Direct Lithium Extraction: Process Control and Quality Metrics

SEP 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DLE Technology Background and Objectives

Direct Lithium Extraction (DLE) has emerged as a revolutionary approach to lithium production, representing a significant departure from traditional extraction methods that have dominated the industry for decades. Conventional lithium extraction primarily relies on evaporation ponds in salt flats or hard-rock mining, both of which present considerable environmental challenges and operational inefficiencies. The evolution of DLE technology began in the early 2000s, with significant acceleration in development occurring over the past decade as global demand for lithium has surged due to the rapid expansion of electric vehicle markets and energy storage systems.

DLE technologies encompass a diverse range of approaches including adsorption, ion exchange, solvent extraction, and membrane processes, all designed to selectively extract lithium from brine resources with greater efficiency and reduced environmental impact. The technological trajectory has been marked by progressive improvements in selectivity, recovery rates, and process economics, with recent innovations focusing on enhancing the precision of process control systems and establishing robust quality metrics.

The primary technical objective of modern DLE development is to achieve consistent, high-purity lithium extraction while minimizing water consumption, chemical usage, and energy requirements. This involves the development of advanced process control architectures capable of real-time monitoring and adjustment of critical parameters such as pH, temperature, flow rates, and chemical concentrations throughout the extraction process. Additionally, there is a growing emphasis on establishing standardized quality metrics that can reliably predict and ensure the production of battery-grade lithium compounds.

Current technological trends in DLE are moving toward more integrated systems that combine multiple separation techniques, advanced automation, and artificial intelligence to optimize extraction efficiency. There is also increasing focus on developing closed-loop systems that minimize waste generation and maximize resource recovery, including the potential valorization of co-products from brine processing. The integration of renewable energy sources to power DLE operations represents another significant trend, aligning with broader sustainability objectives in the mining sector.

The ultimate goal of DLE technology development is to establish economically viable processes that can operate across diverse brine chemistries and geological settings, thereby expanding the global lithium resource base beyond traditional sources. This includes unlocking previously uneconomical resources such as geothermal brines, oilfield produced waters, and low-concentration continental brines, which could dramatically reshape the global lithium supply landscape and support the growing demand for energy transition technologies.

DLE technologies encompass a diverse range of approaches including adsorption, ion exchange, solvent extraction, and membrane processes, all designed to selectively extract lithium from brine resources with greater efficiency and reduced environmental impact. The technological trajectory has been marked by progressive improvements in selectivity, recovery rates, and process economics, with recent innovations focusing on enhancing the precision of process control systems and establishing robust quality metrics.

The primary technical objective of modern DLE development is to achieve consistent, high-purity lithium extraction while minimizing water consumption, chemical usage, and energy requirements. This involves the development of advanced process control architectures capable of real-time monitoring and adjustment of critical parameters such as pH, temperature, flow rates, and chemical concentrations throughout the extraction process. Additionally, there is a growing emphasis on establishing standardized quality metrics that can reliably predict and ensure the production of battery-grade lithium compounds.

Current technological trends in DLE are moving toward more integrated systems that combine multiple separation techniques, advanced automation, and artificial intelligence to optimize extraction efficiency. There is also increasing focus on developing closed-loop systems that minimize waste generation and maximize resource recovery, including the potential valorization of co-products from brine processing. The integration of renewable energy sources to power DLE operations represents another significant trend, aligning with broader sustainability objectives in the mining sector.

The ultimate goal of DLE technology development is to establish economically viable processes that can operate across diverse brine chemistries and geological settings, thereby expanding the global lithium resource base beyond traditional sources. This includes unlocking previously uneconomical resources such as geothermal brines, oilfield produced waters, and low-concentration continental brines, which could dramatically reshape the global lithium supply landscape and support the growing demand for energy transition technologies.

Market Analysis for DLE Solutions

The global market for Direct Lithium Extraction (DLE) solutions is experiencing unprecedented growth, driven primarily by the surging demand for lithium-ion batteries in electric vehicles and energy storage systems. Current market valuations place the DLE technology sector at approximately $1.2 billion in 2023, with projections indicating a compound annual growth rate of 25-30% over the next decade, potentially reaching $12 billion by 2033.

