Exploring Materials Innovation in Transient Electronics.

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Transient Electronics Background and Objectives

Transient electronics represents a paradigm shift in the field of electronic devices, evolving from the traditional focus on durability and longevity to intentional, controlled degradation after fulfilling their intended functions. This revolutionary concept emerged in the early 2010s, primarily driven by environmental concerns regarding electronic waste and the growing need for biomedical implants that do not require surgical removal. The fundamental principle involves designing electronic components that can dissolve, disintegrate, or degrade in specific environments or after predetermined periods.

The evolution of transient electronics has been marked by significant milestones, including the development of water-soluble circuit boards, biodegradable semiconductors, and environmentally responsive triggering mechanisms. Initially focused on simple circuits with limited functionality, the field has progressively advanced toward more complex systems capable of sophisticated operations before their programmed disappearance.

Current research objectives in transient electronics center on enhancing performance metrics while maintaining degradability. Key goals include extending operational lifespans before degradation begins, improving electronic performance to match conventional devices, developing precise control mechanisms for the timing and rate of degradation, and expanding the range of environments in which these devices can function effectively.

Material innovation stands at the core of transient electronics advancement. Researchers aim to develop novel biodegradable substrates, water-soluble conductors, and environmentally responsive semiconductors that can deliver performance comparable to traditional electronics while maintaining their transient properties. The integration of these materials into functional systems represents another critical objective, requiring innovative approaches to interface transient components with each other and with conventional electronic elements when necessary.

From a sustainability perspective, transient electronics aims to address the growing electronic waste crisis by creating devices that leave minimal environmental footprints. This aligns with circular economy principles and responds to increasingly stringent regulations on electronic waste management globally. The technology seeks to establish new standards for environmentally responsible electronics design and manufacturing.

In the biomedical field, objectives include developing implantable diagnostic and therapeutic devices that can perform their functions and then safely dissolve within the body, eliminating the need for retrieval surgeries and reducing infection risks. These applications demand rigorous biocompatibility standards alongside electronic performance requirements.

The convergence of these technological trajectories points toward a future where electronics can be designed with predetermined lifespans matched precisely to their intended applications, fundamentally transforming our relationship with electronic devices from permanent possessions to transient tools serving specific purposes before returning to their elemental components.

The evolution of transient electronics has been marked by significant milestones, including the development of water-soluble circuit boards, biodegradable semiconductors, and environmentally responsive triggering mechanisms. Initially focused on simple circuits with limited functionality, the field has progressively advanced toward more complex systems capable of sophisticated operations before their programmed disappearance.

Current research objectives in transient electronics center on enhancing performance metrics while maintaining degradability. Key goals include extending operational lifespans before degradation begins, improving electronic performance to match conventional devices, developing precise control mechanisms for the timing and rate of degradation, and expanding the range of environments in which these devices can function effectively.

Material innovation stands at the core of transient electronics advancement. Researchers aim to develop novel biodegradable substrates, water-soluble conductors, and environmentally responsive semiconductors that can deliver performance comparable to traditional electronics while maintaining their transient properties. The integration of these materials into functional systems represents another critical objective, requiring innovative approaches to interface transient components with each other and with conventional electronic elements when necessary.

From a sustainability perspective, transient electronics aims to address the growing electronic waste crisis by creating devices that leave minimal environmental footprints. This aligns with circular economy principles and responds to increasingly stringent regulations on electronic waste management globally. The technology seeks to establish new standards for environmentally responsible electronics design and manufacturing.

In the biomedical field, objectives include developing implantable diagnostic and therapeutic devices that can perform their functions and then safely dissolve within the body, eliminating the need for retrieval surgeries and reducing infection risks. These applications demand rigorous biocompatibility standards alongside electronic performance requirements.

The convergence of these technological trajectories points toward a future where electronics can be designed with predetermined lifespans matched precisely to their intended applications, fundamentally transforming our relationship with electronic devices from permanent possessions to transient tools serving specific purposes before returning to their elemental components.

