Direct Lithium Extraction vs Alternative Methods: Comparative Yields

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Extraction Technology Evolution and Objectives

Lithium extraction technologies have evolved significantly over the past century, transitioning from traditional mining methods to more sophisticated approaches. The earliest commercial lithium production began in the 1920s through hard rock mining, primarily from pegmatite deposits containing spodumene, lepidolite, and petalite. This method dominated the industry until the 1950s when extraction from brine sources emerged as a viable alternative, offering lower production costs despite longer processing times.

The 1990s marked a pivotal shift with the rise of lithium-ion battery technology, dramatically increasing global demand and spurring innovation in extraction methodologies. Traditional evaporation pond techniques, while cost-effective, faced criticism for their extensive land use, high water consumption, and lengthy production cycles often exceeding 18 months. These limitations became increasingly problematic as market demand accelerated in the early 2000s with the proliferation of portable electronics and early electric vehicles.

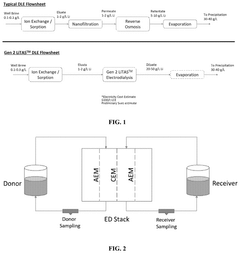

Direct Lithium Extraction (DLE) technologies began emerging in the 2010s as a response to these challenges, promising significantly reduced processing times, smaller environmental footprints, and the ability to access previously uneconomical lithium sources. These technologies utilize various mechanisms including adsorption, ion exchange, and membrane filtration to selectively extract lithium from brines with greater efficiency than traditional methods.

The technological evolution has been driven by several key objectives: increasing lithium recovery rates, reducing production timeframes, minimizing environmental impact, and enabling extraction from lower-grade resources. While traditional evaporation methods typically achieve recovery rates of 30-50%, newer DLE technologies claim potential recovery rates exceeding 90% in significantly shorter timeframes—days rather than months.

Current research focuses on optimizing DLE technologies for commercial-scale deployment, with particular emphasis on reducing energy requirements, improving selectivity for lithium over competing ions, and developing systems capable of processing diverse brine chemistries. Parallel efforts are exploring enhanced hard rock processing techniques and novel sources such as geothermal brines and recycled batteries.

The industry's technological trajectory is increasingly shaped by sustainability imperatives, with growing emphasis on water conservation, carbon footprint reduction, and minimizing chemical usage. This evolution reflects both market pressures for increased supply and regulatory trends favoring environmentally responsible resource extraction. The comparative yields between traditional and emerging extraction methods represent a critical metric in evaluating their commercial viability and potential to address projected supply gaps in the rapidly expanding lithium market.

The 1990s marked a pivotal shift with the rise of lithium-ion battery technology, dramatically increasing global demand and spurring innovation in extraction methodologies. Traditional evaporation pond techniques, while cost-effective, faced criticism for their extensive land use, high water consumption, and lengthy production cycles often exceeding 18 months. These limitations became increasingly problematic as market demand accelerated in the early 2000s with the proliferation of portable electronics and early electric vehicles.

Direct Lithium Extraction (DLE) technologies began emerging in the 2010s as a response to these challenges, promising significantly reduced processing times, smaller environmental footprints, and the ability to access previously uneconomical lithium sources. These technologies utilize various mechanisms including adsorption, ion exchange, and membrane filtration to selectively extract lithium from brines with greater efficiency than traditional methods.

The technological evolution has been driven by several key objectives: increasing lithium recovery rates, reducing production timeframes, minimizing environmental impact, and enabling extraction from lower-grade resources. While traditional evaporation methods typically achieve recovery rates of 30-50%, newer DLE technologies claim potential recovery rates exceeding 90% in significantly shorter timeframes—days rather than months.

Current research focuses on optimizing DLE technologies for commercial-scale deployment, with particular emphasis on reducing energy requirements, improving selectivity for lithium over competing ions, and developing systems capable of processing diverse brine chemistries. Parallel efforts are exploring enhanced hard rock processing techniques and novel sources such as geothermal brines and recycled batteries.

The industry's technological trajectory is increasingly shaped by sustainability imperatives, with growing emphasis on water conservation, carbon footprint reduction, and minimizing chemical usage. This evolution reflects both market pressures for increased supply and regulatory trends favoring environmentally responsible resource extraction. The comparative yields between traditional and emerging extraction methods represent a critical metric in evaluating their commercial viability and potential to address projected supply gaps in the rapidly expanding lithium market.