North America currently leads the DLE market adoption, particularly in the United States where substantial investments are flowing into lithium projects in Nevada, California, and Arkansas. The European market is rapidly expanding as well, with significant developments in Germany and the United Kingdom focused on establishing domestic lithium supply chains to support their growing electric vehicle manufacturing sectors.

The Asia-Pacific region represents the largest potential market for DLE technologies, with China dominating both lithium processing and battery manufacturing. However, Australia and Chile are emerging as critical players in the raw material extraction segment, increasingly adopting advanced DLE methods to improve efficiency and environmental performance.

Market segmentation reveals three primary customer categories for DLE solutions: traditional mining companies transitioning from evaporation ponds to more efficient extraction methods; specialized lithium producers focused exclusively on DLE technologies; and diversified chemical companies expanding into the lithium sector. Each segment presents distinct requirements regarding process control systems and quality metrics implementation.

Demand drivers for advanced process control in DLE operations stem from several factors: increasing pressure to reduce water consumption (DLE uses 50-90% less water than traditional methods); requirements for higher lithium recovery rates (currently averaging 70-80% compared to 40-50% for evaporation methods); and the need for consistent product quality to meet battery-grade specifications (99.5% purity minimum).

Market barriers include high capital expenditure requirements for DLE facilities, technological uncertainties regarding long-term performance, and competition from established extraction methods. Additionally, the lack of standardized quality metrics across the industry creates challenges for technology comparison and evaluation.

Customer needs analysis indicates strong demand for integrated process control systems that can provide real-time monitoring of critical parameters including selectivity, recovery rates, and impurity profiles. End users increasingly require solutions that offer predictive maintenance capabilities, automated quality assurance, and compatibility with existing mining operation management systems.

North America currently leads the DLE market adoption, particularly in the United States where substantial investments are flowing into lithium projects in Nevada, California, and Arkansas. The European market is rapidly expanding as well, with significant developments in Germany and the United Kingdom focused on establishing domestic lithium supply chains to support their growing electric vehicle manufacturing sectors.

The Asia-Pacific region represents the largest potential market for DLE technologies, with China dominating both lithium processing and battery manufacturing. However, Australia and Chile are emerging as critical players in the raw material extraction segment, increasingly adopting advanced DLE methods to improve efficiency and environmental performance.

Market segmentation reveals three primary customer categories for DLE solutions: traditional mining companies transitioning from evaporation ponds to more efficient extraction methods; specialized lithium producers focused exclusively on DLE technologies; and diversified chemical companies expanding into the lithium sector. Each segment presents distinct requirements regarding process control systems and quality metrics implementation.

Demand drivers for advanced process control in DLE operations stem from several factors: increasing pressure to reduce water consumption (DLE uses 50-90% less water than traditional methods); requirements for higher lithium recovery rates (currently averaging 70-80% compared to 40-50% for evaporation methods); and the need for consistent product quality to meet battery-grade specifications (99.5% purity minimum).

Market barriers include high capital expenditure requirements for DLE facilities, technological uncertainties regarding long-term performance, and competition from established extraction methods. Additionally, the lack of standardized quality metrics across the industry creates challenges for technology comparison and evaluation.

Customer needs analysis indicates strong demand for integrated process control systems that can provide real-time monitoring of critical parameters including selectivity, recovery rates, and impurity profiles. End users increasingly require solutions that offer predictive maintenance capabilities, automated quality assurance, and compatibility with existing mining operation management systems.

Current DLE Technical Challenges

Direct Lithium Extraction (DLE) technologies face several significant technical challenges that currently limit their widespread commercial adoption. The primary obstacle remains the selective extraction of lithium ions from complex brine solutions containing numerous competing ions such as sodium, potassium, magnesium, and calcium. These competing ions often exist at concentrations 10-1000 times higher than lithium, creating substantial selectivity challenges for most extraction media.

Process control represents another major hurdle in DLE implementation. Current systems struggle with maintaining consistent performance under variable feed conditions, as natural brine compositions fluctuate significantly based on seasonal changes, extraction depth, and geographical location. This variability necessitates sophisticated real-time monitoring systems that many existing technologies have not yet fully developed.

