How Transient Electronics Advance in Microfluidics Technologies?

SEP 4, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Transient Electronics in Microfluidics: Background and Objectives

Transient electronics represent a revolutionary paradigm in the field of electronic devices, characterized by their ability to dissolve, disintegrate, or degrade in a controlled manner after serving their intended functions. This emerging technology has gained significant attention over the past decade, evolving from simple degradable circuits to sophisticated systems with programmable lifespans. The integration of transient electronics with microfluidics—the science of manipulating fluids at the microscale—creates unprecedented opportunities for applications in healthcare, environmental monitoring, and consumer electronics.

The historical trajectory of transient electronics began in the early 2010s with pioneering work on silicon-based dissolvable circuits. These initial developments focused primarily on biomedical applications, where implantable devices could perform diagnostic or therapeutic functions before harmlessly dissolving in bodily fluids. The field has since expanded to encompass a diverse range of materials, triggering mechanisms, and functional capabilities, with microfluidic integration representing one of the most promising directions for advancement.

Microfluidics technology has simultaneously undergone remarkable development, transitioning from simple channel-based systems to complex lab-on-a-chip platforms capable of performing multiple analytical functions. The convergence of these two technological domains addresses critical challenges in both fields: microfluidics provides controlled environments for transient electronics to operate and dissolve, while transient components enable new functionalities in microfluidic systems.

The primary objective of research in this intersection is to develop fully integrated, environmentally friendly systems that can perform sophisticated sensing, actuation, and computational tasks before disappearing without a trace. This goal encompasses several specific technical targets: enhancing the reliability and predictability of dissolution processes; expanding the functional capabilities of transient components; improving integration techniques between electronic and fluidic elements; and developing standardized fabrication methods suitable for mass production.

Current technological trends indicate accelerating progress toward multifunctional transient electronic systems with precisely controlled degradation profiles. Materials science innovations have expanded the palette of available substrates, conductors, and semiconductors that exhibit transient properties. Simultaneously, advances in microfluidic design have created platforms specifically optimized to house and interface with transient electronic components.

The potential impact of this technological convergence extends across numerous sectors. In healthcare, it promises minimally invasive diagnostic and therapeutic devices that eliminate the need for retrieval surgeries. For environmental applications, it enables widespread deployment of sensors that leave no persistent waste. Consumer electronics could benefit from reduced electronic waste through products designed to degrade after their useful lifetime.

As this field continues to evolve, interdisciplinary collaboration between electronics engineers, materials scientists, microfluidics specialists, and end-use domain experts will be essential to overcome remaining technical barriers and fully realize the transformative potential of transient electronics in microfluidic systems.

The historical trajectory of transient electronics began in the early 2010s with pioneering work on silicon-based dissolvable circuits. These initial developments focused primarily on biomedical applications, where implantable devices could perform diagnostic or therapeutic functions before harmlessly dissolving in bodily fluids. The field has since expanded to encompass a diverse range of materials, triggering mechanisms, and functional capabilities, with microfluidic integration representing one of the most promising directions for advancement.

Microfluidics technology has simultaneously undergone remarkable development, transitioning from simple channel-based systems to complex lab-on-a-chip platforms capable of performing multiple analytical functions. The convergence of these two technological domains addresses critical challenges in both fields: microfluidics provides controlled environments for transient electronics to operate and dissolve, while transient components enable new functionalities in microfluidic systems.

The primary objective of research in this intersection is to develop fully integrated, environmentally friendly systems that can perform sophisticated sensing, actuation, and computational tasks before disappearing without a trace. This goal encompasses several specific technical targets: enhancing the reliability and predictability of dissolution processes; expanding the functional capabilities of transient components; improving integration techniques between electronic and fluidic elements; and developing standardized fabrication methods suitable for mass production.

Current technological trends indicate accelerating progress toward multifunctional transient electronic systems with precisely controlled degradation profiles. Materials science innovations have expanded the palette of available substrates, conductors, and semiconductors that exhibit transient properties. Simultaneously, advances in microfluidic design have created platforms specifically optimized to house and interface with transient electronic components.

