Direct Lithium Extraction Techniques Alignment with Environmental Policy

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DLE Technology Background and Objectives

Direct Lithium Extraction (DLE) technologies have emerged as a revolutionary approach to lithium production, representing a significant departure from traditional extraction methods that have dominated the industry for decades. Conventional lithium extraction primarily relies on evaporation ponds in salt flats or hard-rock mining, both of which present considerable environmental challenges including extensive water consumption, land use, and chemical pollution. The evolution of DLE technologies began in the early 2000s but has gained substantial momentum in the past five years as global demand for lithium has surged due to the rapid expansion of electric vehicle markets and renewable energy storage systems.

The technological trajectory of DLE has been characterized by progressive improvements in selectivity, efficiency, and environmental performance. Early DLE approaches focused primarily on ion exchange and adsorption techniques, while more recent innovations have incorporated electrochemical processes, membrane technologies, and solvent extraction methods. This diversification reflects the industry's recognition that different lithium resources require tailored extraction approaches to optimize recovery rates while minimizing environmental impacts.

The primary objective of modern DLE technology development is to establish extraction processes that align with increasingly stringent environmental policies while maintaining economic viability. Specifically, DLE aims to reduce freshwater consumption by 50-80% compared to traditional methods, minimize land disturbance by over 90%, and significantly decrease chemical usage and waste generation. These objectives directly respond to regulatory frameworks emerging in key lithium-producing regions, including Chile's water conservation mandates, the European Union's Battery Directive, and various national policies implementing the Paris Climate Agreement.

Another critical goal of DLE technology advancement is to expand the viable resource base for lithium production. By enabling efficient extraction from lower-grade brines, geothermal waters, and even seawater, DLE technologies could potentially unlock previously uneconomical lithium resources. This expansion is essential to meet projected demand growth, which industry analysts forecast will increase by 400-500% by 2030, driven primarily by electric vehicle battery production.

The technological evolution of DLE also aims to reduce the time-to-market for lithium production. While traditional evaporation methods require 18-24 months to concentrate lithium, advanced DLE processes can potentially reduce this timeframe to days or weeks. This acceleration aligns with policy objectives in many countries to rapidly develop domestic battery supply chains and reduce dependence on concentrated production regions, particularly in response to supply chain vulnerabilities exposed during recent global disruptions.

The technological trajectory of DLE has been characterized by progressive improvements in selectivity, efficiency, and environmental performance. Early DLE approaches focused primarily on ion exchange and adsorption techniques, while more recent innovations have incorporated electrochemical processes, membrane technologies, and solvent extraction methods. This diversification reflects the industry's recognition that different lithium resources require tailored extraction approaches to optimize recovery rates while minimizing environmental impacts.

The primary objective of modern DLE technology development is to establish extraction processes that align with increasingly stringent environmental policies while maintaining economic viability. Specifically, DLE aims to reduce freshwater consumption by 50-80% compared to traditional methods, minimize land disturbance by over 90%, and significantly decrease chemical usage and waste generation. These objectives directly respond to regulatory frameworks emerging in key lithium-producing regions, including Chile's water conservation mandates, the European Union's Battery Directive, and various national policies implementing the Paris Climate Agreement.

Another critical goal of DLE technology advancement is to expand the viable resource base for lithium production. By enabling efficient extraction from lower-grade brines, geothermal waters, and even seawater, DLE technologies could potentially unlock previously uneconomical lithium resources. This expansion is essential to meet projected demand growth, which industry analysts forecast will increase by 400-500% by 2030, driven primarily by electric vehicle battery production.

The technological evolution of DLE also aims to reduce the time-to-market for lithium production. While traditional evaporation methods require 18-24 months to concentrate lithium, advanced DLE processes can potentially reduce this timeframe to days or weeks. This acceleration aligns with policy objectives in many countries to rapidly develop domestic battery supply chains and reduce dependence on concentrated production regions, particularly in response to supply chain vulnerabilities exposed during recent global disruptions.

Market Analysis for Sustainable Lithium Production

The global lithium market is experiencing unprecedented growth driven by the rapid expansion of electric vehicle (EV) production and renewable energy storage systems. Current projections indicate the lithium market will reach approximately $8.2 billion by 2027, with a compound annual growth rate exceeding 14%. This growth trajectory is directly linked to sustainability imperatives, as governments worldwide implement increasingly stringent environmental regulations that favor cleaner lithium extraction methods over traditional approaches.

