Direct Lithium Extraction: Process Adjustments for Better Yield

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DLE Technology Background and Objectives

Direct Lithium Extraction (DLE) technology has emerged as a revolutionary approach to lithium production, representing a significant departure from traditional extraction methods such as evaporation ponds and hard rock mining. The evolution of DLE began in the early 2000s, with substantial advancements occurring over the past decade as global demand for lithium has surged due to the electric vehicle revolution and renewable energy storage requirements.

DLE technologies aim to extract lithium directly from brine resources with greater efficiency, reduced environmental impact, and accelerated production timelines compared to conventional methods. The technological trajectory has moved from basic adsorption techniques toward more sophisticated approaches including ion exchange, solvent extraction, and membrane-based separation processes, each offering unique advantages for specific brine compositions.

The primary objective of DLE technology development is to achieve higher lithium recovery rates while maintaining economic viability. Current conventional evaporation methods typically recover only 30-50% of available lithium, whereas advanced DLE technologies target recovery rates of 80-90%. This significant improvement addresses the growing concern about lithium supply constraints in meeting projected demand growth of 25-35% annually through 2030.

Another critical objective is reducing the environmental footprint of lithium production. Traditional evaporation ponds require extensive land use (approximately 2,000 hectares for a typical operation) and consume substantial water resources in often water-stressed regions. DLE technologies aim to minimize land disturbance by up to 90% while potentially returning extracted water to aquifers, addressing growing environmental and social license concerns.

Process intensification represents a third key objective, with DLE technologies seeking to reduce production timelines from 18-24 months (typical for evaporation ponds) to days or weeks. This acceleration would enable more responsive supply adjustments to meet market demands and improve project economics through faster returns on investment.

Recent technological trends indicate a focus on developing selective adsorbents with higher lithium affinity and improved regeneration characteristics. Research is increasingly exploring composite materials that combine the advantages of different extraction mechanisms while minimizing interference from competing ions such as magnesium, calcium, and sodium that typically complicate lithium extraction processes.

The ultimate technological goal is developing a universally applicable DLE process that can efficiently extract lithium from diverse brine chemistries worldwide, from South American salars to geothermal brines and oilfield produced waters, thereby expanding the accessible lithium resource base to meet growing global demand.

DLE technologies aim to extract lithium directly from brine resources with greater efficiency, reduced environmental impact, and accelerated production timelines compared to conventional methods. The technological trajectory has moved from basic adsorption techniques toward more sophisticated approaches including ion exchange, solvent extraction, and membrane-based separation processes, each offering unique advantages for specific brine compositions.

The primary objective of DLE technology development is to achieve higher lithium recovery rates while maintaining economic viability. Current conventional evaporation methods typically recover only 30-50% of available lithium, whereas advanced DLE technologies target recovery rates of 80-90%. This significant improvement addresses the growing concern about lithium supply constraints in meeting projected demand growth of 25-35% annually through 2030.

Another critical objective is reducing the environmental footprint of lithium production. Traditional evaporation ponds require extensive land use (approximately 2,000 hectares for a typical operation) and consume substantial water resources in often water-stressed regions. DLE technologies aim to minimize land disturbance by up to 90% while potentially returning extracted water to aquifers, addressing growing environmental and social license concerns.

Process intensification represents a third key objective, with DLE technologies seeking to reduce production timelines from 18-24 months (typical for evaporation ponds) to days or weeks. This acceleration would enable more responsive supply adjustments to meet market demands and improve project economics through faster returns on investment.

Recent technological trends indicate a focus on developing selective adsorbents with higher lithium affinity and improved regeneration characteristics. Research is increasingly exploring composite materials that combine the advantages of different extraction mechanisms while minimizing interference from competing ions such as magnesium, calcium, and sodium that typically complicate lithium extraction processes.

The ultimate technological goal is developing a universally applicable DLE process that can efficiently extract lithium from diverse brine chemistries worldwide, from South American salars to geothermal brines and oilfield produced waters, thereby expanding the accessible lithium resource base to meet growing global demand.

Lithium Market Demand Analysis

The global lithium market is experiencing unprecedented growth, primarily driven by the rapid expansion of electric vehicle (EV) production and renewable energy storage systems. Current market valuations place the global lithium market at approximately $7.5 billion in 2022, with projections indicating a compound annual growth rate (CAGR) of 12-14% through 2030, potentially reaching $18-20 billion by the end of the decade.

