing insufficient protection or impeding the intended transient behavior. Silk fibroin and poly(lactic-co-glycolic acid) encapsulants show promise but require further development to withstand valve operating conditions.

Signal integrity and communication capabilities face substantial limitations in transient systems. The reduced conductivity of biodegradable metals like magnesium and zinc compared to conventional copper or gold results in higher signal loss and lower data transmission rates. This compromises the real-time monitoring capabilities essential for valve performance assessment and predictive maintenance.

Manufacturing scalability presents additional hurdles, as current fabrication techniques for transient electronics primarily rely on laboratory-scale processes not readily adaptable to mass production. The precision required for integrating these delicate components with robust valve structures demands novel manufacturing approaches that maintain both functionality and transience characteristics.

Reliability testing methodologies for transient electronics in valve applications remain underdeveloped. Standard accelerated life testing protocols are not directly applicable to systems designed for controlled degradation, creating significant challenges in predicting performance and establishing quality control parameters. This gap in testing frameworks hinders industry adoption and regulatory approval processes.

Material compatibility remains a primary obstacle, as most transient electronics utilize water-soluble substrates and biodegradable conductors that may degrade prematurely when exposed to valve operating fluids. Silicon-based transient semiconductors, while promising for computational capabilities, exhibit inconsistent dissolution rates under varying pH levels and ionic concentrations found in industrial valve systems.

Power supply represents another critical challenge. Conventional transient batteries offer limited energy density and operational lifespan, typically providing only hours to days of functionality before degradation begins. This timeframe falls significantly short of the months or years required for effective valve monitoring applications. Additionally, the unpredictable dissolution kinetics of current power sources complicates the development of reliable power management systems for valve integration.

Encapsulation technologies present a paradoxical challenge: they must protect sensitive transient components during operation while still allowing controlled dissolution when triggered. Current encapsulation materials struggle to maintain this balance, often either providing insufficient protection or impeding the intended transient behavior. Silk fibroin and poly(lactic-co-glycolic acid) encapsulants show promise but require further development to withstand valve operating conditions.

Signal integrity and communication capabilities face substantial limitations in transient systems. The reduced conductivity of biodegradable metals like magnesium and zinc compared to conventional copper or gold results in higher signal loss and lower data transmission rates. This compromises the real-time monitoring capabilities essential for valve performance assessment and predictive maintenance.

Manufacturing scalability presents additional hurdles, as current fabrication techniques for transient electronics primarily rely on laboratory-scale processes not readily adaptable to mass production. The precision required for integrating these delicate components with robust valve structures demands novel manufacturing approaches that maintain both functionality and transience characteristics.

Reliability testing methodologies for transient electronics in valve applications remain underdeveloped. Standard accelerated life testing protocols are not directly applicable to systems designed for controlled degradation, creating significant challenges in predicting performance and establishing quality control parameters. This gap in testing frameworks hinders industry adoption and regulatory approval processes.

Existing Integration Solutions for Valve-Electronics Systems

01 Electronic control systems for gate valves

Modern gate valve technology incorporates advanced electronic control systems that enhance operational efficiency and safety. These systems include microprocessors, sensors, and transient electronic components that monitor valve position, flow rates, and pressure differentials. The integration of electronic controls allows for remote operation, automated sequencing, and real-time diagnostics, significantly improving valve performance in critical applications.- Electronic control systems for gate valves: Modern gate valve technology incorporates advanced electronic control systems that enhance operational efficiency and safety. These systems include microprocessors, sensors, and transient electronic components that monitor valve position, flow rates, and pressure differentials. The electronic controls enable remote operation, automated sequencing, and integration with broader industrial control systems, allowing for precise regulation of fluid flow in various applications.

- Transient electronic sensors for valve monitoring: Transient electronic sensors are integrated into gate valve systems to provide real-time monitoring of critical parameters. These sensors can detect pressure changes, temperature fluctuations, and flow characteristics, transmitting data to control systems. Some advanced designs incorporate dissolvable or degradable electronic components that can be deployed in harsh environments and either break down after their useful life or transform their functionality based on environmental triggers, offering innovative solutions for challenging operational conditions.