Traditional lithium production methods, particularly evaporation ponds, face mounting scrutiny due to their substantial environmental footprint, including high water consumption (approximately 500,000 gallons per ton of lithium) and significant land disturbance. This creates a distinct market opportunity for Direct Lithium Extraction (DLE) technologies that align with environmental policies while meeting growing demand.

Market segmentation reveals three primary customer categories for sustainable lithium production: EV manufacturers seeking ESG-compliant supply chains, battery producers requiring high-purity lithium, and energy storage system developers. These segments increasingly prioritize environmentally responsible sourcing, with major automotive manufacturers committing to carbon-neutral supply chains by 2030-2035.

Regional analysis shows Europe leading in environmental policy implementation affecting lithium production, with the European Battery Alliance and European Green Deal establishing strict sustainability requirements. North America follows with initiatives like the U.S. Critical Minerals Strategy emphasizing environmentally responsible domestic production. The Asia-Pacific region, while currently dominating production volume, faces increasing pressure to adopt greener extraction methods.

Price premium analysis indicates environmentally sustainable lithium commands 15-20% higher prices than conventionally produced material, reflecting market willingness to pay for reduced environmental impact. This premium is expected to increase as regulatory frameworks mature and consumer awareness grows.

Investment trends show significant capital flowing toward DLE technologies, with venture capital investment in sustainable lithium extraction startups exceeding $450 million in 2022 alone. Major mining companies are simultaneously reallocating R&D budgets toward environmentally aligned extraction methods, recognizing both regulatory necessity and market advantage.

Market barriers include technology scalability challenges, high initial capital requirements for DLE implementation, and regulatory uncertainty in some regions. However, these barriers are progressively diminishing as technology matures and policy frameworks solidify, creating a clear market trajectory favoring environmentally aligned extraction methods over traditional approaches.

Traditional lithium production methods, particularly evaporation ponds, face mounting scrutiny due to their substantial environmental footprint, including high water consumption (approximately 500,000 gallons per ton of lithium) and significant land disturbance. This creates a distinct market opportunity for Direct Lithium Extraction (DLE) technologies that align with environmental policies while meeting growing demand.

Market segmentation reveals three primary customer categories for sustainable lithium production: EV manufacturers seeking ESG-compliant supply chains, battery producers requiring high-purity lithium, and energy storage system developers. These segments increasingly prioritize environmentally responsible sourcing, with major automotive manufacturers committing to carbon-neutral supply chains by 2030-2035.

Regional analysis shows Europe leading in environmental policy implementation affecting lithium production, with the European Battery Alliance and European Green Deal establishing strict sustainability requirements. North America follows with initiatives like the U.S. Critical Minerals Strategy emphasizing environmentally responsible domestic production. The Asia-Pacific region, while currently dominating production volume, faces increasing pressure to adopt greener extraction methods.

Price premium analysis indicates environmentally sustainable lithium commands 15-20% higher prices than conventionally produced material, reflecting market willingness to pay for reduced environmental impact. This premium is expected to increase as regulatory frameworks mature and consumer awareness grows.

Investment trends show significant capital flowing toward DLE technologies, with venture capital investment in sustainable lithium extraction startups exceeding $450 million in 2022 alone. Major mining companies are simultaneously reallocating R&D budgets toward environmentally aligned extraction methods, recognizing both regulatory necessity and market advantage.

Market barriers include technology scalability challenges, high initial capital requirements for DLE implementation, and regulatory uncertainty in some regions. However, these barriers are progressively diminishing as technology matures and policy frameworks solidify, creating a clear market trajectory favoring environmentally aligned extraction methods over traditional approaches.

Global DLE Technology Status and Barriers

Direct Lithium Extraction (DLE) technologies have gained significant momentum globally, yet their implementation faces varying degrees of development and adoption across different regions. In North America, particularly the United States and Canada, substantial investments in DLE research have positioned these countries at the forefront of innovation, with several pilot projects demonstrating promising results in the Salton Sea geothermal brines and Arkansas smackover formations. Meanwhile, South American countries like Chile and Argentina, which possess approximately 60% of the world's lithium reserves in their salt flats, are gradually transitioning from traditional evaporation methods to more sustainable DLE approaches.

