The Role of Gate Valves in Transient Electronics Systems.

SEP 4, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Transient Electronics Gate Valve Technology Background

Transient electronics represents a revolutionary paradigm in electronic systems design, characterized by devices engineered to maintain stable operation for a predetermined period before undergoing controlled degradation. Gate valves, traditionally mechanical components used to regulate fluid flow, have found a novel application within this emerging field as critical control elements that manage the operational lifetime of transient systems.

The concept of transient electronics emerged in the early 2010s, pioneered by researchers seeking alternatives to conventional persistent electronics. Unlike traditional electronic components designed for longevity, transient electronics intentionally incorporate materials and mechanisms that enable controlled dissolution, disintegration, or functional transformation after fulfilling their intended purpose. This controlled obsolescence addresses growing concerns regarding electronic waste management and offers unique advantages in specialized applications.

Gate valve technology in transient electronics has evolved from simple mechanical structures to sophisticated micro-electromechanical systems (MEMS) that can be triggered to initiate degradation processes. These specialized valves function as gatekeepers for reactive agents that, when released, catalyze the dissolution of key electronic components. The integration of these valves represents a critical advancement in achieving precise temporal control over device functionality.

Historical development of transient electronics gate valve technology can be traced through three distinct phases. The initial phase (2010-2015) focused on proof-of-concept designs utilizing basic mechanical triggers. The second phase (2015-2020) saw the miniaturization and integration of these components into functional circuits with rudimentary timing mechanisms. The current phase (2020-present) has witnessed significant advancements in precision control, material compatibility, and triggering mechanisms.

The technological trajectory indicates a convergence of materials science, microfluidics, and electronic engineering in the development of next-generation gate valve solutions. Silicon-based MEMS valves currently dominate the field, though emerging research in biodegradable polymers and stimuli-responsive materials promises to expand the application scope and environmental compatibility of these systems.

Recent technological milestones include the development of remotely triggered gate valves that respond to external stimuli such as electromagnetic fields, pH changes, or specific biochemical markers. These innovations have expanded the potential applications of transient electronics from environmental sensors to advanced biomedical implants that dissolve harmlessly after completing therapeutic functions.

The evolution of gate valve technology continues to address key challenges including reliability, miniaturization, and precise temporal control, driving the field toward increasingly sophisticated transient electronic systems with programmable lifespans and degradation pathways.

The concept of transient electronics emerged in the early 2010s, pioneered by researchers seeking alternatives to conventional persistent electronics. Unlike traditional electronic components designed for longevity, transient electronics intentionally incorporate materials and mechanisms that enable controlled dissolution, disintegration, or functional transformation after fulfilling their intended purpose. This controlled obsolescence addresses growing concerns regarding electronic waste management and offers unique advantages in specialized applications.

Gate valve technology in transient electronics has evolved from simple mechanical structures to sophisticated micro-electromechanical systems (MEMS) that can be triggered to initiate degradation processes. These specialized valves function as gatekeepers for reactive agents that, when released, catalyze the dissolution of key electronic components. The integration of these valves represents a critical advancement in achieving precise temporal control over device functionality.

Historical development of transient electronics gate valve technology can be traced through three distinct phases. The initial phase (2010-2015) focused on proof-of-concept designs utilizing basic mechanical triggers. The second phase (2015-2020) saw the miniaturization and integration of these components into functional circuits with rudimentary timing mechanisms. The current phase (2020-present) has witnessed significant advancements in precision control, material compatibility, and triggering mechanisms.

The technological trajectory indicates a convergence of materials science, microfluidics, and electronic engineering in the development of next-generation gate valve solutions. Silicon-based MEMS valves currently dominate the field, though emerging research in biodegradable polymers and stimuli-responsive materials promises to expand the application scope and environmental compatibility of these systems.

Recent technological milestones include the development of remotely triggered gate valves that respond to external stimuli such as electromagnetic fields, pH changes, or specific biochemical markers. These innovations have expanded the potential applications of transient electronics from environmental sensors to advanced biomedical implants that dissolve harmlessly after completing therapeutic functions.

The evolution of gate valve technology continues to address key challenges including reliability, miniaturization, and precise temporal control, driving the field toward increasingly sophisticated transient electronic systems with programmable lifespans and degradation pathways.

Market Applications for Gate Valves in Transient Systems

Transient electronics systems are witnessing significant market penetration across various industries, with gate valves playing a crucial role in their functionality and performance. The healthcare sector represents one of the most promising markets for gate valve applications in transient systems. These valves enable precise control in biodegradable medical implants that dissolve after completing their therapeutic function, eliminating the need for surgical removal. The market for such implants is projected to grow substantially as they reduce patient recovery time and minimize infection risks associated with secondary procedures.

Environmental monitoring presents another substantial market opportunity. Gate valves in transient environmental sensors allow for controlled dissolution after data collection, preventing long-term ecological impact. These sensors are increasingly deployed in remote or sensitive ecosystems where retrieval would be impractical or potentially damaging. Conservation organizations and government environmental agencies are adopting these solutions to monitor pollution levels, wildlife movements, and climate indicators without leaving persistent electronic waste.