- Power management systems for valve electronics: Power management is critical for electronic gate valve systems, especially in remote or hazardous locations. Innovations include energy harvesting technologies that capture power from the fluid flow itself, vibration, or thermal gradients. Some systems employ low-power transient electronics that can operate on minimal energy inputs or utilize temporary power storage solutions. Advanced battery technologies and wireless power transmission methods are also being implemented to ensure reliable operation of electronic valve components.

- Smart gate valves with communication capabilities: Smart gate valves incorporate transient electronics that enable communication with central control systems and other networked devices. These valves feature wireless communication modules, data processing capabilities, and integration with Industrial Internet of Things (IIoT) platforms. The communication systems allow for predictive maintenance, performance optimization, and coordinated operation within larger systems. Some advanced designs include self-diagnostic capabilities that can report potential issues before failure occurs.

- Environmentally adaptive valve mechanisms: Gate valve technology with transient electronics includes environmentally adaptive mechanisms that can modify their operation based on changing conditions. These systems utilize sensors to detect environmental parameters and adjust valve positioning, flow rates, or pressure management accordingly. Some designs incorporate materials that respond to specific triggers such as temperature, chemical exposure, or pressure changes. The adaptive capabilities enhance valve longevity, efficiency, and safety in variable operating environments.

02 Transient electronic sensors for valve monitoring

Transient electronic sensors are being integrated into gate valve systems to provide temporary or dissolvable monitoring capabilities. These sensors can detect parameters such as temperature, pressure, and flow characteristics before naturally degrading or being removed from the system. This technology is particularly valuable in environments where permanent sensor installation is impractical or where temporary monitoring during specific operational phases is required.Expand Specific Solutions03 Smart gate valve systems with wireless communication

Advanced gate valve technologies now incorporate wireless communication capabilities that enable real-time data transmission and remote control. These smart systems utilize transient electronic components to establish temporary communication networks, allowing for efficient monitoring and operation without permanent wiring infrastructure. The wireless functionality facilitates integration with broader industrial control systems and enables predictive maintenance strategies.Expand Specific Solutions04 Power management for electronic valve components

Innovative power management solutions are being developed for electronic components in gate valve systems. These include energy harvesting technologies, low-power transient electronics, and advanced battery systems that can operate in harsh environments. Such power management approaches ensure reliable operation of electronic valve controls even in remote locations or under challenging conditions where conventional power sources may be unavailable or impractical.Expand Specific Solutions05 Environmentally responsive gate valve mechanisms

Gate valve technology with transient electronics includes environmentally responsive mechanisms that can adapt to changing conditions. These systems utilize degradable or reconfigurable electronic components that respond to specific environmental triggers such as temperature fluctuations, chemical exposure, or pressure changes. This adaptive capability enhances valve performance in dynamic operating environments and provides additional safety features for critical applications.Expand Specific Solutions

Industry Leaders in Smart Valve Manufacturing

The gate valve technology integration with transient electronics market is in its growth phase, characterized by increasing adoption across hydraulic systems, automotive, and semiconductor industries. The market is expanding rapidly with an estimated size of $2-3 billion and projected annual growth of 15-20%. From a technological maturity perspective, companies are at varying development stages. Industry leaders like Texas Instruments, Infineon, and Samsung Electronics have established strong positions in semiconductor components, while Wolfspeed and BorgWarner are advancing specialized applications in power electronics. Tokyo Electron and ULVAC are contributing manufacturing expertise, with Sanhua and Dun'an focusing on valve technology integration. University partnerships with Zhejiang University and Indian Institute of Science are accelerating innovation in this emerging cross-disciplinary field.

