Direct Lithium Extraction vs Hybrid Systems: Performance Metrics

SEP 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DLE Technology Background and Objectives

Lithium extraction technologies have evolved significantly over the past decades, transitioning from traditional evaporation methods to more advanced Direct Lithium Extraction (DLE) techniques. The historical development of lithium extraction began with solar evaporation in salt flats, which dominated the industry for decades but faced limitations in efficiency, environmental impact, and production timelines. As global demand for lithium has surged due to the rapid growth of electric vehicles and energy storage systems, the need for more efficient extraction methods has become increasingly critical.

DLE technologies emerged in the early 2000s as promising alternatives, offering potential solutions to overcome the limitations of conventional methods. These technologies utilize various selective adsorption materials, ion exchange resins, solvent extraction processes, or membrane systems to directly extract lithium from brines with higher recovery rates and reduced environmental footprint. The technical evolution has accelerated particularly in the last decade, with significant breakthroughs in adsorption materials and process optimization.

Hybrid systems represent the latest development in this technological progression, combining elements of traditional methods with innovative DLE approaches. These systems aim to leverage the strengths of multiple technologies while mitigating their individual weaknesses. The integration of DLE with conventional processes potentially offers enhanced efficiency, reduced water consumption, and improved economics compared to standalone technologies.

The primary objectives of current research and development in this field focus on several key performance metrics: increasing lithium recovery rates beyond 90% (compared to 40-50% in traditional methods), reducing processing time from months to days or hours, minimizing water consumption, enhancing selectivity for lithium over other ions, and improving overall economic viability through reduced capital and operational expenditures.

Additionally, technological development aims to address environmental sustainability concerns by reducing the physical footprint of extraction operations, minimizing chemical usage, and enabling the processing of a wider range of brine resources, including those with lower lithium concentrations that were previously considered uneconomical.

The evolution trajectory suggests a continued refinement of both pure DLE and hybrid systems, with particular emphasis on developing technologies that can be customized to specific brine chemistries and geological conditions. Future technical goals include achieving commercial-scale operations with consistent performance across varying brine compositions, further reducing energy requirements, and developing closed-loop systems that minimize waste generation and environmental impact.

DLE technologies emerged in the early 2000s as promising alternatives, offering potential solutions to overcome the limitations of conventional methods. These technologies utilize various selective adsorption materials, ion exchange resins, solvent extraction processes, or membrane systems to directly extract lithium from brines with higher recovery rates and reduced environmental footprint. The technical evolution has accelerated particularly in the last decade, with significant breakthroughs in adsorption materials and process optimization.

Hybrid systems represent the latest development in this technological progression, combining elements of traditional methods with innovative DLE approaches. These systems aim to leverage the strengths of multiple technologies while mitigating their individual weaknesses. The integration of DLE with conventional processes potentially offers enhanced efficiency, reduced water consumption, and improved economics compared to standalone technologies.

The primary objectives of current research and development in this field focus on several key performance metrics: increasing lithium recovery rates beyond 90% (compared to 40-50% in traditional methods), reducing processing time from months to days or hours, minimizing water consumption, enhancing selectivity for lithium over other ions, and improving overall economic viability through reduced capital and operational expenditures.

Additionally, technological development aims to address environmental sustainability concerns by reducing the physical footprint of extraction operations, minimizing chemical usage, and enabling the processing of a wider range of brine resources, including those with lower lithium concentrations that were previously considered uneconomical.

The evolution trajectory suggests a continued refinement of both pure DLE and hybrid systems, with particular emphasis on developing technologies that can be customized to specific brine chemistries and geological conditions. Future technical goals include achieving commercial-scale operations with consistent performance across varying brine compositions, further reducing energy requirements, and developing closed-loop systems that minimize waste generation and environmental impact.

Market Analysis for Lithium Extraction Solutions

The global lithium extraction market is experiencing unprecedented growth, driven primarily by the rapid expansion of electric vehicle production and renewable energy storage systems. Current market valuations place the lithium extraction sector at approximately $4 billion in 2023, with projections indicating a compound annual growth rate (CAGR) of 14.8% through 2030, potentially reaching $12 billion by decade's end. This remarkable growth trajectory underscores the strategic importance of developing efficient extraction technologies.