Demand for lithium has seen a dramatic shift in recent years. While traditionally used in ceramics, glass, and lubricants, today over 74% of lithium demand comes from battery applications. This transition has fundamentally altered market dynamics and supply chain considerations. The International Energy Agency (IEA) estimates that lithium demand could increase by 40 times between 2020 and 2040 in a scenario aligned with climate goals.

Geographically, demand centers are concentrated in regions with significant EV manufacturing capabilities. China currently accounts for approximately 39% of global lithium consumption, followed by Japan and South Korea at 16% and 13% respectively. European demand is growing at the fastest rate, with a 27% year-over-year increase as automotive manufacturers accelerate EV production to meet stringent emissions regulations.

The battery-grade lithium compounds market shows particular strength, with lithium hydroxide demand outpacing lithium carbonate due to its suitability for high-nickel cathode chemistries preferred in long-range EVs. Market prices have demonstrated significant volatility, with spot prices for battery-grade lithium carbonate reaching peaks of $78,000 per tonne in 2022 before moderating to $30,000-40,000 ranges in 2023.

Supply constraints remain a critical market factor. Traditional extraction methods from brine and hard rock sources face environmental scrutiny and lengthy development timelines. This supply-demand imbalance creates a compelling case for Direct Lithium Extraction (DLE) technologies that promise higher yields, faster processing times, and reduced environmental footprints.

Industry analysts forecast a potential supply gap of 0.6-1.2 million tonnes of lithium carbonate equivalent (LCE) by 2030 without significant production innovations. This gap represents a critical opportunity for DLE technologies with enhanced yields to address market needs while commanding premium pricing for more sustainable production methods.

Consumer electronics, grid-scale energy storage, and emerging applications in aerospace and medical devices represent secondary but growing demand segments, collectively accounting for approximately 18% of lithium consumption. These diverse applications provide market resilience but also increase competition for limited lithium resources.

Demand for lithium has seen a dramatic shift in recent years. While traditionally used in ceramics, glass, and lubricants, today over 74% of lithium demand comes from battery applications. This transition has fundamentally altered market dynamics and supply chain considerations. The International Energy Agency (IEA) estimates that lithium demand could increase by 40 times between 2020 and 2040 in a scenario aligned with climate goals.

Geographically, demand centers are concentrated in regions with significant EV manufacturing capabilities. China currently accounts for approximately 39% of global lithium consumption, followed by Japan and South Korea at 16% and 13% respectively. European demand is growing at the fastest rate, with a 27% year-over-year increase as automotive manufacturers accelerate EV production to meet stringent emissions regulations.

The battery-grade lithium compounds market shows particular strength, with lithium hydroxide demand outpacing lithium carbonate due to its suitability for high-nickel cathode chemistries preferred in long-range EVs. Market prices have demonstrated significant volatility, with spot prices for battery-grade lithium carbonate reaching peaks of $78,000 per tonne in 2022 before moderating to $30,000-40,000 ranges in 2023.

Supply constraints remain a critical market factor. Traditional extraction methods from brine and hard rock sources face environmental scrutiny and lengthy development timelines. This supply-demand imbalance creates a compelling case for Direct Lithium Extraction (DLE) technologies that promise higher yields, faster processing times, and reduced environmental footprints.

Industry analysts forecast a potential supply gap of 0.6-1.2 million tonnes of lithium carbonate equivalent (LCE) by 2030 without significant production innovations. This gap represents a critical opportunity for DLE technologies with enhanced yields to address market needs while commanding premium pricing for more sustainable production methods.

Consumer electronics, grid-scale energy storage, and emerging applications in aerospace and medical devices represent secondary but growing demand segments, collectively accounting for approximately 18% of lithium consumption. These diverse applications provide market resilience but also increase competition for limited lithium resources.

DLE Technical Challenges and Global Status

Direct Lithium Extraction (DLE) technologies face several significant technical challenges that have limited widespread commercial adoption despite their promising potential. The primary obstacle remains the selective extraction of lithium ions from complex brine compositions containing numerous competing ions such as sodium, potassium, magnesium, and calcium. Current DLE methods struggle to maintain high selectivity while achieving commercially viable recovery rates above 80%.

