Design of modular electrolyzer systems for scalable hydrogen deployment

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Modular Electrolyzer Technology Background and Objectives

Hydrogen production through water electrolysis has evolved significantly since its discovery in the early 19th century. Initially a laboratory curiosity, electrolysis technology has progressed through several generations, from traditional alkaline systems to more advanced proton exchange membrane (PEM) and solid oxide electrolyzer cells (SOEC). This evolution reflects the growing recognition of hydrogen as a critical energy carrier in the global transition toward decarbonization and renewable energy integration.

The concept of modular electrolyzer systems represents a paradigm shift in hydrogen production infrastructure. Unlike conventional large-scale centralized production facilities, modular designs emphasize scalability, flexibility, and distributed deployment capabilities. This approach aligns with the intermittent nature of renewable energy sources and enables incremental capacity expansion to match growing hydrogen demand across various sectors.

Current technological objectives for modular electrolyzer systems focus on several key areas. Primary among these is cost reduction, as capital expenditure remains a significant barrier to widespread hydrogen adoption. Engineering innovations aim to decrease material costs while maintaining or improving system efficiency, which currently ranges from 60-80% depending on the technology employed. Durability enhancement is another critical goal, with research targeting extended operational lifetimes beyond the current 40,000-60,000 hours for stack components.

Standardization of modular components represents another essential objective, enabling plug-and-play functionality that simplifies installation, operation, and maintenance while reducing system integration costs. This standardization extends to balance-of-plant components, control systems, and grid interfaces, facilitating seamless scaling from kilowatt to megawatt capacities.

The development trajectory for modular electrolyzers also emphasizes operational flexibility to accommodate variable renewable energy inputs. Advanced systems aim to maintain high efficiency across a wide operating range (10-100% of rated capacity) and demonstrate rapid response capabilities for grid-balancing services. This flexibility is crucial for maximizing renewable energy utilization and providing valuable grid support functions.

Safety and regulatory compliance form another cornerstone of development objectives, with designs incorporating advanced monitoring systems, predictive maintenance capabilities, and inherent safety features. These elements are essential for deployment in diverse settings, from industrial facilities to distributed energy hubs closer to points of hydrogen consumption.

The ultimate technological goal is to establish modular electrolyzer systems as a foundational component of a sustainable hydrogen economy, capable of cost-effective scaling to meet projected demand growth across industrial, transportation, and energy storage applications. This vision requires continued innovation in materials science, manufacturing processes, and system integration to achieve the performance and economic targets necessary for widespread commercial adoption.

The concept of modular electrolyzer systems represents a paradigm shift in hydrogen production infrastructure. Unlike conventional large-scale centralized production facilities, modular designs emphasize scalability, flexibility, and distributed deployment capabilities. This approach aligns with the intermittent nature of renewable energy sources and enables incremental capacity expansion to match growing hydrogen demand across various sectors.

Current technological objectives for modular electrolyzer systems focus on several key areas. Primary among these is cost reduction, as capital expenditure remains a significant barrier to widespread hydrogen adoption. Engineering innovations aim to decrease material costs while maintaining or improving system efficiency, which currently ranges from 60-80% depending on the technology employed. Durability enhancement is another critical goal, with research targeting extended operational lifetimes beyond the current 40,000-60,000 hours for stack components.

Standardization of modular components represents another essential objective, enabling plug-and-play functionality that simplifies installation, operation, and maintenance while reducing system integration costs. This standardization extends to balance-of-plant components, control systems, and grid interfaces, facilitating seamless scaling from kilowatt to megawatt capacities.

The development trajectory for modular electrolyzers also emphasizes operational flexibility to accommodate variable renewable energy inputs. Advanced systems aim to maintain high efficiency across a wide operating range (10-100% of rated capacity) and demonstrate rapid response capabilities for grid-balancing services. This flexibility is crucial for maximizing renewable energy utilization and providing valuable grid support functions.

Safety and regulatory compliance form another cornerstone of development objectives, with designs incorporating advanced monitoring systems, predictive maintenance capabilities, and inherent safety features. These elements are essential for deployment in diverse settings, from industrial facilities to distributed energy hubs closer to points of hydrogen consumption.

