Impact of Transient Electronics on Sustainable Manufacturing.

SEP 4, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Transient Electronics Background and Objectives

Transient electronics represents a revolutionary paradigm shift in electronic device design and manufacturing, characterized by the ability to physically disappear or degrade in a controlled manner after serving their intended functions. This emerging field has evolved from traditional permanent electronics to address growing concerns about electronic waste (e-waste) and sustainability challenges in the manufacturing sector. The concept originated in the early 2000s, with significant research acceleration occurring over the past decade as environmental considerations have become increasingly paramount in technological development.

The evolution of transient electronics has followed a trajectory from basic biodegradable components to sophisticated systems with programmable lifespans. Initial research focused primarily on biomedical applications, where implantable devices could naturally dissolve after completing therapeutic functions. However, the potential for broader environmental impact has expanded the scope to consumer electronics, sensors, and industrial applications where product lifecycle management presents significant sustainability challenges.

Current technological trends in this field include the development of water-soluble substrates, environmentally responsive triggering mechanisms, and biodegradable semiconductors. These innovations are converging toward creating fully functional electronic systems that can operate reliably for predetermined periods before harmlessly decomposing into environmentally benign components.

The primary objectives of transient electronics research in sustainable manufacturing contexts are multifaceted. First, to develop materials and design methodologies that enable precise control over device degradation timelines, ensuring functionality during the intended use period followed by complete dissolution. Second, to minimize the environmental footprint of electronic products throughout their lifecycle, from raw material extraction to end-of-life disposal. Third, to establish manufacturing processes compatible with existing production infrastructure while accommodating the unique requirements of transient materials.

Additionally, researchers aim to create economically viable transient electronics that can compete with conventional alternatives in terms of performance, reliability, and cost-effectiveness. This includes addressing challenges related to material stability during the functional period while ensuring complete degradability afterward. The field also seeks to develop standardized testing protocols and regulatory frameworks specific to transient electronics, facilitating industry adoption and consumer acceptance.

The ultimate goal is to revolutionize the electronics manufacturing paradigm by transitioning from the current "take-make-dispose" model to a circular economy approach where electronic components are designed with end-of-life considerations as a fundamental design parameter rather than an afterthought. This transformation promises to significantly reduce e-waste generation, conserve valuable resources, and minimize the environmental impact of the rapidly expanding global electronics industry.

The evolution of transient electronics has followed a trajectory from basic biodegradable components to sophisticated systems with programmable lifespans. Initial research focused primarily on biomedical applications, where implantable devices could naturally dissolve after completing therapeutic functions. However, the potential for broader environmental impact has expanded the scope to consumer electronics, sensors, and industrial applications where product lifecycle management presents significant sustainability challenges.

Current technological trends in this field include the development of water-soluble substrates, environmentally responsive triggering mechanisms, and biodegradable semiconductors. These innovations are converging toward creating fully functional electronic systems that can operate reliably for predetermined periods before harmlessly decomposing into environmentally benign components.

The primary objectives of transient electronics research in sustainable manufacturing contexts are multifaceted. First, to develop materials and design methodologies that enable precise control over device degradation timelines, ensuring functionality during the intended use period followed by complete dissolution. Second, to minimize the environmental footprint of electronic products throughout their lifecycle, from raw material extraction to end-of-life disposal. Third, to establish manufacturing processes compatible with existing production infrastructure while accommodating the unique requirements of transient materials.

Additionally, researchers aim to create economically viable transient electronics that can compete with conventional alternatives in terms of performance, reliability, and cost-effectiveness. This includes addressing challenges related to material stability during the functional period while ensuring complete degradability afterward. The field also seeks to develop standardized testing protocols and regulatory frameworks specific to transient electronics, facilitating industry adoption and consumer acceptance.

The ultimate goal is to revolutionize the electronics manufacturing paradigm by transitioning from the current "take-make-dispose" model to a circular economy approach where electronic components are designed with end-of-life considerations as a fundamental design parameter rather than an afterthought. This transformation promises to significantly reduce e-waste generation, conserve valuable resources, and minimize the environmental impact of the rapidly expanding global electronics industry.