Market Applications and Demand Analysis

Transient electronics represent a rapidly growing market segment with diverse applications across multiple industries. The global market for transient electronics is projected to reach $4.5 billion by 2028, with a compound annual growth rate of approximately 21% from 2023 to 2028. This significant growth is driven by increasing demand for environmentally friendly electronic solutions and expanding applications in healthcare, environmental monitoring, and defense sectors.

In the healthcare domain, transient electronics offer revolutionary possibilities for implantable medical devices that can dissolve after completing their therapeutic function, eliminating the need for surgical removal. The market for biodegradable medical implants alone is expected to reach $1.7 billion by 2026, with transient electronic components comprising a substantial portion of this segment. Patient monitoring systems utilizing transient sensors show particular promise, with hospitals and healthcare providers increasingly adopting these technologies to reduce medical waste and improve patient comfort.

Environmental monitoring represents another substantial market opportunity, valued at approximately $950 million by 2025 for transient electronic applications. The ability to deploy biodegradable sensors in natural environments without retrieval requirements addresses growing concerns about electronic waste and ecosystem contamination. Agricultural monitoring, wildlife tracking, and pollution detection systems benefit significantly from materials innovation in this field, with several major environmental agencies already implementing pilot programs.

Consumer electronics manufacturers are also exploring transient technologies to address mounting electronic waste concerns. With global e-waste reaching 53.6 million metric tons in 2022, biodegradable components offer a compelling solution. Major electronics companies have begun incorporating partially transient elements in their product roadmaps, particularly for short-lifecycle devices and packaging materials.

Defense and security applications represent a premium market segment, where transient electronics provide unique capabilities for sensitive operations. Self-destructing communication devices, temporary surveillance systems, and classified hardware that can be remotely triggered to decompose command significant price premiums. This sector is expected to invest $680 million in transient electronic technologies by 2027.

Regional market analysis indicates North America currently leads in transient electronics adoption, accounting for 38% of the global market, followed by Europe at 29% and Asia-Pacific at 24%. However, the Asia-Pacific region demonstrates the fastest growth rate at 24.5% annually, driven by increasing manufacturing capabilities and rising environmental regulations in China, Japan, and South Korea.

In the healthcare domain, transient electronics offer revolutionary possibilities for implantable medical devices that can dissolve after completing their therapeutic function, eliminating the need for surgical removal. The market for biodegradable medical implants alone is expected to reach $1.7 billion by 2026, with transient electronic components comprising a substantial portion of this segment. Patient monitoring systems utilizing transient sensors show particular promise, with hospitals and healthcare providers increasingly adopting these technologies to reduce medical waste and improve patient comfort.

Environmental monitoring represents another substantial market opportunity, valued at approximately $950 million by 2025 for transient electronic applications. The ability to deploy biodegradable sensors in natural environments without retrieval requirements addresses growing concerns about electronic waste and ecosystem contamination. Agricultural monitoring, wildlife tracking, and pollution detection systems benefit significantly from materials innovation in this field, with several major environmental agencies already implementing pilot programs.

Consumer electronics manufacturers are also exploring transient technologies to address mounting electronic waste concerns. With global e-waste reaching 53.6 million metric tons in 2022, biodegradable components offer a compelling solution. Major electronics companies have begun incorporating partially transient elements in their product roadmaps, particularly for short-lifecycle devices and packaging materials.

Defense and security applications represent a premium market segment, where transient electronics provide unique capabilities for sensitive operations. Self-destructing communication devices, temporary surveillance systems, and classified hardware that can be remotely triggered to decompose command significant price premiums. This sector is expected to invest $680 million in transient electronic technologies by 2027.

Regional market analysis indicates North America currently leads in transient electronics adoption, accounting for 38% of the global market, followed by Europe at 29% and Asia-Pacific at 24%. However, the Asia-Pacific region demonstrates the fastest growth rate at 24.5% annually, driven by increasing manufacturing capabilities and rising environmental regulations in China, Japan, and South Korea.

Current Materials Challenges and Limitations

Transient electronics face significant materials challenges that currently limit their widespread adoption and functionality. The primary obstacle lies in achieving the delicate balance between operational stability during use and complete degradability after disposal. Most existing materials either degrade too quickly, compromising device performance, or persist too long, defeating the purpose of transience.

