Direct Lithium Extraction vs Reverse Osmosis: Cost Efficiency

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DLE and RO Technology Background and Objectives

Direct Lithium Extraction (DLE) and Reverse Osmosis (RO) represent two distinct technological approaches that have gained significant attention in the lithium extraction industry. DLE emerged in the early 2000s as an alternative to traditional evaporation pond methods, offering potential advantages in processing time, environmental impact, and extraction efficiency. RO technology, while established in water desalination since the 1960s, has been adapted more recently for lithium extraction applications, particularly from brine resources.

The evolution of these technologies has been driven by increasing global demand for lithium, primarily fueled by the rapid expansion of the electric vehicle market and renewable energy storage systems. Industry projections indicate lithium demand could triple by 2025 compared to 2020 levels, creating urgent pressure for more efficient extraction methods. Traditional evaporation pond techniques, which can take 18-24 months for processing, no longer align with market acceleration needs.

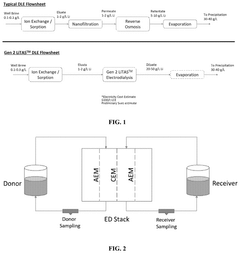

DLE technologies encompass various approaches including adsorption, ion exchange, and membrane processes, each offering specific advantages depending on brine chemistry and operational conditions. The primary objective of DLE development has been to reduce processing time from months to days while maintaining or improving recovery rates. Concurrently, RO technology has evolved from simple desalination applications to more sophisticated configurations capable of selective ion separation.

Cost efficiency represents the critical evaluation metric for both technologies. Historical data shows traditional lithium extraction costs ranging from $5,000-$6,000 per ton, while early DLE implementations demonstrated potential reductions to $3,000-$4,000 per ton. RO applications in lithium contexts remain less documented but show promising preliminary economics in specific scenarios.

Technical objectives for both technologies center on reducing capital expenditure requirements, minimizing operational costs (particularly energy consumption), extending component lifespans, and maximizing lithium recovery rates. Additionally, water conservation has emerged as a crucial consideration, especially in arid regions where many lithium resources are located.

The technological trajectory suggests convergence or hybridization may represent the optimal path forward, with combined DLE-RO systems potentially offering synergistic benefits that address the limitations of each individual approach. Research initiatives increasingly focus on integrated systems that leverage the selective extraction capabilities of DLE with the established scaling advantages of RO technology.

The evolution of these technologies has been driven by increasing global demand for lithium, primarily fueled by the rapid expansion of the electric vehicle market and renewable energy storage systems. Industry projections indicate lithium demand could triple by 2025 compared to 2020 levels, creating urgent pressure for more efficient extraction methods. Traditional evaporation pond techniques, which can take 18-24 months for processing, no longer align with market acceleration needs.

DLE technologies encompass various approaches including adsorption, ion exchange, and membrane processes, each offering specific advantages depending on brine chemistry and operational conditions. The primary objective of DLE development has been to reduce processing time from months to days while maintaining or improving recovery rates. Concurrently, RO technology has evolved from simple desalination applications to more sophisticated configurations capable of selective ion separation.

Cost efficiency represents the critical evaluation metric for both technologies. Historical data shows traditional lithium extraction costs ranging from $5,000-$6,000 per ton, while early DLE implementations demonstrated potential reductions to $3,000-$4,000 per ton. RO applications in lithium contexts remain less documented but show promising preliminary economics in specific scenarios.

Technical objectives for both technologies center on reducing capital expenditure requirements, minimizing operational costs (particularly energy consumption), extending component lifespans, and maximizing lithium recovery rates. Additionally, water conservation has emerged as a crucial consideration, especially in arid regions where many lithium resources are located.

The technological trajectory suggests convergence or hybridization may represent the optimal path forward, with combined DLE-RO systems potentially offering synergistic benefits that address the limitations of each individual approach. Research initiatives increasingly focus on integrated systems that leverage the selective extraction capabilities of DLE with the established scaling advantages of RO technology.