The regeneration efficiency of extraction media constitutes a critical limitation. Most DLE technologies require frequent regeneration of adsorption materials or ion exchange membranes, which consumes significant quantities of chemicals and water. The degradation of extraction media over multiple cycles further complicates process economics, with many systems showing performance decline after 100-500 regeneration cycles.

Energy consumption remains prohibitively high for many DLE approaches, particularly those utilizing membrane or electrochemical systems. Current energy requirements range from 10-60 kWh per kilogram of lithium carbonate equivalent (LCE) produced, significantly impacting operational costs and environmental footprint compared to traditional evaporation pond methods.

Water management presents substantial challenges, especially in water-scarce regions where many lithium resources are located. While DLE promises reduced water consumption compared to evaporation ponds, many technologies still require 10-20 cubic meters of fresh water per ton of LCE for regeneration and washing processes.

Scaling issues persist in many DLE systems, with mineral precipitation and fouling of extraction media occurring during continuous operation. These scaling problems reduce extraction efficiency and increase maintenance requirements, particularly in brines with high concentrations of calcium and magnesium.

The development of robust quality metrics and standardized performance indicators remains underdeveloped across the industry. The lack of standardized testing protocols makes technology comparison difficult, hampering investment decisions and technology selection processes for commercial implementation.

Process control represents another major hurdle in DLE implementation. Current systems struggle with maintaining consistent performance under variable feed conditions, as natural brine compositions fluctuate significantly based on seasonal changes, extraction depth, and geographical location. This variability necessitates sophisticated real-time monitoring systems that many existing technologies have not yet fully developed.

The regeneration efficiency of extraction media constitutes a critical limitation. Most DLE technologies require frequent regeneration of adsorption materials or ion exchange membranes, which consumes significant quantities of chemicals and water. The degradation of extraction media over multiple cycles further complicates process economics, with many systems showing performance decline after 100-500 regeneration cycles.

Energy consumption remains prohibitively high for many DLE approaches, particularly those utilizing membrane or electrochemical systems. Current energy requirements range from 10-60 kWh per kilogram of lithium carbonate equivalent (LCE) produced, significantly impacting operational costs and environmental footprint compared to traditional evaporation pond methods.

Water management presents substantial challenges, especially in water-scarce regions where many lithium resources are located. While DLE promises reduced water consumption compared to evaporation ponds, many technologies still require 10-20 cubic meters of fresh water per ton of LCE for regeneration and washing processes.

Scaling issues persist in many DLE systems, with mineral precipitation and fouling of extraction media occurring during continuous operation. These scaling problems reduce extraction efficiency and increase maintenance requirements, particularly in brines with high concentrations of calcium and magnesium.

The development of robust quality metrics and standardized performance indicators remains underdeveloped across the industry. The lack of standardized testing protocols makes technology comparison difficult, hampering investment decisions and technology selection processes for commercial implementation.

Process Control Systems for DLE

01 Real-time monitoring and control systems for DLE processes

Advanced monitoring systems are essential for Direct Lithium Extraction (DLE) processes to maintain optimal extraction conditions. These systems utilize sensors and analytical tools to continuously track key parameters such as pH, temperature, flow rates, and ion concentrations throughout the extraction process. Real-time data collection enables immediate adjustments to process variables, ensuring consistent lithium recovery rates and product quality while minimizing reagent consumption and energy usage.- Real-time monitoring systems for DLE processes: Advanced monitoring systems are essential for Direct Lithium Extraction (DLE) processes to ensure optimal performance. These systems collect real-time data on various parameters such as flow rates, pressure, temperature, and chemical composition throughout the extraction process. By continuously monitoring these metrics, operators can quickly identify deviations from optimal conditions and make necessary adjustments to maintain process efficiency and product quality.

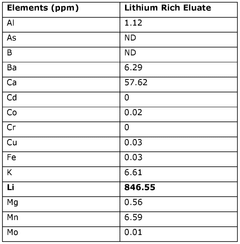

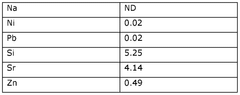

- Quality control metrics for lithium purity and yield: Quality control metrics are crucial for evaluating the effectiveness of DLE processes. These metrics include lithium purity levels, extraction yield, recovery rates, and contaminant profiles. Implementing standardized testing protocols allows for consistent measurement of these parameters across different batches. Advanced analytical techniques can be employed to detect impurities at very low concentrations, ensuring that the final lithium product meets industry specifications and regulatory requirements.