The potential impact of this technological convergence extends across numerous sectors. In healthcare, it promises minimally invasive diagnostic and therapeutic devices that eliminate the need for retrieval surgeries. For environmental applications, it enables widespread deployment of sensors that leave no persistent waste. Consumer electronics could benefit from reduced electronic waste through products designed to degrade after their useful lifetime.

As this field continues to evolve, interdisciplinary collaboration between electronics engineers, materials scientists, microfluidics specialists, and end-use domain experts will be essential to overcome remaining technical barriers and fully realize the transformative potential of transient electronics in microfluidic systems.

Market Applications and Demand Analysis for Dissolvable Microfluidic Systems

The global market for dissolvable microfluidic systems is experiencing significant growth, driven by increasing demand for sustainable healthcare solutions and environmentally friendly diagnostic tools. Current market analysis indicates that the transient electronics sector within microfluidics is expanding at a compound annual growth rate exceeding 15%, with particularly strong adoption in medical diagnostics and environmental monitoring applications.

Healthcare applications represent the largest market segment for dissolvable microfluidic systems. The demand for implantable medical devices that can perform their function and then safely dissolve without requiring surgical removal has created a substantial market opportunity. These systems address critical needs in post-operative monitoring, controlled drug delivery, and temporary diagnostic applications where device retrieval is challenging or potentially harmful to patients.

Environmental monitoring represents another rapidly growing application area. Dissolvable microfluidic systems enable the deployment of distributed sensor networks that can collect data and then harmlessly degrade, eliminating the need for sensor retrieval in remote or inaccessible locations. This capability is particularly valuable for water quality monitoring, soil analysis, and ecological studies in sensitive environments.

Consumer electronics manufacturers are increasingly exploring biodegradable microfluidic components as part of their sustainability initiatives. The market for environmentally responsible electronics is expanding as consumers become more environmentally conscious and regulatory pressures for reducing electronic waste intensify. Dissolvable microfluidic systems offer a promising solution for components in temporary-use consumer devices.

Agricultural applications represent an emerging market with significant growth potential. Smart farming initiatives are driving demand for dissolvable soil sensors and monitoring systems that can track moisture levels, nutrient content, and other critical parameters without leaving persistent electronic waste in agricultural environments.

Market barriers include concerns about reliability, performance consistency, and cost-effectiveness compared to conventional microfluidic systems. Current dissolvable systems typically command premium pricing due to specialized materials and manufacturing processes, limiting widespread adoption in price-sensitive markets.

Regional analysis shows North America and Europe leading in research and development activities, while Asia-Pacific represents the fastest-growing market for commercial applications. This regional distribution reflects differences in healthcare infrastructure, environmental regulations, and industrial development priorities.

The demand forecast indicates accelerating adoption as manufacturing processes mature and costs decrease. Industry experts project that as production scales up and material science advances continue, dissolvable microfluidic systems will achieve price parity with conventional alternatives in specific application areas within the next 3-5 years, substantially expanding their addressable market.

Healthcare applications represent the largest market segment for dissolvable microfluidic systems. The demand for implantable medical devices that can perform their function and then safely dissolve without requiring surgical removal has created a substantial market opportunity. These systems address critical needs in post-operative monitoring, controlled drug delivery, and temporary diagnostic applications where device retrieval is challenging or potentially harmful to patients.

Environmental monitoring represents another rapidly growing application area. Dissolvable microfluidic systems enable the deployment of distributed sensor networks that can collect data and then harmlessly degrade, eliminating the need for sensor retrieval in remote or inaccessible locations. This capability is particularly valuable for water quality monitoring, soil analysis, and ecological studies in sensitive environments.

Consumer electronics manufacturers are increasingly exploring biodegradable microfluidic components as part of their sustainability initiatives. The market for environmentally responsible electronics is expanding as consumers become more environmentally conscious and regulatory pressures for reducing electronic waste intensify. Dissolvable microfluidic systems offer a promising solution for components in temporary-use consumer devices.