Global Market Demand Analysis for Lithium Resources

The global lithium market has experienced unprecedented growth in recent years, primarily driven by the rapid expansion of electric vehicle (EV) production and renewable energy storage systems. Annual demand for lithium reached approximately 86,000 metric tons of lithium carbonate equivalent (LCE) in 2022, with projections indicating a potential surge to over 1.5 million metric tons by 2035. This represents a compound annual growth rate (CAGR) of about 25% over the forecast period, significantly outpacing supply capabilities under current extraction methodologies.

The EV sector remains the dominant consumer of lithium resources, accounting for roughly 80% of total demand. Major automotive manufacturers have announced ambitious electrification targets, with companies like Volkswagen, GM, and Ford committing billions to EV development. Tesla alone consumed nearly 35,000 metric tons of LCE in 2022 for battery production. This trend is expected to intensify as EV adoption accelerates globally, particularly in China, Europe, and North America.

Energy storage systems represent the second-largest demand segment, currently utilizing approximately 10% of global lithium production. This sector is projected to grow at a CAGR of 30% through 2030 as grid-scale storage becomes increasingly vital for renewable energy integration. The remaining demand is distributed across consumer electronics, industrial applications, and emerging technologies.

Geographically, China dominates lithium consumption, processing approximately 75% of all lithium raw materials and manufacturing about 70% of the world's lithium-ion batteries. Europe has emerged as the second-largest demand center, followed by North America, with both regions actively developing domestic battery production capabilities to reduce dependency on Asian supply chains.

Price volatility has characterized the lithium market, with spot prices for battery-grade lithium carbonate fluctuating between $8,000 and $80,000 per metric ton over the past five years. This volatility underscores the critical need for more efficient and scalable extraction technologies like Direct Lithium Extraction (DLE), which could potentially unlock previously uneconomical resources.

The supply-demand imbalance is expected to persist through at least 2030, with current extraction methods (evaporation ponds and hard-rock mining) unable to scale production rapidly enough to meet projected demand. This gap creates significant market opportunities for alternative extraction technologies that can deliver higher yields with reduced environmental impact and shorter production timelines.

The EV sector remains the dominant consumer of lithium resources, accounting for roughly 80% of total demand. Major automotive manufacturers have announced ambitious electrification targets, with companies like Volkswagen, GM, and Ford committing billions to EV development. Tesla alone consumed nearly 35,000 metric tons of LCE in 2022 for battery production. This trend is expected to intensify as EV adoption accelerates globally, particularly in China, Europe, and North America.

Energy storage systems represent the second-largest demand segment, currently utilizing approximately 10% of global lithium production. This sector is projected to grow at a CAGR of 30% through 2030 as grid-scale storage becomes increasingly vital for renewable energy integration. The remaining demand is distributed across consumer electronics, industrial applications, and emerging technologies.

Geographically, China dominates lithium consumption, processing approximately 75% of all lithium raw materials and manufacturing about 70% of the world's lithium-ion batteries. Europe has emerged as the second-largest demand center, followed by North America, with both regions actively developing domestic battery production capabilities to reduce dependency on Asian supply chains.

Price volatility has characterized the lithium market, with spot prices for battery-grade lithium carbonate fluctuating between $8,000 and $80,000 per metric ton over the past five years. This volatility underscores the critical need for more efficient and scalable extraction technologies like Direct Lithium Extraction (DLE), which could potentially unlock previously uneconomical resources.

The supply-demand imbalance is expected to persist through at least 2030, with current extraction methods (evaporation ponds and hard-rock mining) unable to scale production rapidly enough to meet projected demand. This gap creates significant market opportunities for alternative extraction technologies that can deliver higher yields with reduced environmental impact and shorter production timelines.

Current Extraction Methods and Technical Barriers

Lithium extraction methods have evolved significantly over the past decades, with several established techniques dominating the industry. Traditional extraction methods include solar evaporation, which remains the most widely used approach globally. This process involves pumping lithium-rich brine into large evaporation ponds where solar energy gradually concentrates the solution over 18-24 months. While cost-effective in regions with high solar radiation and low precipitation, this method suffers from low recovery rates (typically 30-50%) and significant water consumption, making it increasingly problematic in water-stressed regions.

Hard-rock mining represents another conventional approach, extracting lithium from minerals such as spodumene through crushing, heating, and chemical processing. This method offers higher concentration yields but requires substantial energy input and produces considerable waste material, resulting in higher production costs compared to brine operations.