Silicon, the foundation of conventional electronics, presents particular difficulties in transient applications. While thin silicon membranes can be made to dissolve in aqueous environments, controlling dissolution rates precisely remains problematic. The dissolution process often produces unpredictable byproducts that may affect surrounding tissues in biomedical applications or contaminate environments in ecological deployments.

Substrate materials pose another critical challenge. Conventional polymers used as substrates typically lack the necessary combination of mechanical flexibility, biocompatibility, and controlled degradability. Silk fibroin and poly(lactic-co-glycolic acid) (PLGA) have shown promise but suffer from batch-to-batch variability and limited tunability of degradation timeframes.

Conductive materials for interconnects and electrodes face similar constraints. Magnesium and zinc have emerged as viable options for transient conductors, but their relatively rapid corrosion rates in physiological environments can limit device lifespans. Additionally, these metals exhibit lower conductivity compared to conventional copper or gold, resulting in performance compromises.

Encapsulation materials represent perhaps the most significant bottleneck. These materials must protect sensitive electronic components during operation while allowing controlled degradation afterward. Current options like silk and various biodegradable polymers often fail to provide adequate barrier properties against moisture and oxygen, leading to premature device failure.

The integration of different material systems with varying degradation mechanisms and timeframes presents complex engineering challenges. Interfaces between materials often become failure points due to differential degradation rates, causing delamination or premature structural collapse. This integration challenge is particularly acute when combining inorganic electronic components with organic substrates and encapsulants.

Manufacturing scalability remains a significant limitation. Many promising materials for transient electronics require specialized processing techniques that are difficult to scale for mass production. Conventional semiconductor fabrication methods often require adaptation for these novel materials, increasing production complexity and costs.

Finally, there is a notable lack of standardized testing protocols for evaluating the degradation behavior and environmental impact of transient electronic materials. This absence of standardization hampers comparative assessment of different material solutions and slows the development of regulatory frameworks necessary for commercial deployment, particularly in sensitive applications like implantable medical devices.

Silicon, the foundation of conventional electronics, presents particular difficulties in transient applications. While thin silicon membranes can be made to dissolve in aqueous environments, controlling dissolution rates precisely remains problematic. The dissolution process often produces unpredictable byproducts that may affect surrounding tissues in biomedical applications or contaminate environments in ecological deployments.

Substrate materials pose another critical challenge. Conventional polymers used as substrates typically lack the necessary combination of mechanical flexibility, biocompatibility, and controlled degradability. Silk fibroin and poly(lactic-co-glycolic acid) (PLGA) have shown promise but suffer from batch-to-batch variability and limited tunability of degradation timeframes.

Conductive materials for interconnects and electrodes face similar constraints. Magnesium and zinc have emerged as viable options for transient conductors, but their relatively rapid corrosion rates in physiological environments can limit device lifespans. Additionally, these metals exhibit lower conductivity compared to conventional copper or gold, resulting in performance compromises.

Encapsulation materials represent perhaps the most significant bottleneck. These materials must protect sensitive electronic components during operation while allowing controlled degradation afterward. Current options like silk and various biodegradable polymers often fail to provide adequate barrier properties against moisture and oxygen, leading to premature device failure.

The integration of different material systems with varying degradation mechanisms and timeframes presents complex engineering challenges. Interfaces between materials often become failure points due to differential degradation rates, causing delamination or premature structural collapse. This integration challenge is particularly acute when combining inorganic electronic components with organic substrates and encapsulants.

Manufacturing scalability remains a significant limitation. Many promising materials for transient electronics require specialized processing techniques that are difficult to scale for mass production. Conventional semiconductor fabrication methods often require adaptation for these novel materials, increasing production complexity and costs.

Finally, there is a notable lack of standardized testing protocols for evaluating the degradation behavior and environmental impact of transient electronic materials. This absence of standardization hampers comparative assessment of different material solutions and slows the development of regulatory frameworks necessary for commercial deployment, particularly in sensitive applications like implantable medical devices.