The ultimate technological goal is to establish modular electrolyzer systems as a foundational component of a sustainable hydrogen economy, capable of cost-effective scaling to meet projected demand growth across industrial, transportation, and energy storage applications. This vision requires continued innovation in materials science, manufacturing processes, and system integration to achieve the performance and economic targets necessary for widespread commercial adoption.

Hydrogen Market Demand Analysis

The global hydrogen market is experiencing unprecedented growth, driven by the increasing focus on decarbonization and the transition to clean energy sources. Current estimates value the global hydrogen market at approximately 150 billion USD, with projections suggesting growth to reach 600 billion USD by 2050. This substantial market expansion is primarily fueled by industrial applications, transportation needs, and energy storage requirements.

Industrial demand currently dominates the hydrogen market, with petroleum refining and ammonia production accounting for over 60% of hydrogen consumption. However, emerging applications in steel manufacturing, where hydrogen serves as a clean reducing agent replacing coal, are expected to create significant new demand streams. The steel industry alone could potentially consume 18-24 million tons of hydrogen annually by 2050.

Transportation represents another rapidly growing segment for hydrogen demand. Fuel cell electric vehicles (FCEVs), particularly in heavy-duty transport, long-haul trucking, and maritime applications, are gaining traction due to hydrogen's advantages in range and refueling time compared to battery alternatives. Market forecasts indicate that hydrogen could power up to 400 million passenger vehicles, 15-20 million trucks, and around 5 million buses globally by 2050.

Energy storage applications are emerging as a critical driver for hydrogen demand, especially in regions with high renewable energy penetration. Hydrogen's ability to store large amounts of energy for extended periods makes it particularly valuable for seasonal storage and grid balancing. This sector is projected to consume between 30-50 million tons of hydrogen annually by 2050.

Geographically, demand is shifting from traditional centers in Europe and North America to include significant growth in Asia-Pacific, particularly China, Japan, and South Korea. These countries have established ambitious hydrogen strategies with clear deployment targets and substantial investment commitments.

The demand for green hydrogen specifically, produced via electrolysis powered by renewable energy, is growing exponentially. While currently representing less than 2% of total hydrogen production, green hydrogen demand is projected to increase by 50-fold by 2050, driven by decarbonization policies and falling production costs.

Modular electrolyzer systems are particularly well-positioned to address this growing market due to their scalability and flexibility in deployment. The ability to incrementally scale hydrogen production capacity aligns perfectly with the gradual adoption curves expected across various sectors, allowing for capital-efficient market entry and expansion strategies.

Industrial demand currently dominates the hydrogen market, with petroleum refining and ammonia production accounting for over 60% of hydrogen consumption. However, emerging applications in steel manufacturing, where hydrogen serves as a clean reducing agent replacing coal, are expected to create significant new demand streams. The steel industry alone could potentially consume 18-24 million tons of hydrogen annually by 2050.

Transportation represents another rapidly growing segment for hydrogen demand. Fuel cell electric vehicles (FCEVs), particularly in heavy-duty transport, long-haul trucking, and maritime applications, are gaining traction due to hydrogen's advantages in range and refueling time compared to battery alternatives. Market forecasts indicate that hydrogen could power up to 400 million passenger vehicles, 15-20 million trucks, and around 5 million buses globally by 2050.

Energy storage applications are emerging as a critical driver for hydrogen demand, especially in regions with high renewable energy penetration. Hydrogen's ability to store large amounts of energy for extended periods makes it particularly valuable for seasonal storage and grid balancing. This sector is projected to consume between 30-50 million tons of hydrogen annually by 2050.

Geographically, demand is shifting from traditional centers in Europe and North America to include significant growth in Asia-Pacific, particularly China, Japan, and South Korea. These countries have established ambitious hydrogen strategies with clear deployment targets and substantial investment commitments.

The demand for green hydrogen specifically, produced via electrolysis powered by renewable energy, is growing exponentially. While currently representing less than 2% of total hydrogen production, green hydrogen demand is projected to increase by 50-fold by 2050, driven by decarbonization policies and falling production costs.

Modular electrolyzer systems are particularly well-positioned to address this growing market due to their scalability and flexibility in deployment. The ability to incrementally scale hydrogen production capacity aligns perfectly with the gradual adoption curves expected across various sectors, allowing for capital-efficient market entry and expansion strategies.