European advancements in DLE technology have been primarily research-focused, with Germany and the United Kingdom leading initiatives to develop more efficient extraction processes from geothermal brines. In Asia, China has made significant strides in adapting and scaling DLE technologies, particularly in Tibetan salt lakes, while Australia combines traditional mining with emerging DLE methods for its hard rock lithium resources.

Despite these global developments, DLE technologies face substantial barriers to widespread commercial implementation. Technical challenges remain paramount, including the selective recovery of lithium in the presence of competing ions, particularly magnesium, calcium, and sodium, which often require complex pre-treatment processes. The variability of brine compositions across different geographical locations necessitates customized solutions rather than one-size-fits-all approaches, significantly increasing development costs and implementation timelines.

Economic barriers present another significant hurdle, as the capital expenditure for DLE facilities remains considerably higher than traditional evaporation ponds, despite lower operational costs in the long term. The uncertainty in scaling laboratory results to commercial production creates financial risks that deter investment, particularly in regions with less developed infrastructure or regulatory frameworks.

Environmental considerations, while driving the shift toward DLE, also present challenges. Water usage efficiency, though improved compared to evaporation methods, remains a concern in water-stressed regions. Additionally, the management of chemical reagents used in ion exchange and adsorption processes requires careful handling to prevent secondary environmental impacts.

Regulatory frameworks vary significantly across jurisdictions, creating a complex landscape for technology deployment. While some countries have established clear guidelines for DLE operations, others lack specific regulations, creating uncertainty for project developers and investors. Indigenous rights and community acceptance further complicate implementation in many lithium-rich regions, requiring comprehensive stakeholder engagement strategies.

The technological maturity of different DLE methods varies considerably, with ion exchange and adsorption techniques approaching commercial readiness while newer approaches like membrane separation and solvent extraction require further development to achieve economic viability at scale.

European advancements in DLE technology have been primarily research-focused, with Germany and the United Kingdom leading initiatives to develop more efficient extraction processes from geothermal brines. In Asia, China has made significant strides in adapting and scaling DLE technologies, particularly in Tibetan salt lakes, while Australia combines traditional mining with emerging DLE methods for its hard rock lithium resources.

Despite these global developments, DLE technologies face substantial barriers to widespread commercial implementation. Technical challenges remain paramount, including the selective recovery of lithium in the presence of competing ions, particularly magnesium, calcium, and sodium, which often require complex pre-treatment processes. The variability of brine compositions across different geographical locations necessitates customized solutions rather than one-size-fits-all approaches, significantly increasing development costs and implementation timelines.

Economic barriers present another significant hurdle, as the capital expenditure for DLE facilities remains considerably higher than traditional evaporation ponds, despite lower operational costs in the long term. The uncertainty in scaling laboratory results to commercial production creates financial risks that deter investment, particularly in regions with less developed infrastructure or regulatory frameworks.

Environmental considerations, while driving the shift toward DLE, also present challenges. Water usage efficiency, though improved compared to evaporation methods, remains a concern in water-stressed regions. Additionally, the management of chemical reagents used in ion exchange and adsorption processes requires careful handling to prevent secondary environmental impacts.

Regulatory frameworks vary significantly across jurisdictions, creating a complex landscape for technology deployment. While some countries have established clear guidelines for DLE operations, others lack specific regulations, creating uncertainty for project developers and investors. Indigenous rights and community acceptance further complicate implementation in many lithium-rich regions, requiring comprehensive stakeholder engagement strategies.

The technological maturity of different DLE methods varies considerably, with ion exchange and adsorption techniques approaching commercial readiness while newer approaches like membrane separation and solvent extraction require further development to achieve economic viability at scale.

Current DLE Solution Assessment

01 Environmentally friendly lithium extraction methods

Various direct lithium extraction techniques have been developed to minimize environmental impact while maintaining efficiency. These methods focus on reducing water usage, minimizing land disturbance, and decreasing chemical waste compared to traditional evaporation pond methods. The technologies include selective adsorption processes, membrane filtration systems, and electrochemical approaches that align with environmental policies by preserving natural resources and ecosystems while extracting lithium for clean energy applications.- Environmentally friendly lithium extraction methods: Direct lithium extraction techniques that minimize environmental impact are being developed to align with sustainability policies. These methods focus on reducing water usage, minimizing land disturbance, and decreasing chemical waste compared to traditional evaporation pond methods. Advanced technologies include selective adsorption materials and membrane-based systems that can extract lithium while maintaining ecological balance in sensitive areas.

