Direct Lithium Extraction vs Batch Processes: Cost-Effectiveness

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DLE Technology Background and Objectives

Lithium extraction technologies have evolved significantly over the past century, with traditional methods primarily relying on evaporation ponds in salt flats. These batch processes, while established and relatively simple, require extensive land use, consume substantial water resources, and operate on lengthy production cycles often spanning 18-24 months. The emergence of Direct Lithium Extraction (DLE) technologies represents a paradigm shift in the lithium production landscape, offering potentially faster, more efficient, and environmentally sustainable alternatives.

DLE encompasses a family of technologies that selectively extract lithium from brine resources through various mechanisms including adsorption, ion exchange, solvent extraction, and membrane processes. The fundamental objective of DLE development is to accelerate lithium recovery while minimizing environmental impact and maximizing resource utilization efficiency. This approach aims to address the growing global demand for lithium, projected to increase by 400-500% by 2030, driven primarily by the electric vehicle and energy storage sectors.

The technical evolution of lithium extraction reflects broader industry trends toward process intensification and sustainability. Traditional evaporation methods yield recovery rates of approximately 40-50%, whereas advanced DLE technologies demonstrate potential recovery rates of 70-90% in significantly reduced timeframes of hours or days rather than months. This dramatic improvement in extraction efficiency represents a critical advancement in meeting escalating market demands.

Current DLE technology development focuses on several key objectives: reducing operational costs to achieve economic parity with conventional methods; minimizing water consumption and environmental footprint; improving selectivity to enhance lithium purity; and developing scalable systems capable of processing diverse brine chemistries across various geographical contexts. These objectives align with the industry's need to expand production capacity while adhering to increasingly stringent environmental regulations and sustainability expectations.

The cost-effectiveness comparison between DLE and traditional batch processes represents a complex technical challenge involving multiple variables including capital expenditure, operational expenses, recovery rates, and production timelines. While DLE technologies typically require higher initial investment and energy inputs, they offer potential advantages in terms of reduced land requirements, water conservation, and accelerated time-to-market. The economic viability threshold continues to evolve as technology matures and economies of scale develop within the DLE sector.

Understanding the technical trajectory of lithium extraction methods provides essential context for evaluating current cost-effectiveness comparisons and projecting future competitive landscapes in this critical mineral supply chain. The ongoing refinement of DLE technologies represents a significant opportunity to transform lithium production economics while addressing sustainability imperatives.

DLE encompasses a family of technologies that selectively extract lithium from brine resources through various mechanisms including adsorption, ion exchange, solvent extraction, and membrane processes. The fundamental objective of DLE development is to accelerate lithium recovery while minimizing environmental impact and maximizing resource utilization efficiency. This approach aims to address the growing global demand for lithium, projected to increase by 400-500% by 2030, driven primarily by the electric vehicle and energy storage sectors.

The technical evolution of lithium extraction reflects broader industry trends toward process intensification and sustainability. Traditional evaporation methods yield recovery rates of approximately 40-50%, whereas advanced DLE technologies demonstrate potential recovery rates of 70-90% in significantly reduced timeframes of hours or days rather than months. This dramatic improvement in extraction efficiency represents a critical advancement in meeting escalating market demands.

Current DLE technology development focuses on several key objectives: reducing operational costs to achieve economic parity with conventional methods; minimizing water consumption and environmental footprint; improving selectivity to enhance lithium purity; and developing scalable systems capable of processing diverse brine chemistries across various geographical contexts. These objectives align with the industry's need to expand production capacity while adhering to increasingly stringent environmental regulations and sustainability expectations.

The cost-effectiveness comparison between DLE and traditional batch processes represents a complex technical challenge involving multiple variables including capital expenditure, operational expenses, recovery rates, and production timelines. While DLE technologies typically require higher initial investment and energy inputs, they offer potential advantages in terms of reduced land requirements, water conservation, and accelerated time-to-market. The economic viability threshold continues to evolve as technology matures and economies of scale develop within the DLE sector.