The defense and security sector utilizes gate valves in transient electronics for secure communications and surveillance systems designed to degrade after mission completion. These systems prevent sensitive technology from falling into unauthorized hands if devices are lost or captured. Military applications include self-destructing reconnaissance drones, temporary communication networks, and classified data storage devices with controlled lifespans.

Consumer electronics represents an emerging market with significant growth potential. As electronic waste concerns intensify, manufacturers are exploring transient components that facilitate easier recycling and reduce environmental impact. Gate valves in these applications control the timing of component degradation, allowing for planned obsolescence that aligns with environmental goals rather than marketing strategies.

Agricultural technology applications are expanding rapidly, with transient soil sensors utilizing gate valves to control dissolution timing after harvest seasons. These sensors monitor moisture levels, nutrient content, and soil health throughout growing cycles, then harmlessly decompose to prevent accumulation of electronic waste in agricultural lands.

The industrial Internet of Things (IoT) sector is adopting transient electronics with gate valve mechanisms for temporary monitoring during manufacturing processes, construction projects, or maintenance operations. These systems provide critical data during specific phases of industrial operations without requiring retrieval from difficult-to-access locations.

Each of these market applications demonstrates the versatility of gate valves in transient electronics systems, with market adoption accelerating as environmental regulations tighten and sustainability becomes a primary design consideration across industries.

Environmental monitoring presents another substantial market opportunity. Gate valves in transient environmental sensors allow for controlled dissolution after data collection, preventing long-term ecological impact. These sensors are increasingly deployed in remote or sensitive ecosystems where retrieval would be impractical or potentially damaging. Conservation organizations and government environmental agencies are adopting these solutions to monitor pollution levels, wildlife movements, and climate indicators without leaving persistent electronic waste.

The defense and security sector utilizes gate valves in transient electronics for secure communications and surveillance systems designed to degrade after mission completion. These systems prevent sensitive technology from falling into unauthorized hands if devices are lost or captured. Military applications include self-destructing reconnaissance drones, temporary communication networks, and classified data storage devices with controlled lifespans.

Consumer electronics represents an emerging market with significant growth potential. As electronic waste concerns intensify, manufacturers are exploring transient components that facilitate easier recycling and reduce environmental impact. Gate valves in these applications control the timing of component degradation, allowing for planned obsolescence that aligns with environmental goals rather than marketing strategies.

Agricultural technology applications are expanding rapidly, with transient soil sensors utilizing gate valves to control dissolution timing after harvest seasons. These sensors monitor moisture levels, nutrient content, and soil health throughout growing cycles, then harmlessly decompose to prevent accumulation of electronic waste in agricultural lands.

The industrial Internet of Things (IoT) sector is adopting transient electronics with gate valve mechanisms for temporary monitoring during manufacturing processes, construction projects, or maintenance operations. These systems provide critical data during specific phases of industrial operations without requiring retrieval from difficult-to-access locations.

Each of these market applications demonstrates the versatility of gate valves in transient electronics systems, with market adoption accelerating as environmental regulations tighten and sustainability becomes a primary design consideration across industries.

Current Challenges in Transient Electronics Valve Integration

Despite significant advancements in transient electronics systems, the integration of gate valves presents several persistent challenges that impede widespread adoption and optimal performance. One primary obstacle is the material compatibility issue between conventional valve components and transient electronics. Traditional gate valve materials such as stainless steel, brass, or specialized alloys are designed for durability and longevity, which fundamentally contradicts the controlled degradation requirements of transient systems.

Miniaturization remains another critical challenge, as current gate valve technologies struggle to achieve the microscale dimensions necessary for seamless integration with transient electronic circuits. Even the most advanced microvalves typically measure several millimeters in diameter, whereas transient electronic applications often require sub-millimeter control components to maintain system efficiency and functionality within strict spatial constraints.

The triggering mechanisms for dissolution or degradation present significant technical hurdles. Engineering gate valves that can maintain operational integrity under normal conditions yet respond predictably to specific dissolution triggers (such as moisture, pH changes, or thermal stimuli) requires sophisticated material science innovations that have not yet been fully realized. Current solutions often exhibit unpredictable degradation timelines or incomplete dissolution of valve components.

Power requirements pose additional complications, as conventional gate valve actuation mechanisms demand substantial energy inputs incompatible with the limited power budgets of transient electronic systems. Most existing microvalve technologies require continuous power for state maintenance, whereas transient applications necessitate energy-efficient, potentially passive control mechanisms that can function with minimal or intermittent power supply.

Reliability and precision control during the functional lifetime of the device represent ongoing challenges. Researchers struggle to develop gate valve mechanisms that maintain consistent performance characteristics throughout their intended operational period before controlled degradation begins. Premature degradation or performance drift can compromise critical system functions in medical implants or environmental sensors.

Biocompatibility concerns further complicate integration efforts, particularly for medical applications. The degradation products of valve components must be non-toxic and safely metabolized or excreted by biological systems. Current materials often produce byproducts that may trigger inflammatory responses or accumulate in tissues, limiting their suitability for in vivo applications.

Manufacturing scalability presents a significant barrier to commercialization. Current fabrication techniques for specialized microvalves compatible with transient electronics typically involve complex, multi-step processes that are difficult to scale for mass production. This manufacturing challenge substantially increases costs and limits accessibility of transient electronic systems incorporating flow control mechanisms.