- Regulatory compliance frameworks for lithium extraction: Frameworks for ensuring direct lithium extraction techniques comply with environmental regulations and policies are being established. These frameworks include assessment protocols, monitoring systems, and reporting requirements that help companies align their extraction operations with local and international environmental standards. They address issues such as groundwater protection, ecosystem preservation, and emissions control throughout the lithium extraction process.

- Water conservation in lithium extraction processes: Water conservation technologies for direct lithium extraction are being developed to align with water management policies. These innovations include closed-loop water systems, brine recycling methods, and water-efficient extraction processes that significantly reduce freshwater consumption. Such approaches are particularly important in arid regions where lithium deposits are often found and water resources are scarce.

- Carbon footprint reduction in lithium production: Methods to reduce the carbon footprint of direct lithium extraction are being developed to align with climate policies. These include renewable energy integration, energy-efficient extraction processes, and carbon capture technologies. By minimizing greenhouse gas emissions throughout the lithium production chain, these techniques help meet carbon reduction targets while maintaining production efficiency.

- Community engagement and social responsibility in lithium mining: Approaches for engaging local communities and ensuring social responsibility in direct lithium extraction projects are being developed. These include transparent consultation processes, benefit-sharing mechanisms, and indigenous rights protection frameworks. Such approaches help align extraction activities with social policies and ensure that lithium production contributes positively to local development while respecting cultural values and traditional land uses.

02 Regulatory compliance frameworks for lithium extraction

Comprehensive regulatory frameworks have been established to ensure direct lithium extraction operations comply with environmental policies. These frameworks include guidelines for environmental impact assessments, monitoring requirements, and reporting standards. They address issues such as groundwater protection, ecosystem preservation, and restoration requirements. Companies implementing these frameworks can demonstrate policy alignment through certification processes, stakeholder engagement protocols, and transparent environmental performance metrics.Expand Specific Solutions03 Water conservation technologies in lithium extraction

Water conservation is a critical aspect of aligning lithium extraction with environmental policies. Advanced technologies have been developed to minimize water consumption through closed-loop systems, water recycling processes, and alternative extraction methods that don't rely on evaporation. These technologies include selective ion exchange systems, membrane distillation, and dry extraction processes that significantly reduce freshwater requirements and prevent contamination of local water resources, making lithium extraction more sustainable in water-stressed regions.Expand Specific Solutions04 Carbon footprint reduction in lithium processing

Innovative approaches to reduce the carbon footprint of lithium extraction and processing have been developed to align with climate policy goals. These include renewable energy integration at extraction facilities, energy-efficient processing methods, and carbon capture technologies. By optimizing extraction processes, utilizing green energy sources, and implementing advanced heat recovery systems, these technologies significantly lower greenhouse gas emissions associated with lithium production, supporting the transition to low-carbon energy systems while meeting growing demand for battery materials.Expand Specific Solutions05 Community engagement and social responsibility frameworks

Comprehensive frameworks for community engagement and social responsibility have been developed to ensure lithium extraction projects align with broader environmental policy objectives. These frameworks include protocols for indigenous consultation, benefit-sharing mechanisms, and participatory monitoring programs. By incorporating local knowledge, addressing community concerns, and creating transparent communication channels, these approaches help secure social license to operate while ensuring environmental protection measures reflect local priorities and values, creating more sustainable and equitable lithium extraction practices.Expand Specific Solutions

Key Industry Players and Competitive Landscape

Direct Lithium Extraction (DLE) technology is currently in an early growth phase, with the global market expected to expand significantly due to increasing demand for lithium in battery production. The market size is projected to reach several billion dollars by 2030, driven by environmental policy alignment that favors sustainable extraction methods. Technologically, DLE remains in development with varying maturity levels across different approaches. Leading players include Koch Technology Solutions and Schlumberger Technologies, who leverage their industrial expertise; academic institutions like MIT and University of Manchester contributing fundamental research; and specialized companies such as Watercycle Technologies, International Battery Metals, and Evove developing proprietary extraction methods. Forager Station and Li Industries represent emerging startups focusing on electrochemical extraction and recycling technologies, respectively, indicating a diversifying competitive landscape.