- Automated control systems for process optimization: Automated control systems play a vital role in optimizing DLE processes by maintaining operational parameters within predetermined ranges. These systems utilize feedback loops to adjust process variables such as solvent flow rates, pH levels, and residence times based on real-time data. Machine learning algorithms can be incorporated to predict optimal operating conditions and make proactive adjustments, reducing energy consumption and maximizing lithium recovery while minimizing waste generation.

- Selective ion exchange technologies for lithium extraction: Selective ion exchange technologies are key components in modern DLE processes, offering high selectivity for lithium ions over competing ions such as sodium, potassium, and magnesium. These technologies utilize specialized adsorbents or membranes designed to preferentially capture lithium from brine solutions. Process control parameters for these systems include adsorption/desorption cycles, regeneration protocols, and ion exchange kinetics. Monitoring the performance of these selective materials over time is essential for maintaining extraction efficiency.

- Data analytics and reporting frameworks for DLE operations: Comprehensive data analytics and reporting frameworks enable effective management of DLE operations by transforming raw process data into actionable insights. These systems integrate data from multiple sources to generate performance dashboards, trend analyses, and predictive maintenance alerts. Standardized reporting protocols ensure consistent documentation of process parameters, quality metrics, and environmental impacts. Advanced analytics can identify correlations between operating conditions and product quality, supporting continuous process improvement initiatives.

02 Quality metrics and analytical methods for lithium purity assessment

Specialized analytical techniques are implemented to assess the purity and quality of extracted lithium products. These methods include spectroscopic analysis, chromatography, and electrochemical testing to quantify lithium concentration and identify impurities. Quality metrics focus on parameters such as lithium recovery percentage, product concentration, and contaminant levels. Establishing standardized testing protocols ensures consistent product quality across different production batches and enables compliance with industry specifications for battery-grade lithium compounds.Expand Specific Solutions03 Process optimization algorithms and machine learning applications

Advanced computational methods are employed to optimize Direct Lithium Extraction processes. Machine learning algorithms analyze historical process data to identify patterns and correlations between operating parameters and extraction efficiency. These systems can predict optimal process conditions, detect anomalies, and recommend adjustments to maximize lithium recovery while minimizing resource consumption. Adaptive control systems continuously refine process parameters based on feedback loops, enabling the extraction process to respond to variations in brine composition or equipment performance.Expand Specific Solutions04 Environmental impact monitoring and sustainability metrics

Environmental monitoring systems track the ecological footprint of Direct Lithium Extraction operations. These systems measure water usage, energy consumption, chemical utilization, and waste generation throughout the extraction process. Sustainability metrics quantify the environmental performance of DLE facilities, enabling comparison with traditional evaporation pond methods. Continuous monitoring helps identify opportunities for reducing environmental impact through process modifications, recycling of process water, and optimization of reagent usage, supporting more sustainable lithium production practices.Expand Specific Solutions05 Integration of DLE quality control with downstream processing

Quality control systems for Direct Lithium Extraction are integrated with downstream processing operations to ensure end-to-end product quality. These integrated systems track lithium from extraction through purification, concentration, and conversion to final products such as lithium carbonate or hydroxide. Quality metrics at each processing stage help maintain consistency throughout the production chain. Automated data exchange between process stages enables adjustments to upstream extraction parameters based on downstream quality requirements, ensuring that the final lithium products meet specifications for battery manufacturing and other applications.Expand Specific Solutions

Key Industry Players in DLE Market

Direct Lithium Extraction (DLE) technology is currently in an early growth phase, with the global market expected to expand significantly due to increasing demand for lithium in battery production. The market size is projected to reach several billion dollars by 2030, driven by the electric vehicle revolution. Technologically, DLE is still evolving, with varying levels of maturity across different approaches. Leading players like Schlumberger Technologies and Koch Technology Solutions are developing advanced process control systems, while companies such as Evove, Watercycle Technologies, and Ganfeng Lithium are focusing on membrane-based extraction methods. Academic institutions including Penn State Research Foundation and the Institute of Process Engineering (Chinese Academy of Sciences) are contributing fundamental research to improve quality metrics and efficiency. The competitive landscape features both established energy companies and specialized startups working to optimize extraction rates, purity levels, and environmental performance.