Direct Lithium Extraction (DLE) technologies are gaining significant market traction, currently representing about 10% of global lithium production but expected to reach 25% by 2030. This shift is particularly evident in North America and Europe, where environmental regulations and water scarcity concerns are accelerating adoption of these more sustainable methods compared to traditional evaporation ponds.

Hybrid systems, combining DLE with conventional methods, are emerging as a promising market segment with an estimated growth rate exceeding 20% annually. These systems are particularly attractive in regions with existing brine operations looking to improve efficiency without complete infrastructure overhaul. Market analysis indicates that hybrid approaches may capture up to 15% of new lithium production capacity additions by 2028.

Customer segmentation reveals three primary market drivers: large-scale battery manufacturers seeking stable supply chains, automotive OEMs pursuing vertical integration strategies, and energy storage developers requiring high-purity lithium compounds. Each segment prioritizes different performance metrics, with battery manufacturers focusing on purity levels, automotive companies on cost efficiency, and energy storage developers on scalability and environmental impact.

Regional market dynamics show significant variations. Asia-Pacific remains the dominant market for end-use consumption, while South America leads in production capacity. North America is experiencing the fastest growth in DLE technology adoption, driven by substantial government investments and private sector innovation. European markets are increasingly focused on hybrid systems that can operate within strict environmental regulatory frameworks.

Pricing trends indicate a premium for lithium produced via DLE methods, commanding 8-12% higher prices due to higher purity levels and reduced environmental impact. This premium is expected to narrow as technology matures and economies of scale are realized, potentially reaching parity with conventional methods by 2027-2028.

Direct Lithium Extraction (DLE) technologies are gaining significant market traction, currently representing about 10% of global lithium production but expected to reach 25% by 2030. This shift is particularly evident in North America and Europe, where environmental regulations and water scarcity concerns are accelerating adoption of these more sustainable methods compared to traditional evaporation ponds.

Hybrid systems, combining DLE with conventional methods, are emerging as a promising market segment with an estimated growth rate exceeding 20% annually. These systems are particularly attractive in regions with existing brine operations looking to improve efficiency without complete infrastructure overhaul. Market analysis indicates that hybrid approaches may capture up to 15% of new lithium production capacity additions by 2028.

Customer segmentation reveals three primary market drivers: large-scale battery manufacturers seeking stable supply chains, automotive OEMs pursuing vertical integration strategies, and energy storage developers requiring high-purity lithium compounds. Each segment prioritizes different performance metrics, with battery manufacturers focusing on purity levels, automotive companies on cost efficiency, and energy storage developers on scalability and environmental impact.

Regional market dynamics show significant variations. Asia-Pacific remains the dominant market for end-use consumption, while South America leads in production capacity. North America is experiencing the fastest growth in DLE technology adoption, driven by substantial government investments and private sector innovation. European markets are increasingly focused on hybrid systems that can operate within strict environmental regulatory frameworks.

Pricing trends indicate a premium for lithium produced via DLE methods, commanding 8-12% higher prices due to higher purity levels and reduced environmental impact. This premium is expected to narrow as technology matures and economies of scale are realized, potentially reaching parity with conventional methods by 2027-2028.

Current DLE and Hybrid Systems Technical Challenges

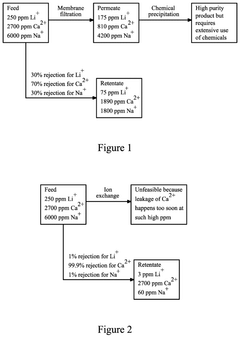

Despite significant advancements in Direct Lithium Extraction (DLE) technologies, both standalone DLE systems and hybrid approaches face substantial technical challenges that limit their widespread commercial adoption. Current DLE methods struggle with selectivity issues, as most ion exchange materials and adsorbents cannot effectively discriminate between lithium and competing ions such as sodium, potassium, and magnesium in brine solutions. This selectivity challenge significantly impacts process efficiency and final product purity.