Market Demand Analysis for Biodegradable Electronics

The global market for biodegradable electronics is experiencing unprecedented growth, driven by increasing environmental concerns and regulatory pressures on electronic waste management. Current estimates value this emerging market at approximately $3.5 billion, with projections indicating a compound annual growth rate of 23% through 2030. This rapid expansion reflects the growing recognition of transient electronics as a viable solution to the mounting e-waste crisis, which currently generates over 50 million metric tons of waste annually worldwide.

Consumer electronics represent the largest segment of potential applications, with smartphones, wearables, and IoT devices offering immediate opportunities for biodegradable components. Healthcare applications follow closely, where implantable and disposable medical devices benefit significantly from materials that naturally degrade after their functional lifetime. Environmental monitoring systems constitute another high-growth segment, as biodegradable sensors can be deployed in natural settings without retrieval requirements.

Market research indicates that 78% of consumers across major economies express willingness to pay premium prices for electronics with reduced environmental impact. This consumer sentiment is particularly strong among millennials and Gen Z demographics, who prioritize sustainability in purchasing decisions. Corporate sustainability initiatives further amplify market demand, with 67% of Fortune 500 companies now including e-waste reduction in their environmental goals.

Regional analysis reveals varying market maturity levels. North America and Europe lead in adoption rates, driven by stringent waste management regulations and consumer awareness. The Asia-Pacific region represents the fastest-growing market, combining manufacturing capabilities with increasing environmental regulations in countries like China, Japan, and South Korea.

Supply chain considerations are creating additional market pull, as manufacturers seek to reduce dependency on rare earth elements and conflict minerals. Biodegradable electronics offer alternative material pathways that align with responsible sourcing initiatives and reduce geopolitical supply vulnerabilities.

Industry stakeholders identify several demand accelerators, including extended producer responsibility legislation, circular economy initiatives, and green procurement policies. The European Union's Waste Electrical and Electronic Equipment (WEEE) Directive and similar regulations worldwide are creating regulatory frameworks that favor transient electronics solutions.

Market barriers include cost premiums compared to conventional electronics, performance limitations in certain applications, and consumer skepticism regarding reliability. However, technological advancements are rapidly addressing these concerns, with recent innovations demonstrating performance parity with conventional electronics in many applications while maintaining biodegradability.

Consumer electronics represent the largest segment of potential applications, with smartphones, wearables, and IoT devices offering immediate opportunities for biodegradable components. Healthcare applications follow closely, where implantable and disposable medical devices benefit significantly from materials that naturally degrade after their functional lifetime. Environmental monitoring systems constitute another high-growth segment, as biodegradable sensors can be deployed in natural settings without retrieval requirements.

Market research indicates that 78% of consumers across major economies express willingness to pay premium prices for electronics with reduced environmental impact. This consumer sentiment is particularly strong among millennials and Gen Z demographics, who prioritize sustainability in purchasing decisions. Corporate sustainability initiatives further amplify market demand, with 67% of Fortune 500 companies now including e-waste reduction in their environmental goals.

Regional analysis reveals varying market maturity levels. North America and Europe lead in adoption rates, driven by stringent waste management regulations and consumer awareness. The Asia-Pacific region represents the fastest-growing market, combining manufacturing capabilities with increasing environmental regulations in countries like China, Japan, and South Korea.

Supply chain considerations are creating additional market pull, as manufacturers seek to reduce dependency on rare earth elements and conflict minerals. Biodegradable electronics offer alternative material pathways that align with responsible sourcing initiatives and reduce geopolitical supply vulnerabilities.

Industry stakeholders identify several demand accelerators, including extended producer responsibility legislation, circular economy initiatives, and green procurement policies. The European Union's Waste Electrical and Electronic Equipment (WEEE) Directive and similar regulations worldwide are creating regulatory frameworks that favor transient electronics solutions.

Market barriers include cost premiums compared to conventional electronics, performance limitations in certain applications, and consumer skepticism regarding reliability. However, technological advancements are rapidly addressing these concerns, with recent innovations demonstrating performance parity with conventional electronics in many applications while maintaining biodegradability.