Agricultural applications represent an emerging market with significant growth potential. Smart farming initiatives are driving demand for dissolvable soil sensors and monitoring systems that can track moisture levels, nutrient content, and other critical parameters without leaving persistent electronic waste in agricultural environments.

Market barriers include concerns about reliability, performance consistency, and cost-effectiveness compared to conventional microfluidic systems. Current dissolvable systems typically command premium pricing due to specialized materials and manufacturing processes, limiting widespread adoption in price-sensitive markets.

Regional analysis shows North America and Europe leading in research and development activities, while Asia-Pacific represents the fastest-growing market for commercial applications. This regional distribution reflects differences in healthcare infrastructure, environmental regulations, and industrial development priorities.

The demand forecast indicates accelerating adoption as manufacturing processes mature and costs decrease. Industry experts project that as production scales up and material science advances continue, dissolvable microfluidic systems will achieve price parity with conventional alternatives in specific application areas within the next 3-5 years, substantially expanding their addressable market.

Current Technological Landscape and Challenges in Transient Microfluidics

Transient microfluidics represents a convergence of two rapidly evolving fields: transient electronics and microfluidic technologies. The current technological landscape shows significant advancements globally, with research centers in North America, Europe, and East Asia leading development efforts. The University of Illinois, Northwestern University, and KAIST have established themselves as pioneers in transient electronics integration with microfluidic platforms. Commercial interest has grown substantially since 2018, with major medical device manufacturers investing in research partnerships.

The fundamental architecture of transient microfluidic systems typically consists of biodegradable polymers (such as poly(lactic-co-glycolic acid) or silk fibroin) as structural materials, water-soluble metals (magnesium, zinc, or iron) for conductive components, and silicon-based semiconductors designed for controlled dissolution. Recent innovations have introduced stimuli-responsive materials that can dissolve or degrade upon specific triggers including pH changes, enzymatic activity, or electromagnetic stimulation.

Despite promising developments, several significant technical challenges persist in the field. Material compatibility remains a primary concern, as the integration of transient electronic components with fluid-handling structures often creates interface stability issues. Current transient materials exhibit limited functionality compared to their conventional counterparts, with lower electrical conductivity, reduced mechanical strength, and restricted operational temperature ranges.

Controlled degradation timing presents another major hurdle. Achieving precise dissolution rates in varied physiological environments proves difficult, with current systems showing significant variability in degradation profiles. This unpredictability limits applications requiring specific operational lifetimes followed by complete dissolution. Furthermore, encapsulation technologies that can protect sensitive components during operation while allowing controlled degradation afterward remain underdeveloped.

Manufacturing scalability constitutes a substantial barrier to widespread adoption. Current fabrication methods for transient microfluidic devices rely heavily on laboratory-scale techniques that are difficult to translate to mass production. The integration of multiple material types with different degradation properties requires complex multi-step fabrication processes that are not easily automated or standardized.

Biocompatibility and safety concerns persist, particularly regarding degradation byproducts in biological environments. While individual components may demonstrate acceptable biocompatibility, their degradation products and potential synergistic toxicity effects remain inadequately characterized. Regulatory pathways for these novel devices are still evolving, creating uncertainty for commercial development.

Power supply integration represents another significant challenge, as conventional batteries are incompatible with the transient paradigm. Current solutions utilizing biodegradable batteries or wireless power transfer have limited energy density and operational duration, restricting the functionality of active transient microfluidic systems.

The fundamental architecture of transient microfluidic systems typically consists of biodegradable polymers (such as poly(lactic-co-glycolic acid) or silk fibroin) as structural materials, water-soluble metals (magnesium, zinc, or iron) for conductive components, and silicon-based semiconductors designed for controlled dissolution. Recent innovations have introduced stimuli-responsive materials that can dissolve or degrade upon specific triggers including pH changes, enzymatic activity, or electromagnetic stimulation.