Miniaturization remains another critical challenge, as current gate valve technologies struggle to achieve the microscale dimensions necessary for seamless integration with transient electronic circuits. Even the most advanced microvalves typically measure several millimeters in diameter, whereas transient electronic applications often require sub-millimeter control components to maintain system efficiency and functionality within strict spatial constraints.

The triggering mechanisms for dissolution or degradation present significant technical hurdles. Engineering gate valves that can maintain operational integrity under normal conditions yet respond predictably to specific dissolution triggers (such as moisture, pH changes, or thermal stimuli) requires sophisticated material science innovations that have not yet been fully realized. Current solutions often exhibit unpredictable degradation timelines or incomplete dissolution of valve components.

Power requirements pose additional complications, as conventional gate valve actuation mechanisms demand substantial energy inputs incompatible with the limited power budgets of transient electronic systems. Most existing microvalve technologies require continuous power for state maintenance, whereas transient applications necessitate energy-efficient, potentially passive control mechanisms that can function with minimal or intermittent power supply.

Reliability and precision control during the functional lifetime of the device represent ongoing challenges. Researchers struggle to develop gate valve mechanisms that maintain consistent performance characteristics throughout their intended operational period before controlled degradation begins. Premature degradation or performance drift can compromise critical system functions in medical implants or environmental sensors.

Biocompatibility concerns further complicate integration efforts, particularly for medical applications. The degradation products of valve components must be non-toxic and safely metabolized or excreted by biological systems. Current materials often produce byproducts that may trigger inflammatory responses or accumulate in tissues, limiting their suitability for in vivo applications.

Manufacturing scalability presents a significant barrier to commercialization. Current fabrication techniques for specialized microvalves compatible with transient electronics typically involve complex, multi-step processes that are difficult to scale for mass production. This manufacturing challenge substantially increases costs and limits accessibility of transient electronic systems incorporating flow control mechanisms.

Gate Valve Implementation Strategies for Transient Systems

01 Gate valve design and structure

Gate valves have specific structural designs that allow for efficient flow control. The design typically includes a gate or wedge that moves perpendicular to the flow path to control fluid passage. These valves are characterized by their full bore opening which minimizes pressure drop when fully open. Various structural improvements focus on the sealing mechanism, gate design, and overall valve body construction to enhance performance and durability.- Gate valve sealing mechanisms: Gate valves employ various sealing mechanisms to prevent leakage when in closed position. These mechanisms include specialized seat designs, sealing rings, and pressure-responsive elements that ensure tight closure under different operating conditions. The sealing surfaces may be made of metal, elastomers, or composite materials depending on the application requirements, temperature range, and media being controlled.

- Gate valve actuation systems: Various actuation systems are employed in gate valves to control the movement of the gate element. These include manual handwheel operations, gear-driven mechanisms for larger valves, and automated systems using electric, pneumatic, or hydraulic actuators. The actuation systems are designed to provide sufficient force for reliable operation while ensuring smooth movement of the gate to prevent damage to the sealing surfaces.

- Gate valve body designs: The body design of gate valves varies based on application requirements and installation constraints. Common configurations include bolted bonnet designs for maintenance access, pressure-sealed bonnets for high-pressure applications, and split-body designs for specific installation needs. The body material selection depends on factors such as operating pressure, temperature, and corrosion resistance requirements.

- Gate valve flow control features: Gate valves incorporate various flow control features to optimize performance in different applications. These include wedge-shaped gates for positive sealing, parallel gates for specific flow requirements, and knife gates for slurry applications. Some designs feature bypass systems to equalize pressure across the gate before opening, reducing operating torque and wear on components.

- Gate valve maintenance innovations: Innovations in gate valve design focus on improving maintenance procedures and extending service life. These include replaceable seats and seals that can be serviced without removing the valve from the line, back-seating capabilities to allow stem packing replacement under pressure, and self-cleaning features that prevent buildup of debris on sealing surfaces. Advanced materials and coatings are also employed to reduce wear and extend maintenance intervals.

02 Sealing mechanisms in gate valves

Effective sealing is crucial for gate valve performance. Various sealing mechanisms are employed including metal-to-metal seals, elastomeric seals, and composite sealing arrangements. Innovations in this area focus on improving leak prevention, extending seal life, and maintaining sealing effectiveness under varying pressure and temperature conditions. Advanced sealing technologies help minimize maintenance requirements and increase valve reliability in demanding applications.Expand Specific Solutions03 Actuation systems for gate valves

Gate valves employ various actuation systems to control the movement of the gate element. These include manual handwheel operation, gear-driven mechanisms, pneumatic actuators, hydraulic systems, and electric motor drives. Innovations in actuation focus on improving operational efficiency, providing precise control, reducing operating torque requirements, and enabling remote operation capabilities for applications in hazardous or difficult-to-access environments.Expand Specific Solutions04 Materials and manufacturing techniques for gate valves