Current State and Challenges in Electrolyzer Technology

Electrolyzer technology has evolved significantly over the past decades, with three main types dominating the market: alkaline electrolyzers (AEL), proton exchange membrane electrolyzers (PEMEL), and solid oxide electrolyzers (SOEL). Each technology presents distinct advantages and limitations in the context of modular hydrogen production systems. Currently, alkaline electrolyzers represent the most mature and commercially deployed technology, offering lower capital costs but suffering from limited dynamic operation capabilities and lower current densities.

Globally, electrolyzer manufacturing capacity is expanding rapidly, with projections indicating a potential increase from the current 8 GW/year to over 60 GW/year by 2030. However, this growth faces significant challenges related to supply chain constraints, particularly regarding critical materials such as platinum group metals for PEM electrolyzers and specialized ceramics for solid oxide systems.

A major technical challenge in current electrolyzer design involves balancing efficiency with durability. Most commercial systems operate at 65-75% efficiency (LHV basis), with laboratory demonstrations reaching 80-85%. However, maintaining this efficiency over the 60,000+ hour lifetime required for commercial viability remains problematic, especially under the variable loading conditions necessary for integration with renewable energy sources.

Modularization presents its own set of challenges. Current electrolyzer designs often prioritize economies of scale through larger installations rather than true modularity. The balance of plant components—water purification systems, power electronics, gas handling equipment—frequently represent 50-70% of system costs and are not optimized for modular deployment. Standardization of interfaces between modules remains limited, creating barriers to the "plug-and-play" scalability needed for distributed hydrogen production.

Heat management represents another significant challenge, particularly for PEM and solid oxide systems. Effective thermal integration could improve overall system efficiency by 10-15%, but current modular designs struggle to implement sophisticated heat recovery systems at smaller scales.

Manufacturing processes for electrolyzers remain largely semi-automated, with significant manual assembly steps that limit production scaling and increase quality variation. The transition to automated manufacturing techniques, similar to those used in fuel cell production, is progressing slowly due to high capital investment requirements and technical complexity.

Regulatory frameworks and certification standards for modular hydrogen systems remain underdeveloped in many regions, creating market uncertainty and deployment barriers. This is particularly problematic for smaller, distributed systems that might operate in diverse environments with varying safety requirements and grid connection standards.

Globally, electrolyzer manufacturing capacity is expanding rapidly, with projections indicating a potential increase from the current 8 GW/year to over 60 GW/year by 2030. However, this growth faces significant challenges related to supply chain constraints, particularly regarding critical materials such as platinum group metals for PEM electrolyzers and specialized ceramics for solid oxide systems.

A major technical challenge in current electrolyzer design involves balancing efficiency with durability. Most commercial systems operate at 65-75% efficiency (LHV basis), with laboratory demonstrations reaching 80-85%. However, maintaining this efficiency over the 60,000+ hour lifetime required for commercial viability remains problematic, especially under the variable loading conditions necessary for integration with renewable energy sources.

Modularization presents its own set of challenges. Current electrolyzer designs often prioritize economies of scale through larger installations rather than true modularity. The balance of plant components—water purification systems, power electronics, gas handling equipment—frequently represent 50-70% of system costs and are not optimized for modular deployment. Standardization of interfaces between modules remains limited, creating barriers to the "plug-and-play" scalability needed for distributed hydrogen production.

Heat management represents another significant challenge, particularly for PEM and solid oxide systems. Effective thermal integration could improve overall system efficiency by 10-15%, but current modular designs struggle to implement sophisticated heat recovery systems at smaller scales.

Manufacturing processes for electrolyzers remain largely semi-automated, with significant manual assembly steps that limit production scaling and increase quality variation. The transition to automated manufacturing techniques, similar to those used in fuel cell production, is progressing slowly due to high capital investment requirements and technical complexity.

Regulatory frameworks and certification standards for modular hydrogen systems remain underdeveloped in many regions, creating market uncertainty and deployment barriers. This is particularly problematic for smaller, distributed systems that might operate in diverse environments with varying safety requirements and grid connection standards.

