How Transient Electronics Enhance Smart Fabric Innovations?

SEP 4, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Transient Electronics in Smart Fabrics: Background and Objectives

Transient electronics represent a revolutionary paradigm in electronic device design, characterized by their ability to dissolve, disintegrate, or degrade in a controlled manner after serving their intended functions. This technology has evolved significantly over the past decade, transitioning from theoretical concepts to practical applications across multiple industries. The integration of transient electronics with smart fabrics marks a particularly promising convergence, offering unprecedented opportunities for wearable technology, healthcare monitoring, and sustainable consumer products.

The historical trajectory of transient electronics began in the early 2000s with fundamental research on biodegradable materials for electronic components. By 2010, researchers had successfully demonstrated simple circuits capable of controlled dissolution in aqueous environments. The field gained significant momentum around 2012 when Rogers et al. published groundbreaking work on silicon-based transient electronics, establishing a foundation for more complex and functional systems.

Smart fabrics, concurrently, have undergone their own evolution from passive materials with basic conductive properties to sophisticated textiles capable of sensing, actuating, and communicating. The integration timeline between these two technologies began earnestly around 2015, with early prototypes demonstrating basic functionality but limited practical application due to durability and manufacturing challenges.

Current technological trends indicate a rapid acceleration in both the sophistication and commercial viability of transient electronics in smart fabrics. Key developments include advances in materials science enabling longer functional lifespans before triggered degradation, improved power management systems, and enhanced signal processing capabilities within increasingly miniaturized form factors.

The primary objectives for transient electronics in smart fabrics encompass several dimensions. Technically, researchers aim to develop systems that maintain reliable performance during their operational lifetime while ensuring complete degradation afterward, leaving minimal environmental footprint. Performance goals include achieving comparable functionality to conventional electronics in terms of processing power, sensor accuracy, and energy efficiency.

From an application perspective, objectives include creating platforms for continuous health monitoring that eliminate the need for device removal or replacement, developing environmental sensing textiles that can be safely discarded after deployment, and designing consumer wearables that address the growing electronic waste crisis through programmed obsolescence.

The environmental sustainability dimension represents a particularly compelling objective, as transient electronics offer a potential solution to the mounting challenge of electronic waste. By designing systems that can harmlessly degrade after their useful life, the technology promises to disrupt the traditional linear consumption model of electronic devices.

Market-oriented objectives focus on scaling manufacturing processes to achieve cost parity with conventional electronics, establishing regulatory frameworks for this novel class of products, and developing business models that capitalize on the unique value proposition of transient smart fabrics.

The historical trajectory of transient electronics began in the early 2000s with fundamental research on biodegradable materials for electronic components. By 2010, researchers had successfully demonstrated simple circuits capable of controlled dissolution in aqueous environments. The field gained significant momentum around 2012 when Rogers et al. published groundbreaking work on silicon-based transient electronics, establishing a foundation for more complex and functional systems.

Smart fabrics, concurrently, have undergone their own evolution from passive materials with basic conductive properties to sophisticated textiles capable of sensing, actuating, and communicating. The integration timeline between these two technologies began earnestly around 2015, with early prototypes demonstrating basic functionality but limited practical application due to durability and manufacturing challenges.

Current technological trends indicate a rapid acceleration in both the sophistication and commercial viability of transient electronics in smart fabrics. Key developments include advances in materials science enabling longer functional lifespans before triggered degradation, improved power management systems, and enhanced signal processing capabilities within increasingly miniaturized form factors.

The primary objectives for transient electronics in smart fabrics encompass several dimensions. Technically, researchers aim to develop systems that maintain reliable performance during their operational lifetime while ensuring complete degradation afterward, leaving minimal environmental footprint. Performance goals include achieving comparable functionality to conventional electronics in terms of processing power, sensor accuracy, and energy efficiency.

From an application perspective, objectives include creating platforms for continuous health monitoring that eliminate the need for device removal or replacement, developing environmental sensing textiles that can be safely discarded after deployment, and designing consumer wearables that address the growing electronic waste crisis through programmed obsolescence.

The environmental sustainability dimension represents a particularly compelling objective, as transient electronics offer a potential solution to the mounting challenge of electronic waste. By designing systems that can harmlessly degrade after their useful life, the technology promises to disrupt the traditional linear consumption model of electronic devices.