Direct Lithium Extraction (DLE) technologies have emerged as promising alternatives, employing selective adsorption, ion exchange membranes, or solvent extraction to separate lithium ions from brine solutions. These methods potentially offer recovery rates exceeding 90%, dramatically reduced processing times (hours instead of months), and significantly smaller environmental footprints. However, DLE faces several technical barriers that have limited widespread commercial adoption.

A primary challenge for DLE technologies is selectivity in complex brine compositions. Most lithium-rich brines contain high concentrations of competing ions such as sodium, potassium, magnesium, and calcium, which can interfere with extraction efficiency. Developing sorbents or membranes with high lithium selectivity while maintaining durability under repeated cycling remains technically challenging.

Energy requirements present another significant barrier, particularly for adsorption-based DLE systems that require regeneration cycles. The energy intensity of these processes can undermine their environmental advantages if not optimized properly. Additionally, many DLE technologies struggle with scaling issues when transitioning from laboratory to industrial implementation.

Water consumption, while reduced compared to evaporation ponds, remains a concern for certain DLE approaches. Some technologies require substantial freshwater for regeneration or washing cycles, potentially transferring rather than solving water impact issues in arid regions where many lithium resources are located.

Material durability represents a persistent challenge, as extraction media must withstand thousands of cycles in harsh chemical environments without significant degradation. Current materials often show performance decline over time, necessitating replacement and increasing operational costs. This degradation can also lead to inconsistent lithium yields and quality issues in the final product.

Hard-rock mining represents another conventional approach, extracting lithium from minerals such as spodumene through crushing, heating, and chemical processing. This method offers higher concentration yields but requires substantial energy input and produces considerable waste material, resulting in higher production costs compared to brine operations.

Direct Lithium Extraction (DLE) technologies have emerged as promising alternatives, employing selective adsorption, ion exchange membranes, or solvent extraction to separate lithium ions from brine solutions. These methods potentially offer recovery rates exceeding 90%, dramatically reduced processing times (hours instead of months), and significantly smaller environmental footprints. However, DLE faces several technical barriers that have limited widespread commercial adoption.

A primary challenge for DLE technologies is selectivity in complex brine compositions. Most lithium-rich brines contain high concentrations of competing ions such as sodium, potassium, magnesium, and calcium, which can interfere with extraction efficiency. Developing sorbents or membranes with high lithium selectivity while maintaining durability under repeated cycling remains technically challenging.

Energy requirements present another significant barrier, particularly for adsorption-based DLE systems that require regeneration cycles. The energy intensity of these processes can undermine their environmental advantages if not optimized properly. Additionally, many DLE technologies struggle with scaling issues when transitioning from laboratory to industrial implementation.

Water consumption, while reduced compared to evaporation ponds, remains a concern for certain DLE approaches. Some technologies require substantial freshwater for regeneration or washing cycles, potentially transferring rather than solving water impact issues in arid regions where many lithium resources are located.

Material durability represents a persistent challenge, as extraction media must withstand thousands of cycles in harsh chemical environments without significant degradation. Current materials often show performance decline over time, necessitating replacement and increasing operational costs. This degradation can also lead to inconsistent lithium yields and quality issues in the final product.

Comparative Analysis of Extraction Methodologies

01 Adsorption-based extraction methods

Adsorption-based methods for direct lithium extraction utilize specialized materials that selectively capture lithium ions from brine solutions. These methods typically employ ion exchange resins, inorganic adsorbents, or metal-organic frameworks that have high selectivity for lithium over competing ions such as sodium, potassium, and magnesium. The process generally involves passing lithium-containing brine through columns packed with these adsorbents, followed by desorption steps to recover concentrated lithium solutions. This approach offers advantages in terms of efficiency, reduced environmental footprint, and applicability to low-concentration brines.- Adsorption-based lithium extraction methods: Adsorption-based methods for direct lithium extraction utilize selective adsorbents to capture lithium ions from brine solutions. These methods typically employ ion exchange materials or lithium-selective sorbents that can selectively bind lithium ions while rejecting other ions present in the brine. The adsorption process is followed by desorption steps where lithium is recovered from the adsorbent material. This approach can significantly improve lithium recovery yields compared to traditional evaporation methods, especially from low-concentration brines.