Understanding the technical trajectory of lithium extraction methods provides essential context for evaluating current cost-effectiveness comparisons and projecting future competitive landscapes in this critical mineral supply chain. The ongoing refinement of DLE technologies represents a significant opportunity to transform lithium production economics while addressing sustainability imperatives.

Lithium Market Demand Analysis

The global lithium market has experienced unprecedented growth in recent years, primarily driven by the rapid expansion of electric vehicle (EV) production and renewable energy storage systems. Annual demand for lithium has increased from approximately 200,000 metric tons of lithium carbonate equivalent (LCE) in 2016 to over 500,000 metric tons in 2022, representing a compound annual growth rate (CAGR) of about 16.5%. Industry forecasts project this demand to reach 1.5-2 million metric tons by 2030, indicating continued strong growth trajectory.

Battery manufacturing currently accounts for over 74% of global lithium consumption, with automotive applications representing the largest segment within this category. The remaining demand is distributed across various industries including ceramics and glass (14%), lubricating greases (3%), polymer production (2%), air treatment systems (1%), and other applications (6%). This distribution highlights the critical importance of lithium in modern industrial applications beyond just energy storage.

Geographically, demand is concentrated in regions with significant EV and battery manufacturing capacity. China leads global demand, consuming approximately 39% of worldwide lithium production, followed by Japan and South Korea at 18% and 15% respectively. European demand has grown substantially, now representing about 16% of the global market, while North America accounts for approximately 9%. The remaining 3% is distributed across various other regions.

Price volatility has been a defining characteristic of the lithium market in recent years. Lithium carbonate prices surged from approximately $6,000 per metric ton in 2020 to peak at over $70,000 in late 2022, before correcting to around $30,000 in mid-2023. This volatility underscores the market's sensitivity to supply-demand imbalances and highlights the economic incentive for developing more cost-effective extraction technologies.

The comparison between Direct Lithium Extraction (DLE) and traditional batch processes has significant market implications. Current extraction methods struggle to meet growing demand efficiently, with traditional evaporation ponds requiring 18-24 months for production and yielding recovery rates of only 30-50%. Market analysis indicates that technologies capable of reducing production time while increasing yield could capture substantial market share, particularly as automotive manufacturers seek to secure stable supply chains.

Industry stakeholders increasingly prioritize extraction methods that balance cost-effectiveness with environmental sustainability. Survey data indicates that 68% of major battery manufacturers and 72% of automotive OEMs have established sustainability criteria for their lithium sourcing, creating market pressure for extraction technologies with reduced water consumption and carbon footprint.

Battery manufacturing currently accounts for over 74% of global lithium consumption, with automotive applications representing the largest segment within this category. The remaining demand is distributed across various industries including ceramics and glass (14%), lubricating greases (3%), polymer production (2%), air treatment systems (1%), and other applications (6%). This distribution highlights the critical importance of lithium in modern industrial applications beyond just energy storage.

Geographically, demand is concentrated in regions with significant EV and battery manufacturing capacity. China leads global demand, consuming approximately 39% of worldwide lithium production, followed by Japan and South Korea at 18% and 15% respectively. European demand has grown substantially, now representing about 16% of the global market, while North America accounts for approximately 9%. The remaining 3% is distributed across various other regions.

Price volatility has been a defining characteristic of the lithium market in recent years. Lithium carbonate prices surged from approximately $6,000 per metric ton in 2020 to peak at over $70,000 in late 2022, before correcting to around $30,000 in mid-2023. This volatility underscores the market's sensitivity to supply-demand imbalances and highlights the economic incentive for developing more cost-effective extraction technologies.

The comparison between Direct Lithium Extraction (DLE) and traditional batch processes has significant market implications. Current extraction methods struggle to meet growing demand efficiently, with traditional evaporation ponds requiring 18-24 months for production and yielding recovery rates of only 30-50%. Market analysis indicates that technologies capable of reducing production time while increasing yield could capture substantial market share, particularly as automotive manufacturers seek to secure stable supply chains.