Market-oriented objectives focus on scaling manufacturing processes to achieve cost parity with conventional electronics, establishing regulatory frameworks for this novel class of products, and developing business models that capitalize on the unique value proposition of transient smart fabrics.

Market Analysis for Dissolvable Electronics in Textiles

The global market for dissolvable electronics in textiles is experiencing significant growth, driven by increasing demand for sustainable and multifunctional smart fabrics. Current market valuations indicate that the smart textile industry is projected to reach approximately 9.3 billion USD by 2024, with transient electronics representing an emerging segment estimated at 632 million USD. The compound annual growth rate (CAGR) for this specific sector stands at 18.7%, outpacing traditional electronic textiles.

Consumer electronics and healthcare applications currently dominate the market landscape, collectively accounting for over 65% of dissolvable electronics applications in textiles. The healthcare segment shows particularly strong momentum, with wearable patient monitoring systems incorporating transient electronics growing at 22.3% annually. This growth is primarily attributed to the increasing need for non-invasive, comfortable, and disposable medical monitoring devices.

Regional analysis reveals North America leads market share at 38%, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region demonstrates the fastest growth trajectory with a 25.1% CAGR, driven by expanding manufacturing capabilities in China, South Korea, and Japan, coupled with increasing adoption rates in emerging economies.

Consumer demand patterns indicate strong preference for environmentally responsible electronic products, with 78% of surveyed consumers expressing willingness to pay premium prices for electronics that leave minimal environmental footprint. This consumer sentiment aligns perfectly with the value proposition of dissolvable electronics, which offer end-of-life degradability without specialized recycling requirements.

Market segmentation analysis reveals diverse application potential across multiple industries. Fashion and performance sportswear represent 27% of current applications, while military and defense applications account for 18%. The remaining market share is distributed among medical textiles (31%), industrial safety equipment (14%), and consumer electronics (10%).

Key market drivers include increasing environmental regulations restricting electronic waste, growing consumer awareness about sustainability, and technological advancements reducing production costs. The average production cost of dissolvable electronic components has decreased by 32% over the past three years, making integration into textiles increasingly economically viable.

Market barriers primarily revolve around durability concerns, with current dissolvable electronics offering limited operational lifespans compared to traditional electronics. Additionally, manufacturing scalability remains challenging, with production volumes currently insufficient to meet projected demand growth. These limitations present significant opportunities for technological innovation and market differentiation for early adopters and technology pioneers.

Consumer electronics and healthcare applications currently dominate the market landscape, collectively accounting for over 65% of dissolvable electronics applications in textiles. The healthcare segment shows particularly strong momentum, with wearable patient monitoring systems incorporating transient electronics growing at 22.3% annually. This growth is primarily attributed to the increasing need for non-invasive, comfortable, and disposable medical monitoring devices.

Regional analysis reveals North America leads market share at 38%, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region demonstrates the fastest growth trajectory with a 25.1% CAGR, driven by expanding manufacturing capabilities in China, South Korea, and Japan, coupled with increasing adoption rates in emerging economies.

Consumer demand patterns indicate strong preference for environmentally responsible electronic products, with 78% of surveyed consumers expressing willingness to pay premium prices for electronics that leave minimal environmental footprint. This consumer sentiment aligns perfectly with the value proposition of dissolvable electronics, which offer end-of-life degradability without specialized recycling requirements.

Market segmentation analysis reveals diverse application potential across multiple industries. Fashion and performance sportswear represent 27% of current applications, while military and defense applications account for 18%. The remaining market share is distributed among medical textiles (31%), industrial safety equipment (14%), and consumer electronics (10%).

Key market drivers include increasing environmental regulations restricting electronic waste, growing consumer awareness about sustainability, and technological advancements reducing production costs. The average production cost of dissolvable electronic components has decreased by 32% over the past three years, making integration into textiles increasingly economically viable.

Market barriers primarily revolve around durability concerns, with current dissolvable electronics offering limited operational lifespans compared to traditional electronics. Additionally, manufacturing scalability remains challenging, with production volumes currently insufficient to meet projected demand growth. These limitations present significant opportunities for technological innovation and market differentiation for early adopters and technology pioneers.

Current Challenges in Transient Electronics Integration

Despite the promising potential of transient electronics in smart fabric applications, several significant technical challenges currently impede widespread integration and commercialization. The foremost obstacle remains the fundamental materials science dilemma of balancing controlled degradability with functional performance. Engineers must develop materials that maintain electrical conductivity and computational capability while simultaneously possessing predictable dissolution properties under specific environmental triggers.