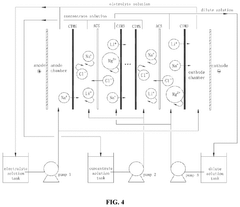

- Membrane-based lithium extraction technologies: Membrane-based technologies for direct lithium extraction utilize selective membranes to separate lithium ions from other components in brine solutions. These technologies include electrodialysis, nanofiltration, and other membrane separation processes that can selectively allow lithium ions to pass through while blocking other ions. Membrane-based methods can achieve higher lithium yields with shorter processing times compared to conventional evaporation ponds, and they typically require less land area and water consumption.

- Electrochemical lithium extraction processes: Electrochemical processes for direct lithium extraction utilize electrical potential to selectively extract lithium ions from brine solutions. These methods include electrochemical intercalation, electrolysis, and other electrochemical techniques that can selectively capture lithium ions. Electrochemical extraction can achieve higher lithium yields with lower energy consumption compared to traditional methods, and it can be effective for brines with varying lithium concentrations.

- Solvent extraction methods for lithium recovery: Solvent extraction methods for direct lithium extraction utilize selective solvents or extractants to separate lithium from brine solutions. These methods typically involve mixing the brine with an organic phase containing a lithium-selective extractant, followed by stripping the lithium from the loaded organic phase. Solvent extraction can achieve high lithium yields and selectivity, particularly from brines with high magnesium content, which traditionally pose challenges for lithium recovery.

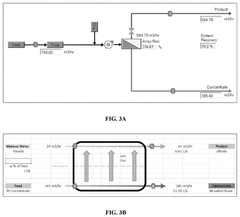

- Process optimization for improved lithium extraction yields: Various process optimization approaches can significantly improve direct lithium extraction yields. These include optimizing operating parameters such as temperature, pressure, and pH; developing more selective extraction materials; implementing multi-stage extraction processes; and integrating different extraction technologies. Advanced process control systems and real-time monitoring can also enhance lithium recovery efficiency. Additionally, pre-treatment of brine solutions to remove impurities can lead to higher lithium yields in subsequent extraction steps.

02 Membrane-based separation technologies

Membrane-based technologies for direct lithium extraction utilize specialized membranes that allow selective passage of lithium ions while blocking other elements. These systems may employ nanofiltration, electrodialysis, or other membrane separation techniques to concentrate lithium from brine sources. The membranes are designed with specific pore sizes and surface chemistries to enhance lithium selectivity. This approach can achieve high recovery rates while minimizing water consumption and chemical usage compared to traditional evaporation methods. Membrane systems can be modular and scalable, making them suitable for various brine compositions and production capacities.Expand Specific Solutions03 Electrochemical lithium extraction processes

Electrochemical methods for direct lithium extraction utilize electrical potential differences to selectively capture and concentrate lithium ions from brines. These processes may involve electrochemical cells with specialized electrodes that intercalate lithium ions during charging and release them during discharging. Some systems combine electrochemical processes with ion-selective membranes to enhance separation efficiency. Electrochemical extraction can achieve high lithium recovery rates with reduced processing time compared to traditional evaporation ponds. These methods are particularly advantageous for processing brines with varying compositions and can be powered by renewable energy sources to reduce operational costs.Expand Specific Solutions04 Solvent extraction and chemical precipitation

Solvent extraction and chemical precipitation methods for direct lithium extraction involve the use of specific chemicals that react selectively with lithium to form separable compounds. These processes typically use organic solvents with lithium-selective extractants or precipitation agents that form lithium-rich phases that can be separated from the brine solution. After extraction, lithium is recovered through stripping or precipitation steps to produce concentrated lithium solutions or compounds. These methods can achieve high purity lithium products and are adaptable to various brine compositions. The processes can be optimized to minimize reagent consumption and environmental impact while maximizing lithium recovery yields.Expand Specific Solutions05 Process optimization and yield enhancement techniques

Various techniques have been developed to optimize direct lithium extraction processes and enhance yields. These include pre-treatment methods to remove impurities, multi-stage extraction systems, advanced process control strategies, and hybrid approaches combining different extraction technologies. Some innovations focus on reducing energy consumption, minimizing waste generation, and improving lithium recovery rates through process intensification. Other developments include the use of artificial intelligence and machine learning for real-time optimization of extraction parameters based on brine composition variations. These optimization techniques can significantly improve the economic viability of direct lithium extraction operations while reducing their environmental footprint.Expand Specific Solutions