Process efficiency represents another major challenge, with many DLE technologies requiring multiple processing cycles to achieve desired concentration levels. This iterative approach increases operational costs and extends processing time, reducing economic viability compared to traditional evaporation methods in certain contexts. Additionally, the energy intensity of DLE processes—particularly those utilizing electrical or thermal inputs for adsorption-desorption cycles—presents sustainability concerns that must be addressed through process optimization.

Water consumption remains problematic for certain DLE technologies, especially those requiring significant freshwater for regeneration or washing cycles. This creates a paradoxical situation where lithium extraction, often conducted in water-scarce regions, may further strain local water resources. Material durability constitutes another significant challenge, as ion exchange materials and membranes frequently degrade under repeated cycling in harsh brine environments, necessitating frequent replacement and increasing operational costs.

Globally, DLE development shows geographic concentration patterns. North American companies lead in innovation, with significant research clusters in California and Texas focusing on adsorption and ion exchange technologies. Several Canadian firms have developed proprietary DLE processes targeting the "Lithium Triangle" resources in South America. European research centers, particularly in Germany and France, focus on membrane-based extraction methods with emphasis on sustainability metrics.

In Asia, Chinese companies have made substantial investments in DLE technologies, particularly those applicable to salt lake resources in Tibet and Qinghai provinces. South Korean and Japanese firms focus on highly selective materials development for lithium extraction. Australia combines traditional mining expertise with emerging DLE approaches for processing spodumene concentrates.

The South American "Lithium Triangle" countries (Chile, Argentina, Bolivia) show varying levels of DLE implementation, with Chile leading in pilot projects. These nations face the complex challenge of balancing traditional evaporation methods against newer DLE technologies while considering water conservation imperatives in arid regions.

Process efficiency represents another major challenge, with many DLE technologies requiring multiple processing cycles to achieve desired concentration levels. This iterative approach increases operational costs and extends processing time, reducing economic viability compared to traditional evaporation methods in certain contexts. Additionally, the energy intensity of DLE processes—particularly those utilizing electrical or thermal inputs for adsorption-desorption cycles—presents sustainability concerns that must be addressed through process optimization.

Water consumption remains problematic for certain DLE technologies, especially those requiring significant freshwater for regeneration or washing cycles. This creates a paradoxical situation where lithium extraction, often conducted in water-scarce regions, may further strain local water resources. Material durability constitutes another significant challenge, as ion exchange materials and membranes frequently degrade under repeated cycling in harsh brine environments, necessitating frequent replacement and increasing operational costs.

Globally, DLE development shows geographic concentration patterns. North American companies lead in innovation, with significant research clusters in California and Texas focusing on adsorption and ion exchange technologies. Several Canadian firms have developed proprietary DLE processes targeting the "Lithium Triangle" resources in South America. European research centers, particularly in Germany and France, focus on membrane-based extraction methods with emphasis on sustainability metrics.

In Asia, Chinese companies have made substantial investments in DLE technologies, particularly those applicable to salt lake resources in Tibet and Qinghai provinces. South Korean and Japanese firms focus on highly selective materials development for lithium extraction. Australia combines traditional mining expertise with emerging DLE approaches for processing spodumene concentrates.

The South American "Lithium Triangle" countries (Chile, Argentina, Bolivia) show varying levels of DLE implementation, with Chile leading in pilot projects. These nations face the complex challenge of balancing traditional evaporation methods against newer DLE technologies while considering water conservation imperatives in arid regions.

Current DLE Process Optimization Solutions

01 Adsorption-based extraction methods

Direct lithium extraction techniques using selective adsorption materials to capture lithium ions from brine solutions. These methods typically employ specialized adsorbents that can selectively bind to lithium ions in the presence of competing ions. The process involves passing brine through columns containing these adsorbents, followed by desorption steps to recover concentrated lithium. This approach can significantly improve extraction yields compared to traditional evaporation methods.- Adsorption-based extraction methods: Adsorption-based methods for direct lithium extraction utilize selective adsorbents to capture lithium ions from brine solutions. These methods typically employ ion exchange materials or lithium-selective sorbents that can selectively bind lithium over competing ions like sodium, potassium, and magnesium. The process involves passing brine through columns containing these adsorbents, followed by desorption steps to recover concentrated lithium. This approach can significantly increase lithium recovery yields compared to traditional evaporation methods, with some technologies achieving extraction efficiencies of over 90%.