Industry stakeholders increasingly prioritize extraction methods that balance cost-effectiveness with environmental sustainability. Survey data indicates that 68% of major battery manufacturers and 72% of automotive OEMs have established sustainability criteria for their lithium sourcing, creating market pressure for extraction technologies with reduced water consumption and carbon footprint.

DLE vs Batch Extraction: Current Status and Challenges

Direct Lithium Extraction (DLE) technologies represent a significant advancement over traditional batch extraction methods, yet both approaches continue to coexist in the global lithium production landscape. Currently, conventional evaporation pond methods account for approximately 60% of global lithium production, primarily in the "Lithium Triangle" of South America, while DLE technologies are gaining traction with numerous pilot projects and early commercial implementations worldwide.

The technical status of DLE encompasses several methodologies including adsorption, ion exchange, solvent extraction, and membrane processes. Each approach demonstrates varying levels of maturity, with ion exchange and adsorption technologies leading in commercial readiness. Companies like Lilac Solutions, Standard Lithium, and EnergyX have developed proprietary DLE technologies that have progressed beyond laboratory scale to field demonstrations, achieving lithium recovery rates of 80-90% compared to 40-50% in traditional evaporation methods.

Traditional batch processes, while established and operationally understood, face significant challenges including lengthy production cycles (12-18 months), substantial land and water requirements, and vulnerability to weather conditions. These methods also struggle with declining brine concentrations and increasing impurity levels in many established production regions.

DLE technologies, despite their promise, confront their own set of challenges. Scale-up difficulties represent a primary obstacle, as laboratory successes have not always translated smoothly to industrial implementation. Many DLE processes require significant pre-treatment of brines to remove impurities that can foul extraction media. Additionally, the energy intensity of certain DLE approaches raises questions about their overall environmental footprint, particularly in remote locations where renewable energy may be limited.

Economic viability remains a critical challenge for DLE adoption. Capital expenditure requirements for DLE facilities are typically higher than traditional methods, though this may be offset by reduced land requirements and faster time-to-market. Operating costs vary significantly between different DLE technologies, with energy consumption and sorbent/membrane replacement costs representing key variables that impact long-term cost-effectiveness.

Geographically, DLE development shows distinct patterns. North American companies lead in technology innovation, while implementation efforts are concentrated in both established lithium-producing regions like Chile and Argentina and emerging sources such as the United States, United Kingdom, and Germany. China has also made significant investments in developing proprietary DLE technologies to secure its lithium supply chain.

Regulatory frameworks present another challenge, as many jurisdictions lack specific provisions for these newer extraction technologies, creating uncertainty for project developers and investors regarding permitting and environmental compliance requirements.

The technical status of DLE encompasses several methodologies including adsorption, ion exchange, solvent extraction, and membrane processes. Each approach demonstrates varying levels of maturity, with ion exchange and adsorption technologies leading in commercial readiness. Companies like Lilac Solutions, Standard Lithium, and EnergyX have developed proprietary DLE technologies that have progressed beyond laboratory scale to field demonstrations, achieving lithium recovery rates of 80-90% compared to 40-50% in traditional evaporation methods.

Traditional batch processes, while established and operationally understood, face significant challenges including lengthy production cycles (12-18 months), substantial land and water requirements, and vulnerability to weather conditions. These methods also struggle with declining brine concentrations and increasing impurity levels in many established production regions.

DLE technologies, despite their promise, confront their own set of challenges. Scale-up difficulties represent a primary obstacle, as laboratory successes have not always translated smoothly to industrial implementation. Many DLE processes require significant pre-treatment of brines to remove impurities that can foul extraction media. Additionally, the energy intensity of certain DLE approaches raises questions about their overall environmental footprint, particularly in remote locations where renewable energy may be limited.