Key Industry Players and Competitive Landscape

Direct Lithium Extraction (DLE) technology is emerging as a disruptive force in the lithium extraction market, which is currently in a growth phase with increasing demand driven by battery technologies. The global DLE market is projected to expand significantly, with companies like Lilac Solutions, EnergyX, and International Battery Metals leading innovation. These firms are developing technologies that potentially offer higher yields, reduced environmental impact, and faster extraction times compared to traditional evaporation ponds and hard rock mining. Research institutions such as the Institute of Process Engineering (Chinese Academy of Sciences) and Penn State Research Foundation are advancing the scientific understanding, while established players like Schlumberger and Contemporary Amperex Technology are integrating DLE into their strategic portfolios, indicating the technology's transition from experimental to commercially viable.

Institute of Process Engineering, Chinese Academy of Sciences

Technical Solution: The Institute of Process Engineering at the Chinese Academy of Sciences has developed several innovative Direct Lithium Extraction (DLE) technologies focusing on electrochemical and adsorption-based approaches. Their flagship technology utilizes electrochemical intercalation with specially designed electrode materials that selectively capture lithium ions when an electrical potential is applied. This process achieves lithium recovery rates of 80-90% from various brine sources, including salt lake brines with complex compositions. The institute has also pioneered composite adsorbent materials combining inorganic lithium manganese oxide frameworks with organic polymers that demonstrate exceptional selectivity for lithium over competing ions like sodium and magnesium. Their systems operate in continuous flow configurations with multiple stages to maximize lithium recovery while minimizing reagent consumption. A distinctive feature of their technology is the integration of artificial intelligence algorithms to optimize operational parameters based on real-time monitoring of brine composition and system performance. The institute has successfully scaled their technology from laboratory to pilot scale, processing several cubic meters of brine per day with consistent lithium recovery performance across varying brine chemistries. Their research has demonstrated particular effectiveness in processing high Mg/Li ratio brines that are challenging for conventional extraction methods.

Strengths: Excellent selectivity for lithium in complex brine environments, adaptability to various brine compositions including high Mg/Li ratio sources, integration of AI for process optimization, and reduced chemical consumption compared to conventional methods. Weaknesses: Higher energy requirements for electrochemical approaches, potential electrode degradation requiring periodic replacement, and more complex operation requiring specialized technical expertise.

Koch Technology Solutions LLC

Technical Solution: Koch Technology Solutions has developed an advanced Direct Lithium Extraction (DLE) platform that combines selective adsorption technology with sophisticated process engineering. Their system utilizes proprietary adsorbent materials that selectively capture lithium ions from brine solutions while rejecting competing ions. The process operates in a continuous cycle where lithium-rich brine passes through columns containing these adsorbents, followed by a desorption phase using a small volume of fresh water or mild acid solution to release concentrated lithium. Koch's technology achieves lithium recovery rates of 85-95% compared to traditional evaporation methods' 40-50%, while reducing water consumption by approximately 90%. Their approach features advanced process control systems that optimize operational parameters in real-time based on brine composition and environmental conditions. The modular design allows for scalable implementation from pilot to commercial scale, with processing times measured in hours rather than months. Koch has leveraged their extensive experience in separation technologies from other industries to enhance the efficiency and reliability of their DLE systems, incorporating innovations in fluid dynamics and mass transfer to maximize lithium yield while minimizing energy consumption.

Strengths: High lithium recovery efficiency (85-95%), sophisticated process control systems for optimization, significant reduction in water usage, and leveraging of cross-industry expertise in separation technologies. Weaknesses: Potentially higher capital costs compared to traditional methods, requirement for specialized adsorbent materials with limited suppliers, and need for skilled operators to manage the advanced control systems.

Critical Patents and Innovations in DLE Technology

Lithium ion adsorbents

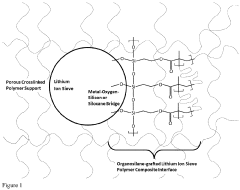

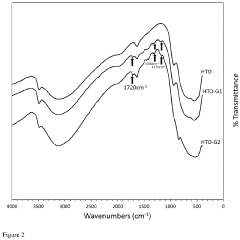

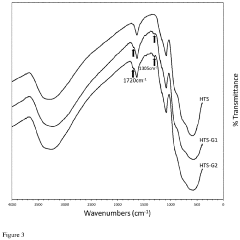

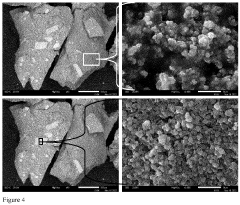

PatentPendingEP4223409A1

Innovation

- Development of an organosilane-grafted lithium ion sieve covalently incorporated into a porous crosslinked polymeric support scaffold, enhancing selectivity and durability through improved porosity and resistance to degradation under turbulent and high-temperature conditions.