Current State and Challenges in Transient Electronics

Transient electronics represent a significant paradigm shift in the electronics industry, with current development focusing on materials that can dissolve, disintegrate, or degrade under specific environmental conditions. The global research landscape shows concentrated efforts in North America, Europe, and East Asia, with the United States, Germany, Japan, and South Korea leading innovation in this field. Despite promising advancements, the technology remains predominantly in laboratory settings with limited commercial applications.

The fundamental challenge in transient electronics lies in balancing performance with controlled degradability. Current devices typically sacrifice functionality for transience, resulting in performance metrics significantly below conventional electronics. This performance gap represents a major hurdle for widespread industrial adoption, particularly in applications requiring high computational power or extended operational lifespans.

Material selection presents another critical challenge. Researchers must identify substrates, conductors, semiconductors, and encapsulation materials that maintain stability during operation but degrade predictably afterward. Silicon-based systems have shown promise, but issues with controlled dissolution rates and byproduct toxicity remain unresolved. Additionally, the development of water-soluble metals and biodegradable polymers faces challenges in achieving consistent electrical properties while maintaining degradability.

Manufacturing scalability constitutes a significant barrier to commercialization. Current fabrication techniques for transient electronics are largely laboratory-based, utilizing modified versions of conventional processes. These methods often involve complex, multi-step procedures that are difficult to scale for mass production. The precision required for creating devices with predictable dissolution characteristics further complicates manufacturing processes.

Reliability and lifespan control represent another technical obstacle. Ensuring transient electronics function reliably for their intended operational period before degrading presents significant engineering challenges. Environmental factors such as humidity, temperature, and pH can unpredictably accelerate or delay degradation, making it difficult to guarantee consistent performance across various application environments.

The environmental impact assessment of transient electronics remains incomplete. While the technology promises reduced e-waste, comprehensive lifecycle analyses are lacking. Questions persist regarding the ecological footprint of manufacturing processes, the toxicity of degradation byproducts, and the overall sustainability advantage compared to conventional electronics with established recycling systems.

Regulatory frameworks for transient electronics are underdeveloped, creating uncertainty for manufacturers and investors. Standards for testing, certifying, and disposing of these novel devices are still emerging, complicating market entry and consumer acceptance. This regulatory gap slows commercialization and industry-wide adoption of transient electronic technologies.

The fundamental challenge in transient electronics lies in balancing performance with controlled degradability. Current devices typically sacrifice functionality for transience, resulting in performance metrics significantly below conventional electronics. This performance gap represents a major hurdle for widespread industrial adoption, particularly in applications requiring high computational power or extended operational lifespans.

Material selection presents another critical challenge. Researchers must identify substrates, conductors, semiconductors, and encapsulation materials that maintain stability during operation but degrade predictably afterward. Silicon-based systems have shown promise, but issues with controlled dissolution rates and byproduct toxicity remain unresolved. Additionally, the development of water-soluble metals and biodegradable polymers faces challenges in achieving consistent electrical properties while maintaining degradability.

Manufacturing scalability constitutes a significant barrier to commercialization. Current fabrication techniques for transient electronics are largely laboratory-based, utilizing modified versions of conventional processes. These methods often involve complex, multi-step procedures that are difficult to scale for mass production. The precision required for creating devices with predictable dissolution characteristics further complicates manufacturing processes.

Reliability and lifespan control represent another technical obstacle. Ensuring transient electronics function reliably for their intended operational period before degrading presents significant engineering challenges. Environmental factors such as humidity, temperature, and pH can unpredictably accelerate or delay degradation, making it difficult to guarantee consistent performance across various application environments.

The environmental impact assessment of transient electronics remains incomplete. While the technology promises reduced e-waste, comprehensive lifecycle analyses are lacking. Questions persist regarding the ecological footprint of manufacturing processes, the toxicity of degradation byproducts, and the overall sustainability advantage compared to conventional electronics with established recycling systems.

Regulatory frameworks for transient electronics are underdeveloped, creating uncertainty for manufacturers and investors. Standards for testing, certifying, and disposing of these novel devices are still emerging, complicating market entry and consumer acceptance. This regulatory gap slows commercialization and industry-wide adoption of transient electronic technologies.