Current Modular Design Solutions for Electrolyzers

01 Modular electrolyzer design for scalability

Modular electrolyzer systems are designed with standardized units that can be easily added or removed to adjust production capacity. This modular approach allows for flexible scaling of hydrogen production based on demand, enabling gradual expansion of facilities without complete system redesign. The modular architecture includes standardized interfaces for electrical, fluid, and control connections, facilitating seamless integration of additional modules.- Modular electrolyzer design for scalability: Modular electrolyzer systems are designed with standardized units that can be easily added or removed to adjust production capacity. This modular approach allows for scalable hydrogen production facilities that can be expanded incrementally as demand increases. The modular design also facilitates maintenance, as individual units can be serviced or replaced without shutting down the entire system, enhancing overall operational efficiency and flexibility.

- Stack configuration and cell architecture: The scalability of electrolyzer systems is significantly influenced by stack configuration and cell architecture. Advanced stack designs incorporate multiple cells arranged in series or parallel configurations to optimize performance and efficiency. These designs focus on maximizing active surface area while minimizing internal resistance, allowing for higher current densities and improved hydrogen production rates. Innovative cell architectures also address issues of heat management and pressure distribution across the system.

- Power management and control systems: Sophisticated power management and control systems are essential for scalable electrolyzer operations. These systems regulate power distribution across multiple electrolyzer modules, ensuring optimal performance under varying load conditions. Advanced control algorithms monitor and adjust operating parameters in real-time, maintaining efficiency across different production scales. Integration with renewable energy sources is facilitated through smart grid interfaces that can handle fluctuating power inputs while maintaining stable electrolyzer operation.

- Balance of plant integration: Balance of plant components are critical for supporting scalable electrolyzer systems. These include water purification systems, gas separation units, heat exchangers, and compression systems that must be appropriately sized to accommodate varying production capacities. Modular balance of plant designs allow for proportional scaling alongside electrolyzer capacity increases. Integration of these components in a space-efficient manner enables compact installation footprints while maintaining accessibility for maintenance and future expansion.

- System monitoring and predictive maintenance: Advanced monitoring systems are implemented in scalable electrolyzer installations to track performance metrics across multiple modules. These systems collect and analyze operational data to identify efficiency trends and potential issues before they cause failures. Predictive maintenance algorithms use this data to schedule targeted maintenance activities, reducing downtime and extending system lifespan. Remote monitoring capabilities allow for centralized oversight of distributed electrolyzer installations, enabling efficient management of large-scale hydrogen production networks.

02 Stack configuration and cell arrangement

Electrolyzer scalability is achieved through optimized stack configurations and cell arrangements. These designs allow for vertical or horizontal stacking of multiple cells to increase production capacity. Advanced stack designs incorporate efficient fluid distribution systems, uniform pressure distribution, and thermal management to maintain performance consistency when scaling up. The cell arrangement enables parallel or series electrical connections to optimize power distribution across the system.Expand Specific Solutions03 Power management and control systems

Scalable electrolyzer systems incorporate sophisticated power management and control architectures that can accommodate varying power inputs and system sizes. These systems include distributed control modules that maintain optimal operation across multiple electrolyzer units, adaptive power electronics for efficient energy conversion, and intelligent load balancing algorithms. The control systems enable seamless integration with renewable energy sources of different capacities, allowing for flexible operation under varying power availability.Expand Specific Solutions04 Balance of plant integration

Scalable electrolyzer systems feature modular balance of plant components that can be sized appropriately for different system capacities. These include water purification systems, gas separation and purification units, heat exchangers, and compression systems that can be expanded in parallel with electrolyzer capacity. The balance of plant design incorporates redundancy options and standardized interfaces to facilitate system expansion while maintaining operational efficiency and safety across different scales.Expand Specific Solutions05 Manufacturing and deployment strategies

Advanced manufacturing approaches enable cost-effective scaling of electrolyzer production. These include automated assembly lines for standardized components, quality control systems that ensure consistency across production batches, and supply chain optimization for critical materials. Deployment strategies focus on containerized or skid-mounted designs that facilitate transportation, installation, and commissioning of modular units. These approaches reduce the time and cost associated with scaling up hydrogen production capacity.Expand Specific Solutions

Key Industry Players in Modular Electrolyzer Market

The modular electrolyzer systems market for hydrogen deployment is in a growth phase, characterized by increasing investments and technological advancements. The market size is expanding rapidly, driven by global decarbonization efforts and hydrogen economy initiatives. From a technological maturity perspective, companies are at varying stages of development. Established industrial players like Robert Bosch, Linde, ABB Group, and Air Products & Chemicals bring manufacturing expertise and global reach, while specialized firms such as McPhy Energy, Bloom Energy, and Enapter are advancing innovative electrolyzer technologies. Asian companies, particularly Chinese entities like Huaneng Group and Shanghai Jia Hydrogen Source Technology, are rapidly scaling up capabilities. The competitive landscape shows a mix of traditional industrial conglomerates diversifying into hydrogen and pure-play hydrogen technology companies focusing on modular, scalable solutions to address deployment challenges.