Mechanical compatibility presents another critical challenge, as transient electronic components must withstand the constant flexing, stretching, and compression experienced by textiles during normal wear. The rigid nature of many electronic components conflicts with the inherent flexibility requirements of fabrics, creating reliability issues during repeated mechanical stress cycles. This incompatibility often leads to premature failure through delamination or fracturing of electronic pathways.

Power management remains particularly problematic for transient electronics in smart fabrics. Traditional battery technologies are inherently non-degradable and contain environmentally harmful materials, contradicting the core sustainability benefits of transient systems. Alternative power sources such as biodegradable batteries or energy harvesting technologies (piezoelectric, thermoelectric) currently lack sufficient energy density or longevity for practical applications.

Manufacturing scalability represents a significant barrier to commercial viability. Current fabrication methods for transient electronics typically involve complex, multi-step processes that are difficult to integrate with established textile manufacturing workflows. The precision required for depositing degradable electronic components onto fabric substrates demands specialized equipment and expertise not readily available in traditional textile production facilities.

Environmental variability poses substantial challenges for controlled degradation mechanisms. Smart fabrics encounter unpredictable exposure to moisture, temperature fluctuations, mechanical stress, and chemical agents during normal use. Designing transient electronics with predictable dissolution timelines under such variable conditions remains technically challenging, risking either premature degradation or persistent environmental presence beyond intended lifespans.

Biocompatibility concerns emerge particularly for smart fabrics designed for direct skin contact or medical applications. The degradation byproducts of transient electronics must be non-toxic and non-irritating, yet current materials often produce intermediate compounds requiring further investigation for long-term safety. This challenge becomes more pronounced for wearable health monitoring applications where prolonged skin contact occurs.

Signal integrity and electromagnetic interference issues also plague current transient electronic systems in textiles. The degradable nature of conductive pathways can lead to increasing impedance over time, resulting in signal deterioration. Additionally, the proximity of multiple transient components in a confined fabric area creates potential for cross-talk and interference, compromising overall system reliability.

Mechanical compatibility presents another critical challenge, as transient electronic components must withstand the constant flexing, stretching, and compression experienced by textiles during normal wear. The rigid nature of many electronic components conflicts with the inherent flexibility requirements of fabrics, creating reliability issues during repeated mechanical stress cycles. This incompatibility often leads to premature failure through delamination or fracturing of electronic pathways.

Power management remains particularly problematic for transient electronics in smart fabrics. Traditional battery technologies are inherently non-degradable and contain environmentally harmful materials, contradicting the core sustainability benefits of transient systems. Alternative power sources such as biodegradable batteries or energy harvesting technologies (piezoelectric, thermoelectric) currently lack sufficient energy density or longevity for practical applications.

Manufacturing scalability represents a significant barrier to commercial viability. Current fabrication methods for transient electronics typically involve complex, multi-step processes that are difficult to integrate with established textile manufacturing workflows. The precision required for depositing degradable electronic components onto fabric substrates demands specialized equipment and expertise not readily available in traditional textile production facilities.

Environmental variability poses substantial challenges for controlled degradation mechanisms. Smart fabrics encounter unpredictable exposure to moisture, temperature fluctuations, mechanical stress, and chemical agents during normal use. Designing transient electronics with predictable dissolution timelines under such variable conditions remains technically challenging, risking either premature degradation or persistent environmental presence beyond intended lifespans.

Biocompatibility concerns emerge particularly for smart fabrics designed for direct skin contact or medical applications. The degradation byproducts of transient electronics must be non-toxic and non-irritating, yet current materials often produce intermediate compounds requiring further investigation for long-term safety. This challenge becomes more pronounced for wearable health monitoring applications where prolonged skin contact occurs.

Signal integrity and electromagnetic interference issues also plague current transient electronic systems in textiles. The degradable nature of conductive pathways can lead to increasing impedance over time, resulting in signal deterioration. Additionally, the proximity of multiple transient components in a confined fabric area creates potential for cross-talk and interference, compromising overall system reliability.