The selection of materials and manufacturing techniques significantly impacts gate valve performance and longevity. Various materials including cast iron, carbon steel, stainless steel, bronze, and specialized alloys are used based on application requirements. Advanced manufacturing methods such as precision casting, forging, CNC machining, and additive manufacturing enable the production of complex valve components with improved dimensional accuracy and surface finish, resulting in better sealing performance and extended service life.Expand Specific Solutions05 Specialized gate valves for specific applications

Gate valves are designed with specific features to meet the requirements of various industrial applications. These include high-pressure gate valves for oil and gas, knife gate valves for slurry applications, cryogenic gate valves for extremely low temperatures, and fire-safe gate valves for hazardous environments. Specialized designs incorporate features such as double isolation capabilities, bidirectional flow control, and resistance to specific corrosive media or extreme operating conditions.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The gate valve market in transient electronics systems is currently in a growth phase, with increasing demand driven by advancements in semiconductor technologies and electronic control systems. The global market size is expanding rapidly, projected to reach significant volumes as industries like automotive, industrial automation, and power electronics adopt transient electronic solutions. Technologically, companies like Applied Materials, Wolfspeed, and Tokyo Electron are leading innovation in semiconductor-based gate valve solutions, while traditional industrial players such as DENSO, Mitsubishi Electric, and Fuji Electric are integrating these components into comprehensive systems. NXP, Analog Devices, and Samsung Electronics are advancing miniaturization and efficiency in consumer applications, creating a competitive landscape where material science expertise and manufacturing scale determine market leadership.

Applied Materials, Inc.

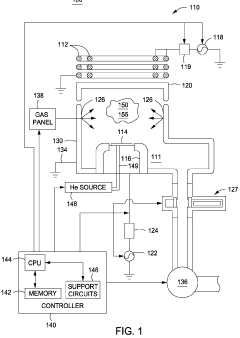

Technical Solution: Applied Materials has leveraged their expertise in semiconductor manufacturing equipment to develop specialized gate valve technologies for transient electronics systems. Their approach focuses on integrating dissolution control mechanisms directly into the substrate materials during the manufacturing process. The company's solution features nanoscale gate structures that can be triggered electrically, thermally, or through specific chemical interactions to initiate controlled breakdown of electronic components. Applied Materials has developed proprietary deposition techniques that enable the creation of sacrificial layers with precisely engineered dissolution rates, allowing for predictable and sequential breakdown of different system components. Their technology incorporates specialized encapsulation materials that protect the gate structures until activation is required, ensuring long-term stability in various environmental conditions. The company has also pioneered manufacturing processes that allow these specialized gate valves to be produced using modified versions of standard semiconductor equipment, facilitating easier adoption by existing electronics manufacturers without requiring entirely new production lines.

Strengths: Exceptional integration with semiconductor manufacturing processes enables cost-effective production; precise control over dissolution timing and rates; compatibility with existing electronics manufacturing infrastructure. Weaknesses: Less flexible for post-manufacturing modifications; requires specialized materials that may have limited suppliers; more challenging to implement in retrofit applications.

International Business Machines Corp.

Technical Solution: IBM has developed a sophisticated gate valve technology for transient electronics that incorporates their expertise in materials science and microelectronics. Their approach utilizes programmable microelectromechanical systems (MEMS) that can precisely control the release of dissolution agents or the exposure of sensitive components to environmental triggers. IBM's solution features a hierarchical control architecture that allows for selective dissolution of specific components while preserving others, enabling multi-stage transience capabilities. The company has integrated their gate valve technology with advanced analytics capabilities that can predict optimal dissolution timing based on environmental monitoring and system status. Their systems incorporate redundant triggering mechanisms to ensure reliability while preventing accidental activation. IBM has also pioneered self-checking valve systems that continuously monitor their own integrity and can report status through secure communication channels before dissolution occurs, making them particularly suitable for high-security applications where confirmation of destruction is required.

Strengths: Advanced analytics integration provides intelligent dissolution timing; exceptional reliability through redundant systems; selective component dissolution capabilities enable sophisticated applications. Weaknesses: Higher complexity increases potential points of failure; requires more sophisticated control systems than simpler alternatives; premium pricing positions technology primarily for high-end applications.