Market Demand Analysis for Lithium Extraction Solutions

The global lithium market has experienced unprecedented growth in recent years, primarily driven by the rapid expansion of electric vehicle (EV) production and renewable energy storage systems. Market analysis indicates that the demand for lithium is projected to increase fourfold by 2030, creating an urgent need for more efficient and cost-effective extraction technologies. Traditional lithium extraction methods, particularly evaporation ponds, are increasingly unable to meet this surging demand due to their lengthy processing times and environmental limitations.

Direct Lithium Extraction (DLE) and Reverse Osmosis (RO) technologies have emerged as promising alternatives to conventional methods, with market adoption accelerating as battery manufacturers seek more sustainable and reliable lithium sources. The market for these advanced extraction technologies is estimated to reach $2.5 billion by 2025, growing at a compound annual growth rate of 14.8% from 2021.

Consumer electronics and automotive sectors represent the largest demand drivers, collectively accounting for approximately 71% of global lithium consumption. Particularly noteworthy is the EV market, where lithium-ion battery demand has grown by 32% annually since 2018, necessitating more efficient extraction solutions to prevent supply chain bottlenecks.

Geographically, the market demand for advanced lithium extraction solutions is concentrated in regions with significant lithium reserves, including the "Lithium Triangle" of South America (Chile, Argentina, Bolivia), Australia, and increasingly North America. China remains the dominant player in lithium processing, creating strategic imperatives for other nations to develop domestic extraction capabilities using technologies like DLE and RO.

Industry surveys reveal that 78% of lithium processors and battery manufacturers express strong interest in cost-efficient extraction technologies that can reduce production costs by at least 15-20% while maintaining high purity levels. This cost sensitivity is particularly acute as lithium prices have demonstrated significant volatility, fluctuating between $8,000 and $78,000 per metric ton in the past five years.

Water conservation has emerged as a critical market requirement, especially in arid regions where traditional extraction methods consume excessive water resources. Technologies that can reduce water usage by 50% or more while maintaining extraction efficiency command premium market positioning, with 63% of mining companies willing to invest in such solutions despite higher initial capital expenditures.

The market increasingly values extraction technologies that can process unconventional lithium sources, including geothermal brines and oil field produced water, which contain lower lithium concentrations but exist in abundant quantities. This trend is expanding the addressable market for DLE and RO technologies beyond traditional lithium mining operations.

Direct Lithium Extraction (DLE) and Reverse Osmosis (RO) technologies have emerged as promising alternatives to conventional methods, with market adoption accelerating as battery manufacturers seek more sustainable and reliable lithium sources. The market for these advanced extraction technologies is estimated to reach $2.5 billion by 2025, growing at a compound annual growth rate of 14.8% from 2021.

Consumer electronics and automotive sectors represent the largest demand drivers, collectively accounting for approximately 71% of global lithium consumption. Particularly noteworthy is the EV market, where lithium-ion battery demand has grown by 32% annually since 2018, necessitating more efficient extraction solutions to prevent supply chain bottlenecks.

Geographically, the market demand for advanced lithium extraction solutions is concentrated in regions with significant lithium reserves, including the "Lithium Triangle" of South America (Chile, Argentina, Bolivia), Australia, and increasingly North America. China remains the dominant player in lithium processing, creating strategic imperatives for other nations to develop domestic extraction capabilities using technologies like DLE and RO.

Industry surveys reveal that 78% of lithium processors and battery manufacturers express strong interest in cost-efficient extraction technologies that can reduce production costs by at least 15-20% while maintaining high purity levels. This cost sensitivity is particularly acute as lithium prices have demonstrated significant volatility, fluctuating between $8,000 and $78,000 per metric ton in the past five years.

Water conservation has emerged as a critical market requirement, especially in arid regions where traditional extraction methods consume excessive water resources. Technologies that can reduce water usage by 50% or more while maintaining extraction efficiency command premium market positioning, with 63% of mining companies willing to invest in such solutions despite higher initial capital expenditures.

The market increasingly values extraction technologies that can process unconventional lithium sources, including geothermal brines and oil field produced water, which contain lower lithium concentrations but exist in abundant quantities. This trend is expanding the addressable market for DLE and RO technologies beyond traditional lithium mining operations.