McPhy Energy SA

Technical Solution: McPhy has developed a modular electrolyzer platform called "McLyzer" that utilizes alkaline electrolysis technology for scalable hydrogen production. Their systems feature standardized modules ranging from 4 MW to 100+ MW capacity, allowing for flexible deployment based on customer requirements. The McLyzer technology incorporates advanced electrode materials and optimized cell designs that operate at 30-80°C with efficiency rates of 4.5-5.5 kWh/Nm³ of hydrogen. McPhy's Augmented McLyzer platform integrates predictive maintenance capabilities and remote monitoring systems that utilize AI algorithms to optimize performance and reduce operational costs. Their modular approach enables rapid scaling through the parallel connection of multiple standardized units, with each module capable of producing 400-800 kg of hydrogen daily. The company has implemented these systems across Europe in various industrial and energy storage applications.

Strengths: Highly standardized modular design allows for flexible capacity scaling and reduced engineering costs. Their systems feature rapid deployment capabilities with pre-assembled modules that can be installed in weeks rather than months. Weaknesses: Limited to alkaline technology which has slower response times compared to PEM electrolyzers, potentially limiting integration with fluctuating renewable energy sources.

Enapter Srl

Technical Solution: Enapter has pioneered a unique approach to modular electrolysis with their AEM (Anion Exchange Membrane) Electrolyzer technology. Their core innovation is the EL 4.0 electrolyzer module - a compact, stackable unit that produces 1.0 kg of hydrogen per day (500 NL/h) while consuming approximately 4.8 kWh/Nm³. These standardized modules can be combined in Enapter's "EL 4.0 Rack" configuration, housing up to 10 modules to produce 10 kg/day. For larger applications, multiple racks can be integrated into containerized solutions called "Enapter Multicore" that scale to MW-class systems producing hundreds of kilograms daily. Their patented AEM technology operates at 35-55°C without requiring precious metal catalysts or highly corrosive electrolytes. Enapter's systems feature advanced digital integration through their Energy Management System (EMS) that enables remote monitoring, predictive maintenance, and automated operation with renewable energy sources. The company has deployed their technology in over 33 countries across various applications from energy storage to industrial processes.

Strengths: Highly modular "building block" approach allows unprecedented scalability from kilowatt to megawatt applications with minimal redesign. Their AEM technology bridges the advantages of both PEM and alkaline systems (fast response, no precious metals). Weaknesses: Individual modules have relatively small capacity compared to competitors, requiring more interconnections and balance of plant equipment for large-scale deployments.

Core Patents and Innovations in Modular Electrolyzer Systems

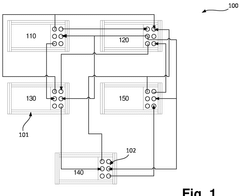

Modular electrolysis system

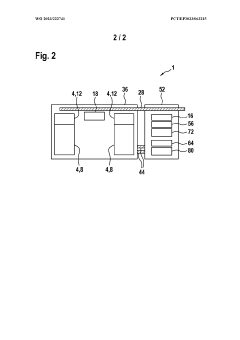

PatentWO2025067694A1

Innovation

- A modular electrolysis system is designed with multiple prefabricated modules that can be easily transported and assembled, featuring advanced separation modules and safety measures to minimize hydrogen crossover and explosion risks. The system includes water-gas separation modules and power supply modules with integrated safety features.