Key Patents and Technical Innovations

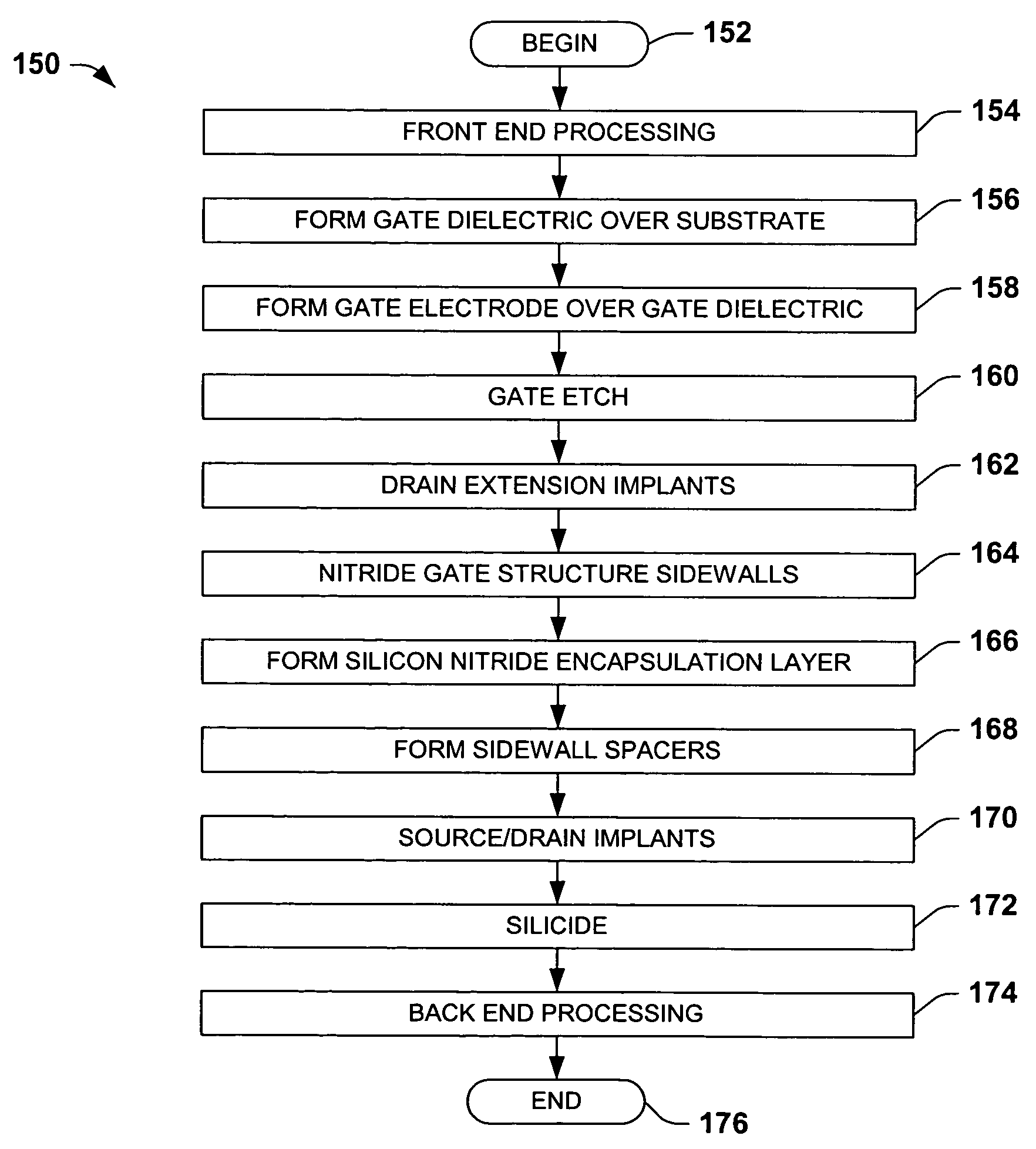

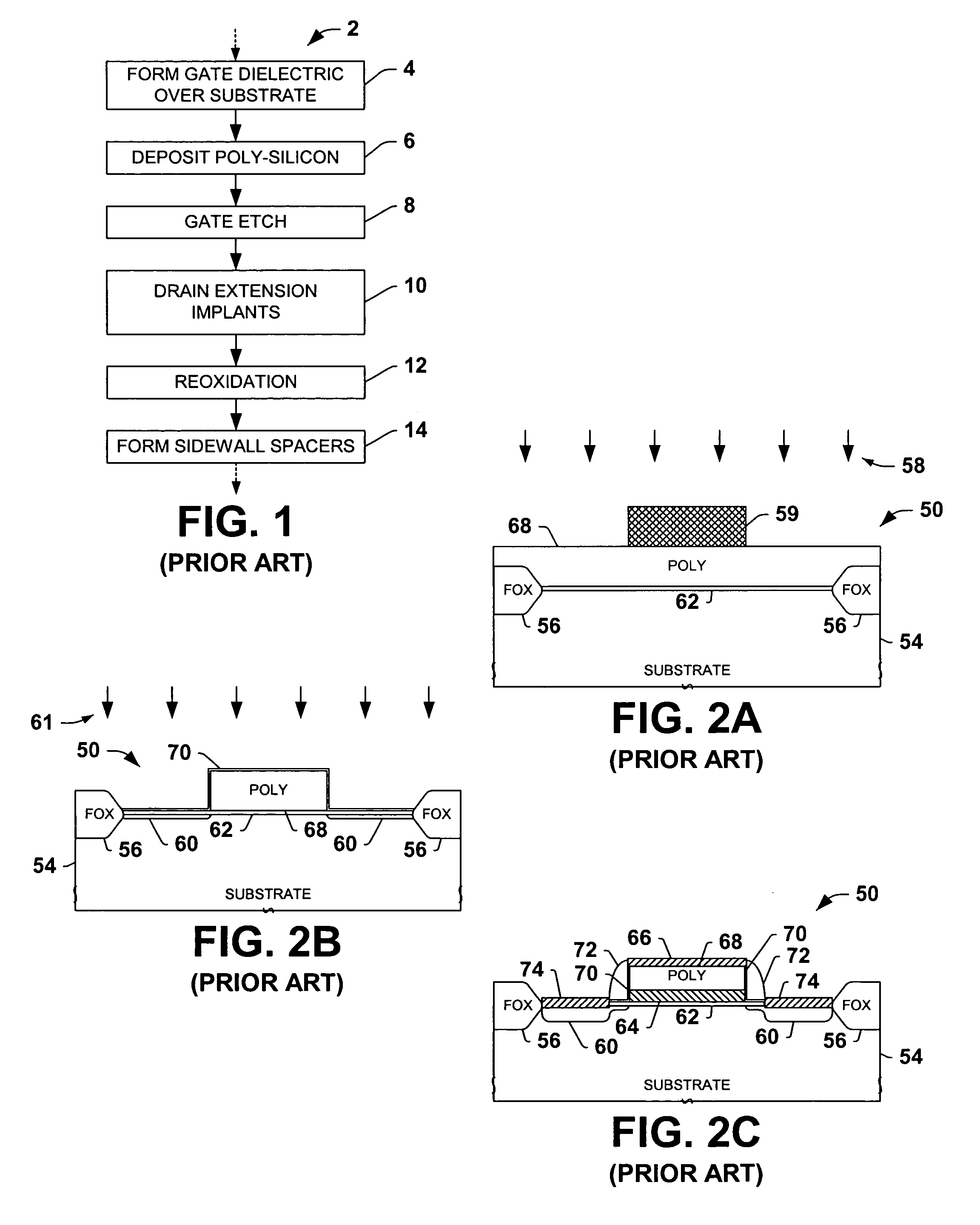

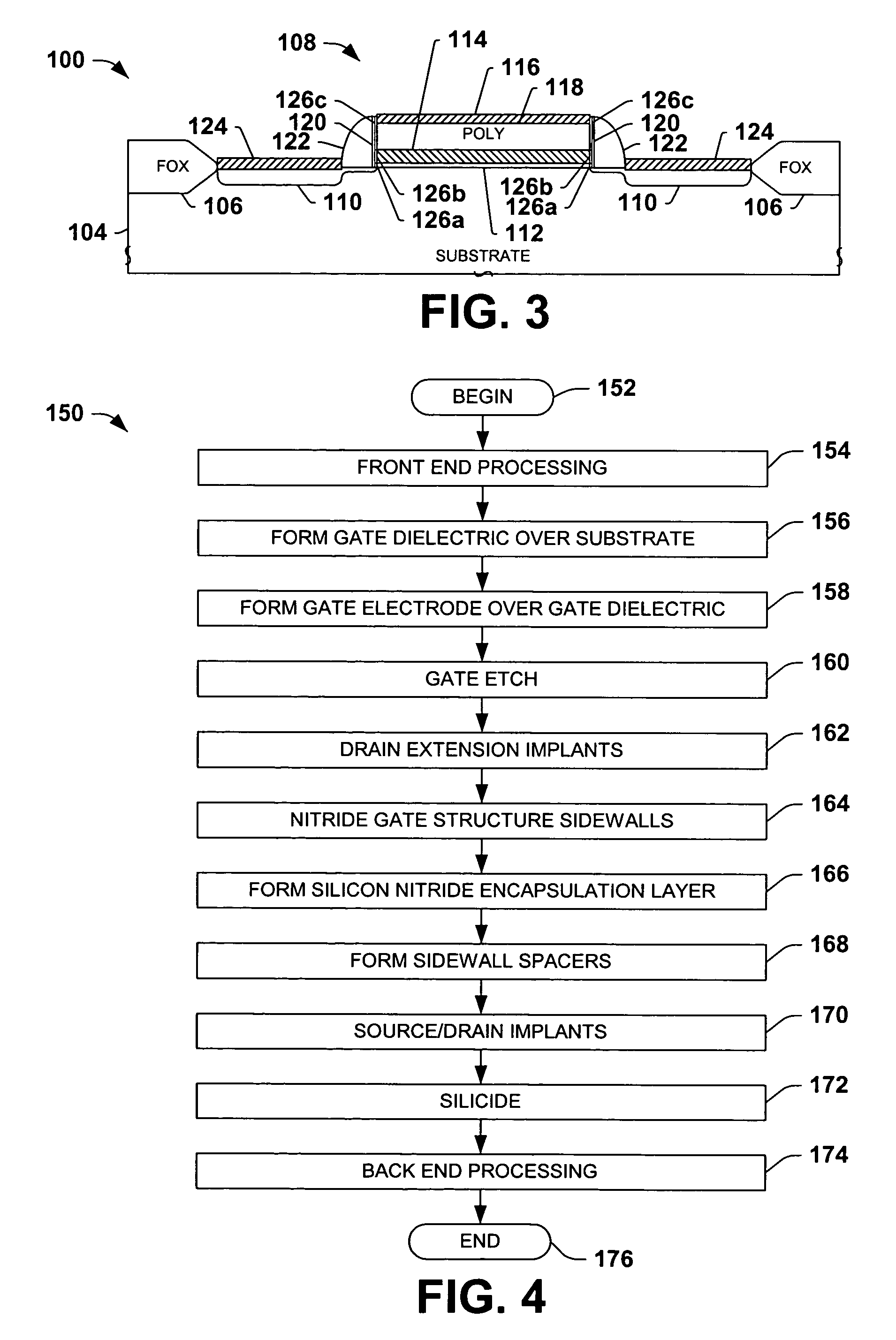

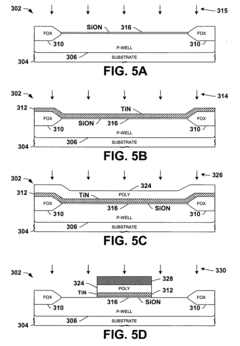

Encapsulated MOS transistor gate structures and methods for making the same

PatentInactiveUS20050079696A1

Innovation

- A silicon nitride encapsulation layer is applied to patterned gate structures, with a nitrided dielectric between the encapsulation layer and gate dielectric, and a nitrided material between the encapsulation layer and the gate electrode, using nitridation techniques like ammonia exposure or decoupled-plasma-nitridation to repair etch or implantation damage without causing oxidation.

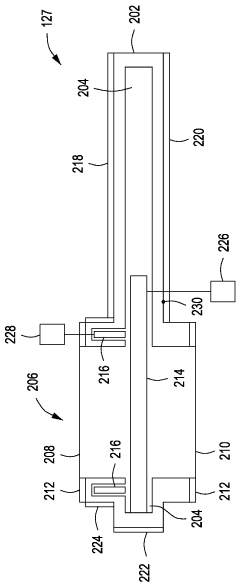

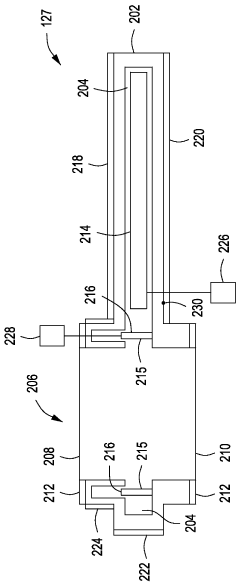

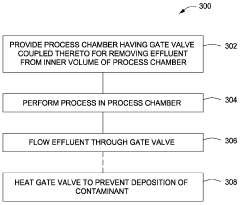

Shuttered gate valve

PatentWO2010129452A2

Innovation

- A gate valve design with a pocket and shutter mechanism that seals the pocket when open, combined with heaters to prevent deposition, ensuring contaminants do not re-enter the process environment.

Environmental Impact and Sustainability Considerations

The integration of gate valves in transient electronics systems presents significant environmental and sustainability implications that warrant careful consideration. These components, while essential for controlling fluid flow in various applications, contribute to environmental footprints throughout their lifecycle. The manufacturing processes for gate valves typically involve resource-intensive extraction of metals like stainless steel, brass, or specialized alloys, resulting in considerable carbon emissions and energy consumption.