Energy consumption remains a critical concern for DLE operations. Most systems require substantial energy inputs for regeneration cycles, pumping operations, and pre-treatment processes. This high energy demand directly affects operational costs and environmental footprint, particularly in remote locations where lithium resources are often found. Hybrid systems that combine DLE with conventional evaporation ponds may reduce some energy requirements but introduce additional complexity.

Material durability presents another significant obstacle. Sorbents and membranes used in DLE systems frequently experience performance degradation after multiple adsorption-desorption cycles. This degradation manifests as reduced capacity, selectivity loss, and physical deterioration, necessitating frequent and costly material replacement. Current materials typically maintain optimal performance for only 200-500 cycles, far below the thousands of cycles needed for economic viability.

Scaling issues further complicate DLE implementation. Many systems suffer from membrane fouling, sorbent clogging, and mineral precipitation during operation. These scaling problems are particularly pronounced in brines with high concentrations of calcium, magnesium, and sulfates. Hybrid systems may mitigate some scaling concerns through pre-treatment steps but add process complexity and cost.

Water management represents a growing challenge, especially in water-stressed regions. While DLE technologies generally use less water than evaporation ponds, they still require significant volumes for processing and regeneration. Hybrid systems may optimize water usage but face challenges in water recycling and wastewater management.

Process integration difficulties arise when attempting to combine DLE with conventional extraction methods or other recovery technologies. Incompatibilities between different process steps, varying operational parameters, and complex control systems create significant engineering challenges. These integration issues often result in suboptimal performance metrics compared to theoretical capabilities.

Economic viability remains perhaps the most significant barrier to widespread adoption. Current DLE and hybrid systems typically have higher capital and operational expenditures compared to conventional methods, with recovery costs estimated between $5,000-$10,000 per ton of lithium carbonate equivalent, significantly above the target threshold for mass market adoption.

Energy consumption remains a critical concern for DLE operations. Most systems require substantial energy inputs for regeneration cycles, pumping operations, and pre-treatment processes. This high energy demand directly affects operational costs and environmental footprint, particularly in remote locations where lithium resources are often found. Hybrid systems that combine DLE with conventional evaporation ponds may reduce some energy requirements but introduce additional complexity.

Material durability presents another significant obstacle. Sorbents and membranes used in DLE systems frequently experience performance degradation after multiple adsorption-desorption cycles. This degradation manifests as reduced capacity, selectivity loss, and physical deterioration, necessitating frequent and costly material replacement. Current materials typically maintain optimal performance for only 200-500 cycles, far below the thousands of cycles needed for economic viability.

Scaling issues further complicate DLE implementation. Many systems suffer from membrane fouling, sorbent clogging, and mineral precipitation during operation. These scaling problems are particularly pronounced in brines with high concentrations of calcium, magnesium, and sulfates. Hybrid systems may mitigate some scaling concerns through pre-treatment steps but add process complexity and cost.

Water management represents a growing challenge, especially in water-stressed regions. While DLE technologies generally use less water than evaporation ponds, they still require significant volumes for processing and regeneration. Hybrid systems may optimize water usage but face challenges in water recycling and wastewater management.

Process integration difficulties arise when attempting to combine DLE with conventional extraction methods or other recovery technologies. Incompatibilities between different process steps, varying operational parameters, and complex control systems create significant engineering challenges. These integration issues often result in suboptimal performance metrics compared to theoretical capabilities.

Economic viability remains perhaps the most significant barrier to widespread adoption. Current DLE and hybrid systems typically have higher capital and operational expenditures compared to conventional methods, with recovery costs estimated between $5,000-$10,000 per ton of lithium carbonate equivalent, significantly above the target threshold for mass market adoption.

Comparative Analysis of DLE vs Hybrid Systems

01 Performance metrics for direct lithium extraction systems

Direct lithium extraction systems require specific performance metrics to evaluate their efficiency and effectiveness. These metrics include extraction rates, selectivity for lithium over other elements, recovery percentages, and energy consumption. Monitoring these performance indicators helps optimize the extraction process and ensure the economic viability of lithium production from various sources such as brines and geothermal waters.- Performance metrics for direct lithium extraction systems: Direct lithium extraction systems require specific performance metrics to evaluate their efficiency and effectiveness. These metrics include extraction rates, selectivity for lithium over other ions, recovery percentages, and energy consumption. Monitoring these performance indicators helps optimize the extraction process and ensure the economic viability of lithium production from brine resources. Advanced measurement techniques and analytical methods are employed to assess these metrics in real-time operation.