Existing Integration Methods for Electronics in Fabrics

01 Biodegradable materials for transient electronics

Biodegradable materials are being incorporated into transient electronic devices to enable controlled dissolution or degradation after their functional lifetime. These materials include water-soluble polymers, silk fibroin, and magnesium-based conductors that can safely decompose in physiological or environmental conditions. This approach allows for the development of implantable medical devices that don't require surgical removal and environmentally friendly electronics that reduce e-waste.- Biodegradable materials for transient electronics: Biodegradable materials are being incorporated into transient electronic devices to enable controlled dissolution or degradation after their functional lifetime. These materials include water-soluble polymers, silk fibroin, and magnesium-based conductors that can safely decompose in biological environments or natural settings. This approach allows for the development of implantable medical devices that don't require surgical removal and environmentally friendly consumer electronics that reduce electronic waste.

- Controlled degradation mechanisms: Advanced triggering mechanisms are being developed to precisely control when and how transient electronics degrade. These include moisture-activated dissolution, thermal triggers, photodegradable components, and pH-responsive materials. By engineering specific environmental response mechanisms, researchers can create electronics that maintain stability during operation but degrade rapidly when exposed to predetermined stimuli, enhancing both functionality during use and complete dissolution afterward.

- Performance enhancement of transient circuits: Innovations in circuit design and materials science are improving the performance of transient electronics while maintaining their degradability. These advancements include high-efficiency transistors made from semiconductor nanomembranes, novel encapsulation techniques that protect sensitive components during operation, and improved power management systems. These developments enable transient electronics to achieve performance metrics closer to conventional electronics while preserving their unique ability to disappear after use.

- Energy harvesting and storage solutions: Specialized energy systems are being developed for transient electronics, including biodegradable batteries, transient supercapacitors, and energy harvesting components that can power devices before degrading safely. These power solutions utilize materials like magnesium anodes, biodegradable electrolytes, and dissolvable current collectors. Some systems incorporate piezoelectric or triboelectric nanogenerators that can harvest energy from body movement or environmental vibrations before eventually degrading along with the rest of the device.

- Application-specific transient electronic designs: Researchers are developing specialized transient electronic platforms for specific applications, particularly in healthcare monitoring, environmental sensing, and secure electronics. These include implantable sensors that monitor post-surgical healing before dissolving, environmental monitors that degrade after collecting data, and security devices that can be remotely triggered to self-destruct. The application-specific designs optimize the balance between functional lifetime, performance requirements, and degradation characteristics based on the intended use case.

02 Trigger mechanisms for controlled dissolution

Various trigger mechanisms are being developed to control the dissolution or degradation of transient electronics. These include thermal triggers, pH-responsive materials, light-activated dissolution, and electrical stimuli that can initiate the breakdown process. By incorporating these trigger mechanisms, transient electronic devices can be designed to dissolve or degrade at specific times or under specific environmental conditions, enhancing their functionality and application range.Expand Specific Solutions03 Enhanced circuit design for transient electronics

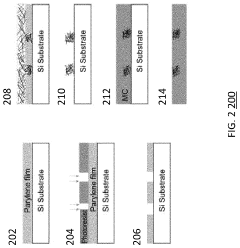

Advanced circuit designs are being implemented to improve the performance of transient electronics while maintaining their dissolvable nature. These designs include flexible circuit architectures, low-power consumption configurations, and novel interconnect strategies that can withstand mechanical stress while still enabling eventual dissolution. The enhanced circuit designs allow for more complex functionality in transient electronic devices before their programmed degradation.Expand Specific Solutions04 Encapsulation technologies for controlled lifetimes

Innovative encapsulation technologies are being developed to precisely control the functional lifetime of transient electronics. These include multi-layer barrier films, engineered polymeric coatings, and composite encapsulants that protect the electronic components from environmental factors until dissolution is desired. By tuning the properties of these encapsulation materials, the operational lifetime of transient devices can be extended from minutes to months depending on application requirements.Expand Specific Solutions05 Integration with wireless power and communication systems

Transient electronics are being enhanced through integration with wireless power transfer and communication systems. This integration enables remote monitoring, data collection, and power delivery without permanent external connections. Technologies such as near-field communication (NFC), radio frequency identification (RFID), and inductive coupling are being adapted for transient electronic platforms, allowing these devices to function effectively before their programmed dissolution while maintaining their transient nature.Expand Specific Solutions

Leading Companies in Smart Textile and Transient Electronics

Transient electronics in smart fabrics is evolving rapidly, currently transitioning from early development to commercialization phase. The market is projected to reach significant scale as wearable technology adoption increases, with estimates suggesting multi-billion dollar potential by 2030. Technologically, academic institutions like Jiangnan University, Drexel University, and Zhejiang University are pioneering fundamental research, while commercial players demonstrate varying maturity levels. Intel and IBM are leveraging their semiconductor expertise for advanced integration solutions, Kolon Glotech and W.L. Gore are applying materials science innovations, and startups like BioSerenity are developing specialized healthcare applications. Companies like Adidas are exploring consumer applications, indicating the technology's readiness for mainstream adoption in specific use cases while broader implementation remains in development.

