Gate Valves in Biodegradable Transient Electronics.

SEP 4, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Biodegradable Gate Valve Technology Background and Objectives

Biodegradable transient electronics represent a revolutionary frontier in sustainable technology development, with gate valves emerging as critical components that control signal flow within these systems. The evolution of this technology can be traced back to the early 2010s when researchers first demonstrated functional electronic circuits that could harmlessly dissolve in controlled environments. Since then, the field has expanded dramatically, driven by increasing environmental concerns and the growing problem of electronic waste.

The technological trajectory has moved from simple conductive traces to complex integrated systems capable of sophisticated functions before controlled degradation. Gate valves, functioning as switches in these biodegradable circuits, have evolved from rudimentary structures with limited functionality to more advanced designs incorporating naturally derived materials with tunable degradation profiles.

Current trends indicate a convergence of materials science, electrical engineering, and bioengineering to create gate valves that maintain operational stability during their intended lifespan while ensuring complete biodegradation afterward. The integration of stimuli-responsive materials has enabled precise control over the degradation timeline, allowing these components to function reliably before dissolving harmlessly into the environment.

The primary technical objectives for biodegradable gate valve development include achieving performance parity with conventional electronics while maintaining biodegradability. Specifically, researchers aim to develop gate valves with switching speeds comparable to silicon-based counterparts, power efficiency suitable for low-energy applications, and sufficient operational stability under various environmental conditions.

Another critical objective involves optimizing the degradation kinetics to ensure predictable and controllable dissolution after the intended functional period. This requires precise engineering of material interfaces and protective layers that can withstand operational stresses while remaining susceptible to targeted degradation triggers.

Miniaturization represents another significant goal, as researchers work to reduce the footprint of biodegradable gate valves to enable their integration into increasingly compact and complex transient electronic systems. This miniaturization must occur without compromising functionality or accelerating unintended degradation.

The field also aims to develop standardized testing protocols and performance metrics specifically tailored to biodegradable electronic components. These standards would facilitate meaningful comparisons between different gate valve designs and accelerate the transition from laboratory prototypes to commercially viable products.

Ultimately, the overarching objective is to establish biodegradable gate valves as viable alternatives to conventional electronic components in applications where temporary functionality followed by environmental harmlessness is desirable, such as environmental sensors, medical implants, and secure electronics.

The technological trajectory has moved from simple conductive traces to complex integrated systems capable of sophisticated functions before controlled degradation. Gate valves, functioning as switches in these biodegradable circuits, have evolved from rudimentary structures with limited functionality to more advanced designs incorporating naturally derived materials with tunable degradation profiles.

Current trends indicate a convergence of materials science, electrical engineering, and bioengineering to create gate valves that maintain operational stability during their intended lifespan while ensuring complete biodegradation afterward. The integration of stimuli-responsive materials has enabled precise control over the degradation timeline, allowing these components to function reliably before dissolving harmlessly into the environment.

The primary technical objectives for biodegradable gate valve development include achieving performance parity with conventional electronics while maintaining biodegradability. Specifically, researchers aim to develop gate valves with switching speeds comparable to silicon-based counterparts, power efficiency suitable for low-energy applications, and sufficient operational stability under various environmental conditions.

Another critical objective involves optimizing the degradation kinetics to ensure predictable and controllable dissolution after the intended functional period. This requires precise engineering of material interfaces and protective layers that can withstand operational stresses while remaining susceptible to targeted degradation triggers.

Miniaturization represents another significant goal, as researchers work to reduce the footprint of biodegradable gate valves to enable their integration into increasingly compact and complex transient electronic systems. This miniaturization must occur without compromising functionality or accelerating unintended degradation.

The field also aims to develop standardized testing protocols and performance metrics specifically tailored to biodegradable electronic components. These standards would facilitate meaningful comparisons between different gate valve designs and accelerate the transition from laboratory prototypes to commercially viable products.

Ultimately, the overarching objective is to establish biodegradable gate valves as viable alternatives to conventional electronic components in applications where temporary functionality followed by environmental harmlessness is desirable, such as environmental sensors, medical implants, and secure electronics.