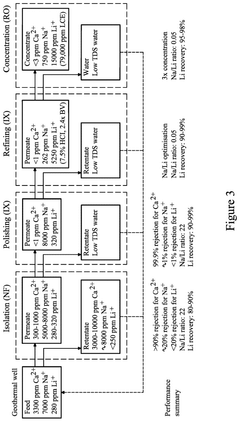

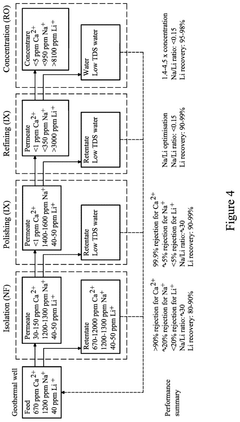

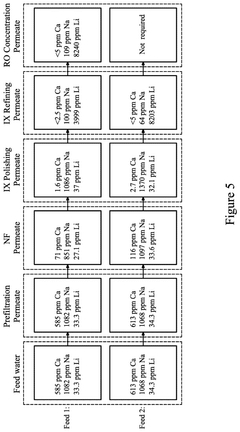

- Hybrid system architecture for resource extraction: Hybrid systems combine multiple technologies to enhance the efficiency of resource extraction processes, including lithium extraction. These architectures integrate conventional and innovative extraction methods, combining the strengths of different approaches while mitigating their individual limitations. The hybrid approach may incorporate membrane technologies, adsorption systems, and electrochemical processes working in tandem to improve overall system performance, reduce energy consumption, and increase extraction yields.

- Performance monitoring and optimization frameworks: Sophisticated monitoring and optimization frameworks are essential for evaluating the performance of lithium extraction systems. These frameworks collect and analyze operational data to identify inefficiencies and opportunities for improvement. They incorporate machine learning algorithms and statistical models to predict system behavior under various conditions and recommend optimal operating parameters. Real-time monitoring capabilities allow for immediate adjustments to maintain peak performance and respond to changing input conditions.

- Energy efficiency metrics in extraction processes: Energy consumption is a critical performance metric for direct lithium extraction and hybrid systems. Comprehensive energy efficiency metrics measure the amount of energy required per unit of lithium produced, accounting for all process stages from pumping and pretreatment to extraction and refinement. These metrics help identify energy-intensive steps and guide the development of more sustainable extraction technologies. Reducing energy requirements is essential for minimizing operational costs and environmental impact of lithium production.

- System integration and data management for performance assessment: Effective performance assessment of lithium extraction systems requires robust data management and system integration. This involves collecting, storing, and analyzing data from multiple sensors and control systems throughout the extraction process. Advanced data management platforms enable comprehensive performance evaluation by correlating various operational parameters with extraction outcomes. These integrated systems support decision-making by providing actionable insights into system performance and identifying opportunities for process optimization and efficiency improvements.

02 Hybrid system architecture for resource extraction

Hybrid systems that combine different extraction technologies can improve overall performance in lithium extraction operations. These architectures integrate multiple processes such as adsorption, membrane filtration, and electrochemical methods to maximize efficiency. The hybrid approach allows for adaptability to different brine compositions and operating conditions, potentially reducing energy consumption while increasing lithium recovery rates.Expand Specific Solutions03 Performance monitoring and analytics for extraction systems

Advanced monitoring and analytics tools are essential for evaluating the performance of lithium extraction systems. These tools collect real-time data on operational parameters, analyze system efficiency, and identify potential bottlenecks or failures. By implementing comprehensive monitoring solutions, operators can optimize extraction processes, predict maintenance needs, and ensure consistent performance of lithium recovery operations.Expand Specific Solutions04 Resource management in hybrid extraction systems