Drexel University

Technical Solution: Drexel University has developed MXene-based transient electronics for smart fabric applications. Their approach leverages two-dimensional titanium carbide MXene nanosheets that offer exceptional electrical conductivity while being ultrathin and flexible enough for textile integration. The research team has created dissolvable electronic circuits by combining MXene with water-soluble polymers like polyvinyl alcohol (PVA), allowing controlled degradation when exposed to moisture. Their smart fabric innovations include temperature and humidity sensors directly printed onto fabric substrates using MXene-based inks, which maintain functionality through normal wear but can be triggered to decompose at end-of-life. Drexel's technology enables wireless power transmission through fabric, eliminating rigid battery components while supporting transient functionality. The university has also pioneered electromagnetic interference (EMI) shielding fabrics using MXene that provide protection during use but can be environmentally degraded when disposed of, addressing electronic waste concerns in wearable technology.

Strengths: MXene materials offer exceptional electrical properties while maintaining flexibility and comfort in fabric applications. The printing process is scalable and compatible with existing textile manufacturing. Weaknesses: Relatively new material with limited long-term stability data, and potential challenges in controlling precise degradation timing in variable environmental conditions.

Intel Corp.

Technical Solution: Intel has developed a comprehensive transient electronics platform specifically targeting smart fabric applications through their "Disappearing Electronics" initiative. Their approach focuses on water-soluble circuit boards made from specialized polymers that can be integrated directly into textile manufacturing processes. Intel's technology utilizes specialized gallium-based conductive inks and ultra-thin silicon components that maintain full functionality until triggered to degrade by specific environmental conditions. The company has created prototype smart garments with embedded transient sensors that can monitor body temperature, heart rate, and movement patterns for athletic performance analysis, with components designed to withstand multiple wash cycles before controlled degradation. Intel's transient memory components allow smart fabrics to temporarily store data locally before transmission, enhancing privacy by ensuring data physically disappears after a predetermined period. Their manufacturing process has been adapted for roll-to-roll production compatible with existing textile manufacturing infrastructure.

Strengths: Advanced integration with existing semiconductor manufacturing processes enables higher performance computing capabilities in transient form. Established supply chain and manufacturing expertise facilitate potential mass production. Weaknesses: Higher power requirements compared to simpler transient systems, and potential environmental concerns regarding complete biodegradability of all components in their complex systems.

Key Patents in Biodegradable Electronic Components

Transient electronics using thermoresponsive materials

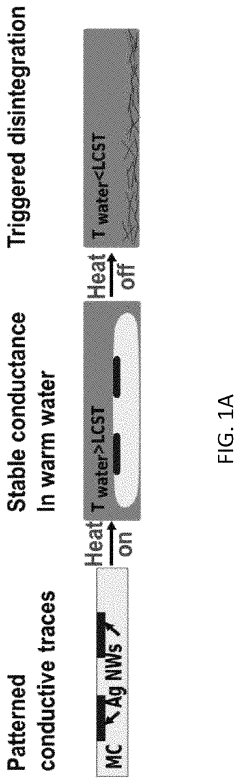

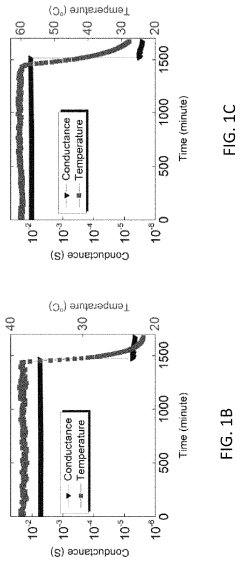

PatentActiveUS10978396B2

Innovation

- Employing thermoresponsive materials with lower critical solution temperature (LCST) behavior, such as methyl cellulose (MC) and poly(N-isopropylacrylamide) (PNIPAm) polymers combined with silver nanowires (AgNWs) to create composite elements where electrical traces are embedded or surface-disposed, enabling stable function in warm environments and rapid disintegration upon cooling.