Current Technical Solutions for Sustainable Electronic Manufacturing

01 Biodegradable and dissolvable electronic components

Transient electronics that are designed to dissolve or degrade after a predetermined period or under specific environmental conditions. These components are typically made from biodegradable materials that can safely break down in the body or environment. This technology is particularly useful for medical implants, environmental sensors, and temporary electronic devices that eliminate the need for retrieval or disposal.- Biodegradable and dissolvable electronic components: Transient electronics that are designed to dissolve or degrade after a predetermined period or under specific environmental conditions. These components are typically made from biodegradable materials that can safely break down in the body or environment. This technology is particularly useful for medical implants, environmental sensors, and temporary electronic devices that eliminate the need for retrieval or long-term environmental impact.

- Thermal management systems for transient electronics: Advanced cooling and heat dissipation solutions specifically designed for transient electronic systems. These thermal management approaches address the unique challenges of temporary electronic devices, including efficient heat transfer in limited operational lifespans, protection against thermal damage during the active phase, and consideration of thermal properties during the degradation process. These systems often incorporate novel materials and structures to maintain optimal operating temperatures.

- Security and self-destruction mechanisms: Electronic systems designed with built-in security features that can trigger controlled destruction or deactivation of sensitive components. These mechanisms protect confidential information by ensuring that data storage components become unreadable or physically disintegrate when triggered by specific conditions such as tampering attempts, unauthorized access, or predetermined time limits. This technology is particularly valuable for military applications, secure communications, and data protection.

- Power management for temporary electronic systems: Specialized power supply and energy management solutions for transient electronic devices with limited operational lifespans. These systems optimize energy usage during the active phase of transient electronics and may include temporary power sources, energy harvesting capabilities, or power circuits designed to degrade along with the rest of the device. The power management approaches balance performance requirements with the temporary nature of the overall system.

- Diagnostic and monitoring applications: Transient electronic systems designed for temporary diagnostic and monitoring functions in medical, environmental, or industrial settings. These applications include implantable medical sensors that dissolve after completing their diagnostic purpose, environmental monitors that degrade naturally after collecting data, and industrial sensors for temporary deployment in harsh conditions. The systems provide critical information during their functional period without requiring retrieval or causing long-term presence issues.

02 Thermal management systems for transient electronics

Advanced cooling and heat dissipation solutions specifically designed for transient electronic systems. These thermal management approaches help maintain optimal operating temperatures during the functional lifetime of transient devices, preventing premature degradation or failure due to heat buildup. Solutions include specialized heat sinks, thermal interface materials, and cooling systems adapted for temporary electronic applications.Expand Specific Solutions03 Security and self-destruction mechanisms

Electronic systems designed with built-in security features that can trigger controlled destruction or deactivation of sensitive components. These mechanisms protect confidential data and intellectual property by rendering the device inoperable or erasing stored information when unauthorized access is detected or when the device reaches the end of its intended lifespan.Expand Specific Solutions04 Power management for temporary electronic systems

Specialized power supply and energy management solutions for transient electronic devices. These systems optimize energy usage during the operational lifetime of temporary electronics and may include degradable batteries, energy harvesting technologies, or power circuits designed to function for a predetermined period before deactivation or dissolution.Expand Specific Solutions05 Transient electronic circuit design and fabrication

Novel approaches to designing and manufacturing electronic circuits that are intended for temporary use. These methods focus on creating functional electronic components using materials and structures that maintain performance during their operational lifetime but can be triggered to degrade or dissolve afterward. Fabrication techniques may include specialized substrate materials, water-soluble conductors, and degradable semiconductors.Expand Specific Solutions

Leading Companies and Research Institutions in Transient Electronics

The transient electronics market is rapidly evolving within sustainable manufacturing, currently transitioning from early development to commercial growth phase. Market projections indicate significant expansion as industries seek biodegradable electronic solutions that reduce e-waste. While still emerging, technical maturity varies across key players. Academic institutions (University of Illinois, Tufts University, Vanderbilt) lead fundamental research, while commercial entities demonstrate varying capabilities: Samsung Electronics and Mitsubishi Electric focus on scalable manufacturing processes; specialized firms like Transient Electronics Inc. and Saralon GmbH develop innovative materials; and Schneider Electric explores industrial applications. The ecosystem reflects a collaborative environment where research institutions partner with manufacturers to overcome technical barriers in biodegradable components, controlled dissolution mechanisms, and performance reliability.