- Membrane-based separation technologies: Membrane-based technologies for direct lithium extraction utilize specialized membranes that selectively allow lithium ions to pass through while blocking other elements. These systems often employ nanofiltration, electrodialysis, or ion-selective membranes to achieve separation. The membrane approach offers advantages in processing speed and can be operated continuously, leading to higher throughput and improved yields. Recent innovations in membrane materials have enhanced selectivity for lithium ions, resulting in higher purity lithium products and increased extraction efficiency from low-concentration brines.

- Electrochemical lithium extraction methods: Electrochemical methods for direct lithium extraction utilize electrical potential differences to selectively capture and release lithium ions. These systems often employ specialized electrodes that can intercalate lithium ions during charging cycles and release them during discharging. The electrochemical approach allows for precise control over the extraction process, resulting in higher yields and purity. Some electrochemical systems can achieve lithium recovery rates exceeding 80% while consuming significantly less water than traditional evaporation methods, making them particularly suitable for environmentally sensitive operations.

- Solvent extraction techniques: Solvent extraction techniques for direct lithium extraction utilize specialized organic solvents or ionic liquids that selectively bind to lithium ions. These methods typically involve mixing the lithium-containing brine with the solvent, allowing the lithium to transfer to the organic phase, followed by back-extraction into an aqueous solution for further processing. Solvent extraction can achieve high selectivity for lithium over competing ions, resulting in improved yields and product purity. Recent innovations in solvent chemistry have enhanced extraction efficiency while reducing environmental impacts and processing costs.

- Process optimization and yield enhancement: Various approaches to optimize direct lithium extraction processes focus on enhancing overall yield through improved process design, integration of multiple extraction technologies, and optimization of operating parameters. These methods often involve precise control of pH, temperature, and flow rates to maximize lithium recovery. Some innovations incorporate pre-treatment steps to remove interfering elements or post-processing techniques to increase final product purity. Advanced process control systems utilizing real-time monitoring and artificial intelligence can dynamically adjust extraction parameters to maintain optimal performance under varying feed conditions, resulting in consistently higher lithium yields.

02 Membrane and electrochemical separation technologies

Advanced membrane and electrochemical technologies for direct lithium extraction that utilize ion-selective membranes or electrochemical cells to separate lithium from other elements. These systems often employ electrical potential differences to drive lithium ions across membranes while blocking competing ions. The technology enables continuous processing of brine with higher recovery rates and reduced processing time compared to conventional methods.Expand Specific Solutions03 Solvent extraction and chemical precipitation methods

Chemical approaches to direct lithium extraction involving specialized solvents or precipitation agents that selectively interact with lithium compounds. These methods typically involve liquid-liquid extraction where lithium is transferred from the aqueous brine phase to an organic phase, or precipitation techniques where lithium is selectively crystallized from solution. These processes can be optimized to achieve higher purity and yield of lithium compounds.Expand Specific Solutions04 Process optimization and yield enhancement techniques

Methods focused on optimizing direct lithium extraction processes to maximize yield through parameter control, process integration, and operational improvements. These approaches include optimizing flow rates, temperature conditions, pH control, and recycling of process streams. Advanced monitoring systems and process control algorithms are employed to maintain optimal extraction conditions, resulting in significantly improved lithium recovery rates.Expand Specific Solutions05 Novel materials and composite systems for lithium capture

Development of innovative materials and composite systems specifically designed for enhanced lithium capture and recovery. These include engineered nanoparticles, composite adsorbents, functionalized polymers, and novel inorganic materials with high lithium selectivity. The materials feature optimized surface properties, pore structures, and functional groups that maximize lithium binding capacity while minimizing interference from competing ions, thereby increasing overall extraction yield.Expand Specific Solutions

Major Industry Players in DLE Technology

Direct Lithium Extraction (DLE) technology is currently in an early growth phase, with the global market expected to reach $1.5 billion by 2030. The competitive landscape features established players like Albemarle and BASF alongside innovative startups such as Lilac Solutions, Energy Exploration Technologies, and International Battery Metals. Technical maturity varies significantly across companies, with Koch Technology Solutions and Saltworks Technologies demonstrating more advanced commercial implementations, while academic institutions like The University of Manchester and North Carolina State University contribute fundamental research. Chinese entities including Guangdong Bangpu and RIST are rapidly advancing their capabilities, particularly in process optimization for yield improvement. The industry is characterized by intense competition to develop scalable, environmentally sustainable extraction methods that can address the growing lithium demand for electric vehicle batteries and energy storage systems.