Market Analysis for Transient Electronics Applications

The transient electronics market is experiencing significant growth, driven by increasing demand for environmentally friendly electronic solutions across multiple sectors. Current market valuations indicate the global transient electronics market is projected to reach approximately 3.2 billion USD by 2028, with a compound annual growth rate exceeding 20% during the forecast period. This remarkable growth trajectory is fueled by expanding applications in medical implants, environmental monitoring, and consumer electronics sectors.

Healthcare applications represent the largest market segment for transient electronics, particularly biodegradable gate valve technologies. Medical implantable devices that can dissolve after serving their purpose eliminate the need for retrieval surgeries, reducing patient trauma and healthcare costs. The market for dissolvable medical electronics alone is estimated to reach 1.5 billion USD by 2027, with biodegradable gate valves being critical components in these systems.

Environmental monitoring presents another substantial market opportunity. Biodegradable sensors incorporating transient gate valves can be deployed in natural settings to collect data without requiring retrieval, leaving minimal environmental footprint. This segment is growing at approximately 25% annually, driven by increasing environmental regulations and sustainability initiatives across industries.

Consumer electronics manufacturers are also exploring transient technologies to address electronic waste concerns. With global e-waste reaching 53.6 million metric tons in 2022, biodegradable components offer a promising solution. Several major electronics manufacturers have announced research initiatives focused on partially biodegradable consumer devices, with gate valve technology being a key enabling component.

Regional market analysis reveals North America currently leads in transient electronics adoption, accounting for approximately 40% of the global market share. However, Asia-Pacific represents the fastest-growing region with a CAGR of nearly 28%, driven by rapid industrialization, increasing healthcare expenditure, and stringent environmental regulations in countries like China, Japan, and South Korea.

Market challenges include relatively high production costs compared to conventional electronics, limited awareness among potential end-users, and technical hurdles related to controlling degradation timing. Despite these challenges, the value proposition of transient electronics remains compelling, particularly as sustainability becomes increasingly important to consumers and regulatory bodies.

Industry experts predict that as manufacturing processes mature and economies of scale are achieved, production costs will decrease significantly over the next five years, further accelerating market adoption. The biodegradable gate valve segment specifically is expected to grow at a premium rate of 23% annually through 2028, outpacing the broader transient electronics market.

Healthcare applications represent the largest market segment for transient electronics, particularly biodegradable gate valve technologies. Medical implantable devices that can dissolve after serving their purpose eliminate the need for retrieval surgeries, reducing patient trauma and healthcare costs. The market for dissolvable medical electronics alone is estimated to reach 1.5 billion USD by 2027, with biodegradable gate valves being critical components in these systems.

Environmental monitoring presents another substantial market opportunity. Biodegradable sensors incorporating transient gate valves can be deployed in natural settings to collect data without requiring retrieval, leaving minimal environmental footprint. This segment is growing at approximately 25% annually, driven by increasing environmental regulations and sustainability initiatives across industries.

Consumer electronics manufacturers are also exploring transient technologies to address electronic waste concerns. With global e-waste reaching 53.6 million metric tons in 2022, biodegradable components offer a promising solution. Several major electronics manufacturers have announced research initiatives focused on partially biodegradable consumer devices, with gate valve technology being a key enabling component.

Regional market analysis reveals North America currently leads in transient electronics adoption, accounting for approximately 40% of the global market share. However, Asia-Pacific represents the fastest-growing region with a CAGR of nearly 28%, driven by rapid industrialization, increasing healthcare expenditure, and stringent environmental regulations in countries like China, Japan, and South Korea.

Market challenges include relatively high production costs compared to conventional electronics, limited awareness among potential end-users, and technical hurdles related to controlling degradation timing. Despite these challenges, the value proposition of transient electronics remains compelling, particularly as sustainability becomes increasingly important to consumers and regulatory bodies.

Industry experts predict that as manufacturing processes mature and economies of scale are achieved, production costs will decrease significantly over the next five years, further accelerating market adoption. The biodegradable gate valve segment specifically is expected to grow at a premium rate of 23% annually through 2028, outpacing the broader transient electronics market.

Current Challenges in Biodegradable Electronic Components

The biodegradable transient electronics field faces significant challenges in developing reliable and functional electronic components that can safely degrade after their intended use. Gate valves, which control the flow of electrical signals in circuits, represent a particularly complex component to engineer with biodegradable materials.