Economic viability remains a critical challenge for DLE adoption. Capital expenditure requirements for DLE facilities are typically higher than traditional methods, though this may be offset by reduced land requirements and faster time-to-market. Operating costs vary significantly between different DLE technologies, with energy consumption and sorbent/membrane replacement costs representing key variables that impact long-term cost-effectiveness.

Geographically, DLE development shows distinct patterns. North American companies lead in technology innovation, while implementation efforts are concentrated in both established lithium-producing regions like Chile and Argentina and emerging sources such as the United States, United Kingdom, and Germany. China has also made significant investments in developing proprietary DLE technologies to secure its lithium supply chain.

Regulatory frameworks present another challenge, as many jurisdictions lack specific provisions for these newer extraction technologies, creating uncertainty for project developers and investors regarding permitting and environmental compliance requirements.

Current DLE and Batch Process Solutions

01 Economic comparison of DLE with traditional extraction methods

Direct Lithium Extraction (DLE) technologies offer cost advantages over traditional extraction methods such as evaporation ponds. These economic benefits include reduced land use requirements, faster production timelines, and higher lithium recovery rates. The cost-effectiveness analysis compares capital expenditure, operational expenses, and overall return on investment between DLE and conventional methods, demonstrating potential for significant economic improvements in lithium production.- Economic efficiency of DLE processes: Direct Lithium Extraction technologies offer cost advantages over traditional extraction methods by reducing processing time and resource requirements. These processes can be optimized to lower operational expenses through improved energy efficiency, reduced chemical consumption, and minimized water usage. Economic analyses show that DLE can achieve competitive production costs while maintaining high lithium recovery rates, making it financially viable for commercial implementation.

- Adsorption-based DLE cost factors: Adsorption-based DLE technologies utilize specialized sorbent materials to selectively capture lithium ions from brine solutions. The cost-effectiveness of these systems depends on sorbent capacity, selectivity, regeneration efficiency, and lifespan. Advanced sorbent materials with high lithium selectivity and multiple regeneration cycles significantly reduce operational costs. Innovations in sorbent design and regeneration processes have improved the economic viability of adsorption-based DLE systems compared to conventional evaporation pond methods.

- Membrane and electrochemical DLE economics: Membrane and electrochemical DLE technologies leverage ion-selective membranes or electrochemical processes to extract lithium from brines. These methods can be more cost-effective than traditional approaches due to their lower land footprint, reduced processing time, and ability to operate continuously. The economic advantages include decreased capital expenditure for facility construction, lower energy consumption, and the potential for valuable by-product recovery. Ongoing developments in membrane materials and electrochemical cell design continue to improve the cost-performance ratio.

- Scalability and implementation costs: The scalability of DLE technologies significantly impacts their cost-effectiveness. Initial capital investments for DLE facilities can be substantial but often require less land area than conventional evaporation ponds. Modular DLE systems allow for phased implementation, reducing upfront capital requirements while enabling production capacity to grow with market demand. The ability to deploy DLE technologies at various scales provides flexibility in investment planning and can accelerate return on investment compared to traditional extraction methods.

- Environmental compliance and sustainability economics: DLE technologies offer economic benefits through improved environmental compliance and sustainability. By reducing water consumption, minimizing chemical usage, and decreasing the environmental footprint, DLE methods can lower costs associated with environmental remediation and regulatory compliance. The reduced environmental impact translates to economic advantages through faster permitting processes, lower environmental liability, and potential access to green financing options. Additionally, the ability to process previously uneconomical lithium resources expands the available resource base, potentially reducing supply constraints and price volatility.