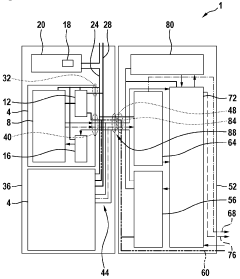

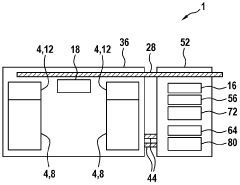

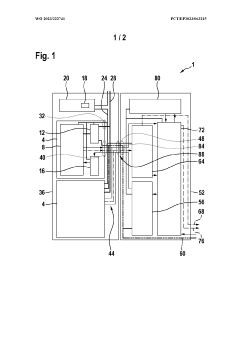

Water electrolyzer system

PatentWO2023222741A2

Innovation

- A modular water electrolyzer system comprising electrolyzer, process, and control modules, designed for automated production, with standardized plug and flange connections, and a common busbar for electrical supply, allowing for faster and more cost-effective assembly and scalability.

Renewable Energy Integration Strategies

The integration of renewable energy sources with modular electrolyzer systems represents a critical pathway for sustainable hydrogen production. Wind and solar power generation, characterized by intermittency and variability, present both challenges and opportunities for hydrogen production systems. Effective integration strategies must address these fluctuations while maintaining operational efficiency and system longevity.

Direct coupling of renewable energy sources with electrolyzers requires sophisticated power management systems that can handle variable inputs. Advanced power electronics, including DC/DC converters and smart inverters, enable efficient energy transfer from renewable sources to electrolyzer stacks while maintaining optimal operating parameters. These systems must incorporate rapid response capabilities to accommodate sudden changes in renewable energy availability.

Hybrid power systems combining multiple renewable sources can significantly enhance reliability and reduce intermittency issues. For instance, wind-solar hybrid configurations can provide more consistent power supply throughout daily and seasonal cycles, reducing the need for extensive energy storage or grid dependency. Such complementary energy profiles improve capacity utilization of electrolyzer systems and reduce operational downtime.

Energy storage integration represents another crucial strategy for renewable-powered hydrogen production. Short-term storage solutions like batteries or supercapacitors can buffer rapid fluctuations in renewable output, while longer-duration storage technologies enable load shifting and extended operation during low renewable generation periods. The strategic sizing of these storage components relative to electrolyzer capacity is essential for cost-effective system design.

Grid-connected operation models offer additional flexibility through bidirectional power flow capabilities. During periods of excess renewable generation, electrolyzers can increase hydrogen production, while during shortfalls, minimal operation can be maintained through grid power. Advanced grid integration strategies may include participation in grid services markets, providing frequency regulation or demand response capabilities that generate additional revenue streams.

Control system architecture for integrated renewable-electrolyzer systems must incorporate predictive algorithms that anticipate renewable generation patterns and optimize hydrogen production accordingly. Machine learning approaches that analyze weather forecasts, historical generation data, and electricity market conditions can dynamically adjust electrolyzer operation to maximize efficiency and economic performance while minimizing stress on system components.

Modular design principles enable scalable deployment that can evolve alongside expanding renewable energy installations. Standardized interfaces between renewable generation, power conditioning equipment, and electrolyzer modules facilitate phased implementation and future capacity expansion with minimal integration challenges.

Direct coupling of renewable energy sources with electrolyzers requires sophisticated power management systems that can handle variable inputs. Advanced power electronics, including DC/DC converters and smart inverters, enable efficient energy transfer from renewable sources to electrolyzer stacks while maintaining optimal operating parameters. These systems must incorporate rapid response capabilities to accommodate sudden changes in renewable energy availability.

Hybrid power systems combining multiple renewable sources can significantly enhance reliability and reduce intermittency issues. For instance, wind-solar hybrid configurations can provide more consistent power supply throughout daily and seasonal cycles, reducing the need for extensive energy storage or grid dependency. Such complementary energy profiles improve capacity utilization of electrolyzer systems and reduce operational downtime.

Energy storage integration represents another crucial strategy for renewable-powered hydrogen production. Short-term storage solutions like batteries or supercapacitors can buffer rapid fluctuations in renewable output, while longer-duration storage technologies enable load shifting and extended operation during low renewable generation periods. The strategic sizing of these storage components relative to electrolyzer capacity is essential for cost-effective system design.

Grid-connected operation models offer additional flexibility through bidirectional power flow capabilities. During periods of excess renewable generation, electrolyzers can increase hydrogen production, while during shortfalls, minimal operation can be maintained through grid power. Advanced grid integration strategies may include participation in grid services markets, providing frequency regulation or demand response capabilities that generate additional revenue streams.