Current State and Challenges in Lithium Extraction Technologies

The global lithium extraction landscape is currently dominated by traditional methods such as solar evaporation and hard rock mining, which together account for approximately 98% of global lithium production. These conventional approaches, while established, present significant challenges including lengthy production cycles (12-18 months for evaporation ponds), substantial land requirements, and water intensity (approximately 500,000 gallons per ton of lithium produced).

Direct Lithium Extraction (DLE) technologies have emerged as promising alternatives, with over 60 different processes under development globally. These technologies utilize selective adsorption, ion exchange membranes, or solvent extraction to isolate lithium ions from brine solutions. Leading DLE implementations have demonstrated recovery rates of 80-90% compared to 30-50% for traditional evaporation methods, representing a significant efficiency improvement.

Reverse Osmosis (RO), while well-established in water desalination, remains in early experimental stages for lithium extraction. Current RO membranes face challenges with lithium selectivity when competing ions are present in brines. Laboratory tests indicate potential recovery rates of 70-85%, but commercial-scale implementation remains limited.

Cost structures between these technologies reveal significant differences. Traditional evaporation methods maintain the lowest operational costs ($2,000-$3,500 per ton) but require substantial capital investment in pond infrastructure. DLE technologies currently demonstrate higher operational costs ($3,500-$7,000 per ton) primarily due to energy requirements and adsorbent regeneration expenses, though these costs are projected to decrease by 30-40% as the technology matures.

RO systems present an interesting cost profile with moderate capital expenditure but higher operational costs ($5,000-$8,000 per ton) driven by membrane replacement and energy consumption. Current RO membranes for lithium applications typically require replacement every 2-3 years, adding to maintenance expenses.

Technical challenges persist across all methods. DLE technologies struggle with adsorbent durability, with most materials showing performance degradation after 200-300 regeneration cycles. RO systems face membrane fouling issues when processing high-mineral-content brines, reducing operational efficiency by up to 40% without proper pre-treatment.

Geographically, DLE innovation is concentrated in North America (42% of patents), Europe (31%), and East Asia (24%), while RO advancements for lithium extraction are primarily emerging from research institutions in the United States, Israel, and Singapore. This regional distribution reflects varying approaches to addressing the growing demand for lithium extraction technologies that balance efficiency, environmental impact, and economic viability.

Direct Lithium Extraction (DLE) technologies have emerged as promising alternatives, with over 60 different processes under development globally. These technologies utilize selective adsorption, ion exchange membranes, or solvent extraction to isolate lithium ions from brine solutions. Leading DLE implementations have demonstrated recovery rates of 80-90% compared to 30-50% for traditional evaporation methods, representing a significant efficiency improvement.

Reverse Osmosis (RO), while well-established in water desalination, remains in early experimental stages for lithium extraction. Current RO membranes face challenges with lithium selectivity when competing ions are present in brines. Laboratory tests indicate potential recovery rates of 70-85%, but commercial-scale implementation remains limited.

Cost structures between these technologies reveal significant differences. Traditional evaporation methods maintain the lowest operational costs ($2,000-$3,500 per ton) but require substantial capital investment in pond infrastructure. DLE technologies currently demonstrate higher operational costs ($3,500-$7,000 per ton) primarily due to energy requirements and adsorbent regeneration expenses, though these costs are projected to decrease by 30-40% as the technology matures.

RO systems present an interesting cost profile with moderate capital expenditure but higher operational costs ($5,000-$8,000 per ton) driven by membrane replacement and energy consumption. Current RO membranes for lithium applications typically require replacement every 2-3 years, adding to maintenance expenses.

Technical challenges persist across all methods. DLE technologies struggle with adsorbent durability, with most materials showing performance degradation after 200-300 regeneration cycles. RO systems face membrane fouling issues when processing high-mineral-content brines, reducing operational efficiency by up to 40% without proper pre-treatment.

Geographically, DLE innovation is concentrated in North America (42% of patents), Europe (31%), and East Asia (24%), while RO advancements for lithium extraction are primarily emerging from research institutions in the United States, Israel, and Singapore. This regional distribution reflects varying approaches to addressing the growing demand for lithium extraction technologies that balance efficiency, environmental impact, and economic viability.