Effective resource management is critical for the operation of hybrid lithium extraction systems. This includes optimizing energy usage, water consumption, chemical reagents, and processing time. Resource management strategies focus on balancing extraction efficiency with environmental impact and operational costs. Advanced algorithms and control systems help allocate resources dynamically based on changing conditions and performance requirements.Expand Specific Solutions05 System integration and performance optimization

Integration of various components in lithium extraction systems requires careful optimization to achieve desired performance metrics. This involves synchronizing different extraction stages, balancing flow rates, and coordinating control systems. Performance optimization techniques include process simulation, parameter tuning, and adaptive control strategies. These approaches help maximize lithium yield while minimizing operational costs and environmental footprint of extraction operations.Expand Specific Solutions

Key Industry Players in Lithium Extraction

The Direct Lithium Extraction (DLE) versus hybrid systems market is currently in a growth phase, with an estimated market size of $1.2-1.5 billion and projected to expand significantly as global lithium demand increases for battery production. The competitive landscape features established energy sector players like Schlumberger and Koch Technology Solutions developing proprietary DLE technologies alongside specialized innovators such as International Battery Metals, Pure Lithium, and Watercycle Technologies. Technical maturity varies considerably, with companies like Vulcan Energy and Saltworks demonstrating commercial-scale implementations, while others remain in pilot phases. Academic-industry partnerships involving institutions like The University of Manchester and National University of Singapore are accelerating technological advancement, particularly in membrane technology and selective extraction methods that promise to improve efficiency and reduce environmental impact compared to traditional extraction methods.

Schlumberger Technologies, Inc.

Technical Solution: Schlumberger has developed NeoLith Energy, an advanced direct lithium extraction (DLE) platform that combines selective adsorption technology with sophisticated process control systems. Their approach utilizes proprietary adsorbent materials that selectively capture lithium ions from brine resources while minimizing co-extraction of impurities. The NeoLith system employs a continuous countercurrent extraction process that maximizes lithium recovery while optimizing reagent consumption. Schlumberger's technology achieves lithium recovery rates of 85-95% with processing times measured in hours rather than the months required for traditional evaporation methods. Their pilot plant in Clayton Valley, Nevada, demonstrates the ability to process diverse brine chemistries with lithium concentrations ranging from 100-500 mg/L. The system incorporates advanced automation and digital monitoring capabilities, leveraging Schlumberger's extensive experience in fluid processing from the oil and gas industry. Their process reduces water consumption by approximately 85% compared to evaporation ponds and can be powered by renewable energy sources to minimize carbon footprint.

Strengths: High lithium recovery efficiency, rapid processing time, sophisticated process control systems, and adaptability to various brine compositions. Weaknesses: Relatively new to commercial-scale lithium production despite extensive experience in other extraction industries, potentially higher operational costs due to advanced technology implementation, and dependence on specialized adsorbent materials.

Vulcan Energie Ressourcen GmbH

Technical Solution: Vulcan Energy has pioneered a Zero Carbon Lithium™ extraction process that combines geothermal energy production with direct lithium extraction (DLE) technology. Their integrated system extracts lithium from geothermal brines in the Upper Rhine Valley of Germany, where lithium concentrations range from 150-200 mg/L. The process begins with hot brine (>120°C) being pumped to the surface, where thermal energy is first harvested for renewable electricity generation. The cooled brine then passes through Vulcan's proprietary DLE process using selective adsorption materials to extract lithium with minimal impurities. Their system achieves lithium recovery rates of approximately 85-90% while producing virtually no carbon emissions due to the use of self-generated renewable energy. The spent brine is reinjected into the reservoir, creating a closed-loop system that minimizes environmental impact and water consumption.

Strengths: Carbon-neutral operation through integration with geothermal energy, closed-loop system with minimal environmental footprint, dual revenue streams from both lithium and energy production. Weaknesses: Limited to geothermal brine resources with sufficient lithium concentrations, higher complexity due to integration of two distinct technologies, and potential scaling challenges when expanding to multiple production sites.

Critical Patents and Innovations in Extraction Methods

Apparatus and process for monovalent ion extraction

PatentPendingUS20250050274A1

Innovation

- The proposed apparatus and process involve a multi-stage system that includes prefiltration, nanofiltration, and ion exchange separation to reduce the ratio of divalent ions to a target monovalent ion, such as lithium, in an aqueous solution. This system effectively enhances the separation efficiency and reduces operating costs.