Despite promising developments, several significant technical challenges persist in the field. Material compatibility remains a primary concern, as the integration of transient electronic components with fluid-handling structures often creates interface stability issues. Current transient materials exhibit limited functionality compared to their conventional counterparts, with lower electrical conductivity, reduced mechanical strength, and restricted operational temperature ranges.

Controlled degradation timing presents another major hurdle. Achieving precise dissolution rates in varied physiological environments proves difficult, with current systems showing significant variability in degradation profiles. This unpredictability limits applications requiring specific operational lifetimes followed by complete dissolution. Furthermore, encapsulation technologies that can protect sensitive components during operation while allowing controlled degradation afterward remain underdeveloped.

Manufacturing scalability constitutes a substantial barrier to widespread adoption. Current fabrication methods for transient microfluidic devices rely heavily on laboratory-scale techniques that are difficult to translate to mass production. The integration of multiple material types with different degradation properties requires complex multi-step fabrication processes that are not easily automated or standardized.

Biocompatibility and safety concerns persist, particularly regarding degradation byproducts in biological environments. While individual components may demonstrate acceptable biocompatibility, their degradation products and potential synergistic toxicity effects remain inadequately characterized. Regulatory pathways for these novel devices are still evolving, creating uncertainty for commercial development.

Power supply integration represents another significant challenge, as conventional batteries are incompatible with the transient paradigm. Current solutions utilizing biodegradable batteries or wireless power transfer have limited energy density and operational duration, restricting the functionality of active transient microfluidic systems.

Current Implementation Approaches for Transient Microfluidic Devices

01 Biodegradable and dissolvable electronic components

Transient electronics that are designed to dissolve or degrade after a predetermined period or under specific environmental conditions. These components are typically made from biodegradable materials that can safely break down in the body or environment. This technology is particularly useful for medical implants, environmental sensors, and temporary electronic devices that eliminate the need for retrieval or long-term environmental impact.- Biodegradable and dissolvable electronic components: Transient electronics that are designed to dissolve or degrade after a predetermined period or under specific environmental conditions. These electronics use biodegradable substrates and water-soluble materials that can safely break down in the body or environment. This technology is particularly valuable for medical implants that don't require permanent placement and environmental sensors that eliminate the need for retrieval.

- Thermal management systems for electronics: Advanced cooling and thermal regulation systems designed for transient electronic operations. These systems manage heat dissipation during high-intensity, short-duration electronic operations to prevent overheating and component failure. The technologies include specialized heat sinks, thermal interface materials, and cooling mechanisms that can handle rapid temperature fluctuations characteristic of transient electronic operations.

- Power management for intermittent electronic systems: Power supply and management solutions specifically designed for transient electronic applications. These systems optimize energy usage during brief operational periods and include rapid charge/discharge capabilities, energy harvesting technologies, and sophisticated power control circuits. The focus is on providing reliable power for short-duration operations while minimizing energy consumption during dormant periods.

- Security features for temporary electronic devices: Security mechanisms designed specifically for transient electronic systems that operate for limited time periods. These include self-destruct capabilities, data wiping protocols, encryption systems for temporary data, and authentication methods for short-term access. Such security features ensure that sensitive information remains protected during the operational lifetime and is completely eliminated when the device's purpose is fulfilled.

- Signal processing for transient electronic operations: Specialized signal processing techniques and circuits designed to handle rapidly changing electronic signals in transient applications. These systems can quickly acquire, process, and respond to signals during brief operational windows. The technology includes high-speed analog-to-digital converters, efficient signal conditioning circuits, and algorithms optimized for processing data from short-duration events.