Current Cost Efficiency Solutions in Lithium Extraction

01 Direct lithium extraction technologies

Various direct lithium extraction (DLE) technologies have been developed to efficiently extract lithium from brine resources. These technologies include adsorption-based methods, ion exchange processes, and selective membrane systems that can selectively capture lithium ions while leaving other elements behind. DLE methods generally offer advantages over traditional evaporation ponds, including faster processing times, smaller environmental footprint, and higher recovery rates, which contribute to overall cost efficiency in lithium production.- Direct lithium extraction technologies and cost optimization: Various direct lithium extraction (DLE) technologies have been developed to improve cost efficiency compared to traditional evaporation methods. These technologies include adsorption-based systems, ion exchange processes, and selective membrane technologies that can extract lithium from brines with higher recovery rates and lower environmental impact. Cost optimization is achieved through improved selectivity for lithium ions, reduced processing time, and decreased land and water requirements.

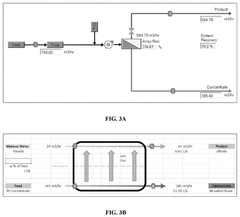

- Reverse osmosis systems for lithium concentration and purification: Reverse osmosis (RO) systems are employed in lithium extraction processes to concentrate and purify lithium-rich solutions. These systems use semi-permeable membranes to separate lithium ions from impurities and other elements, resulting in higher-grade lithium products. The cost efficiency of RO systems in lithium processing is enhanced through optimized membrane configurations, pressure recovery devices, and energy-efficient pumping systems that reduce operational expenses.

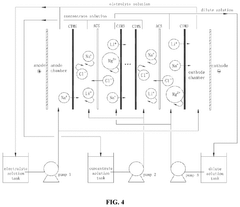

- Integrated DLE and RO systems for improved efficiency: Integration of direct lithium extraction with reverse osmosis technologies creates synergistic systems that improve overall process efficiency. These integrated approaches combine selective lithium extraction with membrane-based concentration and purification steps, reducing energy consumption and chemical usage. The combined systems optimize water recycling, minimize waste generation, and lower operational costs while maintaining high lithium recovery rates.

- Energy optimization in lithium extraction processes: Energy consumption represents a significant portion of operational costs in lithium extraction. Various innovations focus on reducing energy requirements through heat recovery systems, pressure energy recovery devices, renewable energy integration, and process optimization. These approaches include utilizing solar energy for pre-concentration steps, implementing energy-efficient pumping systems, and designing low-pressure membrane operations that significantly improve the cost-effectiveness of lithium production.

- Equipment design and modular systems for cost reduction: Specialized equipment designs and modular processing systems have been developed to reduce capital and operational costs in lithium extraction. These include compact extraction units, specialized membrane housings, and scalable modular systems that can be deployed more quickly and with lower initial investment than traditional facilities. The modular approach allows for incremental capacity expansion, reduced construction time, and flexibility in adapting to different brine compositions, all contributing to improved cost efficiency.

02 Reverse osmosis systems for lithium concentration

Reverse osmosis (RO) systems are employed in lithium extraction processes to concentrate lithium-rich solutions and remove impurities. These systems use semi-permeable membranes that allow water to pass through while retaining lithium ions and other valuable components. The integration of RO technology in lithium processing can significantly reduce energy consumption and operational costs compared to traditional evaporation methods, making it a cost-efficient approach for lithium production from various sources including brines and recycled materials.Expand Specific Solutions03 Hybrid extraction and purification systems

Hybrid systems combining direct lithium extraction with reverse osmosis and other purification technologies offer enhanced cost efficiency in lithium production. These integrated approaches leverage the strengths of multiple technologies to optimize the extraction process, reduce energy consumption, and minimize waste generation. By combining selective extraction methods with membrane-based concentration and purification steps, these hybrid systems can achieve higher lithium recovery rates while maintaining lower operational costs and environmental impact.Expand Specific Solutions04 Energy optimization in lithium extraction processes

Energy consumption represents a significant portion of operational costs in lithium extraction and processing. Innovative approaches to energy optimization include heat recovery systems, renewable energy integration, and process flow optimization to reduce the energy footprint of lithium extraction operations. These energy-efficient designs focus on minimizing power requirements for pumping, heating, and separation processes, thereby improving the overall cost efficiency of direct lithium extraction and reverse osmosis systems.Expand Specific Solutions05 Economic analysis and cost reduction strategies