Control system architecture for integrated renewable-electrolyzer systems must incorporate predictive algorithms that anticipate renewable generation patterns and optimize hydrogen production accordingly. Machine learning approaches that analyze weather forecasts, historical generation data, and electricity market conditions can dynamically adjust electrolyzer operation to maximize efficiency and economic performance while minimizing stress on system components.

Modular design principles enable scalable deployment that can evolve alongside expanding renewable energy installations. Standardized interfaces between renewable generation, power conditioning equipment, and electrolyzer modules facilitate phased implementation and future capacity expansion with minimal integration challenges.

Economic Viability and Cost Reduction Pathways

The economic viability of modular electrolyzer systems for hydrogen production remains a critical factor determining their widespread adoption. Current capital expenditure (CAPEX) for electrolyzer systems ranges from $500-1,000/kW for alkaline technology to $700-1,400/kW for PEM systems, with solid oxide electrolyzers still commanding premium prices of $2,000-3,000/kW. These high initial costs present significant barriers to market penetration despite hydrogen's potential as a clean energy carrier.

Several cost reduction pathways show promise for improving economic feasibility. Manufacturing scale-up represents the most immediate opportunity, with studies indicating potential cost reductions of 40-60% through economies of scale and automated production techniques. The transition from manual assembly to semi-automated and eventually fully automated manufacturing processes could reduce labor costs while improving quality consistency.

Material innovation offers another crucial pathway, particularly for PEM electrolyzers where expensive noble metal catalysts (platinum, iridium) contribute significantly to system costs. Research into reduced-loading catalysts, non-noble metal alternatives, and advanced membrane materials could potentially decrease material costs by 30-45% over the next decade.

System standardization and modular design optimization present additional cost-saving opportunities. The development of standardized balance-of-plant components compatible across multiple electrolyzer technologies could reduce engineering costs and enable more competitive supplier ecosystems. Modular designs that facilitate mass production while maintaining deployment flexibility may achieve 15-25% cost reductions through simplified installation and maintenance procedures.

Integration efficiencies represent another promising avenue, particularly through heat recovery systems and grid-integration technologies that improve overall system efficiency. Advanced power electronics that enable dynamic operation and grid services provision can improve the value proposition by creating additional revenue streams through grid balancing services, potentially improving project economics by 10-20%.

Policy support mechanisms remain essential for bridging the economic gap in early market development. Carbon pricing, renewable hydrogen production incentives, and targeted subsidies for green hydrogen infrastructure can significantly improve project economics during the scaling phase. Analysis suggests that with a combination of technological improvements and supportive policies, renewable hydrogen production costs could decrease from current levels of $4-6/kg to $1.5-3/kg by 2030, making it competitive with fossil-based hydrogen in many applications.

Several cost reduction pathways show promise for improving economic feasibility. Manufacturing scale-up represents the most immediate opportunity, with studies indicating potential cost reductions of 40-60% through economies of scale and automated production techniques. The transition from manual assembly to semi-automated and eventually fully automated manufacturing processes could reduce labor costs while improving quality consistency.

Material innovation offers another crucial pathway, particularly for PEM electrolyzers where expensive noble metal catalysts (platinum, iridium) contribute significantly to system costs. Research into reduced-loading catalysts, non-noble metal alternatives, and advanced membrane materials could potentially decrease material costs by 30-45% over the next decade.

System standardization and modular design optimization present additional cost-saving opportunities. The development of standardized balance-of-plant components compatible across multiple electrolyzer technologies could reduce engineering costs and enable more competitive supplier ecosystems. Modular designs that facilitate mass production while maintaining deployment flexibility may achieve 15-25% cost reductions through simplified installation and maintenance procedures.

Integration efficiencies represent another promising avenue, particularly through heat recovery systems and grid-integration technologies that improve overall system efficiency. Advanced power electronics that enable dynamic operation and grid services provision can improve the value proposition by creating additional revenue streams through grid balancing services, potentially improving project economics by 10-20%.

Policy support mechanisms remain essential for bridging the economic gap in early market development. Carbon pricing, renewable hydrogen production incentives, and targeted subsidies for green hydrogen infrastructure can significantly improve project economics during the scaling phase. Analysis suggests that with a combination of technological improvements and supportive policies, renewable hydrogen production costs could decrease from current levels of $4-6/kg to $1.5-3/kg by 2030, making it competitive with fossil-based hydrogen in many applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!