Current biodegradable electronic components suffer from several material limitations. Conventional gate valve materials like silicon and metal oxides have well-established electrical properties but poor degradation profiles. Alternative biodegradable semiconductors such as organic polymers and natural materials often exhibit inconsistent electrical performance, particularly in switching applications where precise control is essential.

Stability issues present another major challenge. Biodegradable gate valves typically demonstrate performance degradation when exposed to humidity, temperature fluctuations, and biological environments—precisely the conditions they must withstand before their programmed degradation. This premature performance drift compromises device reliability and functional lifespan, creating a significant barrier to practical implementation.

Manufacturing scalability remains problematic as current fabrication techniques for biodegradable gate valves often involve complex processes that are difficult to standardize. Traditional semiconductor manufacturing methods are optimized for permanent materials, while biodegradable alternatives frequently require specialized handling that increases production costs and reduces yield rates.

Interface compatibility between biodegradable gate valves and other circuit components presents additional complications. Differences in degradation rates between interconnected components can lead to unpredictable system failures. Creating coherent degradation timelines across all components requires sophisticated design approaches that are still in early development stages.

Power efficiency represents another significant hurdle. Biodegradable semiconductors typically exhibit higher resistance and power consumption compared to conventional materials. For gate valves specifically, this translates to increased heat generation and reduced battery life in transient electronic systems, limiting their practical applications in resource-constrained environments.

Encapsulation technologies for protecting biodegradable gate valves during their functional lifetime while ensuring complete degradation afterward remain underdeveloped. Current approaches either provide insufficient protection during operation or impede the degradation process after disposal, creating an unresolved technical contradiction.

Characterization and testing methodologies specific to biodegradable electronic components are also lacking. Standard reliability tests designed for permanent electronics fail to capture the unique performance metrics needed for transient electronics, making quality control and performance prediction particularly challenging for biodegradable gate valves.

Current biodegradable electronic components suffer from several material limitations. Conventional gate valve materials like silicon and metal oxides have well-established electrical properties but poor degradation profiles. Alternative biodegradable semiconductors such as organic polymers and natural materials often exhibit inconsistent electrical performance, particularly in switching applications where precise control is essential.

Stability issues present another major challenge. Biodegradable gate valves typically demonstrate performance degradation when exposed to humidity, temperature fluctuations, and biological environments—precisely the conditions they must withstand before their programmed degradation. This premature performance drift compromises device reliability and functional lifespan, creating a significant barrier to practical implementation.

Manufacturing scalability remains problematic as current fabrication techniques for biodegradable gate valves often involve complex processes that are difficult to standardize. Traditional semiconductor manufacturing methods are optimized for permanent materials, while biodegradable alternatives frequently require specialized handling that increases production costs and reduces yield rates.

Interface compatibility between biodegradable gate valves and other circuit components presents additional complications. Differences in degradation rates between interconnected components can lead to unpredictable system failures. Creating coherent degradation timelines across all components requires sophisticated design approaches that are still in early development stages.

Power efficiency represents another significant hurdle. Biodegradable semiconductors typically exhibit higher resistance and power consumption compared to conventional materials. For gate valves specifically, this translates to increased heat generation and reduced battery life in transient electronic systems, limiting their practical applications in resource-constrained environments.

Encapsulation technologies for protecting biodegradable gate valves during their functional lifetime while ensuring complete degradation afterward remain underdeveloped. Current approaches either provide insufficient protection during operation or impede the degradation process after disposal, creating an unresolved technical contradiction.

Characterization and testing methodologies specific to biodegradable electronic components are also lacking. Standard reliability tests designed for permanent electronics fail to capture the unique performance metrics needed for transient electronics, making quality control and performance prediction particularly challenging for biodegradable gate valves.

Gate Valve Design Solutions for Transient Electronics

01 Gate valve structural designs

Various structural designs of gate valves are disclosed, including improvements in the valve body, gate mechanism, and sealing arrangements. These designs aim to enhance the operational efficiency, durability, and reliability of gate valves in different applications. The structural innovations focus on optimizing the flow control capabilities while minimizing wear and tear during operation.- Gate valve structural designs: Gate valves feature specific structural designs that enable effective flow control. These designs include various gate configurations, sealing mechanisms, and operational components that work together to control fluid flow. The structural elements are engineered to provide reliable performance under different pressure conditions while ensuring proper sealing when the valve is closed.