02 Adsorption-based DLE systems and their economic efficiency

Adsorption-based DLE technologies utilize specialized materials to selectively capture lithium ions from brine solutions. These systems demonstrate cost-effectiveness through reduced processing time, lower water consumption, and minimal chemical usage compared to traditional methods. The economic efficiency is further enhanced by the reusability of adsorbent materials, optimization of adsorption-desorption cycles, and the ability to process lower-grade lithium resources that would be uneconomical with conventional extraction techniques.Expand Specific Solutions03 Membrane and ion exchange DLE technologies cost analysis

Membrane and ion exchange DLE technologies offer economic advantages through selective lithium extraction with reduced environmental footprint. These systems demonstrate cost-effectiveness through lower energy requirements, minimal chemical consumption, and the ability to process diverse brine compositions. The economic analysis includes considerations of membrane lifespan, regeneration costs, scaling potential, and overall operational efficiency compared to traditional extraction methods.Expand Specific Solutions04 Scalability and commercialization economics of DLE

The scalability and commercialization aspects of DLE technologies significantly impact their cost-effectiveness. Economic analyses focus on scaling factors, including capital investment requirements, operational complexity, and market readiness. The commercial viability assessment includes production capacity optimization, integration with existing infrastructure, and adaptability to various lithium resource types. These factors collectively determine the economic feasibility of implementing DLE technologies at industrial scales.Expand Specific Solutions05 Environmental and sustainability factors affecting DLE economics

Environmental and sustainability considerations significantly impact the overall cost-effectiveness of DLE technologies. These factors include reduced water consumption, smaller land footprint, lower carbon emissions, and decreased waste generation compared to traditional methods. The economic analysis incorporates potential regulatory compliance costs, environmental remediation expenses, and sustainability certifications that may affect market access and pricing. Additionally, the ability to operate in environmentally sensitive areas provides economic advantages through access to previously untapped lithium resources.Expand Specific Solutions

Key Industry Players in Lithium Extraction

Direct Lithium Extraction (DLE) technology is emerging as a disruptive force in the lithium extraction market, which is currently in a growth phase transitioning from traditional batch processes. The global lithium market is expanding rapidly, driven by electric vehicle battery demand, with projections exceeding $8 billion by 2027. Technologically, DLE is advancing toward commercial maturity with companies at different development stages. Energy Exploration Technologies and Vulcan Energy are pioneering commercial DLE implementations, while established players like Schlumberger and Koch Technology Solutions are leveraging their industrial expertise to scale solutions. Research institutions including The University of Manchester and Xi'an Jiaotong University are advancing fundamental technologies, while specialized firms like Watercycle Technologies and Forager Station focus on innovative extraction methods. This competitive landscape reflects the industry's transition toward more sustainable and cost-effective lithium production methods.

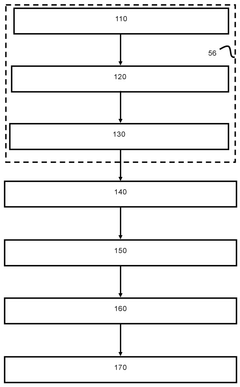

Koch Technology Solutions LLC

Technical Solution: Koch Technology Solutions has developed an advanced Direct Lithium Extraction (DLE) platform called Li-Pro™ that represents a significant advancement over traditional batch processing methods. This technology utilizes a proprietary selective adsorption process with engineered sorbent materials that specifically target lithium ions while minimizing the capture of competing elements like sodium, magnesium, and calcium. The Li-Pro™ system operates as a continuous flow process rather than batch-based, enabling 24/7 operation with consistent output quality. Koch's approach can process brines with lithium concentrations as low as 100 ppm, making previously uneconomical resources viable. The technology achieves lithium recovery rates of 85-95% depending on brine chemistry, substantially higher than the 30-50% typical of evaporation ponds. Processing time is reduced from 18-24 months to just hours, dramatically improving capital efficiency. The system incorporates a closed-loop design that recycles approximately 90% of process water, significantly reducing freshwater requirements compared to traditional methods. Koch has demonstrated the technology at pilot scale with multiple brine chemistries and is currently scaling to commercial production with reported OPEX reductions of 40-60% compared to conventional evaporation methods.