Koch Technology Solutions LLC

Technical Solution: Koch Technology Solutions has developed an advanced ion exchange-based Direct Lithium Extraction (DLE) technology branded as "Li-Pro™" that selectively captures lithium from brine resources. Their system utilizes proprietary ion exchange materials with high selectivity for lithium over competing ions such as sodium, calcium, and magnesium. The process operates in a continuous counter-current mode that maximizes lithium recovery while minimizing reagent consumption. Koch's technology incorporates a multi-stage purification process that produces battery-grade lithium compounds directly, eliminating several downstream processing steps required by traditional methods. The Li-Pro™ system achieves lithium recovery rates of up to 95% while reducing water consumption by approximately 80% compared to conventional evaporation pond methods[5]. Koch has engineered their technology to be compatible with existing environmental regulations by implementing closed-loop water recycling systems that return over 90% of process water to the source aquifer, maintaining hydrological balance in sensitive ecosystems. Their modular design approach allows for scalable implementation with minimal land disturbance, typically requiring less than 10% of the land area needed for traditional evaporation methods[6]. The company has also integrated energy recovery systems that reduce overall power consumption by up to 30%, aligning with carbon reduction targets established in environmental policies.

Strengths: Exceptionally high lithium selectivity and recovery rates (up to 95%), significant reduction in water consumption (80% less than evaporation methods), modular and scalable design with small physical footprint, and advanced water recycling capabilities. Weaknesses: Requires specialized ion exchange materials that may have high initial costs, regeneration of exchange media requires chemical reagents that must be managed carefully, and process optimization is needed for each specific brine composition.

Schlumberger Technologies, Inc.

Technical Solution: Schlumberger Technologies has developed a comprehensive direct lithium extraction (DLE) platform called "NeoLith Energy" that combines selective adsorption technology with advanced digital monitoring and control systems. Their approach utilizes proprietary adsorbent materials engineered at the nanoscale to selectively capture lithium ions from brine solutions while rejecting competing elements. The NeoLith system operates in a continuous carousel configuration that allows simultaneous adsorption and desorption processes, maximizing operational efficiency and throughput. Schlumberger's technology incorporates real-time monitoring with hundreds of sensors that continuously optimize process parameters based on incoming brine composition, enabling adaptive performance across varying resource conditions[9]. The system achieves lithium recovery rates of 85-90% while reducing water consumption by approximately 85% compared to traditional evaporation methods. Their process produces a high-purity lithium chloride solution that requires minimal downstream processing to reach battery-grade specifications. Schlumberger has designed their technology with environmental compliance as a core principle, implementing water recycling systems that return over 95% of process water to source aquifers. The company has successfully deployed pilot plants in multiple geographies, demonstrating consistent performance across diverse brine chemistries while maintaining alignment with local environmental regulations[10]. Their digital integration platform provides comprehensive environmental monitoring, with automated reporting capabilities that facilitate regulatory compliance and transparency.

Strengths: Advanced digital monitoring and control systems for optimized performance, high lithium recovery rates (85-90%), significant water conservation through 95% recycling, and adaptability to varying brine compositions through real-time process adjustments. Weaknesses: Complex system architecture requiring specialized technical expertise for operation and maintenance, higher initial capital investment compared to conventional methods, and potential challenges in remote locations with limited infrastructure.

Critical Patents and Technical Innovations

process

PatentWO2025106417A1

Innovation

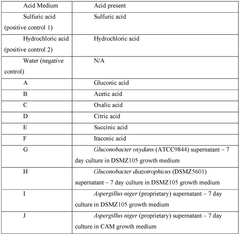

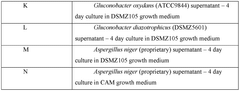

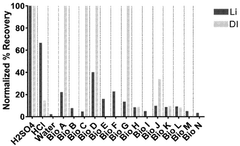

- The use of an acid medium comprising organic acids with a lowest pKa value of at least 4 or dicarboxylic acids with 3 or more carbon atoms and a lowest pKa value of at least 3.5 for desorbing lithium from adsorbents, which minimizes adsorbent damage and allows for environmentally friendly production of these acids through microorganisms.