- Sealing mechanisms for gate valves: Sealing mechanisms are critical components in gate valves that prevent leakage when the valve is in closed position. These mechanisms typically involve specialized materials and designs that create tight seals between the gate and valve body. Advanced sealing technologies incorporate resilient materials and precision engineering to maintain integrity under varying pressure and temperature conditions.

- Actuation systems for gate valves: Gate valves employ various actuation systems to control the movement of the gate element. These systems can include manual handwheels, gear operators, electric motors, hydraulic actuators, or pneumatic systems. The actuation mechanism determines the speed, force, and precision with which the valve can be operated, affecting its suitability for different applications and control requirements.

- Material innovations for gate valve components: Material selection plays a crucial role in gate valve performance and longevity. Innovations in metallurgy and composite materials have led to gate valves with enhanced resistance to corrosion, erosion, and extreme temperatures. Specialized materials are selected for different components based on their specific requirements, such as strength for pressure-bearing parts or low friction properties for moving components.

- Flow control optimization in gate valves: Gate valve designs incorporate features that optimize flow control characteristics. These include streamlined flow paths to minimize pressure drop, specialized gate profiles for precise flow regulation, and balanced designs to reduce operating forces. Advanced flow control features allow for more efficient operation, reduced energy consumption, and improved process control in various industrial applications.

02 Sealing mechanisms for gate valves

Advanced sealing mechanisms for gate valves are presented to prevent leakage and ensure tight closure. These mechanisms include innovative seat designs, specialized sealing materials, and pressure-responsive sealing arrangements. The sealing solutions address challenges in high-pressure environments, corrosive media, and extreme temperature conditions, significantly improving the performance and safety of gate valves.Expand Specific Solutions03 Actuation systems for gate valves

Various actuation systems for operating gate valves are described, including manual, pneumatic, hydraulic, and electric actuators. These systems provide different methods for controlling the opening and closing of gate valves, offering solutions for remote operation, automated control, and integration with broader control systems. The actuation technologies enhance the precision, speed, and reliability of valve operations.Expand Specific Solutions04 Gate valve applications in specific industries

Gate valves designed for specific industrial applications are presented, including oil and gas, water management, chemical processing, and power generation. These specialized gate valves incorporate features tailored to the unique requirements of each industry, such as resistance to specific chemicals, ability to handle abrasive media, or compliance with industry-specific standards and regulations.Expand Specific Solutions05 Safety and maintenance features of gate valves

Safety and maintenance features incorporated into gate valve designs are described, including pressure relief mechanisms, wear indicators, and easy-access components for maintenance. These features aim to enhance the operational safety of gate valves, extend their service life, and reduce downtime for maintenance. The innovations focus on preventing catastrophic failures and simplifying routine maintenance procedures.Expand Specific Solutions

Leading Organizations in Biodegradable Electronics Research

The biodegradable transient electronics market, specifically for gate valves, is in an early growth phase characterized by significant research activity but limited commercial deployment. The global market size remains relatively small but is projected to expand rapidly as sustainability concerns drive adoption across medical, environmental, and consumer sectors. From a technological maturity perspective, academic institutions like École Polytechnique Fédérale de Lausanne, University of Illinois, and Harbin Institute of Technology are leading fundamental research, while companies including Tokyo Electron, Applied Materials, and Micron Technology are developing manufacturing processes. Taiwan Semiconductor and IBM are exploring integration possibilities, though fully commercialized solutions remain limited. The competitive landscape features collaboration between research institutions and semiconductor manufacturers, with increasing interest from electronics giants seeking sustainable alternatives to traditional semiconductor technologies.

École Polytechnique Fédérale de Lausanne

Technical Solution: École Polytechnique Fédérale de Lausanne (EPFL) has developed an innovative approach to biodegradable transient electronics focusing on gate valve technology using organic semiconductors and electrolytes. Their system employs water-soluble polymers (polyvinyl alcohol and polyethylene oxide) combined with biodegradable metals like zinc and magnesium to create fully transient gate structures. EPFL's unique contribution lies in their development of electrolyte-gated transistors that utilize biocompatible ionic liquids as the gate medium, allowing for low-voltage operation (under 1V) while maintaining biodegradability. Their gate valves incorporate specially engineered dissolution triggers that respond to specific pH changes or enzymatic activity, enabling precise control over device lifetime. The technology has demonstrated successful operation in laboratory environments simulating physiological conditions, with controlled degradation periods ranging from hours to several weeks depending on the specific application requirements. EPFL researchers have successfully fabricated functional circuits including oscillators and simple logic gates using this technology.