02 Thermal management systems for transient electronics

Advanced cooling and heat dissipation solutions specifically designed for transient electronic systems. These thermal management approaches address the unique challenges of temporary electronic devices, including flexible heat sinks, phase-change materials, and specialized cooling structures that maintain optimal operating temperatures while preserving the transient nature of the electronics. Effective thermal management extends the functional lifetime of transient devices during their intended operation period.Expand Specific Solutions03 Power supply solutions for transient electronic devices

Specialized power sources designed for transient electronic applications, including biodegradable batteries, energy harvesting systems, and temporary power storage solutions. These power systems are engineered to provide sufficient energy for the intended operational lifetime of the transient device while maintaining compatibility with the overall degradation or dissolution timeline. The power components may utilize environmentally friendly materials that break down alongside the electronic elements.Expand Specific Solutions04 Security applications of transient electronics

Implementation of transient electronic technologies for security and data protection purposes. These applications include self-destructing data storage, tamper-evident electronic seals, and hardware security modules designed to render themselves inoperable under specific conditions. Transient security electronics provide enhanced protection for sensitive information by physically destroying the storage medium or processing components when triggered by unauthorized access attempts or predetermined conditions.Expand Specific Solutions05 Testing and reliability assessment methods for transient electronics

Specialized techniques and methodologies for evaluating the performance, reliability, and dissolution characteristics of transient electronic systems. These methods include accelerated aging tests, environmental exposure protocols, and functional verification under various conditions. Testing approaches must balance the need to verify proper operation during the intended functional period while also confirming appropriate degradation or dissolution behavior after the designated lifetime has elapsed.Expand Specific Solutions

Leading Research Groups and Companies in Transient Microfluidics

Transient electronics in microfluidics is evolving rapidly, currently transitioning from early development to commercial application phases. The market is projected to grow significantly, reaching approximately $4-5 billion by 2025, driven by healthcare and environmental monitoring applications. Technologically, companies demonstrate varying maturity levels: established players like Agilent Technologies and BOE Technology Group lead with commercial solutions, while academic institutions (Duke University, Tsinghua University) focus on fundamental research. Philips and Canon are leveraging their expertise to develop integrated systems, while startups and specialized firms like Caliper Life Sciences are creating innovative microfluidic platforms. The convergence of transient materials science with microfluidic technologies is accelerating development of dissolvable, degradable sensing and diagnostic systems.

Agilent Technologies, Inc.

Technical Solution: Agilent Technologies has developed advanced microfluidic platforms that integrate transient electronic components for precise biological sample analysis. Their technology utilizes dissolvable metallic traces (primarily magnesium, zinc, and silicon) embedded within biodegradable polymers to create sensors that can operate for predetermined periods before harmlessly dissolving. These systems incorporate lab-on-a-chip functionality with programmable dissolution rates controlled through environmental triggers such as pH changes or specific enzymatic activity. Agilent's microfluidic chips feature integrated transient electronics for real-time monitoring of cellular responses, fluid dynamics, and chemical reactions with minimal sample volumes (nanoliter scale). Their platforms employ specialized encapsulation techniques using silk fibroin and poly(lactic-co-glycolic acid) to precisely control the operational lifetime of electronic components, allowing for timed-release applications in diagnostic and therapeutic settings.

Strengths: Industry-leading precision in controlled dissolution timing; exceptional integration capabilities with existing laboratory workflows; comprehensive quality control systems ensuring reproducible results. Weaknesses: Higher cost compared to conventional microfluidics; requires specialized handling protocols; limited shelf-life for certain transient components.

Tsinghua University

Technical Solution: Tsinghua University has developed a groundbreaking transient electronics platform for microfluidic applications focused on environmental monitoring and biomedical diagnostics. Their approach utilizes water-soluble silicon nanomembranes as semiconductor materials combined with magnesium electrodes and calcium oxide dielectrics to create fully functional yet completely dissolvable electronic systems. These components are integrated into polydimethylsiloxane (PDMS) microfluidic channels using a novel transfer printing technique that ensures precise alignment and functionality. The university's research team has demonstrated microfluidic chips with embedded transient flow sensors, temperature monitors, and electrochemical detectors that operate reliably for predetermined periods (ranging from minutes to weeks) before dissolving into non-toxic byproducts. Their most recent innovation incorporates trigger mechanisms that can accelerate dissolution upon exposure to specific biochemical markers or external stimuli such as light or magnetic fields, enabling smart responsive systems for targeted drug delivery and environmental remediation applications.