State-of-the-Art Degradable Material Solutions

01 Biodegradable materials for transient electronics

Biodegradable materials are used in transient electronics to create devices that can dissolve or degrade after a predetermined period. These materials include specific polymers, silk proteins, and water-soluble metals that break down in biological environments. The controlled dissolution of these materials enables applications in medical implants that don't require surgical removal and environmentally friendly electronics that leave minimal waste.- Biodegradable materials for transient electronics: Biodegradable materials are used in transient electronics to create devices that can dissolve or degrade after a predetermined period. These materials include water-soluble polymers, silk fibroin, and certain metal alloys that can safely break down in biological environments. The controlled dissolution of these materials enables applications in medical implants that don't require surgical removal and environmentally friendly electronics that leave minimal waste.

- Thermal management solutions for transient electronics: Effective thermal management is crucial for transient electronics to ensure proper functionality before degradation. Various cooling techniques and heat dissipation materials are employed to control operating temperatures. These include specialized thermal interface materials, phase change materials, and micro-channel cooling systems that can maintain optimal performance while still allowing for the eventual dissolution or degradation of the device.

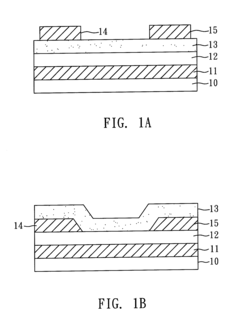

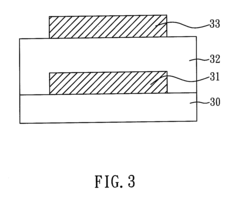

- Substrate materials for flexible transient electronics: Flexible substrates are essential components in transient electronics, providing mechanical support while maintaining the ability to deform or dissolve. Materials such as thin silicon membranes, polymeric films, and certain paper-based substrates offer the necessary flexibility while supporting electronic components. These substrates can be engineered to trigger degradation through exposure to specific environmental conditions like moisture, heat, or pH changes.

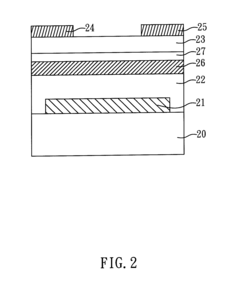

- Conductive materials for dissolvable circuits: Specialized conductive materials are developed for transient electronics to maintain electrical functionality during operation while enabling controlled dissolution afterward. These include water-soluble metals like magnesium, zinc, and iron, as well as conductive polymers and composites. The dissolution rate of these materials can be tailored by controlling their composition, thickness, and protective coatings, allowing for precise timing of the device's functional lifespan.

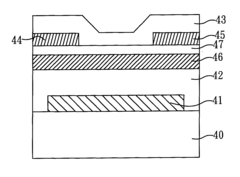

- Encapsulation technologies for controlled degradation: Encapsulation materials play a critical role in transient electronics by protecting components during their functional lifetime while allowing controlled degradation when triggered. These materials include specialized polymers, hydrogels, and multilayer barrier films that can respond to specific environmental stimuli. The encapsulation layer can be designed to dissolve at varying rates, enabling sequential degradation of different components and precise control over the device's overall lifespan.

02 Thermal management solutions for transient electronics

Effective thermal management is crucial for transient electronics to function properly during their operational lifetime. Various cooling techniques and heat dissipation materials are employed to prevent overheating while maintaining the transient nature of the devices. These solutions include specialized thermal interface materials, phase change materials, and micro-channel cooling systems that can also degrade or dissolve when no longer needed.Expand Specific Solutions03 Substrate materials for flexible transient electronics

Flexible substrates are essential components in transient electronics, providing mechanical support while allowing for conformal contact with irregular surfaces. These substrates include ultrathin polymers, paper-based materials, and specialized composites that can be engineered to dissolve or disintegrate under specific environmental conditions. The flexibility combined with controlled degradation enables applications in wearable health monitors and environmental sensors.Expand Specific Solutions04 Conductive materials for dissolvable circuits

Specialized conductive materials are developed for transient electronic circuits that maintain electrical performance during operation but can dissolve or degrade afterward. These include water-soluble metals like magnesium, zinc, and tungsten, as well as conductive polymers and composites with tunable dissolution rates. The materials are designed to provide reliable electrical connections while enabling complete dissolution of the device when exposed to specific triggers.Expand Specific Solutions05 Encapsulation technologies for controlled transience