Strengths: Continuous processing dramatically reduces time-to-market and improves capital utilization; high recovery rates significantly enhance resource economics; ability to process low-concentration brines expands addressable resource base; substantial water conservation reduces environmental impact and operating costs. Weaknesses: Higher energy requirements than evaporation methods impact operational expenses; specialized sorbent materials require periodic regeneration or replacement; technology requires more complex operational expertise than traditional evaporation ponds.

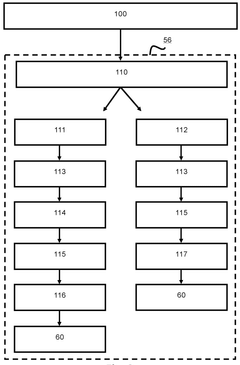

Energy Exploration Technologies, Inc.

Technical Solution: EnergyX has developed a proprietary LiTAS™ (Lithium Ionic Transmission and Separation) technology for Direct Lithium Extraction (DLE). This platform utilizes a mixed matrix membrane (MMM) approach that combines metal-organic frameworks (MOFs) with polymer membranes to create highly selective lithium extraction capabilities. The system operates continuously rather than in batches, allowing for real-time processing of brine without the need for large evaporation ponds. EnergyX's technology can extract lithium directly from brine resources with reported recovery rates of over 90% compared to traditional evaporation methods that typically achieve only 30-50% recovery. The process requires significantly less time (hours vs. months) and operates with minimal water consumption, addressing key cost drivers in lithium production. Their modular design allows for scalable implementation that can be tailored to different brine chemistries and production volumes.

Strengths: Higher lithium recovery rates (>90%) significantly improve resource utilization economics; dramatically reduced processing time from months to hours enables faster ROI; modular design allows for incremental capital investment rather than massive upfront costs. Weaknesses: As a newer technology, lacks long-term operational data in commercial settings; may require higher initial capital investment than traditional evaporation ponds; membrane fouling and replacement costs could impact long-term operational expenses.

Technical Analysis of Breakthrough DLE Patents

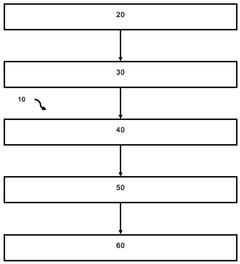

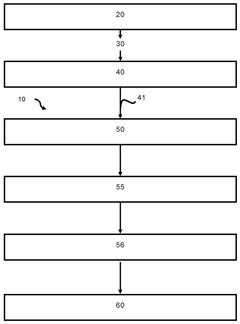

Pressure control in a system and process for extracting lithium enriched eluates from an untreated brine

PatentWO2025036580A1

Innovation

- A system and process that directly injects untreated geothermal brine into a direct lithium extraction unit, utilizing a pressure control unit to manage pressure and optimize lithium extraction, thereby eliminating the need for pre-treatment and reducing costs and environmental impact.

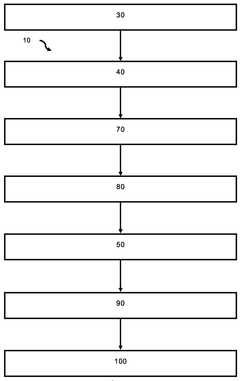

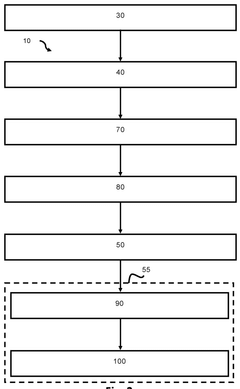

Post processing in a system and process for extracting lithium enriched eluates from an untreated brine

PatentWO2025036579A1

Innovation

- A system and process that directly injects untreated geothermal brine into a direct lithium extraction unit, followed by a membrane purification unit and a foreign ion removal unit, allowing for the extraction of lithium enriched eluates without pre-treatment.

Environmental Impact Assessment of Extraction Methods

The environmental impact of lithium extraction methods represents a critical dimension in evaluating the sustainability of both Direct Lithium Extraction (DLE) and traditional batch processes. DLE technologies demonstrate significant environmental advantages through their reduced land footprint compared to conventional evaporation ponds, which can span thousands of hectares and dramatically alter local ecosystems.