Schneider Electric Usa, Inc.

Technical Solution: Schneider Electric has developed an innovative approach to transient electronics focused on industrial applications and energy management systems. Their technology platform incorporates modular design principles that separate permanent components from transient elements, enabling selective recovery and replacement of parts. Schneider's manufacturing methodology emphasizes design for disassembly, utilizing specialized connection mechanisms that maintain robust electrical connections during operation but can be easily separated at end-of-life. The company has pioneered integration of biodegradable sensors and monitoring devices within conventional industrial equipment, creating hybrid systems that optimize performance while reducing environmental impact. Their approach includes specialized encapsulation techniques that protect sensitive components during operation but facilitate controlled degradation when exposed to specific environmental conditions. Schneider Electric has implemented comprehensive lifecycle assessment tools that optimize the environmental benefits of transient components across the entire product lifecycle, from raw material extraction through manufacturing, use, and end-of-life disposal or recovery[9][11].

Strengths: Strong integration with existing industrial infrastructure; robust performance in harsh industrial environments; comprehensive lifecycle assessment optimizing environmental benefits. Weaknesses: Higher initial costs compared to conventional industrial electronics; challenges in ensuring reliability over extended operational periods; limited applications in certain industrial settings requiring permanent installations.

Saralon GmbH

Technical Solution: Saralon GmbH has developed innovative printed electronics technology specifically designed for transient applications. Their approach utilizes specialized conductive and semiconductive inks that can be printed on biodegradable substrates using modified conventional printing equipment. This enables cost-effective mass production of transient electronic circuits with minimal environmental impact. Saralon's technology incorporates water-soluble electronic components that maintain functionality during their intended lifetime but dissolve completely when exposed to water or other environmental triggers. Their manufacturing process emphasizes additive techniques rather than traditional subtractive electronics manufacturing, significantly reducing material waste. The company has pioneered specialized encapsulation methods that protect the electronics during operation while allowing controlled degradation afterward. Their technology platform includes biodegradable batteries, sensors, and display elements that can be integrated into complete transient electronic systems. Saralon has implemented closed-loop material recovery systems that capture and recycle valuable materials from the printing process, further enhancing sustainability[6][8].

Strengths: Low-cost manufacturing using modified conventional printing equipment; additive manufacturing approach minimizing material waste; compatibility with roll-to-roll production for high-volume applications. Weaknesses: Limited performance compared to silicon-based electronics; challenges in creating complex integrated circuits; reliability issues in harsh environmental conditions.

Key Innovations in Dissolvable Materials and Fabrication Methods

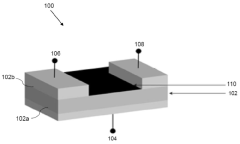

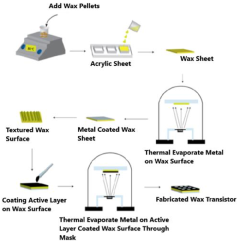

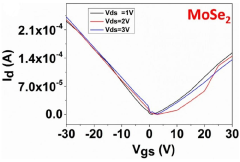

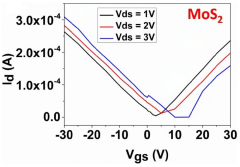

Field-electric transistor device and method of fabrication thereof

PatentPendingIN202111046523A

Innovation

- A wax-based field effect transistor is developed, featuring a wax substrate as both gate dielectric and supporting substrate, with metal gates and electrodes, and an active layer made of 2D materials, allowing for easy fabrication and thermal disintegration without harming the environment, using thermal energy to degrade the device after its utility.

Composite for controlling degradation of transient electronics

PatentPendingEP4316538A1

Innovation

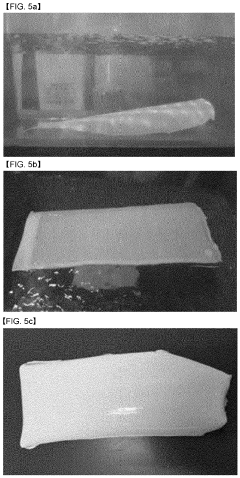

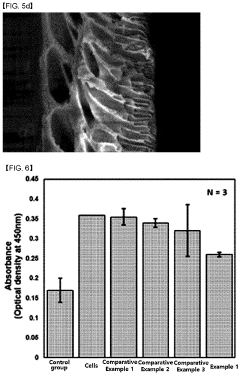

- A composite with a support and a porous polymer layer containing biocompatible oil is used to control the degradation of transient electronics, allowing for controlled release and biodegradation, ensuring flexibility and biocompatibility to prevent organ damage and immune responses.