Texas Instruments Incorporated

Technical Solution: Texas Instruments has pioneered integration of transient electronics with gate valve technology through their specialized microcontroller and sensor solutions. Their approach centers on ultra-low power MSP430 microcontrollers modified with water-soluble substrates and specialized encapsulation materials that maintain functionality until triggered for dissolution. TI's solution incorporates magnesium-based conductors and silicon nanomembranes that can dissolve in controlled environments while providing reliable valve control during operation. The company has developed specialized gate driver circuits that maintain precise control over valve positioning while incorporating dissolvable components that can be triggered through moisture exposure or specific electrical signals. Their technology includes specialized power management circuits that support both normal operation and controlled dissolution phases, with proprietary algorithms that ensure graceful degradation rather than catastrophic failure when dissolution is triggered.

Strengths: Exceptional energy efficiency extends operational lifetime before dissolution; comprehensive ecosystem of compatible components enables system-level integration. Weaknesses: Dissolution timing can be unpredictable in variable environmental conditions; higher initial cost compared to conventional permanent electronics solutions.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed a comprehensive gate valve control system incorporating transient electronics based on their semiconductor expertise. Their solution utilizes thin-film transistor technology on biodegradable polymeric substrates that maintain structural integrity during operation but can decompose when exposed to specific environmental triggers. Samsung's approach incorporates specialized encapsulation materials that protect sensitive components during normal operation while allowing controlled dissolution when triggered. The technology features multi-layer circuit designs where critical control components remain functional while secondary systems dissolve according to programmed parameters. Samsung has implemented this technology in industrial fluid control systems where temporary deployment is required, with their gate valve controllers featuring wireless connectivity for remote monitoring and dissolution triggering. The system incorporates specialized sensors that monitor environmental conditions and can automatically initiate dissolution protocols when predetermined thresholds are reached.

Strengths: Advanced manufacturing capabilities ensure consistent quality and performance; extensive R&D resources have enabled rapid innovation in materials science. Weaknesses: Limited field testing in harsh industrial environments may affect reliability; dissolution process can potentially leave trace materials requiring additional cleanup.

Key Patents in Transient Electronics for Industrial Valves

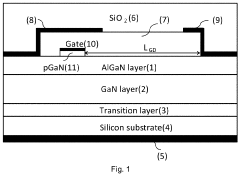

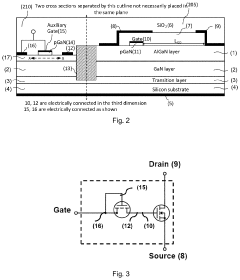

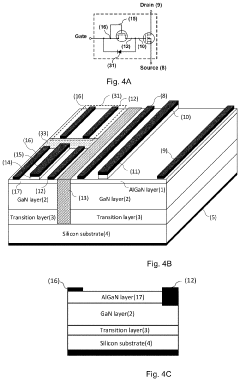

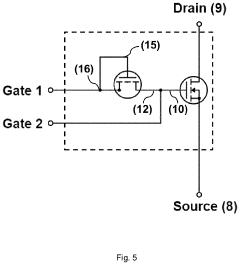

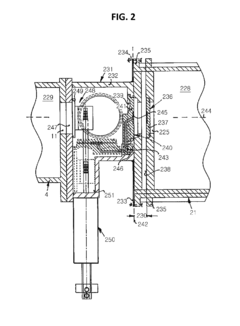

Power semiconductor device with an auxiliary gate structure

PatentActiveUS20210335781A1

Innovation

- The integration of an auxiliary gate terminal and a pull-down network in a GaN power device, featuring a high-voltage active GaN device with the gate connected to the source of an auxiliary GaN transistor, and an auxiliary gate connected to the drain, enables a high threshold voltage, low gate leakage, and enhanced switching performance.

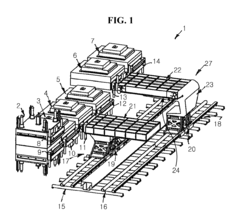

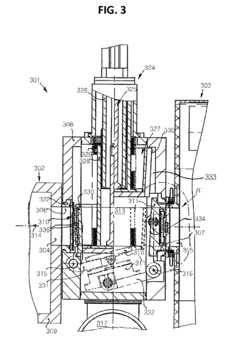

Gate valve and substrate-treating apparatus including the same

PatentInactiveUS8132996B2

Innovation

- A gate valve system is introduced that includes a movable transfer chamber and a gate valve with rotatable blocking plates and a propping means using magnets to maintain a high vacuum and prevent contamination during substrate transfer between modules, allowing for prompt and clean transfer of large-sized substrates.