Water consumption patterns differ markedly between these methodologies. Traditional evaporation processes consume substantial quantities of water in arid regions where lithium brine deposits typically exist, exacerbating water scarcity issues for local communities and ecosystems. In contrast, many DLE technologies offer water recycling capabilities, with some advanced systems achieving recovery rates exceeding 90%, substantially reducing the net water footprint.

Chemical usage presents another environmental consideration. Batch processes typically employ significant quantities of lime and sodium carbonate, generating substantial waste streams. DLE methods often utilize selective adsorbents or ion exchange materials that can be regenerated, potentially reducing chemical consumption and associated waste generation by 30-50% according to recent field trials.

Carbon emissions profiles vary considerably between extraction methodologies. Traditional evaporation ponds rely on solar energy for evaporation but require energy-intensive subsequent processing. DLE systems demand electricity for operation but offer more compact processing with potentially lower overall emissions when powered by renewable energy sources. Life cycle assessments indicate DLE could reduce carbon emissions by 15-30% compared to conventional methods.

Waste management represents a significant environmental challenge for both approaches. Evaporation ponds produce substantial quantities of salt waste and depleted brine that must be managed. DLE systems generate spent adsorbents and concentrated brine streams, though in smaller volumes. Recent innovations in waste valorization show promise for converting these waste streams into valuable by-products like industrial salts and agricultural amendments.

Biodiversity impacts differ substantially between methods. Evaporation ponds create artificial saline environments that disrupt natural habitats and migration patterns, particularly affecting avian species. DLE facilities maintain a smaller physical footprint but may still impact local groundwater dynamics if extraction rates exceed natural recharge capabilities.

Regulatory compliance frameworks increasingly favor technologies with reduced environmental footprints, with several jurisdictions implementing stricter standards for water usage, land disturbance, and waste management in mining operations. This regulatory trend may accelerate the transition toward more environmentally sustainable extraction methodologies in the lithium supply chain.

Water consumption patterns differ markedly between these methodologies. Traditional evaporation processes consume substantial quantities of water in arid regions where lithium brine deposits typically exist, exacerbating water scarcity issues for local communities and ecosystems. In contrast, many DLE technologies offer water recycling capabilities, with some advanced systems achieving recovery rates exceeding 90%, substantially reducing the net water footprint.

Chemical usage presents another environmental consideration. Batch processes typically employ significant quantities of lime and sodium carbonate, generating substantial waste streams. DLE methods often utilize selective adsorbents or ion exchange materials that can be regenerated, potentially reducing chemical consumption and associated waste generation by 30-50% according to recent field trials.

Carbon emissions profiles vary considerably between extraction methodologies. Traditional evaporation ponds rely on solar energy for evaporation but require energy-intensive subsequent processing. DLE systems demand electricity for operation but offer more compact processing with potentially lower overall emissions when powered by renewable energy sources. Life cycle assessments indicate DLE could reduce carbon emissions by 15-30% compared to conventional methods.

Waste management represents a significant environmental challenge for both approaches. Evaporation ponds produce substantial quantities of salt waste and depleted brine that must be managed. DLE systems generate spent adsorbents and concentrated brine streams, though in smaller volumes. Recent innovations in waste valorization show promise for converting these waste streams into valuable by-products like industrial salts and agricultural amendments.

Biodiversity impacts differ substantially between methods. Evaporation ponds create artificial saline environments that disrupt natural habitats and migration patterns, particularly affecting avian species. DLE facilities maintain a smaller physical footprint but may still impact local groundwater dynamics if extraction rates exceed natural recharge capabilities.

Regulatory compliance frameworks increasingly favor technologies with reduced environmental footprints, with several jurisdictions implementing stricter standards for water usage, land disturbance, and waste management in mining operations. This regulatory trend may accelerate the transition toward more environmentally sustainable extraction methodologies in the lithium supply chain.