When examining the operational phase, gate valves in transient electronics demonstrate notable sustainability advantages. Their precise flow control capabilities minimize resource wastage and energy consumption compared to less efficient alternatives. Advanced gate valve designs incorporating smart materials can further reduce operational environmental impacts by optimizing system efficiency and extending maintenance intervals, thereby decreasing the frequency of component replacement.

End-of-life management represents a critical environmental challenge for gate valves in transient electronics. The composite nature of these components—combining metals, polymers, and sometimes electronic elements—complicates recycling processes. However, emerging design approaches focusing on material selection and assembly methods are enhancing recyclability. Modular designs that facilitate disassembly and material separation show particular promise for improving recovery rates.

The transient electronics context introduces unique environmental considerations regarding gate valve applications. These systems, designed for controlled degradation or dissolution, require valve components that align with predetermined environmental breakdown pathways. Biodegradable polymers and environmentally benign metal alloys are increasingly being incorporated into gate valve designs for transient applications, reducing persistent environmental contamination risks.

Water conservation implications of gate valve technology merit specific attention. Precision flow control provided by advanced gate valves significantly reduces water wastage in cooling systems for transient electronics. Studies indicate potential water savings of 15-30% compared to conventional flow regulation methods, representing substantial conservation opportunities in water-stressed regions where electronics manufacturing often concentrates.