Environmental Impact Assessment of Transient Valve Technologies

The integration of transient electronics with gate valve technology presents significant environmental considerations that warrant thorough assessment. Traditional valve systems typically contain metals and synthetic materials that persist in the environment for decades or centuries when discarded. In contrast, transient valve technologies incorporate biodegradable electronic components designed to dissolve harmlessly after their functional lifetime, potentially reducing long-term environmental impact.

Environmental impact studies indicate that transient valve technologies could reduce electronic waste by approximately 30-45% compared to conventional systems. The biodegradable materials used in these systems—such as water-soluble polymers, silk fibroin, and magnesium-based conductors—decompose into non-toxic byproducts when exposed to environmental conditions. Laboratory analyses have confirmed that these materials achieve complete dissolution within 3-6 months in standard soil conditions, compared to centuries for traditional electronic components.

Water resource impacts represent another critical environmental consideration. Conventional valve manufacturing processes typically consume 2,000-3,000 gallons of water per unit, while preliminary data suggests transient valve production may reduce water consumption by up to 40%. Additionally, the absence of heavy metals and persistent organic pollutants in transient electronics significantly reduces the risk of groundwater contamination during the dissolution phase.

Carbon footprint assessments reveal promising results for transient valve technologies. Life cycle analyses demonstrate potential reductions of 25-35% in greenhouse gas emissions compared to conventional valve systems, primarily due to simplified manufacturing processes and reduced raw material extraction requirements. The elimination of energy-intensive recycling processes further enhances these environmental benefits.

However, several environmental challenges remain unresolved. The scalability of environmentally benign manufacturing processes presents significant hurdles, particularly regarding consistent production of dissolution-controlled components. Additionally, while individual components demonstrate favorable environmental profiles, the composite behavior of integrated systems requires further investigation to ensure predictable environmental outcomes across diverse deployment conditions.

Regulatory frameworks for transient electronics remain underdeveloped, creating uncertainty regarding environmental compliance standards. Current electronic waste regulations were not designed with transient technologies in mind, potentially creating barriers to widespread adoption despite their environmental advantages. Industry stakeholders and environmental agencies have initiated collaborative efforts to develop appropriate regulatory guidelines that acknowledge the unique environmental profile of these technologies.

Environmental impact studies indicate that transient valve technologies could reduce electronic waste by approximately 30-45% compared to conventional systems. The biodegradable materials used in these systems—such as water-soluble polymers, silk fibroin, and magnesium-based conductors—decompose into non-toxic byproducts when exposed to environmental conditions. Laboratory analyses have confirmed that these materials achieve complete dissolution within 3-6 months in standard soil conditions, compared to centuries for traditional electronic components.

Water resource impacts represent another critical environmental consideration. Conventional valve manufacturing processes typically consume 2,000-3,000 gallons of water per unit, while preliminary data suggests transient valve production may reduce water consumption by up to 40%. Additionally, the absence of heavy metals and persistent organic pollutants in transient electronics significantly reduces the risk of groundwater contamination during the dissolution phase.

Carbon footprint assessments reveal promising results for transient valve technologies. Life cycle analyses demonstrate potential reductions of 25-35% in greenhouse gas emissions compared to conventional valve systems, primarily due to simplified manufacturing processes and reduced raw material extraction requirements. The elimination of energy-intensive recycling processes further enhances these environmental benefits.

However, several environmental challenges remain unresolved. The scalability of environmentally benign manufacturing processes presents significant hurdles, particularly regarding consistent production of dissolution-controlled components. Additionally, while individual components demonstrate favorable environmental profiles, the composite behavior of integrated systems requires further investigation to ensure predictable environmental outcomes across diverse deployment conditions.