Process and product

PatentPendingUS20250161879A1

Innovation

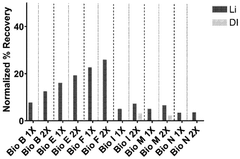

- The process involves contacting an aqueous lithium solution with a lithium sorbent to absorb lithium, followed by separation of the loaded sorbent and depleted solution, and subsequent treatment to regenerate the sorbent. This process utilizes pH control to maintain the lithium depleted solution at a pH of about 3 to 7 and employs ultrafiltration or nanofiltration membranes for separation.

Environmental Policy Compliance Framework

The Environmental Policy Compliance Framework for Direct Lithium Extraction (DLE) techniques establishes a structured approach to ensure these emerging technologies align with increasingly stringent environmental regulations. This framework integrates multiple regulatory dimensions including water usage restrictions, carbon emission limits, land use regulations, and waste management protocols that vary significantly across jurisdictions where lithium extraction occurs.

At its foundation, the framework categorizes environmental policies into four tiers of compliance requirements: mandatory regulatory standards, industry best practices, voluntary sustainability commitments, and future-oriented policy anticipation. Each DLE technology must be evaluated against these tiers to determine its regulatory viability across different markets and operating environments.

Water conservation policies represent a critical component within this framework, as traditional lithium extraction methods consume between 500,000 to 2 million gallons of water per ton of lithium produced. DLE techniques must demonstrate quantifiable reductions in water consumption to meet basin-specific water allocation regulations, particularly in water-stressed regions like Chile's Atacama Desert and Argentina's lithium triangle areas.

Carbon footprint assessment protocols within the framework require lifecycle analysis of energy inputs for DLE operations. This includes evaluating power source options, with renewable energy integration pathways becoming increasingly mandatory rather than optional in jurisdictions with carbon neutrality targets. Technologies demonstrating lower energy intensity receive preferential regulatory treatment under emerging carbon pricing mechanisms.

The framework also addresses chemical usage compliance, establishing thresholds for sorbent materials and processing agents used in DLE. These must align with regional chemical registration systems such as REACH in Europe and TSCA in the United States, with particular attention to aquatic toxicity profiles and biodegradation characteristics of any compounds that may contact groundwater systems.

Land disturbance minimization represents another key policy dimension, with DLE technologies evaluated based on their spatial footprint compared to traditional evaporation ponds. The framework incorporates indigenous land rights considerations and cultural heritage protection protocols that have become increasingly prominent in lithium-rich regions with significant indigenous populations.

Monitoring and verification protocols constitute the operational backbone of the compliance framework, establishing standardized methodologies for continuous environmental impact assessment. These include real-time groundwater monitoring requirements, regular reporting cycles, and third-party verification processes that ensure ongoing compliance rather than point-in-time certification.

At its foundation, the framework categorizes environmental policies into four tiers of compliance requirements: mandatory regulatory standards, industry best practices, voluntary sustainability commitments, and future-oriented policy anticipation. Each DLE technology must be evaluated against these tiers to determine its regulatory viability across different markets and operating environments.

Water conservation policies represent a critical component within this framework, as traditional lithium extraction methods consume between 500,000 to 2 million gallons of water per ton of lithium produced. DLE techniques must demonstrate quantifiable reductions in water consumption to meet basin-specific water allocation regulations, particularly in water-stressed regions like Chile's Atacama Desert and Argentina's lithium triangle areas.

Carbon footprint assessment protocols within the framework require lifecycle analysis of energy inputs for DLE operations. This includes evaluating power source options, with renewable energy integration pathways becoming increasingly mandatory rather than optional in jurisdictions with carbon neutrality targets. Technologies demonstrating lower energy intensity receive preferential regulatory treatment under emerging carbon pricing mechanisms.

The framework also addresses chemical usage compliance, establishing thresholds for sorbent materials and processing agents used in DLE. These must align with regional chemical registration systems such as REACH in Europe and TSCA in the United States, with particular attention to aquatic toxicity profiles and biodegradation characteristics of any compounds that may contact groundwater systems.

Land disturbance minimization represents another key policy dimension, with DLE technologies evaluated based on their spatial footprint compared to traditional evaporation ponds. The framework incorporates indigenous land rights considerations and cultural heritage protection protocols that have become increasingly prominent in lithium-rich regions with significant indigenous populations.