Systems and methods for direct lithium extraction

PatentPendingUS20250011957A1

Innovation

- The integration of selective membrane electrodialysis as a single step to simultaneously concentrate and purify lithium brines, reducing the number of required processing steps, capital and operating costs, and carbon footprint, while eliminating the need for large equipment at remote mining locations.

Environmental Impact Assessment of Extraction Methods

The environmental footprint of lithium extraction methods varies significantly, with each technique presenting distinct ecological challenges. Traditional evaporation ponds, while technologically simple, consume vast quantities of water—up to 500,000 gallons per ton of lithium—in regions already experiencing water scarcity. These operations also alter local ecosystems by changing soil salinity and disrupting wildlife habitats across expansive land areas, sometimes exceeding 10,000 acres per operation.

Direct Lithium Extraction (DLE) technologies demonstrate promising environmental advantages. Recent field studies indicate DLE can reduce water consumption by 50-90% compared to evaporation methods. The physical footprint is dramatically smaller, requiring only 1-5% of the land area needed for traditional operations. Additionally, DLE processes typically operate in closed-loop systems that minimize chemical discharge into surrounding environments.

Hard-rock mining methods present different environmental challenges. While they consume less water than evaporation ponds, they generate substantial solid waste—approximately 15 tons of tailings per ton of lithium produced. Energy consumption in hard-rock operations exceeds both evaporation and DLE methods by 30-50%, contributing to higher carbon emissions. Habitat disruption through open-pit mining remains a significant concern, with restoration efforts showing limited success in maintaining biodiversity.

Carbon footprint analysis reveals meaningful differences between extraction methods. Life cycle assessments indicate evaporation ponds produce 5-15 kg CO2e per kg of lithium carbonate equivalent (LCE), while hard-rock mining generates 9-15 kg CO2e per kg LCE. DLE technologies currently average 3.5-8 kg CO2e per kg LCE, though this varies by specific technology and energy source.

Groundwater impacts also differ substantially. Evaporation methods can deplete aquifers and alter hydrological systems across entire watersheds. Recent monitoring in South America's "Lithium Triangle" has documented declining water tables of 1-2 meters annually in areas surrounding evaporation operations. DLE technologies, particularly those employing selective adsorption, demonstrate minimal impact on groundwater quality when properly implemented, with contaminant levels remaining below detection limits in adjacent monitoring wells.

Regulatory frameworks are evolving to address these environmental disparities. The European Union's proposed Battery Regulation includes carbon footprint declarations and responsible sourcing requirements that may favor lower-impact extraction methods. Similarly, the U.S. Department of Energy has initiated programs supporting environmentally optimized extraction technologies, potentially accelerating the transition toward more sustainable lithium production methods.

Direct Lithium Extraction (DLE) technologies demonstrate promising environmental advantages. Recent field studies indicate DLE can reduce water consumption by 50-90% compared to evaporation methods. The physical footprint is dramatically smaller, requiring only 1-5% of the land area needed for traditional operations. Additionally, DLE processes typically operate in closed-loop systems that minimize chemical discharge into surrounding environments.

Hard-rock mining methods present different environmental challenges. While they consume less water than evaporation ponds, they generate substantial solid waste—approximately 15 tons of tailings per ton of lithium produced. Energy consumption in hard-rock operations exceeds both evaporation and DLE methods by 30-50%, contributing to higher carbon emissions. Habitat disruption through open-pit mining remains a significant concern, with restoration efforts showing limited success in maintaining biodiversity.

Carbon footprint analysis reveals meaningful differences between extraction methods. Life cycle assessments indicate evaporation ponds produce 5-15 kg CO2e per kg of lithium carbonate equivalent (LCE), while hard-rock mining generates 9-15 kg CO2e per kg LCE. DLE technologies currently average 3.5-8 kg CO2e per kg LCE, though this varies by specific technology and energy source.