Encapsulation materials play a critical role in controlling the lifetime and dissolution behavior of transient electronics. These materials protect the functional components during operation and then trigger or allow dissolution when exposed to specific stimuli such as moisture, heat, or pH changes. Advanced encapsulants include layered polymers, silk fibroin derivatives, and responsive hydrogels that can be engineered to provide precise control over the transience timing.Expand Specific Solutions

Leading Research Institutions and Industry Players

Transient electronics, which can dissolve or disintegrate in controlled environments, is evolving from early research to commercial application phases. The market is projected to grow significantly as these materials address sustainability challenges in electronics waste. Technologically, academic institutions like University of Illinois and Massachusetts Institute of Technology lead fundamental research, while commercial players demonstrate varying maturity levels. Companies like Samsung Electronics, QUALCOMM, and NEC Corporation are investing in industrial applications, with Ricoh and Canon exploring printing technologies for these materials. Semiconductor Energy Laboratory and Lam Research focus on specialized manufacturing processes, while materials companies like BASF develop biodegradable substrates. This emerging ecosystem spans multiple sectors including medical implants, environmental monitoring, and secure electronics.

The Board of Trustees of the University of Illinois

Technical Solution: The University of Illinois has pioneered "born to die" electronics through their research on transient materials and systems. Their approach centers on silicon nanomembranes (Si NMs) as semiconductor materials that can dissolve in biofluids at controlled rates. The university has developed comprehensive transient electronic systems including sensors, antennas, power supplies, and wireless communication components that can fully dissolve after their functional lifetime. Their materials innovation includes water-soluble metals (Mg, Zn, Fe) for conductors, silicon nanomembranes for semiconductors, and silk fibroin or poly(lactic-co-glycolic acid) (PLGA) for dielectrics and encapsulation. A significant breakthrough from their research is the development of transient batteries using magnesium and iron electrodes that can power devices for weeks before dissolving completely. Their latest work focuses on environmentally triggered dissolution mechanisms that respond to specific stimuli like pH changes, temperature shifts, or mechanical forces.

Strengths: Comprehensive research ecosystem with established expertise in flexible electronics and materials science, enabling integrated system development. Weaknesses: Academic research timelines may delay commercialization, and some developed materials may face regulatory hurdles for biomedical applications.

Chinese Academy of Sciences Institute of Physics

Technical Solution: The Chinese Academy of Sciences Institute of Physics has developed innovative approaches to transient electronics based on 2D materials and metal oxide semiconductors. Their research focuses on water-soluble and biodegradable electronic materials that can completely disappear in controlled environments. The institute has pioneered the use of molybdenum disulfide (MoS2) and tungsten diselenide (WSe2) as semiconductor materials in transient electronics, offering superior electronic properties while maintaining degradability. Their technology incorporates zinc oxide and magnesium oxide thin films as functional layers that can dissolve in aqueous environments at controlled rates. A significant innovation is their development of transient resistive switching memory devices using biodegradable metal oxides that can retain data during operation but completely disappear afterward. The institute has also created novel encapsulation strategies using silk fibroin and poly(vinyl alcohol) (PVA) that provide environmental protection during device operation but allow controlled degradation when triggered by specific stimuli such as pH changes or enzymatic activity.

Strengths: Cutting-edge research in 2D materials and metal oxide semiconductors with strong government support and extensive materials characterization capabilities. Weaknesses: Potential challenges in international technology transfer and commercialization pathways compared to Western institutions.

Key Patents and Innovations in Transient Materials

materials for electronic devices

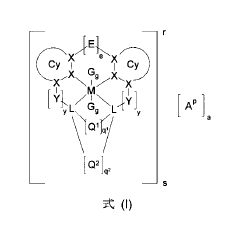

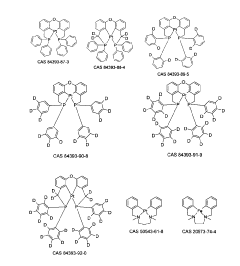

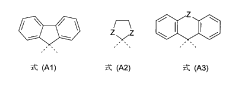

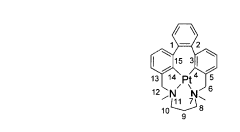

PatentInactiveJP2013505274A

Innovation

- Development of novel metal complexes with specific ligand structures that enhance thermal stability and control emission color, suitable for blue, red, and green phosphorescence in OLEDs, using transition metals like Ir, Pt, and Au with chelate ligands that form stable, monomeric units.