Schlumberger Technologies, Inc.

Technical Solution: Schlumberger has developed an advanced Direct Lithium Extraction (DLE) technology platform called NeoLith Energy that focuses on process control and quality metrics. Their system employs selective adsorption technology with proprietary sorbents designed specifically for lithium extraction from brine resources. The process incorporates real-time monitoring systems with multiple sensor arrays that continuously track lithium concentration, pH levels, temperature, and impurity profiles throughout the extraction process. Schlumberger's approach emphasizes closed-loop control systems that automatically adjust process parameters based on feed composition variations, ensuring consistent lithium recovery rates above 90% across varying brine chemistries[1]. Their technology integrates advanced analytics and machine learning algorithms to optimize operational parameters, reducing reagent consumption by approximately 30% compared to conventional methods. The system features modular design allowing for scalability from pilot to commercial production while maintaining tight quality control metrics, with output lithium concentrates consistently meeting battery-grade specifications (>99.5% purity).

Strengths: Superior process control through advanced sensor integration and real-time monitoring; high recovery rates across diverse brine compositions; reduced chemical consumption through optimization algorithms. Weaknesses: Higher initial capital investment compared to conventional methods; technology still being scaled to full commercial deployment; requires specialized technical expertise for operation and maintenance.

Koch Technology Solutions LLC

Technical Solution: Koch Technology Solutions has developed a comprehensive DLE technology platform called PUROLITE® that centers on ion exchange technology with specialized resin formulations. Their process control system incorporates multi-stage extraction columns with precise flow control and automated regeneration cycles to maximize lithium recovery while minimizing reagent consumption. The technology features proprietary process control software that monitors over 20 critical parameters in real-time, including resin performance metrics, solution chemistry, and contaminant levels[2]. Koch's approach emphasizes quality through continuous inline analysis of lithium concentration and purity at various process stages, with automated adjustment of operating parameters to maintain product specifications. Their system achieves lithium recovery rates of 85-95% while reducing water consumption by up to 90% compared to traditional evaporation methods. The technology includes advanced impurity rejection mechanisms specifically designed to address challenging elements like magnesium, calcium, and boron that typically interfere with lithium extraction processes. Koch has implemented this technology at multiple scales, from pilot plants processing 20 m³/day to commercial installations handling over 500 m³/day of brine.

Strengths: Highly selective ion exchange technology with superior impurity rejection; significant water conservation compared to evaporation ponds; scalable modular design with proven commercial implementations. Weaknesses: Regeneration cycles require careful management of chemical inputs; performance can be affected by high total dissolved solids in certain brines; resin lifetime and replacement costs must be carefully monitored.

Quality Metrics and Standards for Lithium Extraction

Process and product

PatentPendingUS20250161879A1

Innovation

- The process involves contacting an aqueous lithium solution with a lithium sorbent to absorb lithium, followed by separation of the loaded sorbent and depleted solution, and subsequent treatment to regenerate the sorbent. This process utilizes pH control to maintain the lithium depleted solution at a pH of about 3 to 7 and employs ultrafiltration or nanofiltration membranes for separation.

Process and product

PatentWO2025105970A1

Innovation

- A DLE process using a lithium sorbent with a high specific surface area, combined with ultrafiltration or nanofiltration membranes for separation, and a pH-controlled upload step to optimize lithium absorption and reduce impurity carryover.

Environmental Impact Assessment

The environmental impact of Direct Lithium Extraction (DLE) technologies represents a critical consideration in their development and implementation. Traditional lithium extraction methods, particularly evaporation ponds, have significant environmental footprints including high water consumption, land use disruption, and chemical contamination. DLE technologies offer promising alternatives with potentially reduced environmental impacts, though comprehensive assessment remains essential.