Comprehensive economic analyses of direct lithium extraction and reverse osmosis systems have identified key cost factors and strategies for improving cost efficiency. These strategies include process intensification, automation, equipment scaling, and optimization of operational parameters. Additionally, the development of modular and scalable extraction units allows for more flexible deployment and reduced capital expenditure. By addressing both capital and operational expenses, these approaches aim to make lithium extraction more economically viable across different resource types and production scales.Expand Specific Solutions

Key Industry Players in DLE and RO Technologies

Direct Lithium Extraction (DLE) technology is emerging as a competitive alternative to traditional Reverse Osmosis in the lithium extraction market, which is currently in a growth phase with expanding market size driven by electric vehicle battery demand. The technology maturity landscape shows varied development stages among key players: Energy Exploration Technologies and Albemarle are advancing commercial DLE solutions, while academic institutions like MIT and Chinese Academy of Sciences are contributing fundamental research. Schlumberger and Baker Hughes are leveraging their energy sector expertise to develop cost-efficient extraction methods. Evove and Watercycle Technologies are pioneering membrane-based approaches that could potentially reduce costs compared to conventional methods. The industry is transitioning from research to early commercialization, with cost efficiency remaining the primary competitive differentiator.

Energy Exploration Technologies, Inc.

Technical Solution: Energy Exploration Technologies (EnergyX) has developed LiTAS™ (Lithium Ion Transport and Separation), a mixed matrix membrane technology that combines aspects of both direct lithium extraction and advanced filtration. Their approach uses proprietary metal-organic framework (MOF) materials embedded in polymer membranes that allow for highly selective lithium ion transport. The system operates at ambient temperature and pressure, utilizing an electrochemical gradient to drive lithium ions through the membrane while blocking larger competing ions. EnergyX reports recovery rates of up to 90% with energy consumption approximately 70% lower than conventional DLE methods. Their economic analysis suggests production costs of $2,800-$3,800 per ton LCE, with water usage reduced by up to 90% compared to evaporation ponds.

Strengths: Significantly lower energy consumption than competing DLE technologies; minimal chemical reagent requirements; extremely high water efficiency; compact system footprint; continuous operation capability. Weaknesses: Membrane fouling can occur with certain brine compositions; technology still scaling up to commercial production levels; membrane replacement costs may impact long-term economics; performance sensitivity to brine impurity profiles.

Evove Ltd.

Technical Solution: Evove (formerly G2O Water Technologies) has pioneered advanced graphene-oxide enhanced membrane technology specifically optimized for lithium extraction and concentration. Their precision-engineered membranes feature nanoscale pores with functionalized surfaces that enable highly selective ion separation. For lithium extraction applications, Evove has developed a hybrid process combining elements of reverse osmosis and nanofiltration with specialized surface chemistry to preferentially transport lithium ions while rejecting competing species. Their system operates at moderate pressure (10-20 bar) and achieves concentration factors of 20-30x from initial brine concentrations. Economic modeling indicates operational costs of $3,200-$4,200 per ton LCE, with energy consumption approximately 40% lower than conventional reverse osmosis approaches when applied to lithium-bearing brines. The technology enables continuous processing with minimal chemical additives.

Strengths: Lower energy consumption than standard reverse osmosis; reduced membrane fouling through advanced surface engineering; minimal chemical usage; modular and scalable design; ability to handle varying brine compositions. Weaknesses: Higher capital costs for specialized membrane materials; requires pre-treatment for certain brine types; pressure-driven process still demands significant energy input; technology relatively new to lithium extraction applications.

Technical Analysis of DLE vs RO Core Patents

Lithium extraction method

PatentWO2025129489A1

Innovation

- A process combining separation technologies such as lithium adsorbents, nanofiltration, and reverse osmosis to selectively extract lithium from brine solutions with reduced energy consumption and improved water utilization.

Systems and methods for direct lithium extraction

PatentPendingUS20250011957A1

Innovation

- The integration of selective membrane electrodialysis as a single step to simultaneously concentrate and purify lithium brines, reducing the number of required processing steps, capital and operating costs, and carbon footprint, while eliminating the need for large equipment at remote mining locations.