Process and product

PatentPendingUS20250161879A1

Innovation

- The process involves contacting an aqueous lithium solution with a lithium sorbent to absorb lithium, followed by separation of the loaded sorbent and depleted solution, and subsequent treatment to regenerate the sorbent. This process utilizes pH control to maintain the lithium depleted solution at a pH of about 3 to 7 and employs ultrafiltration or nanofiltration membranes for separation.

Environmental Impact Assessment

The environmental footprint of lithium extraction technologies represents a critical dimension in evaluating their overall sustainability and long-term viability. Direct Lithium Extraction (DLE) methods demonstrate significant environmental advantages compared to traditional evaporation pond approaches, primarily through reduced land disturbance and water consumption. Typical DLE operations require approximately 90% less land area than conventional methods, preserving natural habitats and minimizing ecosystem disruption in sensitive brine-rich regions.

Water conservation emerges as another substantial environmental benefit of DLE technologies. While evaporation ponds can consume up to 500,000 gallons of water per ton of lithium produced, advanced DLE systems have demonstrated capabilities to reduce this figure by 50-70%, depending on the specific technology employed. This water efficiency becomes increasingly crucial in arid regions where lithium resources and water scarcity often coincide.

Hybrid systems, which combine elements of DLE with conventional methods, present an intermediate environmental profile. These systems typically achieve a 30-50% reduction in land use compared to traditional approaches while offering water conservation benefits that fall between pure DLE and conventional methods. The environmental performance of hybrid systems varies considerably based on their specific configuration and the proportion of DLE technology incorporated.

Carbon emissions represent another significant environmental consideration. DLE processes generally require more energy input than passive evaporation systems, potentially increasing the carbon footprint if powered by fossil fuel sources. However, when coupled with renewable energy sources, DLE operations can achieve carbon neutrality while maintaining their other environmental advantages. Several pilot projects have demonstrated successful integration of solar power with DLE operations, reducing lifecycle emissions by up to 40%.

Chemical usage and waste management constitute important environmental metrics for both technologies. DLE systems typically utilize selective adsorbents or ion exchange materials that require periodic regeneration with chemical solutions. These processes generate waste streams that require proper treatment and disposal. Hybrid systems often present more complex waste management challenges due to the combination of multiple extraction methodologies, though recent innovations have focused on closed-loop designs that minimize external environmental impacts.

Groundwater protection represents a final critical environmental consideration. DLE technologies generally offer superior groundwater protection compared to evaporation ponds, which risk leakage and contamination of surrounding aquifers. Advanced monitoring systems integrated with modern DLE installations provide real-time data on potential environmental impacts, enabling rapid response to any detected anomalies and ensuring regulatory compliance.

Water conservation emerges as another substantial environmental benefit of DLE technologies. While evaporation ponds can consume up to 500,000 gallons of water per ton of lithium produced, advanced DLE systems have demonstrated capabilities to reduce this figure by 50-70%, depending on the specific technology employed. This water efficiency becomes increasingly crucial in arid regions where lithium resources and water scarcity often coincide.

Hybrid systems, which combine elements of DLE with conventional methods, present an intermediate environmental profile. These systems typically achieve a 30-50% reduction in land use compared to traditional approaches while offering water conservation benefits that fall between pure DLE and conventional methods. The environmental performance of hybrid systems varies considerably based on their specific configuration and the proportion of DLE technology incorporated.

Carbon emissions represent another significant environmental consideration. DLE processes generally require more energy input than passive evaporation systems, potentially increasing the carbon footprint if powered by fossil fuel sources. However, when coupled with renewable energy sources, DLE operations can achieve carbon neutrality while maintaining their other environmental advantages. Several pilot projects have demonstrated successful integration of solar power with DLE operations, reducing lifecycle emissions by up to 40%.

Chemical usage and waste management constitute important environmental metrics for both technologies. DLE systems typically utilize selective adsorbents or ion exchange materials that require periodic regeneration with chemical solutions. These processes generate waste streams that require proper treatment and disposal. Hybrid systems often present more complex waste management challenges due to the combination of multiple extraction methodologies, though recent innovations have focused on closed-loop designs that minimize external environmental impacts.