Regulatory frameworks worldwide are increasingly addressing the environmental aspects of components used in electronics systems. The European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations specifically impact material selection for gate valves, driving innovation toward more environmentally compatible alternatives. Similar regulatory trends are emerging in North America and Asia, creating a global shift toward sustainable valve technologies.

When examining the operational phase, gate valves in transient electronics demonstrate notable sustainability advantages. Their precise flow control capabilities minimize resource wastage and energy consumption compared to less efficient alternatives. Advanced gate valve designs incorporating smart materials can further reduce operational environmental impacts by optimizing system efficiency and extending maintenance intervals, thereby decreasing the frequency of component replacement.

End-of-life management represents a critical environmental challenge for gate valves in transient electronics. The composite nature of these components—combining metals, polymers, and sometimes electronic elements—complicates recycling processes. However, emerging design approaches focusing on material selection and assembly methods are enhancing recyclability. Modular designs that facilitate disassembly and material separation show particular promise for improving recovery rates.

The transient electronics context introduces unique environmental considerations regarding gate valve applications. These systems, designed for controlled degradation or dissolution, require valve components that align with predetermined environmental breakdown pathways. Biodegradable polymers and environmentally benign metal alloys are increasingly being incorporated into gate valve designs for transient applications, reducing persistent environmental contamination risks.