Water usage metrics indicate that DLE processes can reduce water consumption by 50-90% compared to conventional evaporation methods. This represents a substantial improvement in water conservation, particularly significant in arid regions where lithium brine resources are often located. However, certain DLE technologies still require substantial water inputs for process operations and regeneration cycles, necessitating careful water management strategies.

Energy consumption presents another key environmental consideration. While DLE technologies eliminate the lengthy evaporation period of traditional methods, they typically require higher energy inputs for adsorption, ion exchange, or membrane processes. Current data suggests energy requirements ranging from 5-15 kWh per kilogram of lithium carbonate equivalent (LCE) produced, though this varies significantly between specific technologies and implementation contexts.

Chemical usage in DLE processes introduces potential environmental risks through reagent consumption and waste generation. Advanced process control systems can optimize chemical dosing and regeneration cycles, reducing both consumption rates and waste volumes. Monitoring systems tracking pH levels, reagent concentrations, and regeneration efficiency provide essential data for minimizing chemical footprints while maintaining extraction performance.

Waste management represents a significant challenge for DLE operations. Process residues may contain concentrated levels of other elements present in brines, including boron, magnesium, and various heavy metals. Effective waste characterization, treatment, and disposal protocols must be established, with continuous monitoring to prevent contamination of surrounding ecosystems.

Land use impacts of DLE facilities are generally less extensive than traditional evaporation pond operations, with physical footprints potentially reduced by 90%. However, infrastructure requirements for energy supply, water treatment, and chemical storage must be considered in comprehensive environmental assessments.

Carbon footprint analysis indicates that DLE technologies, when powered by renewable energy sources, can significantly reduce greenhouse gas emissions associated with lithium production. Life cycle assessment studies suggest potential reductions of 30-60% in carbon emissions compared to conventional methods, though these benefits depend heavily on energy sourcing and process optimization.

Regulatory compliance frameworks for DLE environmental impacts continue to evolve, with increasing emphasis on water conservation, chemical management, and ecosystem protection. Developing standardized environmental impact metrics specific to DLE technologies will be essential for meaningful comparison between different extraction approaches and implementation contexts.

Water usage metrics indicate that DLE processes can reduce water consumption by 50-90% compared to conventional evaporation methods. This represents a substantial improvement in water conservation, particularly significant in arid regions where lithium brine resources are often located. However, certain DLE technologies still require substantial water inputs for process operations and regeneration cycles, necessitating careful water management strategies.

Energy consumption presents another key environmental consideration. While DLE technologies eliminate the lengthy evaporation period of traditional methods, they typically require higher energy inputs for adsorption, ion exchange, or membrane processes. Current data suggests energy requirements ranging from 5-15 kWh per kilogram of lithium carbonate equivalent (LCE) produced, though this varies significantly between specific technologies and implementation contexts.

Chemical usage in DLE processes introduces potential environmental risks through reagent consumption and waste generation. Advanced process control systems can optimize chemical dosing and regeneration cycles, reducing both consumption rates and waste volumes. Monitoring systems tracking pH levels, reagent concentrations, and regeneration efficiency provide essential data for minimizing chemical footprints while maintaining extraction performance.

Waste management represents a significant challenge for DLE operations. Process residues may contain concentrated levels of other elements present in brines, including boron, magnesium, and various heavy metals. Effective waste characterization, treatment, and disposal protocols must be established, with continuous monitoring to prevent contamination of surrounding ecosystems.

Land use impacts of DLE facilities are generally less extensive than traditional evaporation pond operations, with physical footprints potentially reduced by 90%. However, infrastructure requirements for energy supply, water treatment, and chemical storage must be considered in comprehensive environmental assessments.

Carbon footprint analysis indicates that DLE technologies, when powered by renewable energy sources, can significantly reduce greenhouse gas emissions associated with lithium production. Life cycle assessment studies suggest potential reductions of 30-60% in carbon emissions compared to conventional methods, though these benefits depend heavily on energy sourcing and process optimization.

Regulatory compliance frameworks for DLE environmental impacts continue to evolve, with increasing emphasis on water conservation, chemical management, and ecosystem protection. Developing standardized environmental impact metrics specific to DLE technologies will be essential for meaningful comparison between different extraction approaches and implementation contexts.