Monitoring and verification protocols constitute the operational backbone of the compliance framework, establishing standardized methodologies for continuous environmental impact assessment. These include real-time groundwater monitoring requirements, regular reporting cycles, and third-party verification processes that ensure ongoing compliance rather than point-in-time certification.

Water Conservation and Land Use Impact

Direct Lithium Extraction (DLE) technologies present significant advantages over traditional evaporation methods in terms of water conservation and land use impact. Traditional lithium extraction from brine requires extensive evaporation ponds that consume vast quantities of water—approximately 500,000 gallons per ton of lithium—in regions already experiencing water scarcity. This practice has led to severe groundwater depletion in the "Lithium Triangle" spanning Chile, Argentina, and Bolivia, where indigenous communities face increasing water insecurity.

DLE technologies dramatically reduce water consumption by up to 70% compared to conventional methods. Advanced adsorption-based DLE systems can process brine and return it to aquifers within hours rather than months, maintaining hydrological balance in sensitive ecosystems. Membrane-based DLE technologies further enhance water efficiency by enabling selective lithium extraction without significant water loss, addressing a critical environmental policy concern in arid lithium-producing regions.

Land use impact represents another crucial environmental consideration. Traditional evaporation ponds require approximately 2,000 hectares of land per 20,000 tons of annual lithium carbonate production. This extensive footprint disrupts local ecosystems, fragments wildlife habitats, and competes with agricultural land use. DLE technologies operate with a substantially smaller physical footprint—typically less than 10% of the land required by evaporation ponds for equivalent production capacity.

Environmental policies increasingly emphasize minimizing ecosystem disruption in critical mineral extraction. DLE technologies align with these policies by reducing surface disturbance and preserving biodiversity. The European Union's Critical Raw Materials Act and similar frameworks in North America explicitly favor extraction methods with reduced environmental footprints, creating regulatory incentives for DLE adoption.

Recent environmental impact assessments demonstrate that DLE projects can achieve lithium recovery while maintaining compliance with stringent water management regulations. For instance, closed-loop DLE systems implemented in Nevada have demonstrated the ability to extract lithium while meeting the Western States Water Council's conservation standards. These systems incorporate water recycling mechanisms that achieve up to 90% reuse rates, establishing new benchmarks for responsible resource extraction.

The alignment between DLE technologies and environmental policy frameworks represents a significant shift toward sustainable lithium production. As global demand for lithium continues to surge with the electric vehicle revolution, the water conservation and reduced land use impacts of DLE technologies position them as environmentally preferable alternatives that satisfy both resource needs and environmental protection mandates.

DLE technologies dramatically reduce water consumption by up to 70% compared to conventional methods. Advanced adsorption-based DLE systems can process brine and return it to aquifers within hours rather than months, maintaining hydrological balance in sensitive ecosystems. Membrane-based DLE technologies further enhance water efficiency by enabling selective lithium extraction without significant water loss, addressing a critical environmental policy concern in arid lithium-producing regions.

Land use impact represents another crucial environmental consideration. Traditional evaporation ponds require approximately 2,000 hectares of land per 20,000 tons of annual lithium carbonate production. This extensive footprint disrupts local ecosystems, fragments wildlife habitats, and competes with agricultural land use. DLE technologies operate with a substantially smaller physical footprint—typically less than 10% of the land required by evaporation ponds for equivalent production capacity.

Environmental policies increasingly emphasize minimizing ecosystem disruption in critical mineral extraction. DLE technologies align with these policies by reducing surface disturbance and preserving biodiversity. The European Union's Critical Raw Materials Act and similar frameworks in North America explicitly favor extraction methods with reduced environmental footprints, creating regulatory incentives for DLE adoption.

Recent environmental impact assessments demonstrate that DLE projects can achieve lithium recovery while maintaining compliance with stringent water management regulations. For instance, closed-loop DLE systems implemented in Nevada have demonstrated the ability to extract lithium while meeting the Western States Water Council's conservation standards. These systems incorporate water recycling mechanisms that achieve up to 90% reuse rates, establishing new benchmarks for responsible resource extraction.

The alignment between DLE technologies and environmental policy frameworks represents a significant shift toward sustainable lithium production. As global demand for lithium continues to surge with the electric vehicle revolution, the water conservation and reduced land use impacts of DLE technologies position them as environmentally preferable alternatives that satisfy both resource needs and environmental protection mandates.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!