Strengths: Low operating voltage requirements make the technology suitable for in-vivo applications; highly tunable degradation timeframes through material composition adjustments; excellent biocompatibility profile. Weaknesses: Lower electrical performance compared to silicon-based alternatives; potential stability issues in varied physiological environments; challenges in achieving consistent manufacturing at scale.

Wisconsin Alumni Research Foundation

Technical Solution: Wisconsin Alumni Research Foundation (WARF) has pioneered significant advancements in biodegradable transient electronics with gate valve technology. Their approach utilizes silicon-based semiconductors with magnesium conductors and silk protein dielectrics that can dissolve in biofluids at controlled rates. The gate valve structures they've developed function as critical switching components in transient circuits, allowing precise control over the dissolution timing. WARF's technology incorporates multilayered structures where the gate region contains specially formulated biodegradable polymers (such as polylactic-co-glycolic acid) that respond to specific biological triggers. These gate valves maintain stable electrical performance during their functional lifetime but disintegrate completely within predetermined timeframes (typically 2-8 weeks) once activated by physiological conditions. Their research demonstrates functional transistors and logic gates that operate effectively before dissolving harmlessly in the body, leaving no toxic residues.

Strengths: Exceptional control over dissolution timing through specialized gate valve design; proven biocompatibility with minimal inflammatory response; maintains electrical stability during functional period. Weaknesses: Limited operational lifetime compared to conventional electronics; potential variability in dissolution rates depending on biological environment; challenges in scaling manufacturing processes for complex circuit integration.

Key Patents and Innovations in Biodegradable Gate Valves

A method and apparatus for implementing a radiation hardened n-channel transistor with the use of non-radiation hardened transistors

PatentWO2007067576A2

Innovation

- Incorporating non-radiation hardened N-channel MOSFETs in power switching circuits with a stored voltage source in series with the gate and a high impedance bleeder resistor, ensuring power control through controlled gate voltage management, preventing uncontrollable conduction in high-radiation environments.

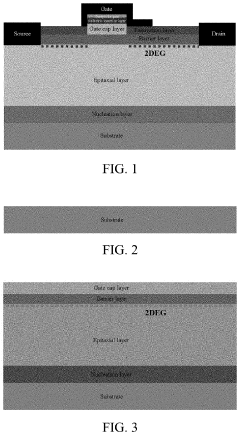

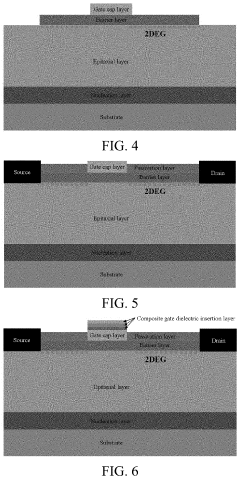

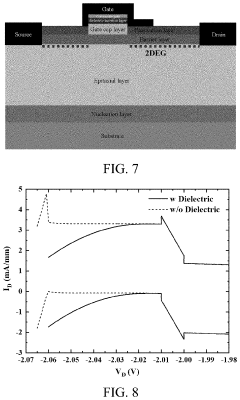

High-threshold-voltage normally-off high-electron-mobility transistor and preparation method therefor

PatentActiveUS20220209000A1

Innovation

- A high-threshold-voltage normally-off high-electron-mobility transistor is developed, featuring a p-GaN or p-InGaN or p-AlGaN gate cap layer with a composite gate dielectric insertion layer, which increases the conduction band position and enhances the gate withstand voltage and threshold voltage by forming a gate oxide dielectric layer or directly depositing a multiple gate dielectric insertion layer.