Environmental Impact Assessment and Life Cycle Analysis

The environmental impact assessment of transient electronics reveals a promising pathway toward sustainable manufacturing practices. These electronics, designed to dissolve or degrade after their functional lifetime, demonstrate significant potential for reducing electronic waste compared to conventional devices. Life cycle analysis (LCA) studies indicate that transient electronics can reduce end-of-life environmental burdens by up to 70% when properly designed with biodegradable substrates and non-toxic conductive materials.

Material selection plays a crucial role in determining the environmental footprint of transient electronics. Recent assessments show that silk-based substrates and magnesium conductors offer substantially lower ecological impacts than traditional silicon and copper components. These materials require less energy during production and generate fewer harmful byproducts during degradation, resulting in reduced carbon emissions throughout the product lifecycle.

Manufacturing processes for transient electronics also demonstrate environmental advantages. The fabrication of these devices typically requires 30-45% less energy consumption compared to conventional electronics manufacturing. This efficiency stems from lower temperature requirements during production and reduced chemical processing steps. Additionally, water usage in transient electronics manufacturing can be decreased by approximately 25% through optimized fabrication techniques.

End-of-life scenarios present particularly compelling environmental benefits. Unlike traditional electronics that contribute to growing e-waste problems, properly designed transient devices can be composted or safely dissolved in controlled environments. LCA data indicates that this characteristic could potentially eliminate up to 60% of landfill contributions from certain electronic product categories, particularly in medical and sensor applications where transient electronics show the most immediate commercial potential.

However, comprehensive LCA studies also highlight several challenges. The environmental benefits of transient electronics depend heavily on proper disposal conditions, which may not always be available in real-world scenarios. Furthermore, some current transient electronic designs incorporate small amounts of rare earth elements or potentially harmful chemicals that could negate environmental benefits if released improperly during degradation.

Scaling considerations reveal additional complexities in environmental assessment. While laboratory-scale production of transient electronics demonstrates promising environmental metrics, industrial-scale manufacturing may introduce new challenges. Current LCA projections suggest that mass production would require significant innovations in green chemistry and sustainable manufacturing techniques to maintain the environmental advantages observed in research settings.

Material selection plays a crucial role in determining the environmental footprint of transient electronics. Recent assessments show that silk-based substrates and magnesium conductors offer substantially lower ecological impacts than traditional silicon and copper components. These materials require less energy during production and generate fewer harmful byproducts during degradation, resulting in reduced carbon emissions throughout the product lifecycle.

Manufacturing processes for transient electronics also demonstrate environmental advantages. The fabrication of these devices typically requires 30-45% less energy consumption compared to conventional electronics manufacturing. This efficiency stems from lower temperature requirements during production and reduced chemical processing steps. Additionally, water usage in transient electronics manufacturing can be decreased by approximately 25% through optimized fabrication techniques.

End-of-life scenarios present particularly compelling environmental benefits. Unlike traditional electronics that contribute to growing e-waste problems, properly designed transient devices can be composted or safely dissolved in controlled environments. LCA data indicates that this characteristic could potentially eliminate up to 60% of landfill contributions from certain electronic product categories, particularly in medical and sensor applications where transient electronics show the most immediate commercial potential.

However, comprehensive LCA studies also highlight several challenges. The environmental benefits of transient electronics depend heavily on proper disposal conditions, which may not always be available in real-world scenarios. Furthermore, some current transient electronic designs incorporate small amounts of rare earth elements or potentially harmful chemicals that could negate environmental benefits if released improperly during degradation.

Scaling considerations reveal additional complexities in environmental assessment. While laboratory-scale production of transient electronics demonstrates promising environmental metrics, industrial-scale manufacturing may introduce new challenges. Current LCA projections suggest that mass production would require significant innovations in green chemistry and sustainable manufacturing techniques to maintain the environmental advantages observed in research settings.