Patent

Innovation

- Integration of transient electronic components that can dissolve or degrade under specific environmental conditions, enabling smart fabrics with predetermined lifespans and reduced electronic waste.

- Novel interconnection methods between transient electronic circuits and textile substrates that maintain functionality during wear while ensuring complete degradability when triggered.

- Implementation of self-powered transient systems through energy harvesting technologies (e.g., piezoelectric, thermoelectric) integrated directly into the fabric structure.

Environmental Impact Assessment of Transient Smart Fabrics

The environmental implications of transient electronics in smart fabrics represent a critical dimension of sustainability assessment that warrants thorough examination. As these technologies gain prominence in wearable applications, their ecological footprint throughout the product lifecycle demands careful consideration. Transient smart fabrics, designed to decompose under specific environmental conditions, offer promising alternatives to conventional electronic waste management challenges.

Primary environmental benefits stem from the biodegradability of transient components, which can significantly reduce electronic waste accumulation. Traditional electronic textiles often contain persistent materials that remain in landfills for decades or centuries, whereas transient electronics can be engineered to dissolve in controlled environments within weeks or months. This characteristic substantially mitigates long-term soil and water contamination risks associated with e-waste.

Water consumption represents another crucial environmental factor in the assessment of transient smart fabrics. Manufacturing processes for these advanced materials typically require less water compared to conventional electronics production, particularly when utilizing water-soluble substrates and conductive materials. However, the dissolution process itself may introduce dissolved electronic compounds into water systems, necessitating comprehensive toxicity evaluations.

Carbon footprint analysis reveals mixed results for transient electronics in smart fabrics. While production energy requirements may be comparable to conventional electronics, the reduced need for mining rare earth elements and precious metals offers significant carbon reduction opportunities. Additionally, the elimination of energy-intensive recycling processes further enhances the environmental profile of these technologies.

Material toxicity concerns persist despite the transient nature of these electronics. Certain biodegradable polymers and conductive materials may release potentially harmful compounds during decomposition. Recent research has focused on developing non-toxic alternatives, including silk-based substrates and zinc-based conductors that decompose into environmentally benign compounds.

Regulatory frameworks for environmental assessment of transient smart fabrics remain underdeveloped globally. Current electronic waste regulations inadequately address the unique characteristics of transient technologies, creating uncertainty regarding proper disposal protocols and environmental safety standards. Industry stakeholders and policymakers must collaborate to establish appropriate guidelines that balance innovation with ecological protection.

Life cycle assessment methodologies specific to transient electronics are emerging as essential tools for comprehensive environmental impact evaluation. These approaches consider resource extraction, manufacturing processes, use phase energy consumption, and end-of-life scenarios to provide holistic sustainability metrics for transient smart fabric technologies.

Primary environmental benefits stem from the biodegradability of transient components, which can significantly reduce electronic waste accumulation. Traditional electronic textiles often contain persistent materials that remain in landfills for decades or centuries, whereas transient electronics can be engineered to dissolve in controlled environments within weeks or months. This characteristic substantially mitigates long-term soil and water contamination risks associated with e-waste.

Water consumption represents another crucial environmental factor in the assessment of transient smart fabrics. Manufacturing processes for these advanced materials typically require less water compared to conventional electronics production, particularly when utilizing water-soluble substrates and conductive materials. However, the dissolution process itself may introduce dissolved electronic compounds into water systems, necessitating comprehensive toxicity evaluations.

Carbon footprint analysis reveals mixed results for transient electronics in smart fabrics. While production energy requirements may be comparable to conventional electronics, the reduced need for mining rare earth elements and precious metals offers significant carbon reduction opportunities. Additionally, the elimination of energy-intensive recycling processes further enhances the environmental profile of these technologies.

Material toxicity concerns persist despite the transient nature of these electronics. Certain biodegradable polymers and conductive materials may release potentially harmful compounds during decomposition. Recent research has focused on developing non-toxic alternatives, including silk-based substrates and zinc-based conductors that decompose into environmentally benign compounds.

Regulatory frameworks for environmental assessment of transient smart fabrics remain underdeveloped globally. Current electronic waste regulations inadequately address the unique characteristics of transient technologies, creating uncertainty regarding proper disposal protocols and environmental safety standards. Industry stakeholders and policymakers must collaborate to establish appropriate guidelines that balance innovation with ecological protection.