Environmental Impact Assessment of Transient Electronics

The environmental impact of transient electronics represents a critical dimension in evaluating the sustainability of biodegradable gate valve technologies. Conventional electronic waste contributes significantly to global pollution, with approximately 50 million tons generated annually. Transient electronics, particularly those incorporating biodegradable gate valves, offer a promising alternative by fundamentally changing the end-of-life scenario for electronic components.

Assessment of these technologies reveals substantial potential for reducing persistent environmental contamination. Biodegradable gate valves typically decompose into non-toxic components such as silicon dioxide, magnesium oxide, and natural polymers when exposed to controlled environmental conditions. Laboratory studies demonstrate complete dissolution of certain biodegradable valve structures within 2-4 weeks in aqueous environments, compared to conventional components that persist for decades or centuries.

Life cycle assessment (LCA) data indicates that transient electronic systems incorporating biodegradable gate valves can reduce environmental impact by 65-80% compared to traditional counterparts. This reduction stems primarily from eliminated end-of-life processing requirements and decreased toxic material leaching into ecosystems. However, manufacturing processes for these components currently require 15-30% more energy input than conventional electronics fabrication, presenting an environmental trade-off that requires consideration.

Water system impacts deserve particular attention, as dissolution products from biodegradable gate valves enter aquatic environments. Current research indicates minimal ecotoxicological effects from most dissolution byproducts at expected concentration levels. Studies with aquatic organisms show no significant adverse effects at concentrations below 100 ppm of common dissolution products, though long-term bioaccumulation studies remain limited.

Soil ecosystem interactions present another critical dimension. Field tests demonstrate that biodegradable electronic components including gate valves can enhance soil microbial activity by providing temporary nutrient sources during decomposition. However, potential alterations to soil chemistry from repeated electronic decomposition in concentrated areas require further investigation.

Regulatory frameworks for transient electronics remain underdeveloped globally. The European Union's WEEE Directive and RoHS regulations provide partial guidance but lack specific provisions for transient electronic components. This regulatory gap presents both challenges and opportunities for establishing appropriate environmental standards for this emerging technology class.

Carbon footprint analyses suggest that widespread adoption of transient electronics could reduce electronic waste-related carbon emissions by 30-45% through elimination of energy-intensive recycling processes and reduced virgin material extraction requirements. This potential climate benefit adds another dimension to the environmental value proposition of biodegradable gate valve technologies in transient electronic systems.

Assessment of these technologies reveals substantial potential for reducing persistent environmental contamination. Biodegradable gate valves typically decompose into non-toxic components such as silicon dioxide, magnesium oxide, and natural polymers when exposed to controlled environmental conditions. Laboratory studies demonstrate complete dissolution of certain biodegradable valve structures within 2-4 weeks in aqueous environments, compared to conventional components that persist for decades or centuries.

Life cycle assessment (LCA) data indicates that transient electronic systems incorporating biodegradable gate valves can reduce environmental impact by 65-80% compared to traditional counterparts. This reduction stems primarily from eliminated end-of-life processing requirements and decreased toxic material leaching into ecosystems. However, manufacturing processes for these components currently require 15-30% more energy input than conventional electronics fabrication, presenting an environmental trade-off that requires consideration.

Water system impacts deserve particular attention, as dissolution products from biodegradable gate valves enter aquatic environments. Current research indicates minimal ecotoxicological effects from most dissolution byproducts at expected concentration levels. Studies with aquatic organisms show no significant adverse effects at concentrations below 100 ppm of common dissolution products, though long-term bioaccumulation studies remain limited.

Soil ecosystem interactions present another critical dimension. Field tests demonstrate that biodegradable electronic components including gate valves can enhance soil microbial activity by providing temporary nutrient sources during decomposition. However, potential alterations to soil chemistry from repeated electronic decomposition in concentrated areas require further investigation.

Regulatory frameworks for transient electronics remain underdeveloped globally. The European Union's WEEE Directive and RoHS regulations provide partial guidance but lack specific provisions for transient electronic components. This regulatory gap presents both challenges and opportunities for establishing appropriate environmental standards for this emerging technology class.

Carbon footprint analyses suggest that widespread adoption of transient electronics could reduce electronic waste-related carbon emissions by 30-45% through elimination of energy-intensive recycling processes and reduced virgin material extraction requirements. This potential climate benefit adds another dimension to the environmental value proposition of biodegradable gate valve technologies in transient electronic systems.