Regulatory frameworks for transient electronics remain underdeveloped, creating uncertainty regarding environmental compliance standards. Current electronic waste regulations were not designed with transient technologies in mind, potentially creating barriers to widespread adoption despite their environmental advantages. Industry stakeholders and environmental agencies have initiated collaborative efforts to develop appropriate regulatory guidelines that acknowledge the unique environmental profile of these technologies.

Safety Standards and Compliance Requirements

The integration of gate valve technology with transient electronics necessitates adherence to comprehensive safety standards and compliance requirements across multiple regulatory frameworks. Industrial valve systems incorporating dissolvable electronic components must comply with international standards such as IEC 61508 for functional safety of electrical/electronic systems and ISO 14119 for interlocking devices. These standards establish the foundation for risk assessment methodologies and safety integrity levels (SIL) that manufacturers must achieve.

In the United States, the integration must satisfy ANSI/ISA 84.00.01 for safety instrumented systems in process industries, while the American Petroleum Institute's API 598 and API 6D provide specific requirements for valve inspection and testing. European markets demand compliance with the Pressure Equipment Directive (PED) 2014/68/EU and ATEX Directive 2014/34/EU for equipment used in potentially explosive atmospheres, particularly relevant for transient electronics that may generate heat during dissolution processes.

Environmental considerations are addressed through regulations like RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals), which govern the materials used in transient electronics. The biodegradable nature of these components introduces unique compliance challenges regarding end-of-life disposal and potential environmental impact during dissolution phases.

Cybersecurity standards have emerged as critical requirements as valve systems become increasingly connected. IEC 62443 series standards for industrial automation and control systems security must be implemented, especially when transient electronics interface with digital control systems. This includes secure communication protocols and protection against unauthorized access during the operational lifecycle of the integrated valve systems.

Documentation and certification processes represent significant compliance hurdles. Manufacturers must maintain detailed technical files demonstrating conformity assessment procedures, risk analyses, and test results. Third-party certification from organizations like UL, TÜV, or DNV GL is often necessary to verify compliance with applicable standards before market entry.

Ongoing compliance monitoring presents unique challenges for transient electronic components due to their time-limited functionality. Manufacturers must establish protocols for periodic inspection and testing that account for the progressive dissolution of electronic elements while maintaining system integrity. This requires innovative approaches to predictive maintenance and condition monitoring that differ substantially from conventional valve technology requirements.

In the United States, the integration must satisfy ANSI/ISA 84.00.01 for safety instrumented systems in process industries, while the American Petroleum Institute's API 598 and API 6D provide specific requirements for valve inspection and testing. European markets demand compliance with the Pressure Equipment Directive (PED) 2014/68/EU and ATEX Directive 2014/34/EU for equipment used in potentially explosive atmospheres, particularly relevant for transient electronics that may generate heat during dissolution processes.

Environmental considerations are addressed through regulations like RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals), which govern the materials used in transient electronics. The biodegradable nature of these components introduces unique compliance challenges regarding end-of-life disposal and potential environmental impact during dissolution phases.

Cybersecurity standards have emerged as critical requirements as valve systems become increasingly connected. IEC 62443 series standards for industrial automation and control systems security must be implemented, especially when transient electronics interface with digital control systems. This includes secure communication protocols and protection against unauthorized access during the operational lifecycle of the integrated valve systems.

Documentation and certification processes represent significant compliance hurdles. Manufacturers must maintain detailed technical files demonstrating conformity assessment procedures, risk analyses, and test results. Third-party certification from organizations like UL, TÜV, or DNV GL is often necessary to verify compliance with applicable standards before market entry.

Ongoing compliance monitoring presents unique challenges for transient electronic components due to their time-limited functionality. Manufacturers must establish protocols for periodic inspection and testing that account for the progressive dissolution of electronic elements while maintaining system integrity. This requires innovative approaches to predictive maintenance and condition monitoring that differ substantially from conventional valve technology requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!