Economic Feasibility and ROI Analysis

The economic feasibility of Direct Lithium Extraction (DLE) versus traditional batch processes represents a critical consideration for industry stakeholders. Initial capital expenditure for DLE technologies typically ranges between $20-30 million for medium-scale operations, approximately 15-25% higher than conventional evaporation pond systems. However, this higher upfront investment is counterbalanced by significantly reduced operational timeframes, with DLE processes capable of extracting lithium in hours rather than the 18-24 months required for traditional evaporation methods.

Return on Investment (ROI) analysis indicates that DLE technologies can achieve breakeven points within 3-5 years of operation, compared to 5-7 years for conventional batch processes. This accelerated ROI is primarily attributed to DLE's higher recovery rates, which typically reach 80-90% versus 40-50% for traditional methods. When factoring in the rapidly escalating market value of battery-grade lithium carbonate, currently averaging $75,000 per metric ton, the economic advantage of higher recovery rates becomes increasingly pronounced.

Operational expenditure comparisons reveal that DLE processes consume approximately 50-70% less water than evaporation ponds, translating to substantial cost savings in water-scarce regions where water prices can exceed $5 per cubic meter. Energy consumption presents a more complex picture, with DLE requiring 35-45% more electricity per ton of lithium produced, but this disadvantage is partially offset by reduced labor requirements, with DLE facilities typically operating with 30-40% fewer personnel.

Sensitivity analysis across various market scenarios demonstrates that DLE maintains economic advantages even under moderate price fluctuations. At lithium carbonate prices above $50,000 per ton, DLE consistently outperforms batch processes in terms of net present value (NPV). However, should prices fall below this threshold, the economic advantage narrows significantly, particularly for operations in regions with high electricity costs.

Long-term economic modeling suggests that as DLE technologies mature and achieve economies of scale, capital costs are projected to decrease by 15-20% over the next five years. This trend, coupled with increasing environmental regulations that may impose additional costs on water-intensive batch processes, further strengthens the economic case for DLE implementation. Companies adopting DLE technologies now may therefore secure both immediate operational benefits and strategic long-term cost advantages as the lithium market continues its expansion to meet growing demand from the electric vehicle and energy storage sectors.

Return on Investment (ROI) analysis indicates that DLE technologies can achieve breakeven points within 3-5 years of operation, compared to 5-7 years for conventional batch processes. This accelerated ROI is primarily attributed to DLE's higher recovery rates, which typically reach 80-90% versus 40-50% for traditional methods. When factoring in the rapidly escalating market value of battery-grade lithium carbonate, currently averaging $75,000 per metric ton, the economic advantage of higher recovery rates becomes increasingly pronounced.

Operational expenditure comparisons reveal that DLE processes consume approximately 50-70% less water than evaporation ponds, translating to substantial cost savings in water-scarce regions where water prices can exceed $5 per cubic meter. Energy consumption presents a more complex picture, with DLE requiring 35-45% more electricity per ton of lithium produced, but this disadvantage is partially offset by reduced labor requirements, with DLE facilities typically operating with 30-40% fewer personnel.

Sensitivity analysis across various market scenarios demonstrates that DLE maintains economic advantages even under moderate price fluctuations. At lithium carbonate prices above $50,000 per ton, DLE consistently outperforms batch processes in terms of net present value (NPV). However, should prices fall below this threshold, the economic advantage narrows significantly, particularly for operations in regions with high electricity costs.

Long-term economic modeling suggests that as DLE technologies mature and achieve economies of scale, capital costs are projected to decrease by 15-20% over the next five years. This trend, coupled with increasing environmental regulations that may impose additional costs on water-intensive batch processes, further strengthens the economic case for DLE implementation. Companies adopting DLE technologies now may therefore secure both immediate operational benefits and strategic long-term cost advantages as the lithium market continues its expansion to meet growing demand from the electric vehicle and energy storage sectors.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!