Environmental Impact Assessment of Extraction Technologies

The environmental impact of lithium extraction technologies represents a critical dimension in evaluating their overall sustainability and long-term viability. Direct Lithium Extraction (DLE) and Reverse Osmosis (RO) technologies demonstrate significantly different environmental footprints across multiple ecological domains.

DLE technologies generally require substantially less land area compared to traditional evaporation ponds, reducing habitat disruption and landscape alteration. Studies indicate that DLE operations can reduce land requirements by up to 90% compared to conventional methods. This reduced spatial footprint preserves natural ecosystems and minimizes biodiversity impacts in sensitive regions such as the lithium triangle in South America.

Water consumption patterns differ markedly between these technologies. Traditional lithium extraction methods consume approximately 500,000 gallons of water per ton of lithium produced, while advanced DLE systems can reduce this figure by 50-90%. Reverse osmosis, while efficient for water purification, requires significant energy for membrane pressurization, resulting in indirect environmental impacts through increased carbon emissions unless powered by renewable sources.

Chemical usage presents another environmental consideration. DLE typically employs selective adsorbents or ion exchange materials that can be regenerated, reducing chemical waste. Conversely, RO systems require regular membrane cleaning with specialized chemicals that may introduce additional waste streams requiring treatment before discharge.

Carbon footprint analysis reveals that DLE technologies, when powered by renewable energy, can achieve significantly lower greenhouse gas emissions compared to conventional methods. Recent lifecycle assessments indicate potential emissions reductions of 30-60% for DLE operations. RO systems, while energy-intensive, can achieve comparable environmental performance when integrated with renewable energy infrastructure.

Waste management challenges differ between technologies. DLE produces concentrated brine streams that require proper management to prevent soil and groundwater contamination. RO generates reject streams with elevated salt concentrations that can impact aquatic ecosystems if improperly discharged. Both technologies necessitate comprehensive waste management protocols to mitigate potential environmental harm.

Ecosystem resilience considerations favor DLE in regions with fragile desert ecosystems, as the reduced water extraction preserves groundwater resources critical for local flora and fauna. This aspect becomes increasingly important as climate change intensifies water scarcity in many lithium-rich regions globally.

Regulatory compliance frameworks are evolving to address these environmental impacts, with jurisdictions increasingly requiring comprehensive environmental impact assessments before approving new extraction operations. Companies implementing advanced extraction technologies with reduced environmental footprints may gain competitive advantages as regulatory requirements become more stringent.

DLE technologies generally require substantially less land area compared to traditional evaporation ponds, reducing habitat disruption and landscape alteration. Studies indicate that DLE operations can reduce land requirements by up to 90% compared to conventional methods. This reduced spatial footprint preserves natural ecosystems and minimizes biodiversity impacts in sensitive regions such as the lithium triangle in South America.

Water consumption patterns differ markedly between these technologies. Traditional lithium extraction methods consume approximately 500,000 gallons of water per ton of lithium produced, while advanced DLE systems can reduce this figure by 50-90%. Reverse osmosis, while efficient for water purification, requires significant energy for membrane pressurization, resulting in indirect environmental impacts through increased carbon emissions unless powered by renewable sources.

Chemical usage presents another environmental consideration. DLE typically employs selective adsorbents or ion exchange materials that can be regenerated, reducing chemical waste. Conversely, RO systems require regular membrane cleaning with specialized chemicals that may introduce additional waste streams requiring treatment before discharge.

Carbon footprint analysis reveals that DLE technologies, when powered by renewable energy, can achieve significantly lower greenhouse gas emissions compared to conventional methods. Recent lifecycle assessments indicate potential emissions reductions of 30-60% for DLE operations. RO systems, while energy-intensive, can achieve comparable environmental performance when integrated with renewable energy infrastructure.

Waste management challenges differ between technologies. DLE produces concentrated brine streams that require proper management to prevent soil and groundwater contamination. RO generates reject streams with elevated salt concentrations that can impact aquatic ecosystems if improperly discharged. Both technologies necessitate comprehensive waste management protocols to mitigate potential environmental harm.