Groundwater protection represents a final critical environmental consideration. DLE technologies generally offer superior groundwater protection compared to evaporation ponds, which risk leakage and contamination of surrounding aquifers. Advanced monitoring systems integrated with modern DLE installations provide real-time data on potential environmental impacts, enabling rapid response to any detected anomalies and ensuring regulatory compliance.

Economic Feasibility Analysis

The economic feasibility of Direct Lithium Extraction (DLE) versus hybrid systems represents a critical consideration for industry stakeholders. Initial capital expenditure for DLE technologies typically ranges between $20,000-$30,000 per ton of annual production capacity, significantly higher than traditional evaporation pond methods. However, this higher upfront investment must be evaluated against the substantially reduced production timeline—DLE can extract lithium in days rather than the 18-24 months required for evaporation ponds.

Operational expenditure analysis reveals that DLE systems generally incur higher energy costs, with electricity consumption averaging 2.5-4 kWh per kilogram of lithium carbonate equivalent (LCE) produced. Water consumption efficiency presents a notable advantage, with DLE requiring approximately 50-70 liters per kilogram of LCE compared to evaporation methods' 500+ liters. This translates to potential operational savings in water-scarce regions where water costs are escalating.

Hybrid systems, which combine conventional methods with selective DLE technologies, demonstrate promising economic metrics with approximately 15-25% lower total production costs compared to pure DLE implementations. The economic balance shifts favorably toward hybrid systems in regions with moderate brine concentrations (250-500 ppm Li) and favorable climate conditions for partial evaporation.

Return on investment calculations indicate that while DLE systems require 3-5 years to reach profitability, hybrid systems can potentially achieve this milestone in 2-4 years. This accelerated ROI timeline makes hybrid approaches particularly attractive for mid-sized operations seeking to balance innovation with financial constraints.

Market sensitivity analysis demonstrates that DLE economics improve dramatically with increasing lithium prices—at market prices above $15,000/ton, the premium technology costs become increasingly justified. Conversely, hybrid systems maintain economic viability even at lower price points around $10,000/ton, providing greater resilience against market volatility.

Scale economics further favor hybrid implementations, with cost efficiencies improving by approximately 18-22% when production scales from 5,000 to 20,000 tons annually, compared to 12-15% for pure DLE systems. This differential becomes particularly significant for large-scale operations targeting production volumes exceeding 10,000 tons per year.

Operational expenditure analysis reveals that DLE systems generally incur higher energy costs, with electricity consumption averaging 2.5-4 kWh per kilogram of lithium carbonate equivalent (LCE) produced. Water consumption efficiency presents a notable advantage, with DLE requiring approximately 50-70 liters per kilogram of LCE compared to evaporation methods' 500+ liters. This translates to potential operational savings in water-scarce regions where water costs are escalating.

Hybrid systems, which combine conventional methods with selective DLE technologies, demonstrate promising economic metrics with approximately 15-25% lower total production costs compared to pure DLE implementations. The economic balance shifts favorably toward hybrid systems in regions with moderate brine concentrations (250-500 ppm Li) and favorable climate conditions for partial evaporation.

Return on investment calculations indicate that while DLE systems require 3-5 years to reach profitability, hybrid systems can potentially achieve this milestone in 2-4 years. This accelerated ROI timeline makes hybrid approaches particularly attractive for mid-sized operations seeking to balance innovation with financial constraints.

Market sensitivity analysis demonstrates that DLE economics improve dramatically with increasing lithium prices—at market prices above $15,000/ton, the premium technology costs become increasingly justified. Conversely, hybrid systems maintain economic viability even at lower price points around $10,000/ton, providing greater resilience against market volatility.

Scale economics further favor hybrid implementations, with cost efficiencies improving by approximately 18-22% when production scales from 5,000 to 20,000 tons annually, compared to 12-15% for pure DLE systems. This differential becomes particularly significant for large-scale operations targeting production volumes exceeding 10,000 tons per year.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!