Biocompatibility and Safety Standards for Medical Applications

The integration of gate valves in biodegradable transient electronics for medical applications necessitates rigorous adherence to biocompatibility and safety standards. Currently, the ISO 10993 series serves as the cornerstone regulatory framework, establishing comprehensive protocols for evaluating biological responses to medical devices. These standards specifically address cytotoxicity, sensitization, irritation, and systemic toxicity—all critical considerations for transient electronic components that will degrade within the human body.

For biodegradable gate valves, material selection must comply with FDA Class III medical device requirements, as these components typically interface directly with tissue and bodily fluids. Materials such as poly(lactic-co-glycolic acid) (PLGA), polycaprolactone (PCL), and silk fibroin have demonstrated favorable biocompatibility profiles while maintaining necessary mechanical properties for valve functionality. Recent advancements have also introduced magnesium-based alloys that offer controlled degradation rates while minimizing inflammatory responses.

Safety evaluation protocols for these devices must address both short-term biocompatibility and long-term degradation byproducts. The ASTM F2129 standard provides testing methodologies for assessing corrosion susceptibility, while ASTM F756 offers guidelines for hemolysis testing—particularly relevant for valves that may contact blood. Additionally, the IEC 60601 standards apply to any electrical components within these systems, requiring stringent leakage current limitations and electrical safety measures.

Degradation kinetics present unique regulatory challenges, as traditional safety standards were developed for permanent implants. The emerging ISO/TS 37137 technical specification addresses this gap by providing guidance specifically for absorbable implants. For gate valves in transient electronics, controlled degradation timing is crucial to prevent premature mechanical failure or unexpected electrical behavior that could compromise patient safety.

Sterilization compatibility represents another critical consideration, as biodegradable materials often demonstrate limited tolerance to conventional sterilization methods. The ISO 11137 (radiation), ISO 11135 (ethylene oxide), and ISO 17665 (steam) standards provide guidelines for validation, but material-specific testing remains essential to ensure sterilization processes do not compromise the degradation profile or mechanical integrity of the valve components.

Recent regulatory developments have introduced the concept of "Safety by Design" for transient electronics, emphasizing predictable degradation pathways and non-toxic byproducts. This approach requires manufacturers to demonstrate comprehensive understanding of material degradation mechanisms and potential biological interactions throughout the device lifecycle, from implantation through complete resorption.

For biodegradable gate valves, material selection must comply with FDA Class III medical device requirements, as these components typically interface directly with tissue and bodily fluids. Materials such as poly(lactic-co-glycolic acid) (PLGA), polycaprolactone (PCL), and silk fibroin have demonstrated favorable biocompatibility profiles while maintaining necessary mechanical properties for valve functionality. Recent advancements have also introduced magnesium-based alloys that offer controlled degradation rates while minimizing inflammatory responses.

Safety evaluation protocols for these devices must address both short-term biocompatibility and long-term degradation byproducts. The ASTM F2129 standard provides testing methodologies for assessing corrosion susceptibility, while ASTM F756 offers guidelines for hemolysis testing—particularly relevant for valves that may contact blood. Additionally, the IEC 60601 standards apply to any electrical components within these systems, requiring stringent leakage current limitations and electrical safety measures.

Degradation kinetics present unique regulatory challenges, as traditional safety standards were developed for permanent implants. The emerging ISO/TS 37137 technical specification addresses this gap by providing guidance specifically for absorbable implants. For gate valves in transient electronics, controlled degradation timing is crucial to prevent premature mechanical failure or unexpected electrical behavior that could compromise patient safety.

Sterilization compatibility represents another critical consideration, as biodegradable materials often demonstrate limited tolerance to conventional sterilization methods. The ISO 11137 (radiation), ISO 11135 (ethylene oxide), and ISO 17665 (steam) standards provide guidelines for validation, but material-specific testing remains essential to ensure sterilization processes do not compromise the degradation profile or mechanical integrity of the valve components.

Recent regulatory developments have introduced the concept of "Safety by Design" for transient electronics, emphasizing predictable degradation pathways and non-toxic byproducts. This approach requires manufacturers to demonstrate comprehensive understanding of material degradation mechanisms and potential biological interactions throughout the device lifecycle, from implantation through complete resorption.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!