Strengths: Cutting-edge research in dissolution chemistry and materials science; innovative trigger mechanisms for controlled degradation; strong focus on environmental sustainability. Weaknesses: Technology remains primarily in research phase; scalability challenges for mass production; dissolution byproducts may require further optimization for certain applications.

Key Patents and Scientific Breakthroughs in Dissolvable Microelectronics

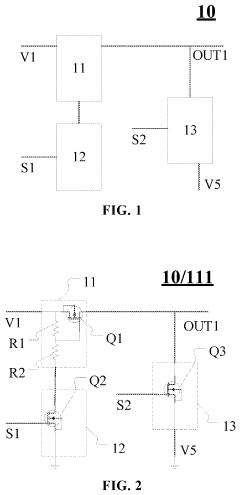

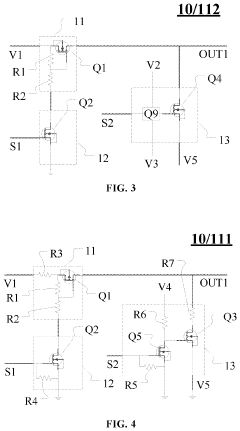

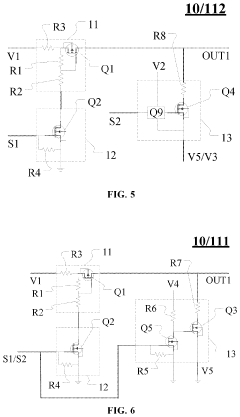

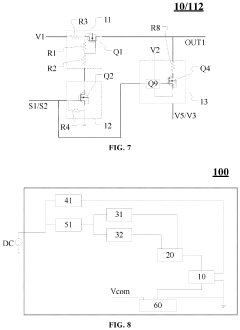

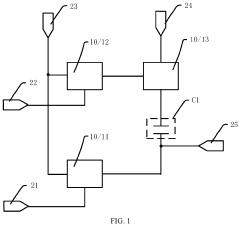

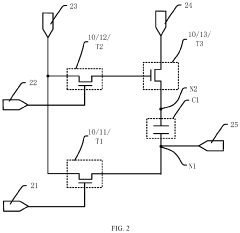

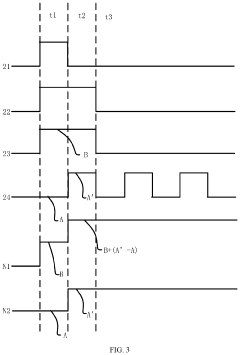

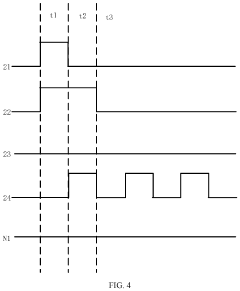

Microfluidic apparatus, and drive circuit and drive method thereof

PatentActiveUS20230166258A1

Innovation

- A new drive circuit is designed incorporating switch units with MOS transistors and resistors, and FPGA output signals are used to control these units, enabling output signals of up to 200V or more, ensuring sufficient voltage for liquid droplet movement and manipulation.

Driving circuit and driving method thereof, and electrowetting panel and driving method thereof

PatentActiveUS11366306B2

Innovation

- A driving circuit with a voltage-boosting unit, comprising multiple modules and a capacitor, that enhances the electric potential output by controlling signal transmission periods to achieve high voltage levels, allowing for efficient droplet movement and reduced signal channel requirements.

Biocompatibility and Safety Considerations for Implantable Applications

The integration of transient electronics with microfluidic technologies presents significant biocompatibility and safety challenges when considering implantable applications. These devices, designed to dissolve or degrade after fulfilling their function, must meet stringent biocompatibility requirements to prevent adverse tissue reactions, inflammation, or immune responses when placed within the human body.