Life cycle assessment methodologies specific to transient electronics are emerging as essential tools for comprehensive environmental impact evaluation. These approaches consider resource extraction, manufacturing processes, use phase energy consumption, and end-of-life scenarios to provide holistic sustainability metrics for transient smart fabric technologies.

Durability and Lifecycle Management Strategies

The durability of transient electronics in smart fabrics presents a unique paradox: these components are designed to degrade under specific conditions while maintaining functionality during their intended lifecycle. Managing this balance requires sophisticated strategies that extend beyond traditional textile durability approaches.

Controlled degradation mechanisms represent the cornerstone of lifecycle management for transient electronics in smart fabrics. These mechanisms can be engineered to respond to specific triggers such as moisture, temperature, or enzymatic activity. By precisely calibrating these degradation pathways, manufacturers can ensure that electronic components maintain integrity during use but decompose predictably at end-of-life.

Environmental exposure testing protocols have been developed specifically for transient smart textiles. These protocols simulate various wear conditions, washing cycles, and environmental stressors to validate both the functional lifespan and the controlled degradation timeline. Recent advancements include accelerated testing methods that can compress years of wear into weeks of laboratory evaluation.

Encapsulation technologies play a critical role in extending the functional lifespan of transient components. Biodegradable polymers like polylactic acid (PLA) and polyhydroxyalkanoates (PHA) provide temporary protection while remaining compatible with the transient nature of the electronics. Multi-layer encapsulation systems can be designed with progressive degradation properties, maintaining protection during use while facilitating decomposition afterward.

Modular design approaches have emerged as a practical solution to the durability challenge. By creating detachable electronic modules that can be removed before washing or replaced when damaged, manufacturers can extend the overall garment lifespan while maintaining the transient properties of the electronic components. This approach has shown particular promise in medical monitoring garments where hygiene requirements are stringent.

Predictive maintenance algorithms represent the cutting edge of durability management. By incorporating self-diagnostic capabilities into smart fabrics, these systems can monitor component degradation in real-time and alert users before failure occurs. Machine learning models trained on degradation patterns can predict remaining useful life with increasing accuracy, allowing for timely maintenance or replacement.

End-of-life recovery systems complete the lifecycle management strategy. These systems may include chemical processes that accelerate the breakdown of remaining electronic components or physical separation techniques that isolate valuable materials for recycling. Some innovative approaches incorporate biodegradable markers that facilitate automated sorting during the recycling process.

Controlled degradation mechanisms represent the cornerstone of lifecycle management for transient electronics in smart fabrics. These mechanisms can be engineered to respond to specific triggers such as moisture, temperature, or enzymatic activity. By precisely calibrating these degradation pathways, manufacturers can ensure that electronic components maintain integrity during use but decompose predictably at end-of-life.

Environmental exposure testing protocols have been developed specifically for transient smart textiles. These protocols simulate various wear conditions, washing cycles, and environmental stressors to validate both the functional lifespan and the controlled degradation timeline. Recent advancements include accelerated testing methods that can compress years of wear into weeks of laboratory evaluation.

Encapsulation technologies play a critical role in extending the functional lifespan of transient components. Biodegradable polymers like polylactic acid (PLA) and polyhydroxyalkanoates (PHA) provide temporary protection while remaining compatible with the transient nature of the electronics. Multi-layer encapsulation systems can be designed with progressive degradation properties, maintaining protection during use while facilitating decomposition afterward.

Modular design approaches have emerged as a practical solution to the durability challenge. By creating detachable electronic modules that can be removed before washing or replaced when damaged, manufacturers can extend the overall garment lifespan while maintaining the transient properties of the electronic components. This approach has shown particular promise in medical monitoring garments where hygiene requirements are stringent.

Predictive maintenance algorithms represent the cutting edge of durability management. By incorporating self-diagnostic capabilities into smart fabrics, these systems can monitor component degradation in real-time and alert users before failure occurs. Machine learning models trained on degradation patterns can predict remaining useful life with increasing accuracy, allowing for timely maintenance or replacement.

End-of-life recovery systems complete the lifecycle management strategy. These systems may include chemical processes that accelerate the breakdown of remaining electronic components or physical separation techniques that isolate valuable materials for recycling. Some innovative approaches incorporate biodegradable markers that facilitate automated sorting during the recycling process.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!