Koch Technology Solutions LLC

Technical Solution: Koch Technology Solutions has developed a comprehensive Direct Lithium Extraction platform that combines selective absorption technology with advanced separation processes. Their system utilizes proprietary ion-exchange materials that selectively capture lithium from brine solutions while minimizing co-extraction of impurities. The process operates in a multi-stage configuration where brine flows through absorption columns, lithium is captured, and then eluted using a specialized solution to produce a concentrated lithium product. Koch's technology incorporates sophisticated process control systems that continuously optimize operating parameters based on real-time data analytics, maximizing lithium yield while minimizing reagent consumption. Their approach achieves lithium recovery rates of approximately 85-90% with significantly reduced processing time compared to conventional methods. The system includes integrated water treatment and recycling capabilities, minimizing freshwater requirements and environmental impact.

Strengths: Advanced process control systems for optimized operation, integrated water recycling capabilities, robust engineering from an established industrial technology provider, and scalable design for various production capacities. Weaknesses: Potentially higher capital costs due to sophisticated control systems, complex integration requirements with existing operations, and possible need for specialized technical support for maintenance and optimization.

Energy Exploration Technologies, Inc.

Technical Solution: Energy Exploration Technologies (EnergyX) has pioneered a membrane-based Direct Lithium Extraction technology called LiTAS (Lithium Ion Transport and Separation). This system utilizes specialized metal-organic framework (MOF) membranes that allow lithium ions to pass through while blocking larger ions like sodium, magnesium, and calcium. The process operates at ambient temperature and pressure, requiring minimal energy input compared to conventional methods. EnergyX's approach can extract lithium from various sources including continental brines, geothermal brines, and even seawater. Their technology achieves lithium recovery rates of approximately 90% in a matter of days rather than the 18+ months required for traditional evaporation ponds. The system's modular design enables scalable deployment with a small physical footprint, and it can be powered by renewable energy sources to minimize carbon emissions.

Strengths: Highly selective lithium extraction with minimal pre-treatment requirements, energy-efficient operation, rapid processing time, and versatility across different brine sources. Weaknesses: Membrane fouling may occur in certain brine compositions requiring additional maintenance, relatively new technology with limited large-scale commercial implementation history, and potential challenges in membrane durability over extended operational periods.

Key Patents and Innovations in Yield Enhancement

Method for improving lithium yield in a direct lithium extraction process

PatentWO2025163572A1

Innovation

- A method involving a screening process using sieve elements with specific mesh sizes to separate lithium-selective media into desired particle sizes and remove contaminants, followed by dewatering and cleaning, ensuring optimal particle distribution and purity for improved lithium uptake.

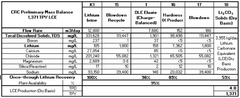

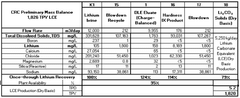

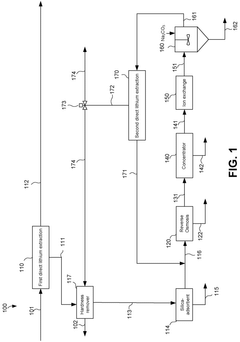

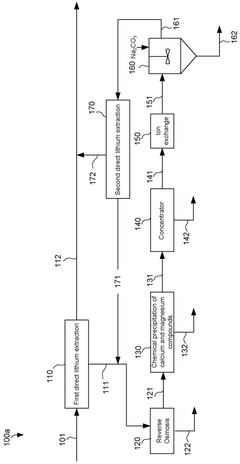

Process and system for recovering lithium carbonate from a saltwater

PatentWO2025123138A1

Innovation

- A process involving two direct lithium extraction (DLE) processes is applied, where the first DLE process extracts lithium from saltwater, producing a lithium recovery solution and a depleted brine. The lithium recovery solution is then mixed with sodium carbonate to form lithium carbonate solids and mother liquor. The mother liquor is recycled through a second DLE process, further extracting lithium and producing additional lithium recovery solutions, which are then mixed and precipitated with sodium carbonate to form more lithium carbonate solids.