Material selection represents a critical factor in ensuring biocompatibility. Silicon, magnesium, zinc, and various biodegradable polymers have emerged as promising materials for transient electronic components. These materials must undergo rigorous testing to verify their degradation products do not cause toxicity or accumulate in vital organs. Recent studies have demonstrated that magnesium-based conductors and silicon-based semiconductors can safely dissolve in physiological environments, producing byproducts that remain below harmful concentration thresholds.

The degradation kinetics of transient electronic systems must be precisely controlled to match the intended therapeutic timeline. Premature dissolution could lead to device failure, while delayed degradation might cause prolonged foreign body responses. Encapsulation strategies using biocompatible polymers like poly(lactic-co-glycolic acid) (PLGA) and silk fibroin have shown promise in modulating dissolution rates while maintaining tissue compatibility.

Sterilization compatibility presents another significant challenge. Traditional sterilization methods such as ethylene oxide exposure, gamma irradiation, or autoclave processing may compromise the integrity or functionality of sensitive transient electronic components. Novel sterilization approaches that preserve device performance while ensuring sterility are actively being developed, including low-temperature hydrogen peroxide plasma techniques and supercritical CO2 sterilization.

Long-term safety monitoring remains essential, as the complete biological effects of degrading electronics require thorough investigation. Researchers are developing advanced imaging techniques and biomarkers to track material degradation in vivo without requiring device retrieval. These monitoring systems help ensure that dissolution products are effectively cleared through natural metabolic pathways rather than accumulating in tissues.

Regulatory frameworks for transient implantable electronics are still evolving. The FDA and similar international bodies are working to establish appropriate testing protocols and safety standards specific to this emerging technology class. Manufacturers must navigate complex regulatory pathways that address both the initial functionality of the device and its safe degradation profile over time.

The intersection of microfluidics with transient electronics introduces additional considerations regarding fluid-tissue interfaces and potential leakage of degradation byproducts. Hermetic sealing technologies and biocompatible microfluidic channels are being engineered to prevent unintended fluid exchange between device components and surrounding tissues during both operation and degradation phases.

Material selection represents a critical factor in ensuring biocompatibility. Silicon, magnesium, zinc, and various biodegradable polymers have emerged as promising materials for transient electronic components. These materials must undergo rigorous testing to verify their degradation products do not cause toxicity or accumulate in vital organs. Recent studies have demonstrated that magnesium-based conductors and silicon-based semiconductors can safely dissolve in physiological environments, producing byproducts that remain below harmful concentration thresholds.

The degradation kinetics of transient electronic systems must be precisely controlled to match the intended therapeutic timeline. Premature dissolution could lead to device failure, while delayed degradation might cause prolonged foreign body responses. Encapsulation strategies using biocompatible polymers like poly(lactic-co-glycolic acid) (PLGA) and silk fibroin have shown promise in modulating dissolution rates while maintaining tissue compatibility.

Sterilization compatibility presents another significant challenge. Traditional sterilization methods such as ethylene oxide exposure, gamma irradiation, or autoclave processing may compromise the integrity or functionality of sensitive transient electronic components. Novel sterilization approaches that preserve device performance while ensuring sterility are actively being developed, including low-temperature hydrogen peroxide plasma techniques and supercritical CO2 sterilization.

Long-term safety monitoring remains essential, as the complete biological effects of degrading electronics require thorough investigation. Researchers are developing advanced imaging techniques and biomarkers to track material degradation in vivo without requiring device retrieval. These monitoring systems help ensure that dissolution products are effectively cleared through natural metabolic pathways rather than accumulating in tissues.

Regulatory frameworks for transient implantable electronics are still evolving. The FDA and similar international bodies are working to establish appropriate testing protocols and safety standards specific to this emerging technology class. Manufacturers must navigate complex regulatory pathways that address both the initial functionality of the device and its safe degradation profile over time.

The intersection of microfluidics with transient electronics introduces additional considerations regarding fluid-tissue interfaces and potential leakage of degradation byproducts. Hermetic sealing technologies and biocompatible microfluidic channels are being engineered to prevent unintended fluid exchange between device components and surrounding tissues during both operation and degradation phases.