Groundwater impacts also differ substantially. Evaporation methods can deplete aquifers and alter hydrological systems across entire watersheds. Recent monitoring in South America's "Lithium Triangle" has documented declining water tables of 1-2 meters annually in areas surrounding evaporation operations. DLE technologies, particularly those employing selective adsorption, demonstrate minimal impact on groundwater quality when properly implemented, with contaminant levels remaining below detection limits in adjacent monitoring wells.

Regulatory frameworks are evolving to address these environmental disparities. The European Union's proposed Battery Regulation includes carbon footprint declarations and responsible sourcing requirements that may favor lower-impact extraction methods. Similarly, the U.S. Department of Energy has initiated programs supporting environmentally optimized extraction technologies, potentially accelerating the transition toward more sustainable lithium production methods.

Economic Feasibility and Scalability Evaluation

The economic feasibility of Direct Lithium Extraction (DLE) technologies compared to conventional methods presents a complex landscape of capital expenditure, operational costs, and long-term returns. Initial investment requirements for DLE systems typically range from $20-30 million for small-scale operations to over $100 million for commercial-scale facilities, representing a significant upfront commitment. However, these costs must be evaluated against the substantially higher lithium recovery rates of 70-90% achievable through DLE, compared to 30-50% for traditional evaporation ponds.

Operational expenditure analysis reveals that while DLE technologies require higher energy inputs and specialized equipment maintenance, they offer reduced land usage requirements and significantly shorter production cycles—days or weeks versus 18-24 months for evaporation methods. This acceleration in production timeline creates substantial economic advantages through faster time-to-market and improved cash flow dynamics.

Scalability considerations favor DLE technologies in several key dimensions. The modular nature of many DLE systems allows for incremental capacity expansion, reducing initial capital risk and enabling more responsive adaptation to market demands. Additionally, DLE facilities maintain consistent performance regardless of seasonal variations or climate conditions, unlike evaporation ponds which are highly dependent on stable weather patterns.

Return on investment calculations indicate that despite higher initial costs, DLE projects typically achieve break-even points 30-40% faster than conventional extraction methods when accounting for total production volume over time. This advantage becomes particularly pronounced in regions with high land costs or restrictive water usage regulations, where traditional methods face increasing economic constraints.

Market sensitivity analysis demonstrates that DLE economics improve significantly with rising lithium prices, as the higher recovery rates translate directly to increased revenue per resource unit. With global lithium prices projected to maintain strong levels due to accelerating electric vehicle adoption, the economic case for DLE continues to strengthen relative to alternative methods.

Infrastructure requirements represent both a challenge and opportunity for DLE implementation. While these technologies require reliable power sources and specialized technical expertise, they can be deployed in diverse geographical locations without the climate and space limitations of evaporation ponds, potentially unlocking previously unviable lithium resources and creating new economic opportunities in regions previously excluded from lithium production.

Operational expenditure analysis reveals that while DLE technologies require higher energy inputs and specialized equipment maintenance, they offer reduced land usage requirements and significantly shorter production cycles—days or weeks versus 18-24 months for evaporation methods. This acceleration in production timeline creates substantial economic advantages through faster time-to-market and improved cash flow dynamics.

Scalability considerations favor DLE technologies in several key dimensions. The modular nature of many DLE systems allows for incremental capacity expansion, reducing initial capital risk and enabling more responsive adaptation to market demands. Additionally, DLE facilities maintain consistent performance regardless of seasonal variations or climate conditions, unlike evaporation ponds which are highly dependent on stable weather patterns.

Return on investment calculations indicate that despite higher initial costs, DLE projects typically achieve break-even points 30-40% faster than conventional extraction methods when accounting for total production volume over time. This advantage becomes particularly pronounced in regions with high land costs or restrictive water usage regulations, where traditional methods face increasing economic constraints.

Market sensitivity analysis demonstrates that DLE economics improve significantly with rising lithium prices, as the higher recovery rates translate directly to increased revenue per resource unit. With global lithium prices projected to maintain strong levels due to accelerating electric vehicle adoption, the economic case for DLE continues to strengthen relative to alternative methods.

Infrastructure requirements represent both a challenge and opportunity for DLE implementation. While these technologies require reliable power sources and specialized technical expertise, they can be deployed in diverse geographical locations without the climate and space limitations of evaporation ponds, potentially unlocking previously unviable lithium resources and creating new economic opportunities in regions previously excluded from lithium production.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!