Ecosystem resilience considerations favor DLE in regions with fragile desert ecosystems, as the reduced water extraction preserves groundwater resources critical for local flora and fauna. This aspect becomes increasingly important as climate change intensifies water scarcity in many lithium-rich regions globally.

Regulatory compliance frameworks are evolving to address these environmental impacts, with jurisdictions increasingly requiring comprehensive environmental impact assessments before approving new extraction operations. Companies implementing advanced extraction technologies with reduced environmental footprints may gain competitive advantages as regulatory requirements become more stringent.

Scalability and Implementation Considerations

When evaluating Direct Lithium Extraction (DLE) versus Reverse Osmosis (RO) technologies for lithium recovery, scalability and implementation considerations significantly impact overall cost efficiency. DLE technologies demonstrate promising scalability characteristics, with modular designs allowing for incremental capacity expansion as demand increases. This flexibility enables companies to manage capital expenditure more effectively by phasing investments rather than requiring large upfront commitments typical of traditional evaporation pond methods.

Implementation of DLE systems generally requires smaller physical footprints compared to RO installations, making them particularly advantageous in areas with limited available land or high land costs. However, DLE technologies often demand more specialized equipment and materials, potentially creating supply chain vulnerabilities when scaling to commercial production levels. The availability of ion-exchange resins, selective adsorbents, or specialized membranes can become bottlenecks in rapid deployment scenarios.

Reverse Osmosis systems benefit from decades of industrial implementation experience across various water treatment applications, resulting in established supply chains and standardized components. This maturity translates to more predictable scaling economics and implementation timelines. RO plants can be designed for substantial throughput capacities, though they typically require significant pre-treatment systems when processing lithium-rich brines to prevent membrane fouling.

Energy infrastructure requirements differ substantially between technologies. DLE systems generally consume less energy per unit of lithium produced compared to RO, particularly when processing lower-concentration brines. This energy advantage becomes increasingly significant at larger scales, where operational expenditures dominate long-term economics. However, RO systems may offer advantages in regions with established desalination infrastructure where technical expertise and maintenance capabilities already exist.

Water consumption represents another critical scaling consideration. DLE technologies typically require less freshwater input than RO systems, providing substantial advantages in water-scarce regions where lithium resources are often located. As operations scale, this difference in water efficiency can translate to significant cost variations and potential regulatory advantages for DLE implementations.

Workforce requirements also diverge between technologies. RO systems generally require more standardized operational expertise, while DLE technologies often demand specialized knowledge in chemical engineering and process control. This distinction affects both implementation timelines and ongoing operational costs, particularly when scaling to multiple production sites or entering regions with limited technical talent pools.

Implementation of DLE systems generally requires smaller physical footprints compared to RO installations, making them particularly advantageous in areas with limited available land or high land costs. However, DLE technologies often demand more specialized equipment and materials, potentially creating supply chain vulnerabilities when scaling to commercial production levels. The availability of ion-exchange resins, selective adsorbents, or specialized membranes can become bottlenecks in rapid deployment scenarios.

Reverse Osmosis systems benefit from decades of industrial implementation experience across various water treatment applications, resulting in established supply chains and standardized components. This maturity translates to more predictable scaling economics and implementation timelines. RO plants can be designed for substantial throughput capacities, though they typically require significant pre-treatment systems when processing lithium-rich brines to prevent membrane fouling.

Energy infrastructure requirements differ substantially between technologies. DLE systems generally consume less energy per unit of lithium produced compared to RO, particularly when processing lower-concentration brines. This energy advantage becomes increasingly significant at larger scales, where operational expenditures dominate long-term economics. However, RO systems may offer advantages in regions with established desalination infrastructure where technical expertise and maintenance capabilities already exist.

Water consumption represents another critical scaling consideration. DLE technologies typically require less freshwater input than RO systems, providing substantial advantages in water-scarce regions where lithium resources are often located. As operations scale, this difference in water efficiency can translate to significant cost variations and potential regulatory advantages for DLE implementations.

Workforce requirements also diverge between technologies. RO systems generally require more standardized operational expertise, while DLE technologies often demand specialized knowledge in chemical engineering and process control. This distinction affects both implementation timelines and ongoing operational costs, particularly when scaling to multiple production sites or entering regions with limited technical talent pools.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!