Environmental Impact and Sustainability of Transient Electronic Materials

The environmental impact of transient electronics in microfluidic applications represents a critical consideration as these technologies advance. Traditional electronic waste poses significant environmental challenges, with millions of tons discarded annually, contributing to pollution and resource depletion. Transient electronics offer a promising alternative through their ability to dissolve, degrade, or disintegrate under specific environmental conditions or triggers, substantially reducing e-waste accumulation.

Materials selection plays a fundamental role in determining the environmental footprint of transient electronic systems. Silicon-based substrates, magnesium conductors, silk fibroin, and poly(lactic-co-glycolic acid) (PLGA) represent biodegradable alternatives that minimize environmental persistence. Recent advancements have focused on water-soluble polymers and naturally derived materials that decompose into non-toxic byproducts, addressing concerns about potential ecosystem contamination.

Life cycle assessment (LCA) studies indicate that transient electronics can reduce environmental impact by up to 60% compared to conventional electronics when considering manufacturing, use, and end-of-life phases. However, challenges remain regarding the energy-intensive production processes for certain transient materials, which may partially offset their end-of-life benefits.

The integration of transient electronics with microfluidic technologies creates unique sustainability opportunities. Microfluidic platforms enable precise control over dissolution rates and degradation pathways, allowing for optimized material recovery and minimized environmental release of potentially harmful components. Lab-on-a-chip devices incorporating transient elements can be designed for single-use diagnostic applications with minimal waste generation.

Regulatory frameworks are evolving to address these novel materials, with organizations like the EPA and EU developing guidelines for biodegradable electronics. Industry standards for testing degradation rates, byproduct toxicity, and environmental persistence are being established to ensure consistent sustainability claims and performance.

Future research directions focus on developing fully closed-loop systems where transient electronic materials can be recaptured within microfluidic devices for reprocessing or safe disposal. Innovations in green chemistry approaches are yielding new transient materials with improved functional lifespans followed by complete degradation, balancing performance requirements with environmental considerations.

The economic viability of sustainable transient electronics remains a challenge, with current production costs exceeding those of conventional electronics. However, as manufacturing scales and regulatory pressures regarding e-waste increase, the cost-benefit equation is shifting favorably toward these environmentally responsible alternatives.

Materials selection plays a fundamental role in determining the environmental footprint of transient electronic systems. Silicon-based substrates, magnesium conductors, silk fibroin, and poly(lactic-co-glycolic acid) (PLGA) represent biodegradable alternatives that minimize environmental persistence. Recent advancements have focused on water-soluble polymers and naturally derived materials that decompose into non-toxic byproducts, addressing concerns about potential ecosystem contamination.

Life cycle assessment (LCA) studies indicate that transient electronics can reduce environmental impact by up to 60% compared to conventional electronics when considering manufacturing, use, and end-of-life phases. However, challenges remain regarding the energy-intensive production processes for certain transient materials, which may partially offset their end-of-life benefits.

The integration of transient electronics with microfluidic technologies creates unique sustainability opportunities. Microfluidic platforms enable precise control over dissolution rates and degradation pathways, allowing for optimized material recovery and minimized environmental release of potentially harmful components. Lab-on-a-chip devices incorporating transient elements can be designed for single-use diagnostic applications with minimal waste generation.

Regulatory frameworks are evolving to address these novel materials, with organizations like the EPA and EU developing guidelines for biodegradable electronics. Industry standards for testing degradation rates, byproduct toxicity, and environmental persistence are being established to ensure consistent sustainability claims and performance.

Future research directions focus on developing fully closed-loop systems where transient electronic materials can be recaptured within microfluidic devices for reprocessing or safe disposal. Innovations in green chemistry approaches are yielding new transient materials with improved functional lifespans followed by complete degradation, balancing performance requirements with environmental considerations.

The economic viability of sustainable transient electronics remains a challenge, with current production costs exceeding those of conventional electronics. However, as manufacturing scales and regulatory pressures regarding e-waste increase, the cost-benefit equation is shifting favorably toward these environmentally responsible alternatives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!