Environmental Impact Assessment of DLE Methods

Direct Lithium Extraction (DLE) technologies present significant environmental implications that must be thoroughly assessed when evaluating their implementation. Compared to traditional evaporation pond methods, DLE processes generally demonstrate a substantially reduced physical footprint, with some systems requiring up to 90% less land area for equivalent lithium production. This reduction in spatial requirements translates to minimized habitat disruption and ecosystem fragmentation in sensitive areas such as salt flats and desert environments.

Water consumption represents a critical environmental consideration for DLE operations. While conventional extraction methods can consume up to 500,000 gallons of water per ton of lithium produced, advanced DLE technologies have demonstrated potential reductions of 50-90% in water usage. However, these improvements vary significantly between different DLE methodologies, with ion exchange systems typically requiring less water than adsorption-based approaches.

Chemical usage patterns in DLE systems present both advantages and challenges from an environmental perspective. Most DLE processes utilize specialized sorbents, resins, or membranes that require periodic regeneration with chemical solutions. These regeneration chemicals, including acids, bases, and salt solutions, must be carefully managed to prevent contamination of surrounding water bodies and soil systems. Closed-loop designs that recycle regeneration chemicals have shown promise in minimizing these impacts.

Energy consumption profiles of DLE systems warrant careful consideration in environmental assessments. While DLE eliminates the energy-intensive evaporation phase of traditional methods, it introduces new energy requirements for pumping, processing, and regeneration activities. Current estimates suggest DLE systems consume between 5-15 kWh per kilogram of lithium carbonate equivalent produced, with significant variation based on specific technology implementation and brine characteristics.

Waste management represents another crucial environmental dimension of DLE operations. The concentrated brine streams resulting from DLE processing contain elevated levels of various elements including magnesium, calcium, sodium, and potassium. Proper handling and disposal of these waste streams is essential to prevent soil salinization and groundwater contamination. Some advanced DLE systems have begun incorporating selective recovery of these additional elements as valuable by-products, transforming potential waste streams into additional revenue sources while reducing environmental burden.

Carbon footprint analyses of DLE operations indicate potential for significantly lower greenhouse gas emissions compared to traditional methods, particularly when powered by renewable energy sources. This advantage becomes increasingly important as the lithium industry faces growing pressure to reduce its environmental impact while meeting surging global demand for battery materials.

Water consumption represents a critical environmental consideration for DLE operations. While conventional extraction methods can consume up to 500,000 gallons of water per ton of lithium produced, advanced DLE technologies have demonstrated potential reductions of 50-90% in water usage. However, these improvements vary significantly between different DLE methodologies, with ion exchange systems typically requiring less water than adsorption-based approaches.

Chemical usage patterns in DLE systems present both advantages and challenges from an environmental perspective. Most DLE processes utilize specialized sorbents, resins, or membranes that require periodic regeneration with chemical solutions. These regeneration chemicals, including acids, bases, and salt solutions, must be carefully managed to prevent contamination of surrounding water bodies and soil systems. Closed-loop designs that recycle regeneration chemicals have shown promise in minimizing these impacts.

Energy consumption profiles of DLE systems warrant careful consideration in environmental assessments. While DLE eliminates the energy-intensive evaporation phase of traditional methods, it introduces new energy requirements for pumping, processing, and regeneration activities. Current estimates suggest DLE systems consume between 5-15 kWh per kilogram of lithium carbonate equivalent produced, with significant variation based on specific technology implementation and brine characteristics.

Waste management represents another crucial environmental dimension of DLE operations. The concentrated brine streams resulting from DLE processing contain elevated levels of various elements including magnesium, calcium, sodium, and potassium. Proper handling and disposal of these waste streams is essential to prevent soil salinization and groundwater contamination. Some advanced DLE systems have begun incorporating selective recovery of these additional elements as valuable by-products, transforming potential waste streams into additional revenue sources while reducing environmental burden.

Carbon footprint analyses of DLE operations indicate potential for significantly lower greenhouse gas emissions compared to traditional methods, particularly when powered by renewable energy sources. This advantage becomes increasingly important as the lithium industry faces growing pressure to reduce its environmental impact while meeting surging global demand for battery materials.