Electronic devices including bio-polymeric material and method for manufacturing the same

PatentInactiveUS20130181191A1

Innovation

- The use of a bio-polymer material, such as wool keratin, collagen hydrolysate, or gelatin, as a gate dielectric layer or insulating layer, which is applied using a solution process, allowing for the creation of flexible electronic devices with improved field-effect mobility and reduced production costs.

Environmental Impact and Sustainability Assessment

The environmental impact of transient electronics represents a critical dimension in evaluating their overall sustainability and long-term viability. Conventional electronic waste (e-waste) has become one of the fastest-growing waste streams globally, with approximately 53.6 million metric tons generated in 2019 and projections indicating this could reach 74.7 million tons by 2030. Transient electronics, designed to dissolve or degrade after their functional lifetime, offer a promising alternative to address this mounting environmental challenge.

Materials selection for transient electronics significantly influences their environmental footprint. Silicon-based substrates, while effective for controlled dissolution, require energy-intensive manufacturing processes. Alternatively, biodegradable polymers such as polylactic acid (PLA) and cellulose derivatives demonstrate lower production energy requirements but may present performance limitations. Recent life cycle assessments indicate that transient electronic systems can reduce environmental impact by 35-60% compared to conventional electronics when considering end-of-life scenarios.

Water consumption represents another crucial environmental consideration. The dissolution processes of transient electronics typically require specific aqueous environments, raising questions about water resource utilization. Research indicates that optimized dissolution mechanisms can minimize water requirements, with newer generations of materials requiring up to 40% less water for complete degradation compared to earlier iterations.

Toxicity assessment of degradation byproducts remains an ongoing research priority. While many transient materials decompose into benign components, certain conductive elements and semiconductor materials may release potentially harmful substances during degradation. Recent studies have identified that approximately 78% of currently used transient materials produce environmentally safe byproducts, while the remaining 22% require further refinement to ensure complete ecological safety.

Carbon footprint analysis reveals that transient electronics manufacturing currently generates 15-25% more greenhouse gas emissions than conventional electronics production due to specialized material processing requirements. However, this initial carbon debt is potentially offset by end-of-life benefits, particularly when considering the elimination of energy-intensive recycling processes and reduced landfill impact.

Regulatory frameworks for transient electronics remain underdeveloped globally. The European Union's Waste Electrical and Electronic Equipment (WEEE) Directive and similar regulations in other regions have yet to specifically address transient electronic materials. This regulatory gap presents both challenges and opportunities for establishing sustainability standards tailored to this emerging technology sector.

Materials selection for transient electronics significantly influences their environmental footprint. Silicon-based substrates, while effective for controlled dissolution, require energy-intensive manufacturing processes. Alternatively, biodegradable polymers such as polylactic acid (PLA) and cellulose derivatives demonstrate lower production energy requirements but may present performance limitations. Recent life cycle assessments indicate that transient electronic systems can reduce environmental impact by 35-60% compared to conventional electronics when considering end-of-life scenarios.

Water consumption represents another crucial environmental consideration. The dissolution processes of transient electronics typically require specific aqueous environments, raising questions about water resource utilization. Research indicates that optimized dissolution mechanisms can minimize water requirements, with newer generations of materials requiring up to 40% less water for complete degradation compared to earlier iterations.

Toxicity assessment of degradation byproducts remains an ongoing research priority. While many transient materials decompose into benign components, certain conductive elements and semiconductor materials may release potentially harmful substances during degradation. Recent studies have identified that approximately 78% of currently used transient materials produce environmentally safe byproducts, while the remaining 22% require further refinement to ensure complete ecological safety.

Carbon footprint analysis reveals that transient electronics manufacturing currently generates 15-25% more greenhouse gas emissions than conventional electronics production due to specialized material processing requirements. However, this initial carbon debt is potentially offset by end-of-life benefits, particularly when considering the elimination of energy-intensive recycling processes and reduced landfill impact.