Water conservation implications of gate valve technology merit specific attention. Precision flow control provided by advanced gate valves significantly reduces water wastage in cooling systems for transient electronics. Studies indicate potential water savings of 15-30% compared to conventional flow regulation methods, representing substantial conservation opportunities in water-stressed regions where electronics manufacturing often concentrates.

Regulatory frameworks worldwide are increasingly addressing the environmental aspects of components used in electronics systems. The European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations specifically impact material selection for gate valves, driving innovation toward more environmentally compatible alternatives. Similar regulatory trends are emerging in North America and Asia, creating a global shift toward sustainable valve technologies.

Reliability Testing Methodologies for Transient Gate Valves

Reliability testing for transient gate valves requires specialized methodologies that address their unique operational characteristics in temporary electronic systems. The testing protocols must evaluate both the mechanical integrity and electronic functionality under conditions that simulate real-world deployment scenarios.

Standard reliability testing begins with accelerated life testing, where gate valves are subjected to operational cycles far exceeding normal usage patterns. For transient electronics applications, these tests must incorporate rapid deployment and dissolution phases, typically ranging from hours to weeks depending on the intended application duration.

Environmental stress screening represents a critical component of the testing methodology, exposing transient gate valves to extreme temperature variations (-40°C to 85°C), humidity cycles (10-95% RH), and mechanical vibration (10-2000 Hz). These conditions help identify potential failure modes that might emerge during field deployment in diverse environments.

Dissolution testing forms a unique aspect of transient gate valve evaluation. Controlled exposure to dissolution triggers—such as specific pH levels, enzymatic solutions, or photonic stimulation—must be carefully monitored to ensure predictable and complete dissolution within design parameters. Residue analysis following dissolution provides critical data regarding environmental impact and biocompatibility.

Functional performance testing during the active lifecycle requires precise measurement of flow characteristics, response times, and control accuracy. Specialized test rigs employing microfluidic channels with integrated sensors can capture real-time performance data at millisecond intervals, enabling detailed analysis of valve behavior under varying pressure and flow conditions.

Leak testing methodologies have been adapted specifically for transient applications, utilizing helium mass spectrometry and pressure decay testing at micro-scale. These techniques can detect leakage rates as low as 10^-9 mbar·l/s, ensuring fluid containment integrity throughout the operational lifetime.

Statistical reliability models must be developed using Weibull analysis and Monte Carlo simulations to predict failure rates and establish confidence intervals for transient gate valve performance. These models incorporate data from multiple test iterations and account for the unique degradation patterns observed in transient materials.

Non-destructive evaluation techniques, including acoustic microscopy and X-ray tomography, provide valuable insights into internal structural integrity without compromising the transient nature of the components. These methods enable detection of manufacturing defects and material inconsistencies that might affect reliability.

Standardization efforts for transient electronics testing remain in early stages, with organizations like IEEE and ASTM developing preliminary guidelines. Current best practices recommend comprehensive documentation of test methodologies and results to facilitate cross-comparison between different transient valve technologies and applications.

Standard reliability testing begins with accelerated life testing, where gate valves are subjected to operational cycles far exceeding normal usage patterns. For transient electronics applications, these tests must incorporate rapid deployment and dissolution phases, typically ranging from hours to weeks depending on the intended application duration.

Environmental stress screening represents a critical component of the testing methodology, exposing transient gate valves to extreme temperature variations (-40°C to 85°C), humidity cycles (10-95% RH), and mechanical vibration (10-2000 Hz). These conditions help identify potential failure modes that might emerge during field deployment in diverse environments.

Dissolution testing forms a unique aspect of transient gate valve evaluation. Controlled exposure to dissolution triggers—such as specific pH levels, enzymatic solutions, or photonic stimulation—must be carefully monitored to ensure predictable and complete dissolution within design parameters. Residue analysis following dissolution provides critical data regarding environmental impact and biocompatibility.

Functional performance testing during the active lifecycle requires precise measurement of flow characteristics, response times, and control accuracy. Specialized test rigs employing microfluidic channels with integrated sensors can capture real-time performance data at millisecond intervals, enabling detailed analysis of valve behavior under varying pressure and flow conditions.

Leak testing methodologies have been adapted specifically for transient applications, utilizing helium mass spectrometry and pressure decay testing at micro-scale. These techniques can detect leakage rates as low as 10^-9 mbar·l/s, ensuring fluid containment integrity throughout the operational lifetime.

Statistical reliability models must be developed using Weibull analysis and Monte Carlo simulations to predict failure rates and establish confidence intervals for transient gate valve performance. These models incorporate data from multiple test iterations and account for the unique degradation patterns observed in transient materials.

Non-destructive evaluation techniques, including acoustic microscopy and X-ray tomography, provide valuable insights into internal structural integrity without compromising the transient nature of the components. These methods enable detection of manufacturing defects and material inconsistencies that might affect reliability.

Standardization efforts for transient electronics testing remain in early stages, with organizations like IEEE and ASTM developing preliminary guidelines. Current best practices recommend comprehensive documentation of test methodologies and results to facilitate cross-comparison between different transient valve technologies and applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!