Regulatory Compliance Framework

The regulatory landscape for Direct Lithium Extraction (DLE) technologies is complex and evolving rapidly as governments worldwide recognize the strategic importance of lithium resources. At the international level, organizations such as the International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC) are developing standards specifically addressing lithium extraction processes, with emphasis on environmental impact assessment and resource efficiency metrics.

In the United States, the Environmental Protection Agency (EPA) has established guidelines under the Clean Water Act and Safe Drinking Water Act that directly impact DLE operations, particularly regarding brine disposal and groundwater protection. The Bureau of Land Management (BLM) oversees permitting processes for extraction activities on federal lands, requiring comprehensive environmental impact statements that include detailed process control documentation and quality assurance protocols.

The European Union has implemented the EU Battery Directive (2006/66/EC) and more recently the European Battery Regulation, which establish strict requirements for sustainable sourcing of battery materials including lithium. These regulations mandate traceability systems and environmental performance documentation throughout the supply chain, directly affecting DLE process control requirements.

In lithium-rich regions such as Chile, Argentina, and Australia, country-specific regulatory frameworks govern extraction activities. Chile's Comisión Chilena de Energía Nuclear (CCHEN) and Corporación de Fomento de la Producción (CORFO) have established quota systems and technical requirements for lithium extraction that necessitate sophisticated process monitoring and reporting systems.

Quality metrics for DLE operations are increasingly standardized across jurisdictions, with common requirements including continuous monitoring of extraction efficiency, water consumption rates, chemical usage, and impurity profiles in final products. The International Council on Mining and Metals (ICMM) has published sustainability frameworks that are becoming de facto standards for responsible extraction practices.

Compliance documentation requirements typically include detailed process flow diagrams, control point specifications, calibration records for analytical equipment, and statistical process control charts. Many jurisdictions now require real-time data transmission to regulatory authorities, necessitating integrated digital monitoring systems with appropriate cybersecurity protections.

Emerging regulatory trends indicate movement toward lifecycle assessment requirements, where DLE operations must document not only immediate environmental impacts but also embedded carbon and water footprints. This shift is driving innovation in process control technologies that can provide comprehensive data for sustainability reporting while optimizing extraction efficiency.

In the United States, the Environmental Protection Agency (EPA) has established guidelines under the Clean Water Act and Safe Drinking Water Act that directly impact DLE operations, particularly regarding brine disposal and groundwater protection. The Bureau of Land Management (BLM) oversees permitting processes for extraction activities on federal lands, requiring comprehensive environmental impact statements that include detailed process control documentation and quality assurance protocols.

The European Union has implemented the EU Battery Directive (2006/66/EC) and more recently the European Battery Regulation, which establish strict requirements for sustainable sourcing of battery materials including lithium. These regulations mandate traceability systems and environmental performance documentation throughout the supply chain, directly affecting DLE process control requirements.

In lithium-rich regions such as Chile, Argentina, and Australia, country-specific regulatory frameworks govern extraction activities. Chile's Comisión Chilena de Energía Nuclear (CCHEN) and Corporación de Fomento de la Producción (CORFO) have established quota systems and technical requirements for lithium extraction that necessitate sophisticated process monitoring and reporting systems.

Quality metrics for DLE operations are increasingly standardized across jurisdictions, with common requirements including continuous monitoring of extraction efficiency, water consumption rates, chemical usage, and impurity profiles in final products. The International Council on Mining and Metals (ICMM) has published sustainability frameworks that are becoming de facto standards for responsible extraction practices.

Compliance documentation requirements typically include detailed process flow diagrams, control point specifications, calibration records for analytical equipment, and statistical process control charts. Many jurisdictions now require real-time data transmission to regulatory authorities, necessitating integrated digital monitoring systems with appropriate cybersecurity protections.

Emerging regulatory trends indicate movement toward lifecycle assessment requirements, where DLE operations must document not only immediate environmental impacts but also embedded carbon and water footprints. This shift is driving innovation in process control technologies that can provide comprehensive data for sustainability reporting while optimizing extraction efficiency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!