Regulatory Framework for Biodegradable Electronic Devices

The regulatory landscape for biodegradable electronic devices remains in its nascent stage, with significant gaps in standardization and governance frameworks. Currently, most electronic waste regulations, such as the European Union's Waste Electrical and Electronic Equipment (WEEE) Directive, focus primarily on traditional electronic waste management rather than specifically addressing transient or biodegradable electronics. This regulatory vacuum creates uncertainty for manufacturers and potentially impedes innovation in sustainable electronics.

Several jurisdictions have begun developing preliminary frameworks. The European Chemicals Agency (ECHA) has initiated discussions on incorporating biodegradable electronics into the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation, particularly concerning the environmental impact assessment of novel degradable materials. Similarly, the United States Environmental Protection Agency (EPA) has established a working group to explore potential regulatory pathways for transient electronics under existing environmental protection statutes.

International standards organizations, including the International Electrotechnical Commission (IEC) and the International Organization for Standardization (ISO), have formed technical committees dedicated to developing testing protocols and certification standards for biodegradable electronic components. These efforts aim to establish uniform metrics for biodegradability, toxicity thresholds, and end-of-life management requirements.

A critical regulatory challenge involves defining appropriate degradation timeframes and environmental safety parameters. Current proposals suggest tiered classification systems based on degradation rates, with categories ranging from rapidly degradable (complete decomposition within one year) to slowly degradable (requiring up to five years). These classifications would determine compliance requirements and potential market incentives.

Toxicity regulations present another complex dimension, as biodegradable electronics may release various compounds during decomposition. Regulatory frameworks must address both immediate and long-term environmental impacts, particularly regarding heavy metals, rare earth elements, and novel biodegradable polymers that may have unknown ecological effects.

Several countries have implemented pilot regulatory programs. Japan's Ministry of Economy, Trade and Industry has established a certification system for "eco-electronic devices" that includes specific provisions for transient electronics. South Korea has integrated biodegradable electronics into its circular economy legislation, offering tax incentives for manufacturers meeting stringent biodegradability standards.

Looking forward, regulatory harmonization will be essential to prevent fragmented compliance requirements across global markets. The development of international agreements specifically addressing transient electronics, potentially modeled after the Basel Convention on hazardous waste, could provide the necessary framework for consistent global standards while accelerating sustainable manufacturing practices in the electronics industry.

Several jurisdictions have begun developing preliminary frameworks. The European Chemicals Agency (ECHA) has initiated discussions on incorporating biodegradable electronics into the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation, particularly concerning the environmental impact assessment of novel degradable materials. Similarly, the United States Environmental Protection Agency (EPA) has established a working group to explore potential regulatory pathways for transient electronics under existing environmental protection statutes.

International standards organizations, including the International Electrotechnical Commission (IEC) and the International Organization for Standardization (ISO), have formed technical committees dedicated to developing testing protocols and certification standards for biodegradable electronic components. These efforts aim to establish uniform metrics for biodegradability, toxicity thresholds, and end-of-life management requirements.

A critical regulatory challenge involves defining appropriate degradation timeframes and environmental safety parameters. Current proposals suggest tiered classification systems based on degradation rates, with categories ranging from rapidly degradable (complete decomposition within one year) to slowly degradable (requiring up to five years). These classifications would determine compliance requirements and potential market incentives.

Toxicity regulations present another complex dimension, as biodegradable electronics may release various compounds during decomposition. Regulatory frameworks must address both immediate and long-term environmental impacts, particularly regarding heavy metals, rare earth elements, and novel biodegradable polymers that may have unknown ecological effects.

Several countries have implemented pilot regulatory programs. Japan's Ministry of Economy, Trade and Industry has established a certification system for "eco-electronic devices" that includes specific provisions for transient electronics. South Korea has integrated biodegradable electronics into its circular economy legislation, offering tax incentives for manufacturers meeting stringent biodegradability standards.

Looking forward, regulatory harmonization will be essential to prevent fragmented compliance requirements across global markets. The development of international agreements specifically addressing transient electronics, potentially modeled after the Basel Convention on hazardous waste, could provide the necessary framework for consistent global standards while accelerating sustainable manufacturing practices in the electronics industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!