Regulatory frameworks for transient electronics remain underdeveloped globally. The European Union's Waste Electrical and Electronic Equipment (WEEE) Directive and similar regulations in other regions have yet to specifically address transient electronic materials. This regulatory gap presents both challenges and opportunities for establishing sustainability standards tailored to this emerging technology sector.

Regulatory Framework for Bioresorbable Electronics

The regulatory landscape for bioresorbable electronics represents a complex intersection of medical device regulations, environmental standards, and emerging technology frameworks. Currently, the FDA classifies most transient electronic devices under medical device regulations, requiring manufacturers to demonstrate safety and efficacy through clinical trials before market approval. The European Union's Medical Device Regulation (MDR) similarly addresses these technologies but places additional emphasis on post-market surveillance and environmental impact assessment, particularly regarding degradation byproducts.

A significant regulatory challenge lies in the classification of bioresorbable electronics, as they often blur traditional boundaries between temporary implants and permanent devices. The International Medical Device Regulators Forum (IMDRF) has begun developing specific guidance documents addressing the unique characteristics of transient electronics, focusing on degradation timelines, biocompatibility of degradation products, and long-term safety monitoring protocols.

Material safety standards present another critical regulatory dimension. The ISO 10993 series for biocompatibility testing has been adapted to address the dynamic nature of bioresorbable materials, requiring manufacturers to demonstrate safety not only of the initial device but also of all degradation products and intermediate compounds. This represents a significant expansion of traditional biocompatibility testing paradigms, which typically focus on stable, non-changing materials.

Environmental regulations increasingly impact the development of transient electronics. The EU's Restriction of Hazardous Substances (RoHS) directive and similar regulations worldwide limit the use of certain materials common in electronics manufacturing. Manufacturers must navigate these restrictions while ensuring their devices maintain functionality during the intended operational period before controlled degradation begins.

Regulatory harmonization efforts are underway through organizations like the Global Harmonization Working Party (GHWP) to establish consistent international standards for bioresorbable electronics. These initiatives aim to create a unified framework that addresses both patient safety and environmental considerations while fostering innovation in this rapidly evolving field.

The path to regulatory approval for bioresorbable electronics typically involves extensive documentation of material characterization, degradation kinetics, and safety profiles across the entire device lifecycle. Manufacturers must demonstrate precise control over degradation timelines and provide comprehensive toxicological assessments of all degradation products, representing a significantly more complex regulatory burden than conventional electronic devices face.

A significant regulatory challenge lies in the classification of bioresorbable electronics, as they often blur traditional boundaries between temporary implants and permanent devices. The International Medical Device Regulators Forum (IMDRF) has begun developing specific guidance documents addressing the unique characteristics of transient electronics, focusing on degradation timelines, biocompatibility of degradation products, and long-term safety monitoring protocols.

Material safety standards present another critical regulatory dimension. The ISO 10993 series for biocompatibility testing has been adapted to address the dynamic nature of bioresorbable materials, requiring manufacturers to demonstrate safety not only of the initial device but also of all degradation products and intermediate compounds. This represents a significant expansion of traditional biocompatibility testing paradigms, which typically focus on stable, non-changing materials.

Environmental regulations increasingly impact the development of transient electronics. The EU's Restriction of Hazardous Substances (RoHS) directive and similar regulations worldwide limit the use of certain materials common in electronics manufacturing. Manufacturers must navigate these restrictions while ensuring their devices maintain functionality during the intended operational period before controlled degradation begins.

Regulatory harmonization efforts are underway through organizations like the Global Harmonization Working Party (GHWP) to establish consistent international standards for bioresorbable electronics. These initiatives aim to create a unified framework that addresses both patient safety and environmental considerations while fostering innovation in this rapidly evolving field.

The path to regulatory approval for bioresorbable electronics typically involves extensive documentation of material characterization, degradation kinetics, and safety profiles across the entire device lifecycle. Manufacturers must demonstrate precise control over degradation timelines and provide comprehensive toxicological assessments of all degradation products, representing a significantly more complex regulatory burden than conventional electronic devices face.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!