Resource Economics and Sustainability Considerations

The economic viability of Direct Lithium Extraction (DLE) technologies hinges on several interconnected factors that extend beyond mere technical efficiency. Current lithium production economics favor traditional methods due to established infrastructure and lower initial capital requirements, despite their environmental drawbacks and lower recovery rates.

DLE technologies present a compelling economic case when evaluated through a comprehensive lens. While capital expenditure for DLE facilities typically exceeds that of conventional evaporation ponds, operational expenditure can be significantly reduced through process optimization. Energy consumption remains a critical economic factor, with thermal and electrical requirements varying substantially across different DLE approaches. Recent innovations in energy-efficient sorbents and electrochemical systems have demonstrated potential to reduce these costs by 30-45% compared to first-generation DLE implementations.

Water usage economics also favors DLE methods, which can reduce freshwater consumption by up to 90% compared to traditional evaporation techniques. This advantage becomes increasingly valuable in water-stressed regions where lithium brine resources are often located, potentially avoiding regulatory penalties and community conflicts that could otherwise disrupt operations.

Sustainability considerations are becoming increasingly central to resource economics in the lithium sector. Carbon footprint assessments reveal that optimized DLE processes can reduce greenhouse gas emissions by 30-60% compared to conventional methods, creating potential value through carbon credits and alignment with increasingly stringent ESG requirements from investors and customers.

The circular economy potential of DLE further enhances its economic profile. Advanced process adjustments enable the recovery of valuable by-products such as magnesium, boron, and potassium from brines, potentially offsetting 15-25% of operational costs. Additionally, the smaller physical footprint of DLE facilities—typically 90% less than evaporation ponds—translates to reduced land acquisition and remediation costs.

Market dynamics are increasingly favorable for DLE economics as battery manufacturers and electric vehicle producers seek more sustainable and reliable lithium sources. Premium pricing for responsibly sourced lithium is emerging, with some manufacturers willing to pay 5-10% above market rates for materials produced through environmentally superior methods with verifiable sustainability credentials.

Long-term resource stewardship also factors into the economic equation. DLE's higher recovery rates (potentially 80-95% versus 30-50% for traditional methods) extend the productive life of lithium reserves, improving the net present value of resource assets and supporting more stable long-term supply agreements with customers seeking security of supply.

DLE technologies present a compelling economic case when evaluated through a comprehensive lens. While capital expenditure for DLE facilities typically exceeds that of conventional evaporation ponds, operational expenditure can be significantly reduced through process optimization. Energy consumption remains a critical economic factor, with thermal and electrical requirements varying substantially across different DLE approaches. Recent innovations in energy-efficient sorbents and electrochemical systems have demonstrated potential to reduce these costs by 30-45% compared to first-generation DLE implementations.

Water usage economics also favors DLE methods, which can reduce freshwater consumption by up to 90% compared to traditional evaporation techniques. This advantage becomes increasingly valuable in water-stressed regions where lithium brine resources are often located, potentially avoiding regulatory penalties and community conflicts that could otherwise disrupt operations.

Sustainability considerations are becoming increasingly central to resource economics in the lithium sector. Carbon footprint assessments reveal that optimized DLE processes can reduce greenhouse gas emissions by 30-60% compared to conventional methods, creating potential value through carbon credits and alignment with increasingly stringent ESG requirements from investors and customers.

The circular economy potential of DLE further enhances its economic profile. Advanced process adjustments enable the recovery of valuable by-products such as magnesium, boron, and potassium from brines, potentially offsetting 15-25% of operational costs. Additionally, the smaller physical footprint of DLE facilities—typically 90% less than evaporation ponds—translates to reduced land acquisition and remediation costs.

Market dynamics are increasingly favorable for DLE economics as battery manufacturers and electric vehicle producers seek more sustainable and reliable lithium sources. Premium pricing for responsibly sourced lithium is emerging, with some manufacturers willing to pay 5-10% above market rates for materials produced through environmentally superior methods with verifiable sustainability credentials.

Long-term resource stewardship also factors into the economic equation. DLE's higher recovery rates (potentially 80-95% versus 30-50% for traditional methods) extend the productive life of lithium reserves, improving the net present value of resource assets and supporting more stable long-term supply agreements with customers seeking security of supply.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!